Not sure what you're asking about the two bulkheads and O-rings.

Okay, I went back and looked at your photos.

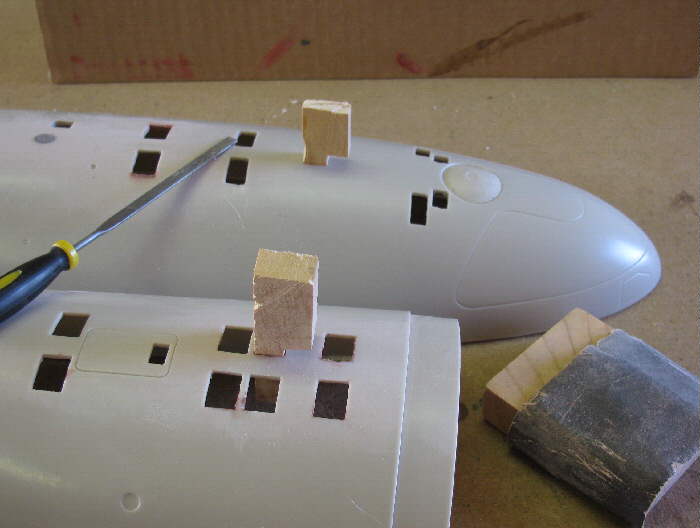

The bulkheads have O-rings to keep water in that section of the cylinder should the ballast bag leak.

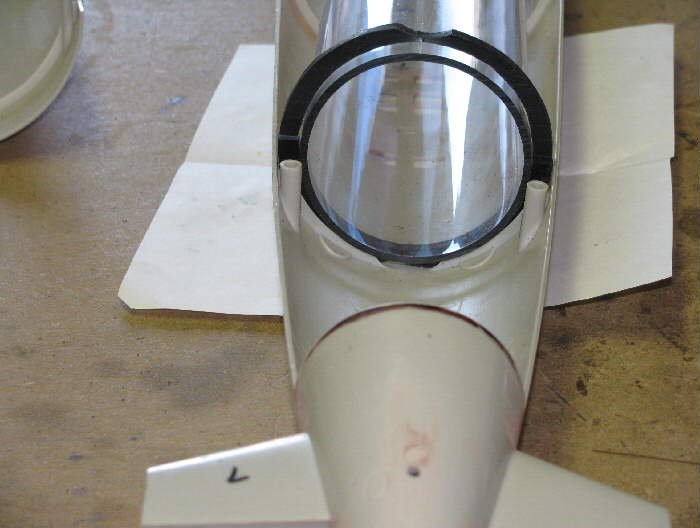

You have an electric through tube and a threaded rod which keeps the bulkheads at a fixed distance from each other.

My tank can be moved forward and backwards to help set trim.

The battery also can be moved and actually sits directly under the ballast containment tank.

Your bulkheads may/should have small vent holes near the top of the bulkhead to let air move through out the cylinder but yet keeps any water in the section.

If your ballast bag leaks and enough water gets up to the vent holes, you have far more serious problems to deal with.

One being a cold swim.

---------------------------------

My switch is an off/on switch to disconnect the battery power..

It only has two terminals.

Okay, I went back and looked at your photos.

The bulkheads have O-rings to keep water in that section of the cylinder should the ballast bag leak.

You have an electric through tube and a threaded rod which keeps the bulkheads at a fixed distance from each other.

My tank can be moved forward and backwards to help set trim.

The battery also can be moved and actually sits directly under the ballast containment tank.

Your bulkheads may/should have small vent holes near the top of the bulkhead to let air move through out the cylinder but yet keeps any water in the section.

If your ballast bag leaks and enough water gets up to the vent holes, you have far more serious problems to deal with.

One being a cold swim.

---------------------------------

My switch is an off/on switch to disconnect the battery power..

It only has two terminals.

Comment