New project

Collapse

X

-

Re: New project

HELLO , @ DrSchmidt

Is an ingenious way to shrink the space occupied by the components , and also the give them stiffness .

Why is it necessary to be so thick material ?,

The submarine does not get too heavy ? ,

From what material are made the parts ? ,

Same method it's used by ENGEL for their models .

It is quite professional .

MARIUS

Comment

-

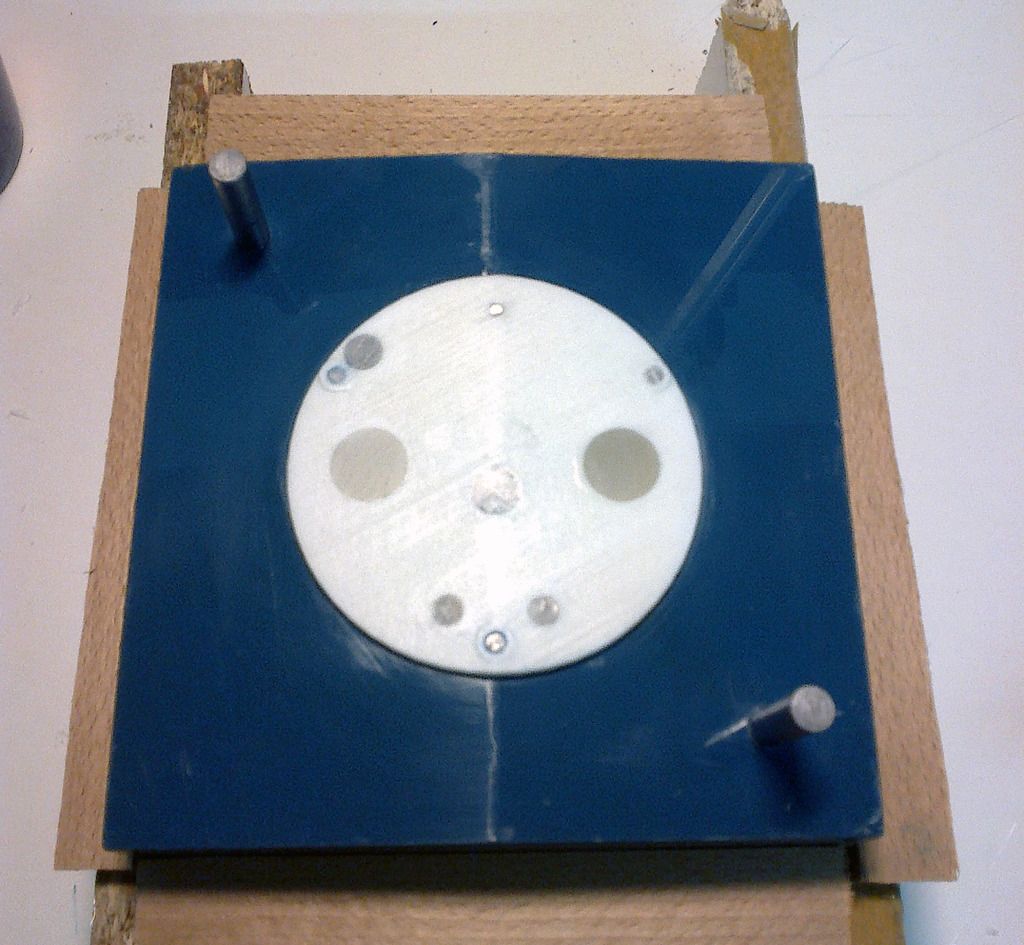

Re: New project

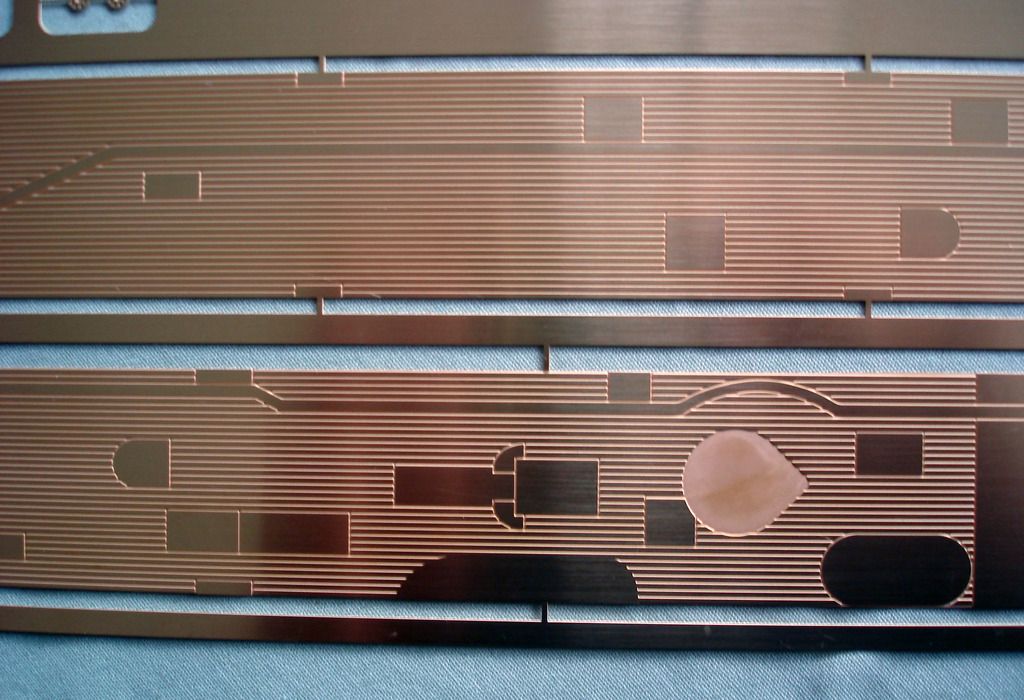

It's 5 mm PVC. I guess similar to the Engel boats, actually designed for an Engel tank, but the overall design is mine. PVC is not really heavy and as everything has to be connected by thread rods, I prefer thicker material, so that everything gets stiff and does not bend under its own weight. Too heavy? We'll see.....it's a prototype.

