Fuses should be of the slow blow type, and of adequate rating. 10A will cover most small to medium size models. It's there to protect the wiring and the sub, rather than the electronics.

Car type are good, but any style e.g. blade or cartridge will suffice. I know a lot of modellers don't run fuses, the only type of model I don't run fuses in, are flying machines. Should be fairly obvious why a fuse isn't a great idea in those.

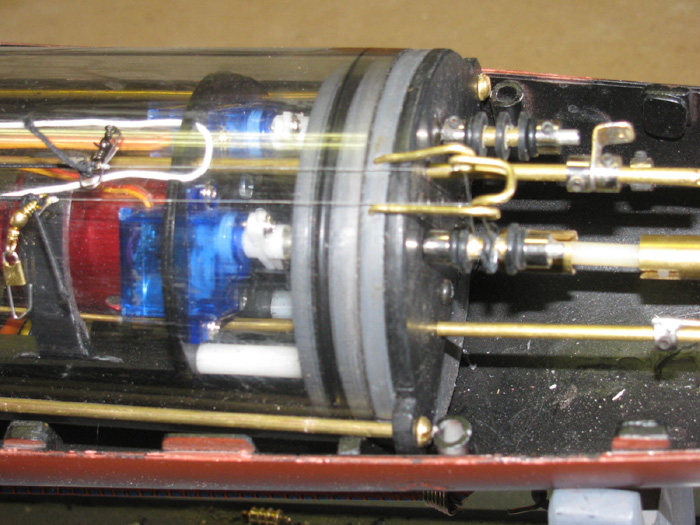

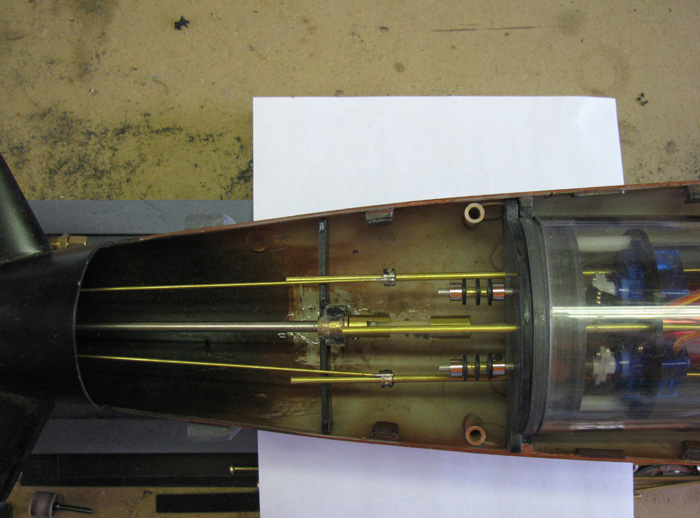

Metal rods won't pose any problem for the radio, however you don't need those rods if you'd read my earlier post, you can use the hull itself to retain the endcaps, lighter, easier and more elegant, and no rods cluttering up the interior of your module.

Car type are good, but any style e.g. blade or cartridge will suffice. I know a lot of modellers don't run fuses, the only type of model I don't run fuses in, are flying machines. Should be fairly obvious why a fuse isn't a great idea in those.

Metal rods won't pose any problem for the radio, however you don't need those rods if you'd read my earlier post, you can use the hull itself to retain the endcaps, lighter, easier and more elegant, and no rods cluttering up the interior of your module.

Comment