The coupler may not be really not necessary. Most of these brushless motors disassemble quite easily with only a few set screws holding the entire assembly together. The shaft is very easily replaced with a longer version which negates the requirement for the shaft extension. That not withstanding, this is a very clean design. Well done.

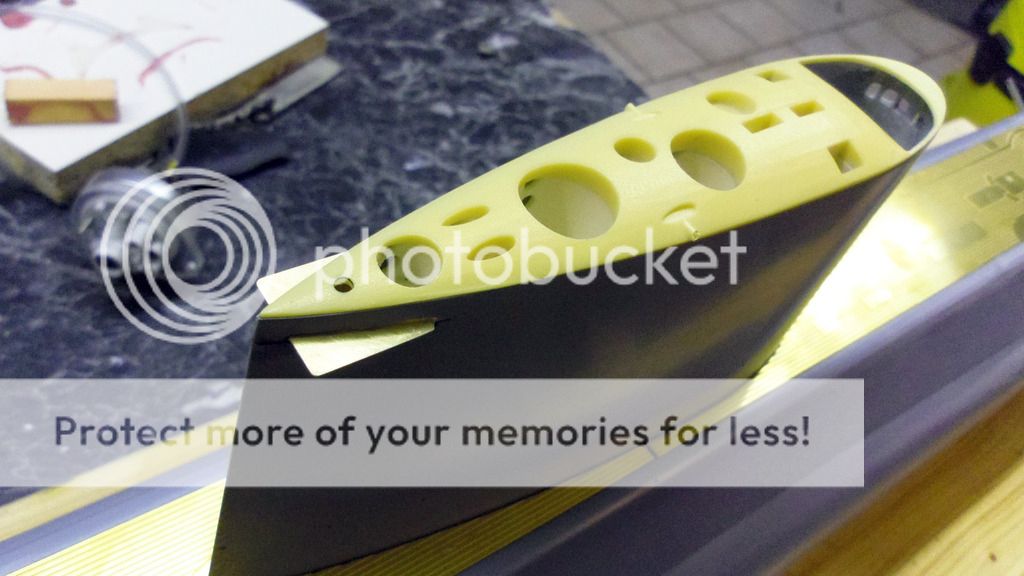

New project

Collapse

X

-

Very nice workmanship. Looking forward to seeing the final assembly and first trial runs!

I went the shaft extension route for the two outriders that will (eventually) go into my Type II. As Matt said, very straight forward.

-JeffRohr 1.....Los!

Comment

-

As I consider to make a small series of these feedthroughs, I wanted to keep the design universal, also adoptable for standard motors. One just makes another motor flange and that's it. With shaft replacement one could actually make the feedthrough much shorter.

Comment

-

http://www.subpirates.com/showthread...ight=brushlessOriginally posted by salmon View PostFor some reason, I thought Matt did one, maybe on his site?