Cheers Andreas

Comment

-

Re: New project

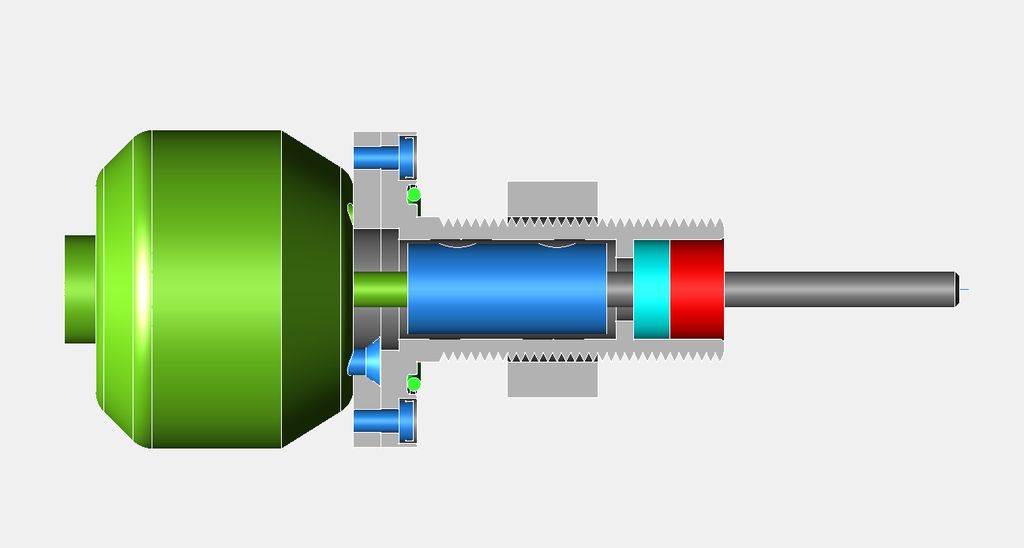

