November 28th ======================

Update:

Cylinder has been water tested.

In to the test tank and no leaks after 5 minutes.

Back in to the tank with weights to hold it down at 15". Bottom of tank.

Left it there for 3 hours. (forgot it)

No leaks.

Out of the tank and left dry outside in the shade.

Put the cylinder in the hull.

Installed the two propeller dog bone connectors.

Connect 2 air hoses. (inlet/outlet)

Snap all magnetic connectors together.

Test all controls. (Good)

In to the test tank.

Vent the ballast tank.

Took about 10 seconds to fully empty the ballast tank.

Time to turn on the air pumps.

Slowly turn the control knob until the first pump comes on.

Then turn all the way for both air pumps.

This is not exciting at all.

I can see the boat coming up but it looks like it is going to take a long time.

Lifted the boat out of the water.

Removed the deck so I can see the cylinder and it's workings.

Back in to the water.

Fill the ballast tank by venting.

Again 10 seconds.

Now the air pumps.

First pump is turned on.

I see the air bubble coming in to the ballast tank.

Turn on the second air pump.

More bubbles.

So the system works.

However the air pumps are not producing the volume needed to bring the boat up.

After 2 minutes the boat is up to about half way on the deck sides.

This will not do.

I check the air hoses for obstructions.

None found.

Just not enough volume.

At this point I do not know if the ballast tank is large enough to bring the boat up to the waterline which was the reason for this last modification.

Enlarged the ballast tank for more positive buoyancy.

I have decide to shelf the Gato for now.

I do not seem to have the correct equipment to make this work properly.

Going to have to rethink this project.

This system was also to see if I could use it in the George Washington.

It does not look good.

I have 2 working subs and a rescue barge I can run.

So I think I will let the Gato and GW sit for a while and ask question of others at the lake on their systems.

The problem is the small diameter of the Gato and GW cylinders.

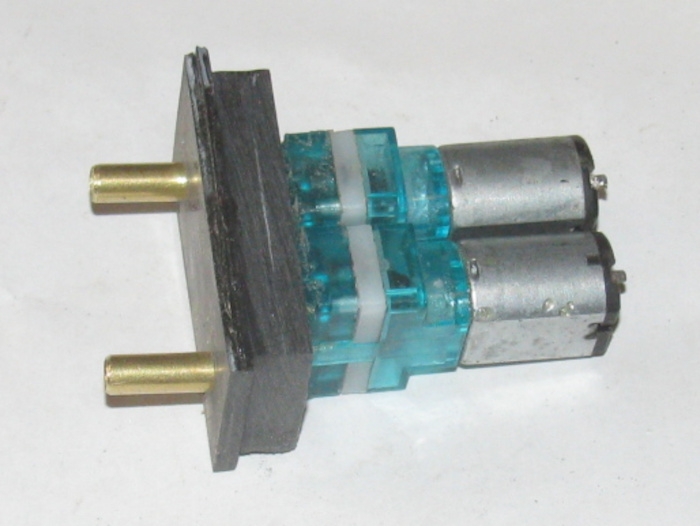

The pumps I have are all to big to fit.

I am going to look in to this system.

Update:

Cylinder has been water tested.

In to the test tank and no leaks after 5 minutes.

Back in to the tank with weights to hold it down at 15". Bottom of tank.

Left it there for 3 hours. (forgot it)

No leaks.

Out of the tank and left dry outside in the shade.

Put the cylinder in the hull.

Installed the two propeller dog bone connectors.

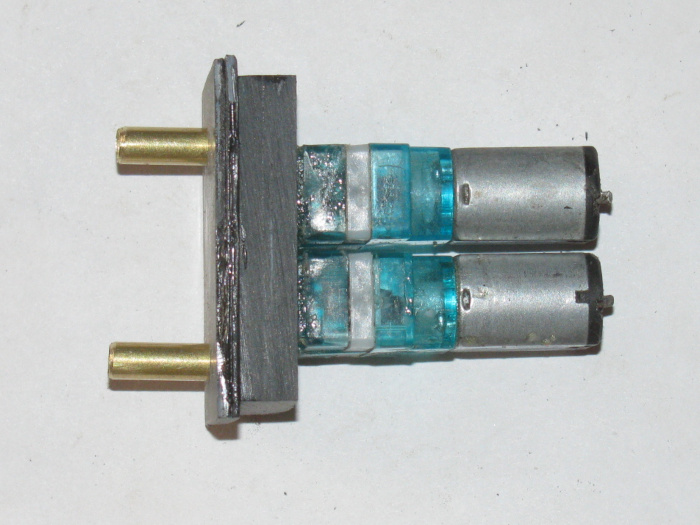

Connect 2 air hoses. (inlet/outlet)

Snap all magnetic connectors together.

