July 23rd ======================

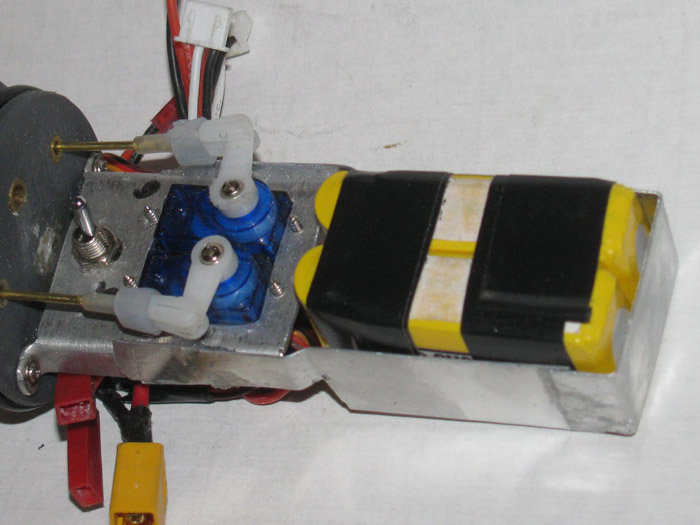

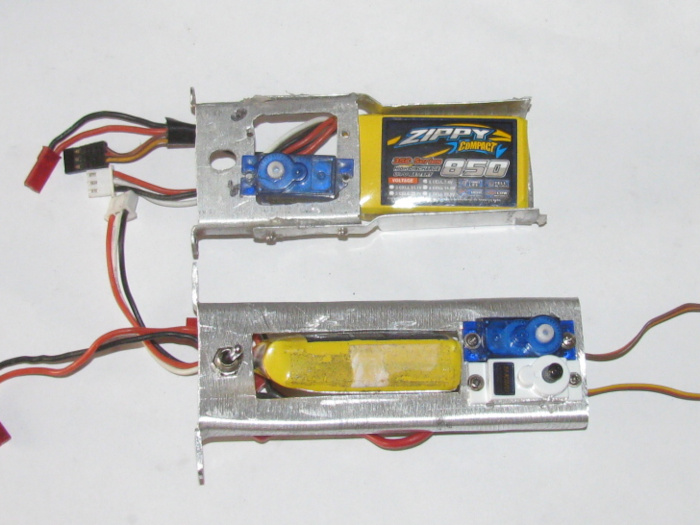

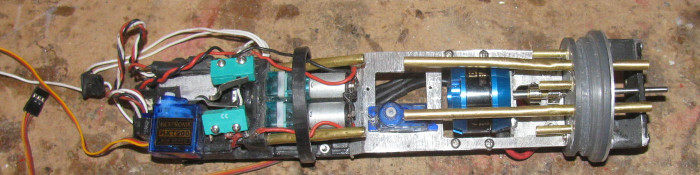

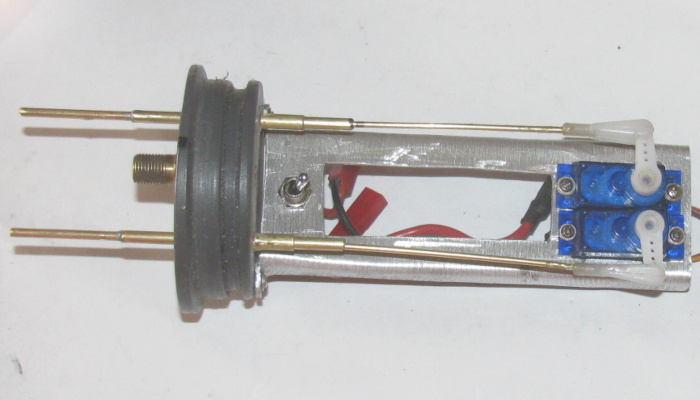

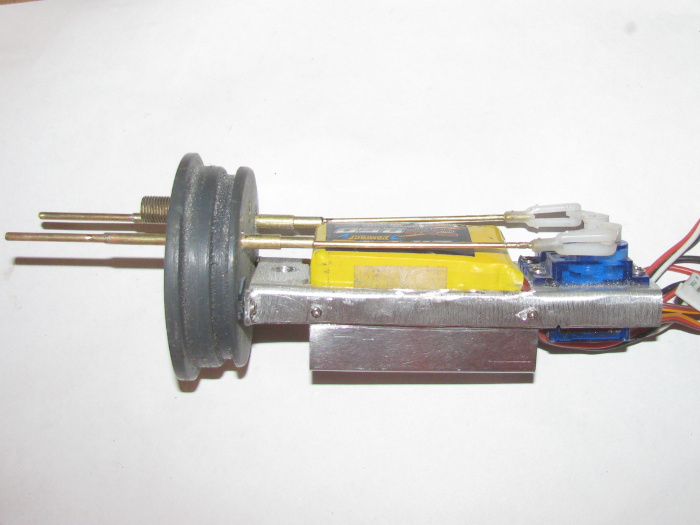

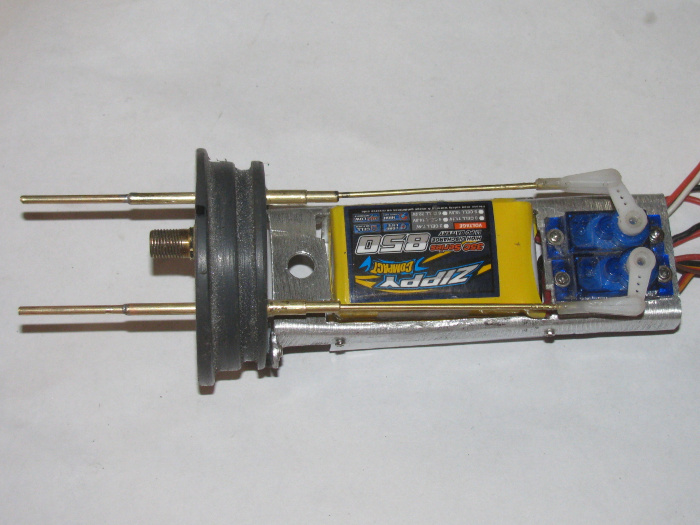

This morning, I assembled the electronics again to test before putting them in the cylinder.

Testing went well.

Everything works.

Stopped to have something to eat.

Back out in the shop, I noticed something I had not noticed before.

The bow planes where not in the up position.

They were about 1/2" lowered.

Interesting!