Comment

-

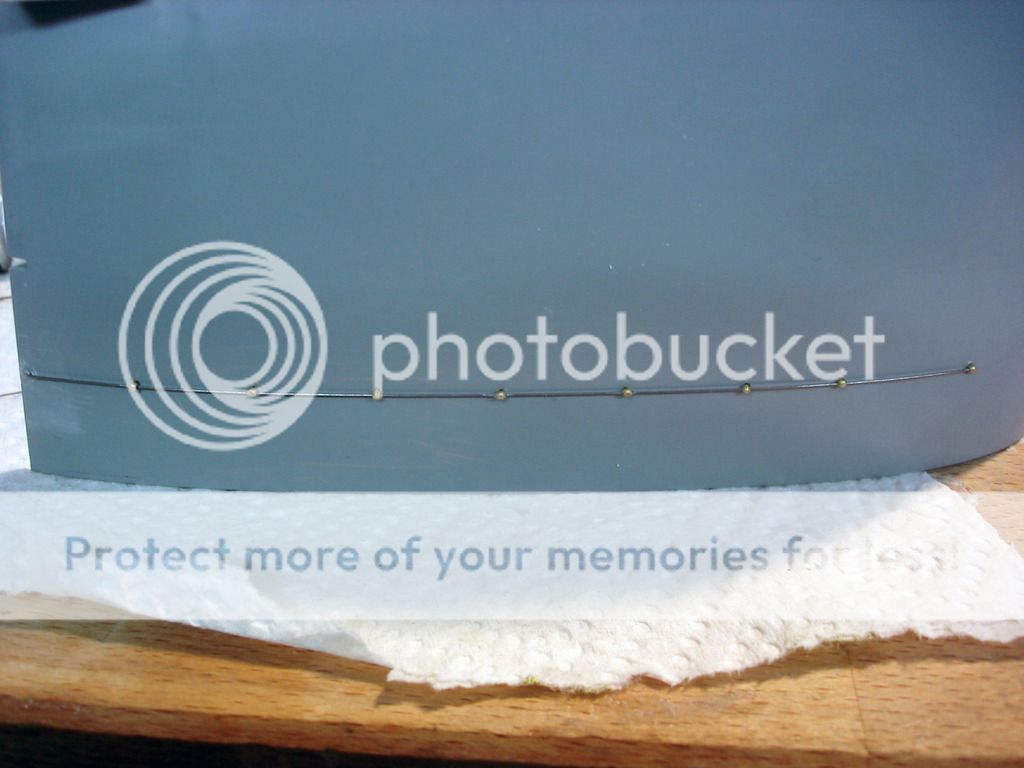

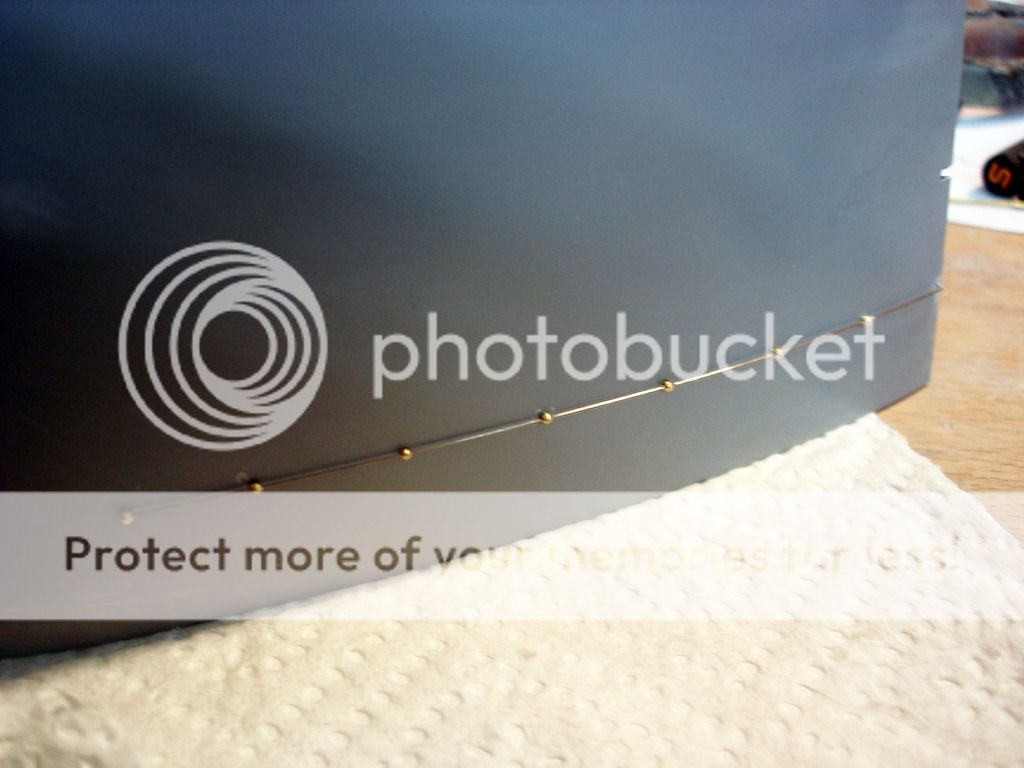

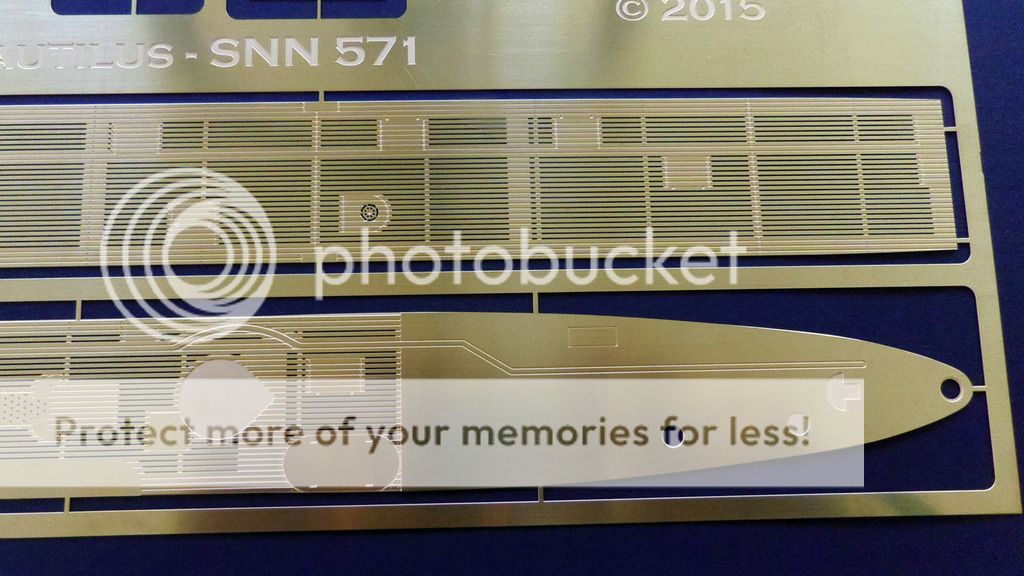

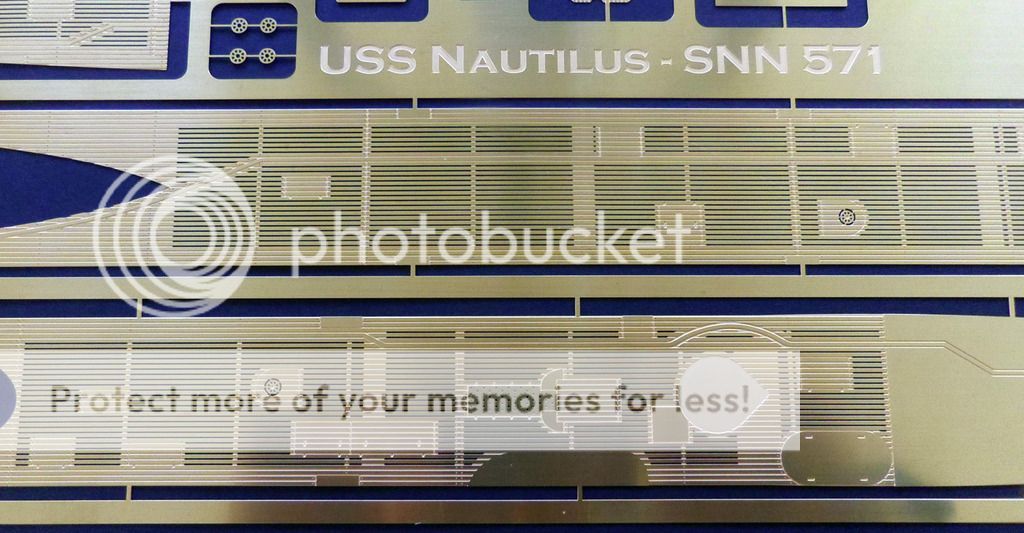

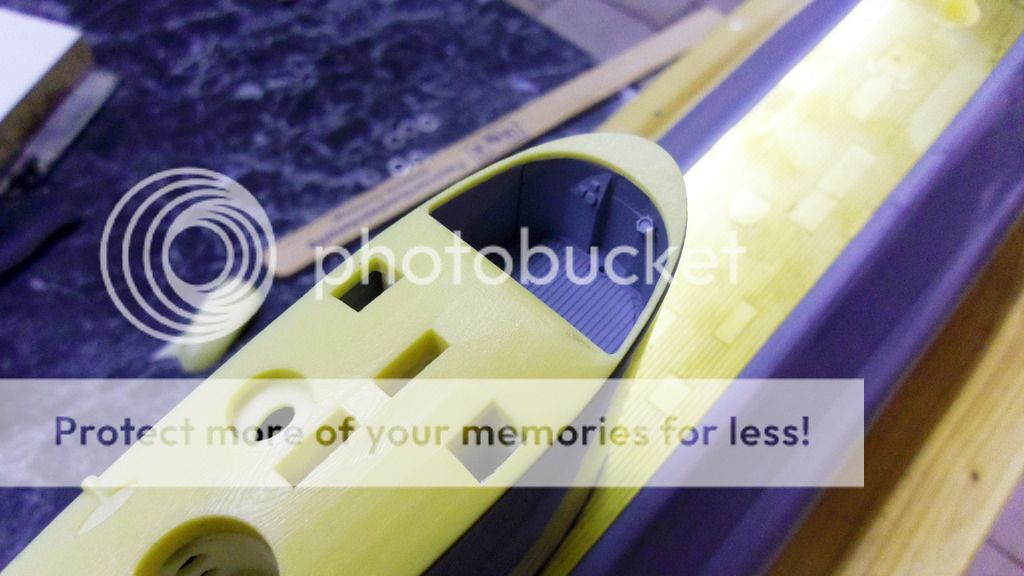