Test all controls. (Good)

In to the test tank.

Vent the ballast tank.

Took about 10 seconds to fully empty the ballast tank.

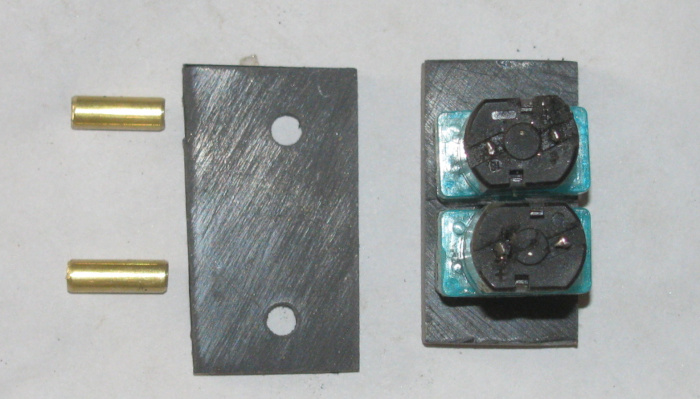

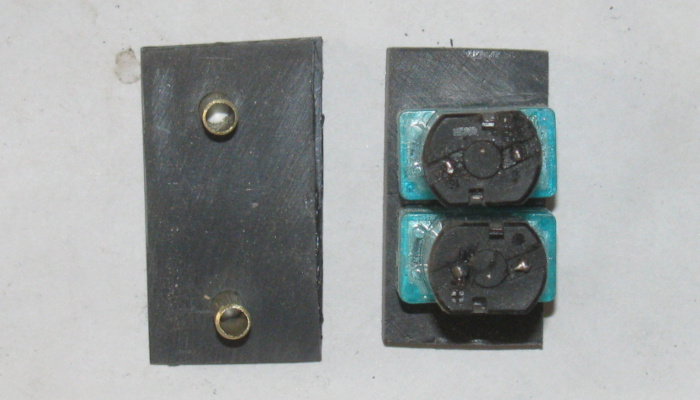

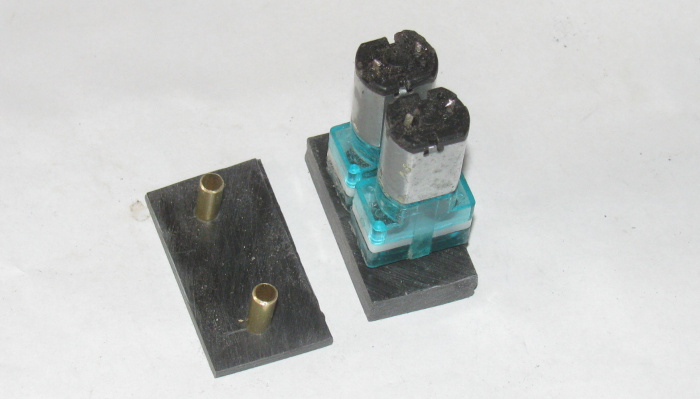

Time to turn on the air pumps.

Slowly turn the control knob until the first pump comes on.

Then turn all the way for both air pumps.

This is not exciting at all.

I can see the boat coming up but it looks like it is going to take a long time.

Lifted the boat out of the water.

Removed the deck so I can see the cylinder and it's workings.

Back in to the water.

Fill the ballast tank by venting.

Again 10 seconds.

Now the air pumps.

First pump is turned on.

I see the air bubble coming in to the ballast tank.

Turn on the second air pump.

More bubbles.

So the system works.

However the air pumps are not producing the volume needed to bring the boat up.

After 2 minutes the boat is up to about half way on the deck sides.

This will not do.

I check the air hoses for obstructions.

None found.

Just not enough volume.

At this point I do not know if the ballast tank is large enough to bring the boat up to the waterline which was the reason for this last modification.

Enlarged the ballast tank for more positive buoyancy.

I have decide to shelf the Gato for now.

I do not seem to have the correct equipment to make this work properly.

Going to have to rethink this project.

This system was also to see if I could use it in the George Washington.

It does not look good.

I have 2 working subs and a rescue barge I can run.

So I think I will let the Gato and GW sit for a while and ask question of others at the lake on their systems.

The problem is the small diameter of the Gato and GW cylinders.

The pumps I have are all to big to fit.

I am going to look in to this system.

Comment