So I powered up the system and put the bow planes in the full down position. (horizontal to level)

Turned everything off.

Did other stuff.

About 45 minutes later, I noticed the bow planes where up a little more than a 1/2" from level.

A little thought explained a lot of things.

I have while building this boat, had several small servos fail.

1 or 2 because I bumper the rudder or rear planes causing a gear to strip in the servos.

I have also had to replace several bow plane retract servos.

Now I can see the issue.

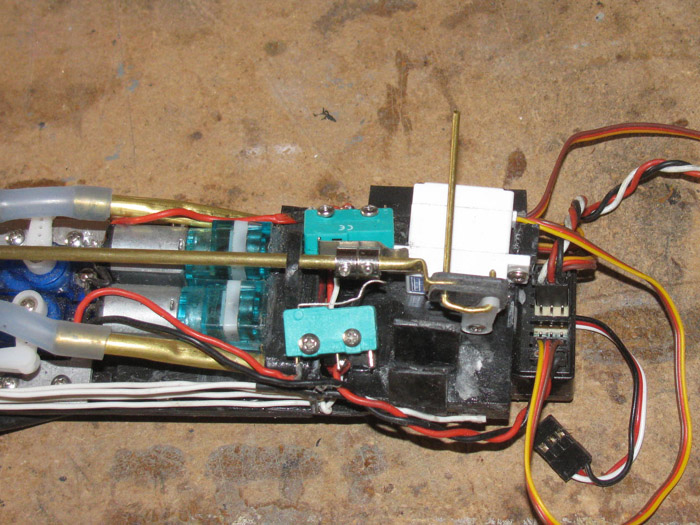

I used rubber boot seals on the control rods.