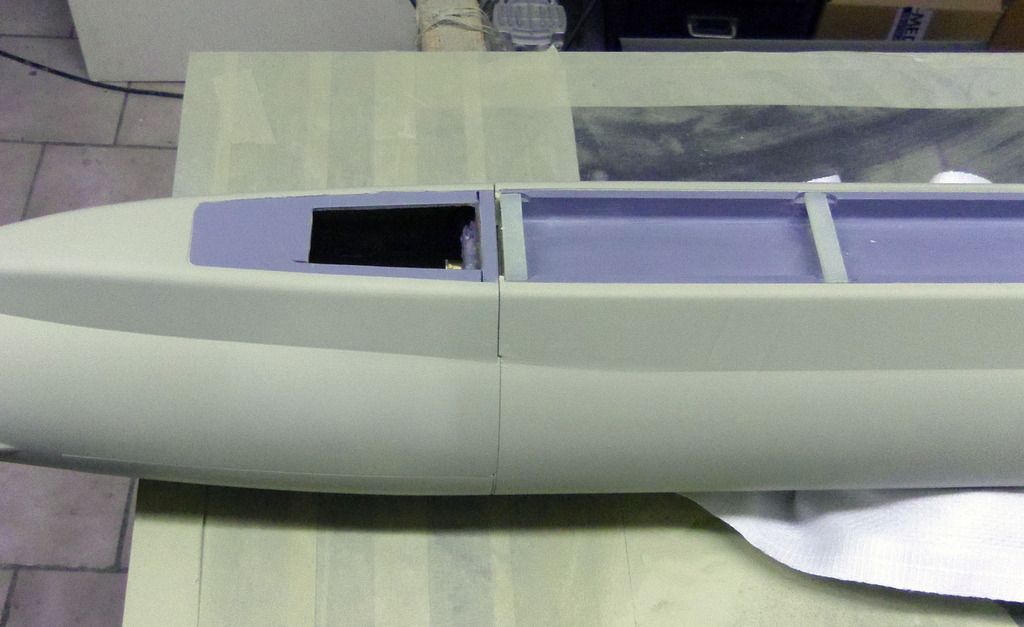

More detail work. The handrail on the sail is installed. I used 0,5 mm brass railing posts. The rail itself is made of 0,3 mm steel wire.