They work well and are easy to install.

But here is what I think is happening.

The boots have a natural at rest center.

When used on the rudder, rear planes and even the bow plane pitch control rods, the servos spend most of their time centered.

Boot in it's natural state.

However, the bow planes retract servo is either all the way up or all the way down.

The rubber boot seal is always under pressure and never sitting at natural.

This causes pressure on the control rod transferred to the servo.

The servo when in the up or down position is fighting the natural center of the boot.

The fix is to remove the boot seal and use o-rings which have no natural center.

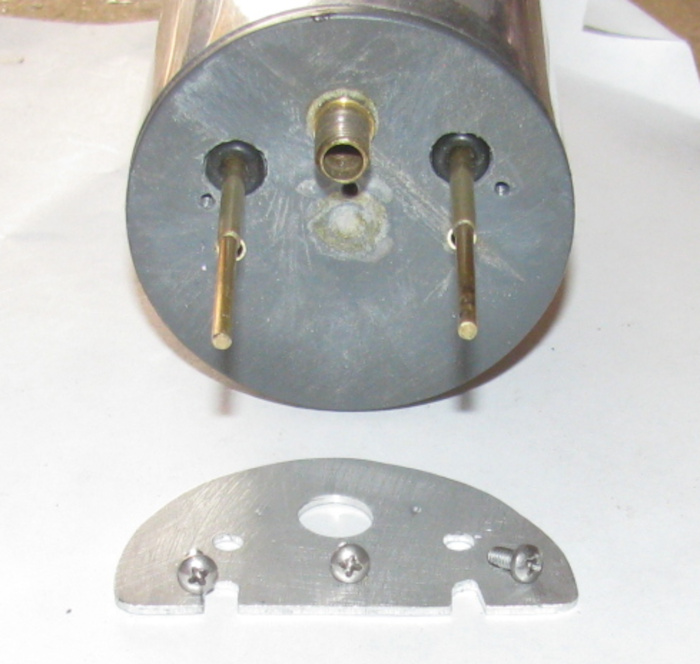

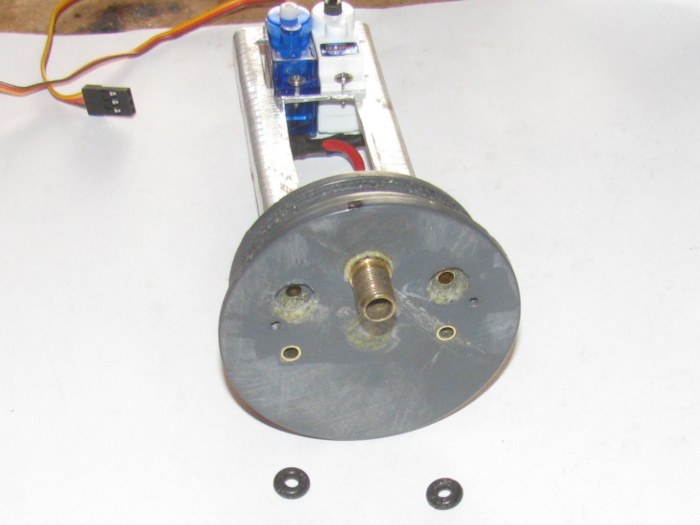

I have already removed 3 boot seals on the rear cap and now I have removed the 2 boot seals from the front cap.

I have removed the boot through cap tubes.

I have cut the o-ring recesses.

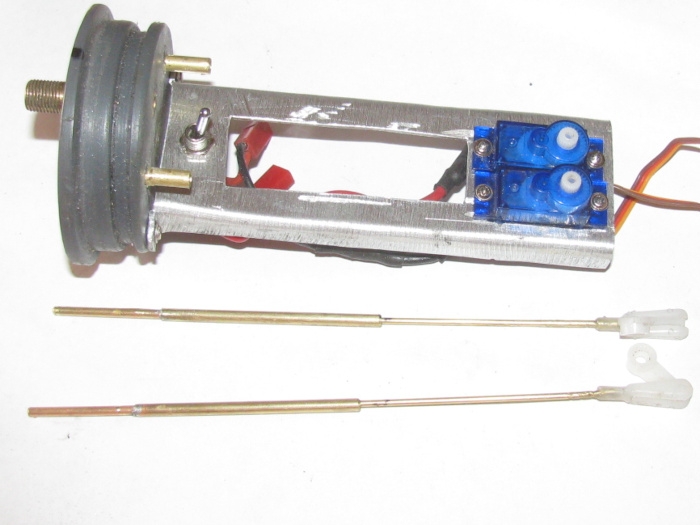

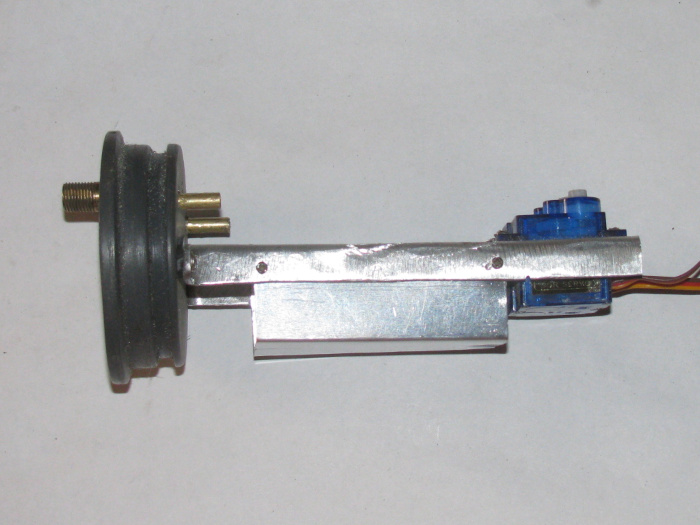

I have installed the 1/8" brass tubes use to guide the control rods.

I have modified the control rods with brass tube sleeves to bring the diameter up to 1/8" for the o-rings.