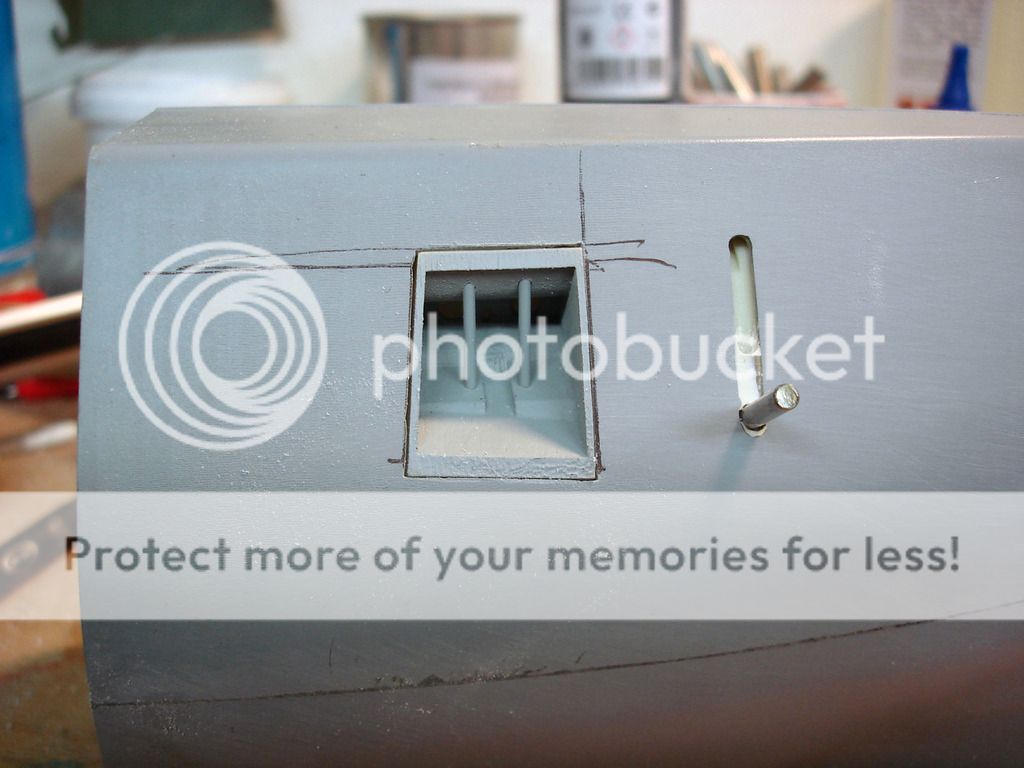

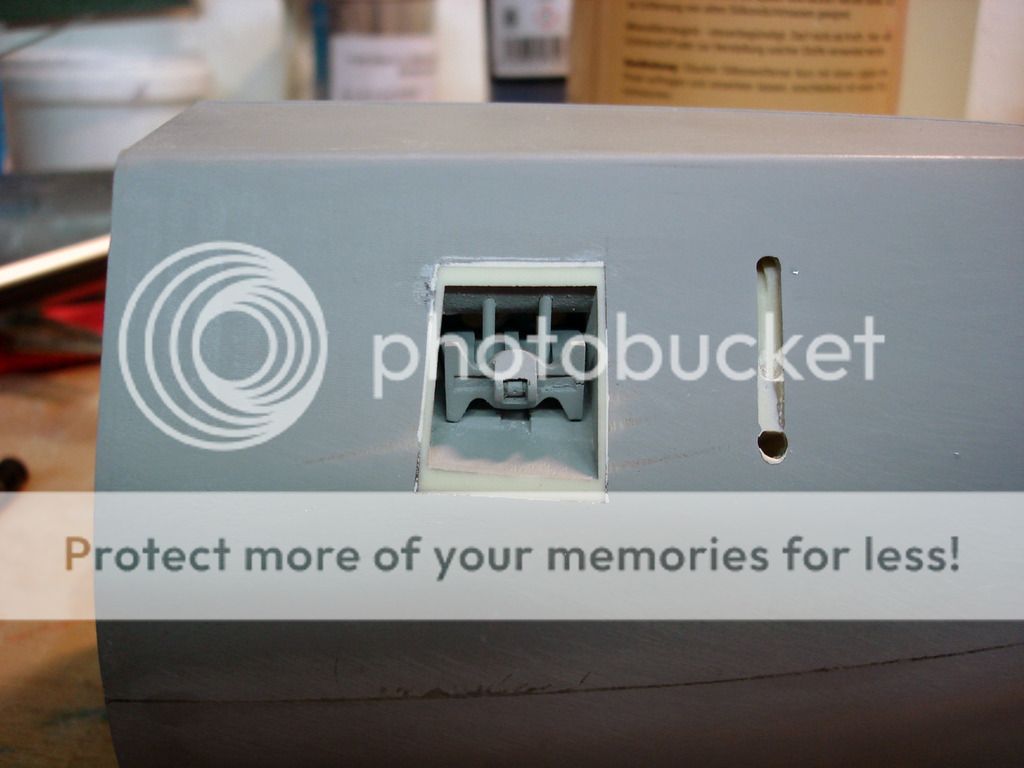

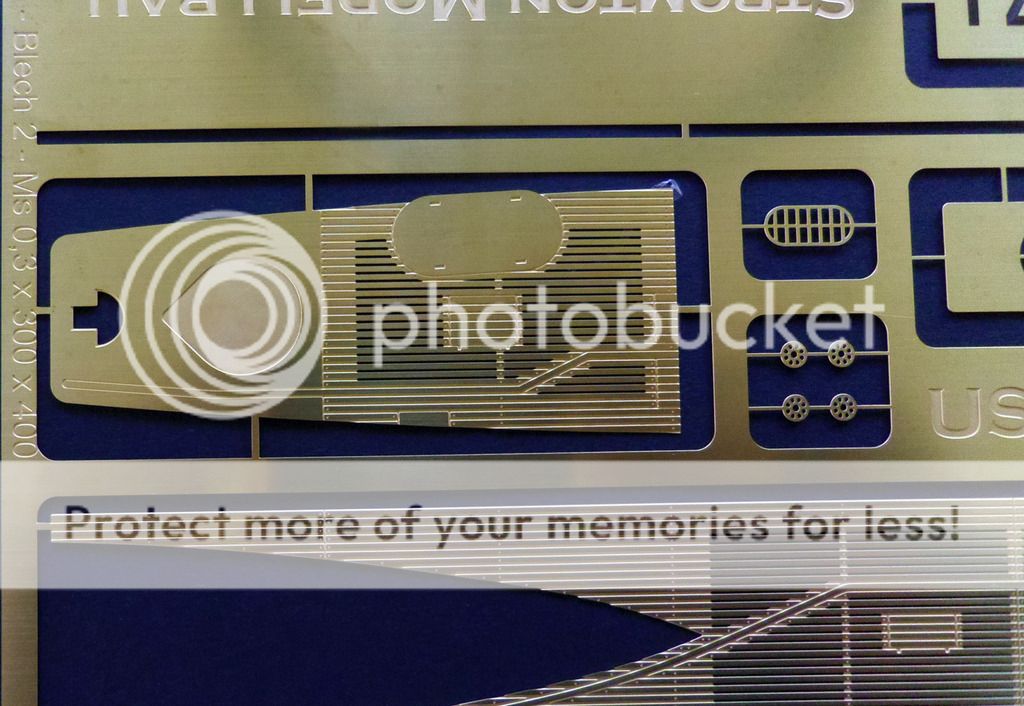

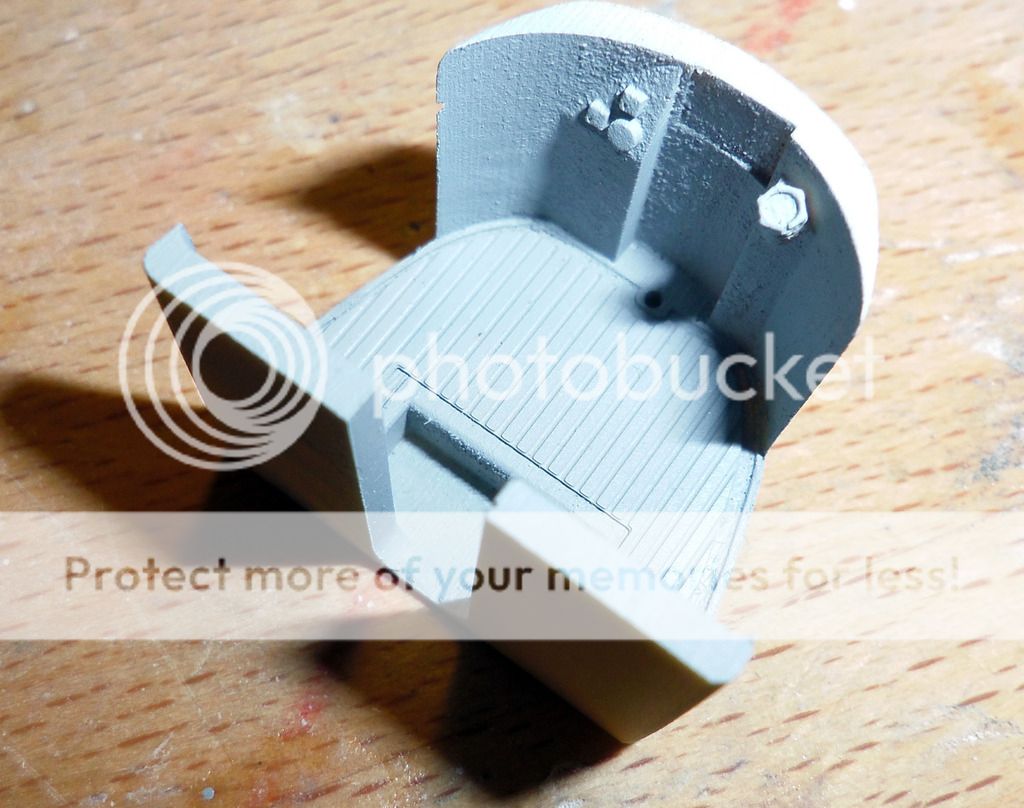

The stern service hatch with positioning bolts:

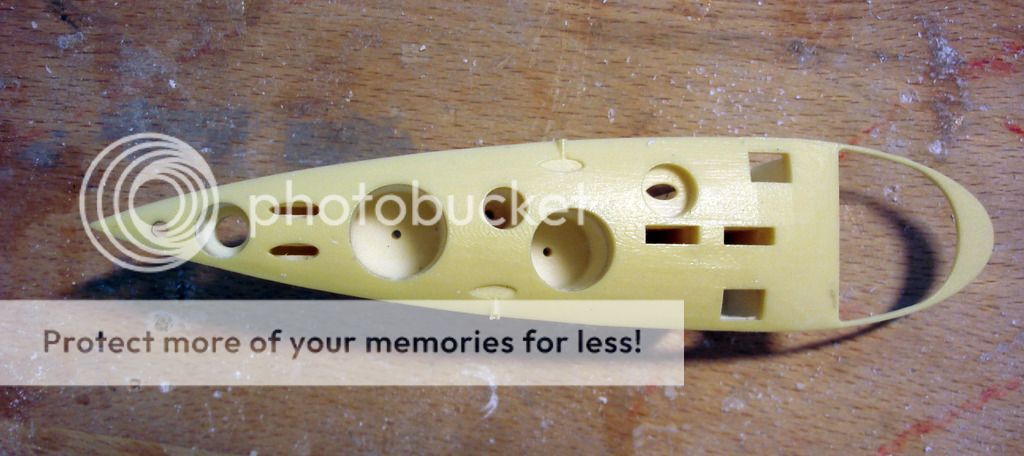

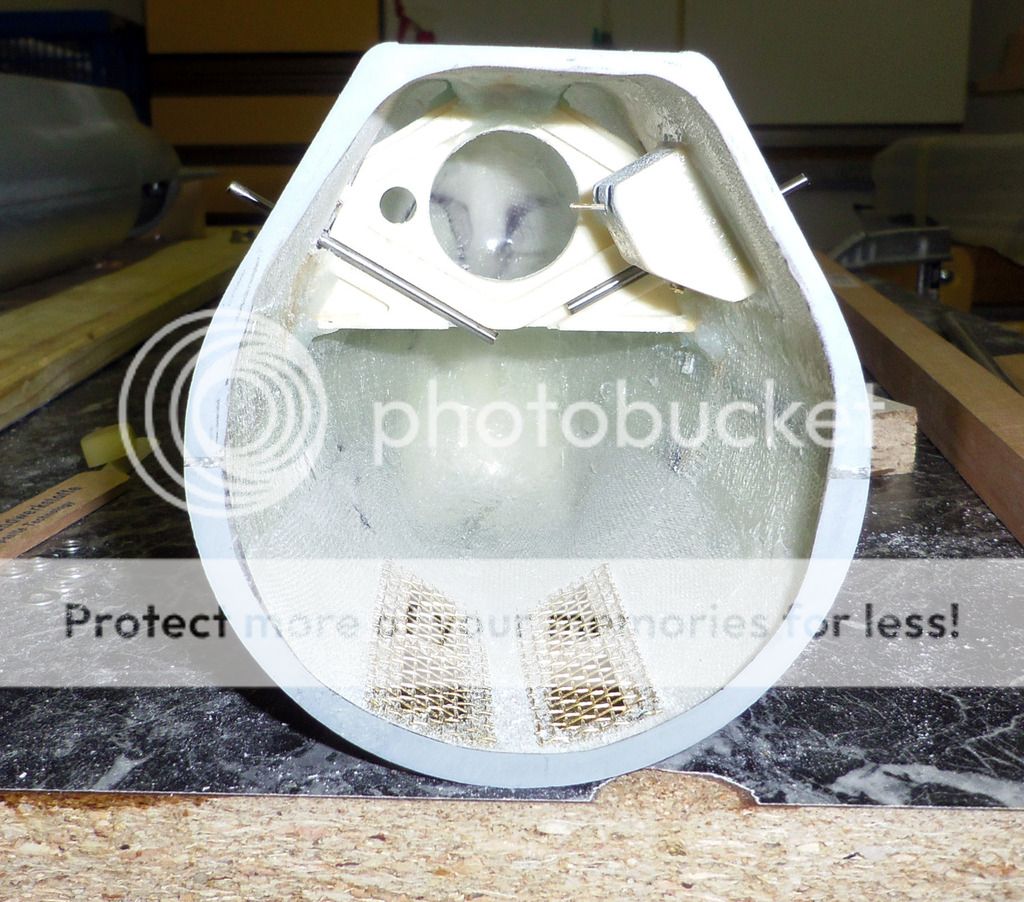

The v-shaped stern bulkhead was aligned to the stern tubes and glued into place. The bras tubes force the bulkhead into the right position:

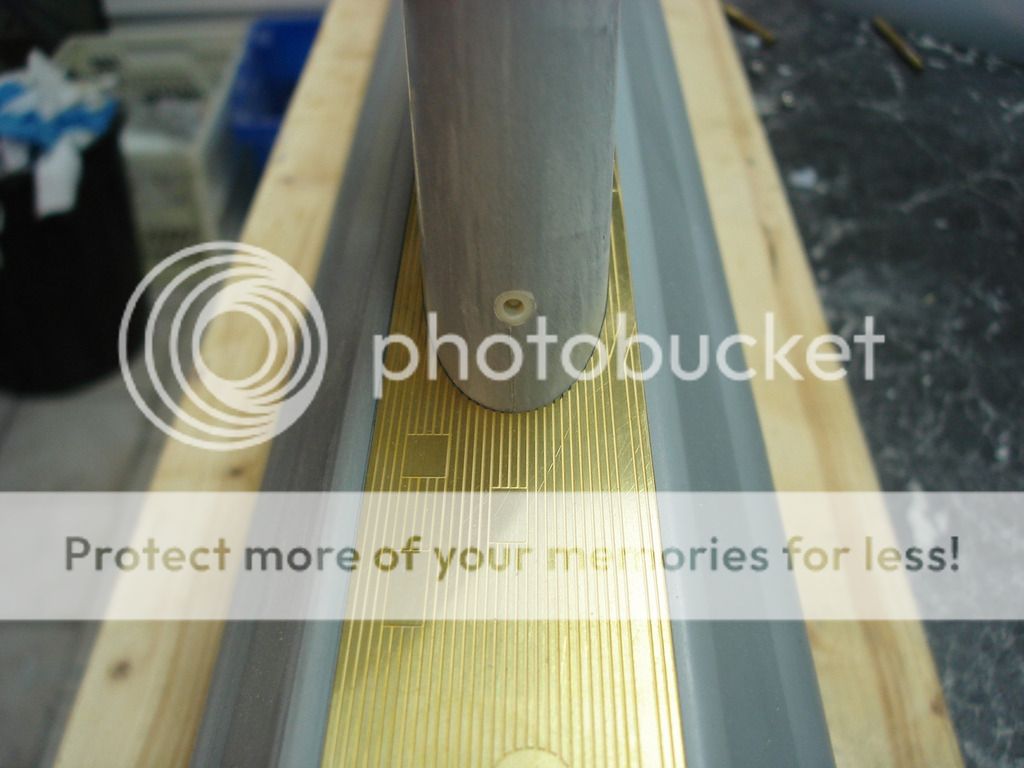

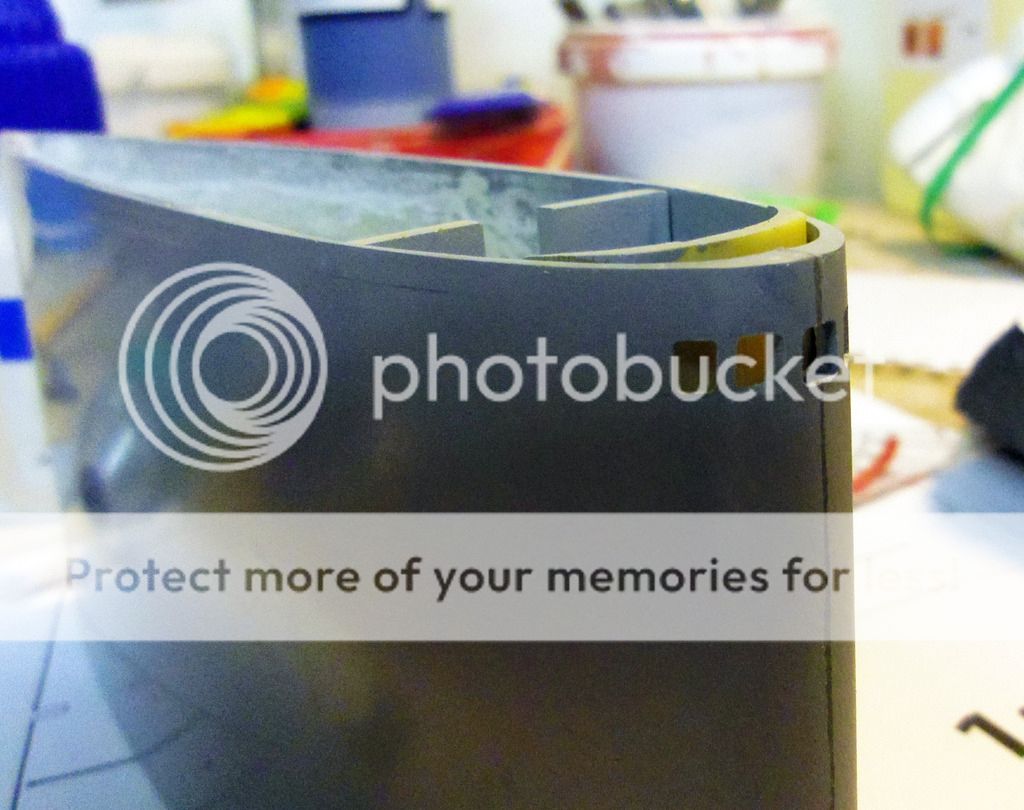

The technics frame then was an easy fix. M4 thread rods and nuts. The 8 mm brass tube is the feed for the piston tank:

Comment

-

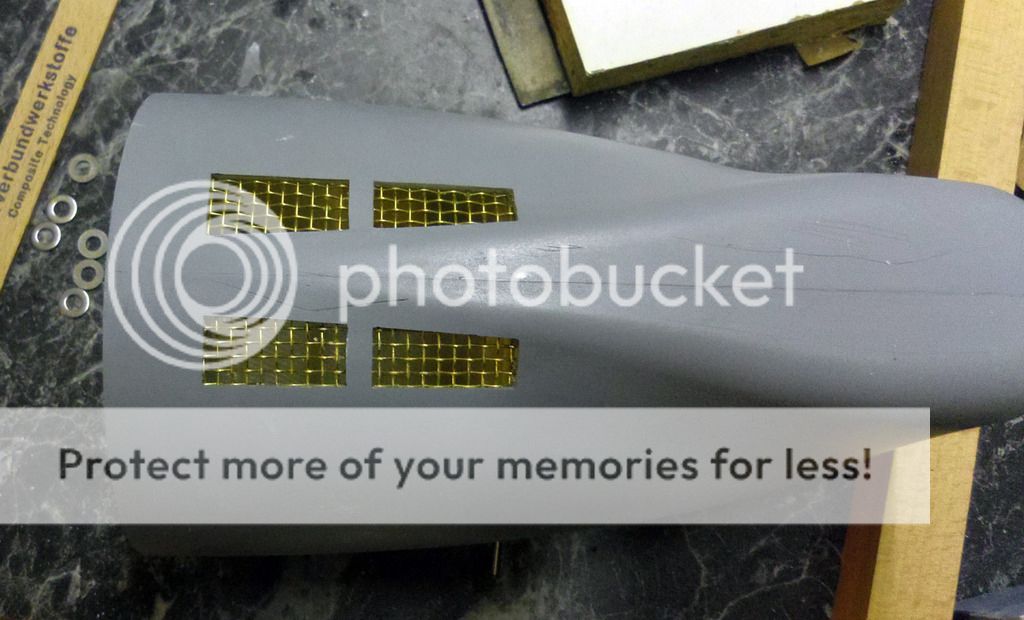

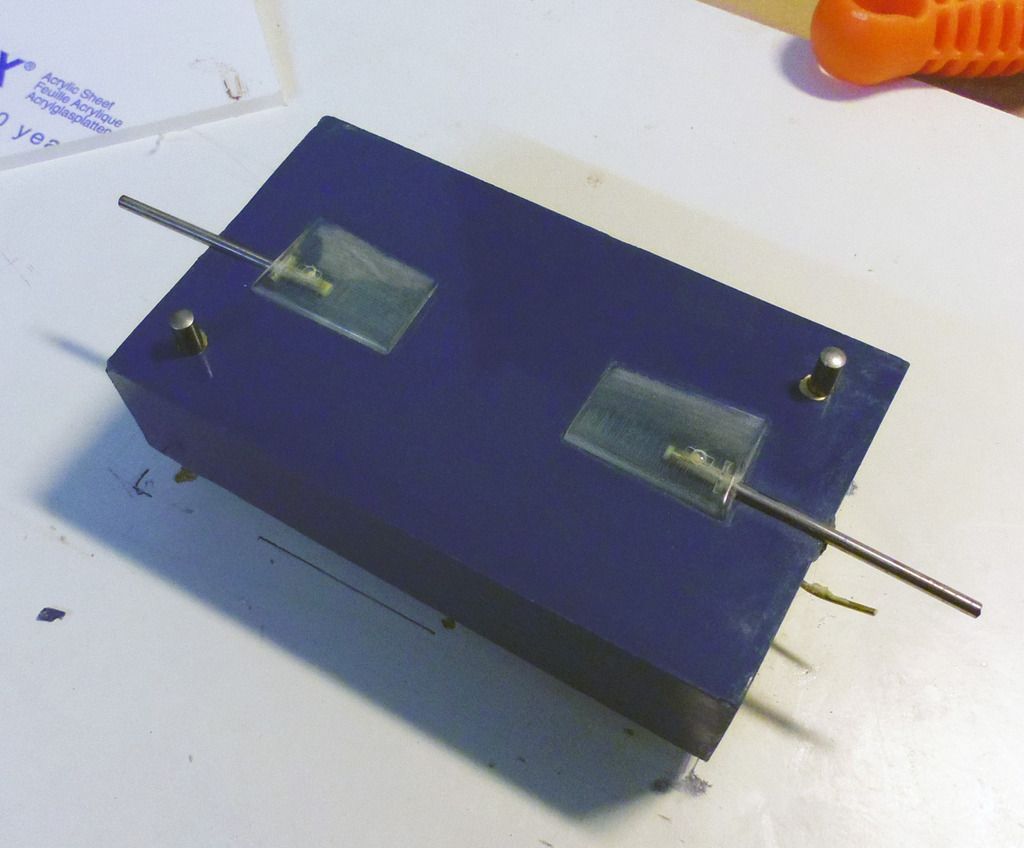

Not too mach space in the back in the boat, but I want a linkage without play. That's my sollution:

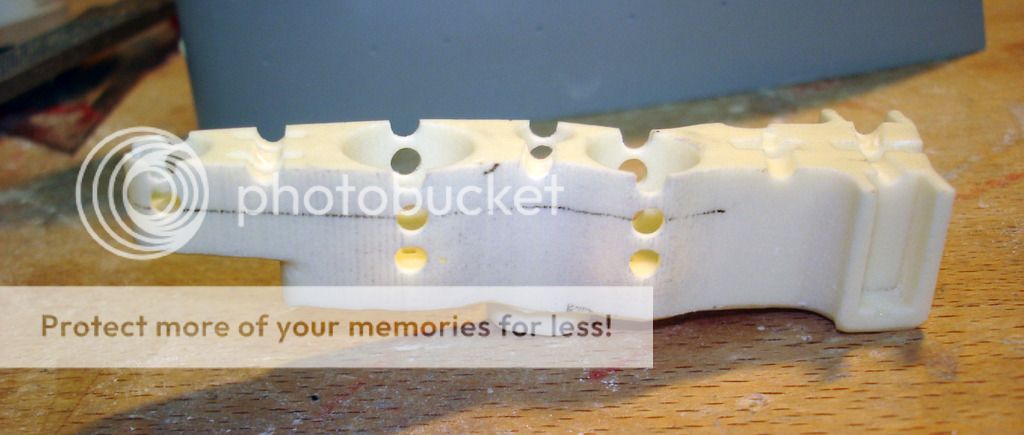

Make a flat on the side of a brass set collar and rill a hole (90° to the thread). Take a brass spherical joint and shorten it:

Solder sperical joint into the set collar and re-drill the center hole of the set collar:

Done:

Comment

-

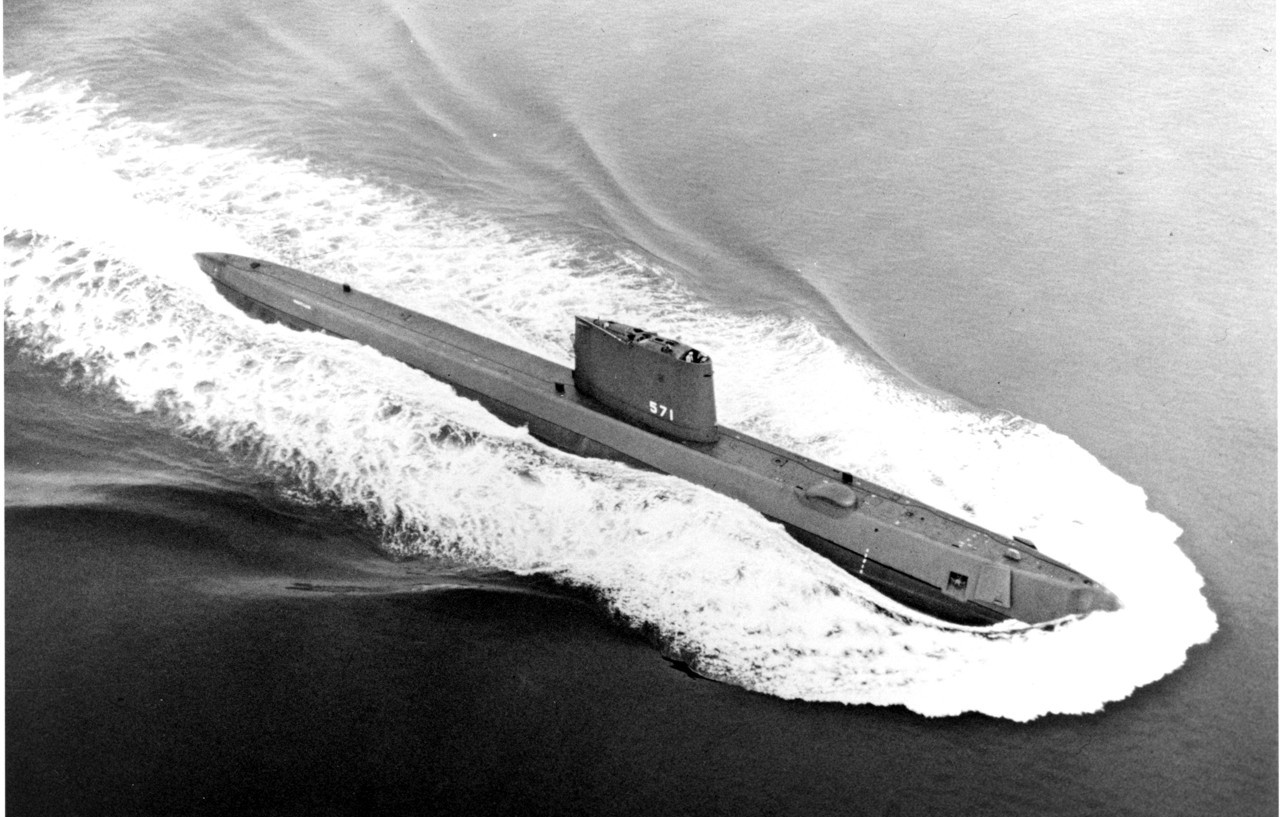

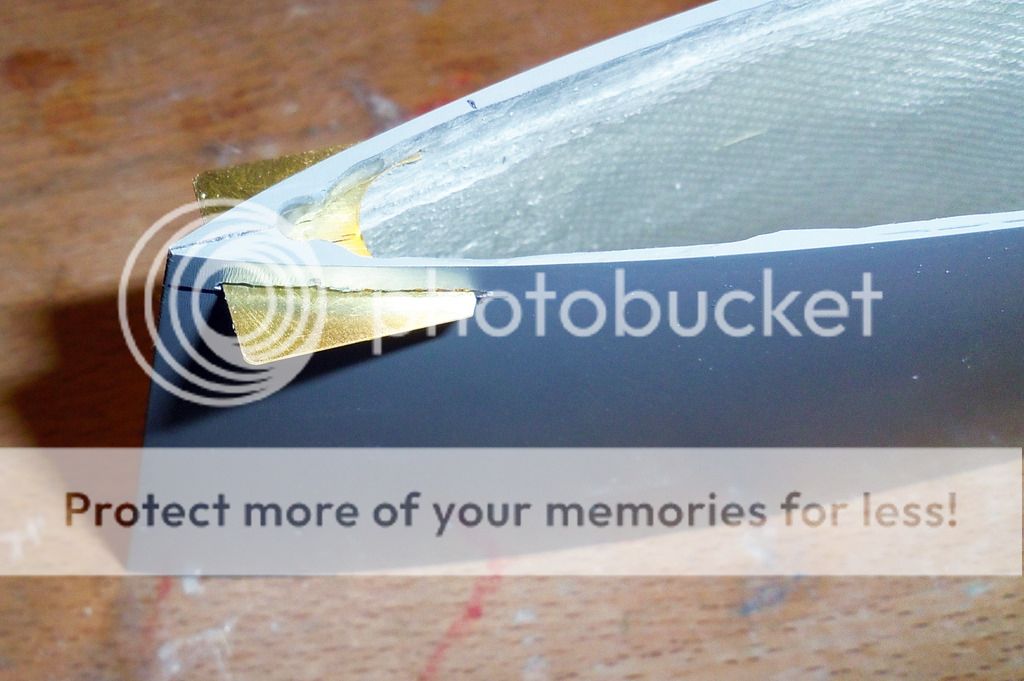

Decided to base my Nautilus model on this paint scheme:

Does anyone have infos about the true colors? Lower hull is black I guess, the upper part ocean grey, the deck seems to be darker (might be an optical illusion because of the planks, though).

Comment

Comment