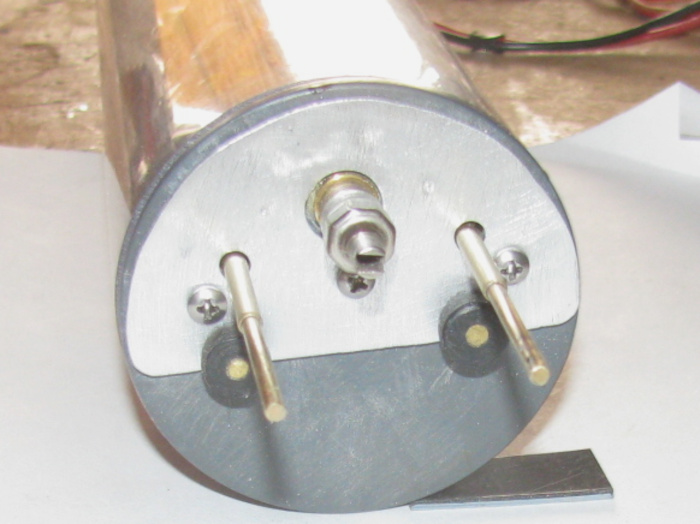

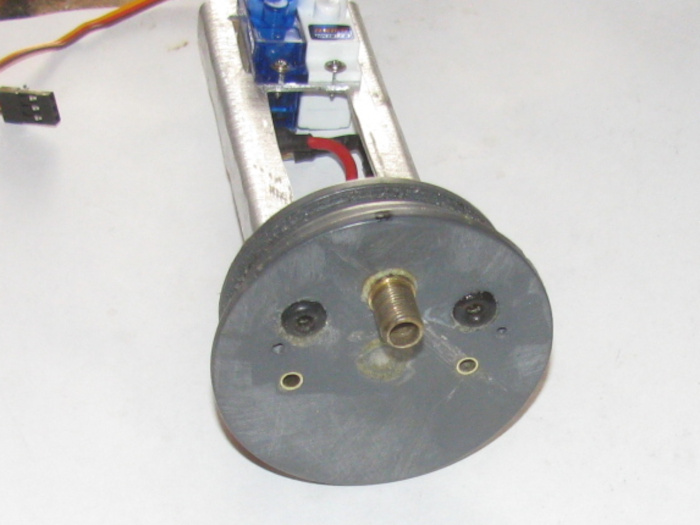

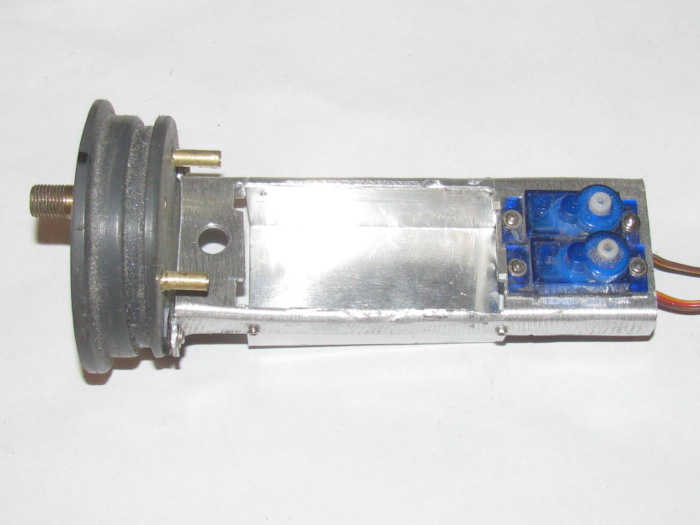

I am making the aluminum pressure plate that will hold the o-ring down in compression.

I looked for 1/8" o-rings and need to look some more.

May have to order some.

The hardware store has not restocked since I bought them out.

I can steal a couple of o-rings from the George Washington which is all apart in a bucket at the moment.

This will keep me moving forward on the Gato.

Control rods going through o-ring seals requires less effort from the servos.

Back out to the shop to finish making the aluminum pressure plate.

Only have to find 3 small bolts to hold the plate against the end cap and drill 3 holes and tap.

This morning, I assembled the electronics again to test before putting them in the cylinder.

Testing went well.

Everything works.

Stopped to have something to eat.

Back out in the shop, I noticed something I had not noticed before.

The bow planes where not in the up position.

They were about 1/2" lowered.

Interesting!

So I powered up the system and put the bow planes in the full down position. (horizontal to level)

Turned everything off.

Did other stuff.

About 45 minutes later, I noticed the bow planes where up a little more than a 1/2" from level.

A little thought explained a lot of things.

I have while building this boat, had several small servos fail.

1 or 2 because I bumper the rudder or rear planes causing a gear to strip in the servos.

I have also had to replace several bow plane retract servos.

Now I can see the issue.

I used rubber boot seals on the control rods.

They work well and are easy to install.

But here is what I think is happening.

The boots have a natural at rest center.

When used on the rudder, rear planes and even the bow plane pitch control rods, the servos spend most of their time centered.

Boot in it's natural state.

However, the bow planes retract servo is either all the way up or all the way down.

The rubber boot seal is always under pressure and never sitting at natural.

This causes pressure on the control rod transferred to the servo.

The servo when in the up or down position is fighting the natural center of the boot.

The fix is to remove the boot seal and use o-rings which have no natural center.

I have already removed 3 boot seals on the rear cap and now I have removed the 2 boot seals from the front cap.

I have removed the boot through cap tubes.

I have cut the o-ring recesses.

I have installed the 1/8" brass tubes use to guide the control rods.

I have modified the control rods with brass tube sleeves to bring the diameter up to 1/8" for the o-rings.

I am making the aluminum pressure plate that will hold the o-ring down in compression.

I looked for 1/8" o-rings and need to look some more.

May have to order some.

The hardware store has not restocked since I bought them out.

I can steal a couple of o-rings from the George Washington which is all apart in a bucket at the moment.

This will keep me moving forward on the Gato.

Control rods going through o-ring seals requires less effort from the servos.

Back out to the shop to finish making the aluminum pressure plate.

Only have to find 3 small bolts to hold the plate against the end cap and drill 3 holes and tap.

Comment