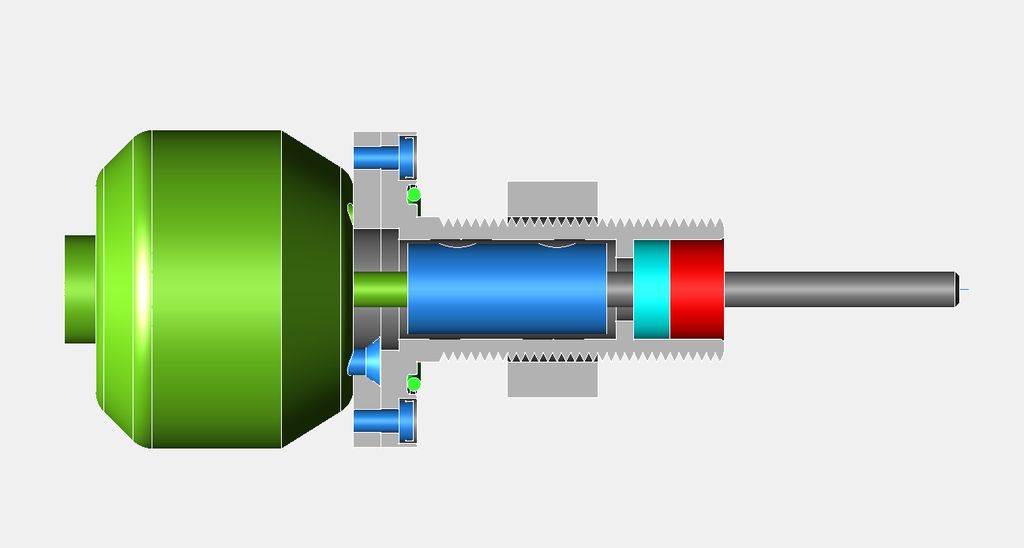

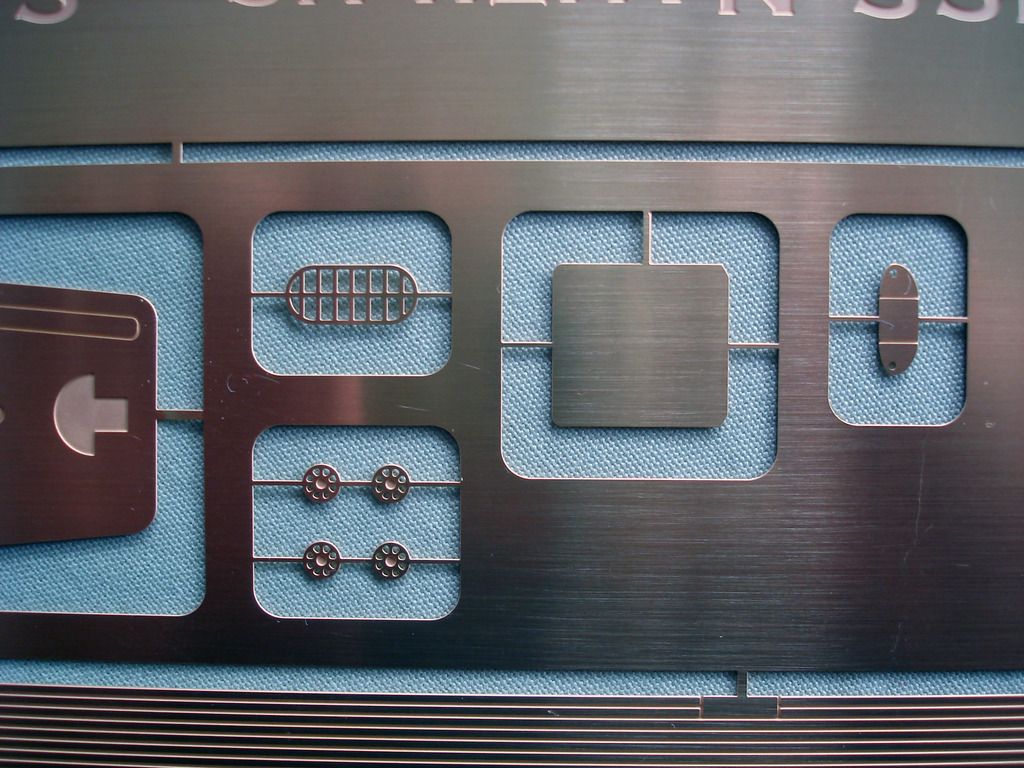

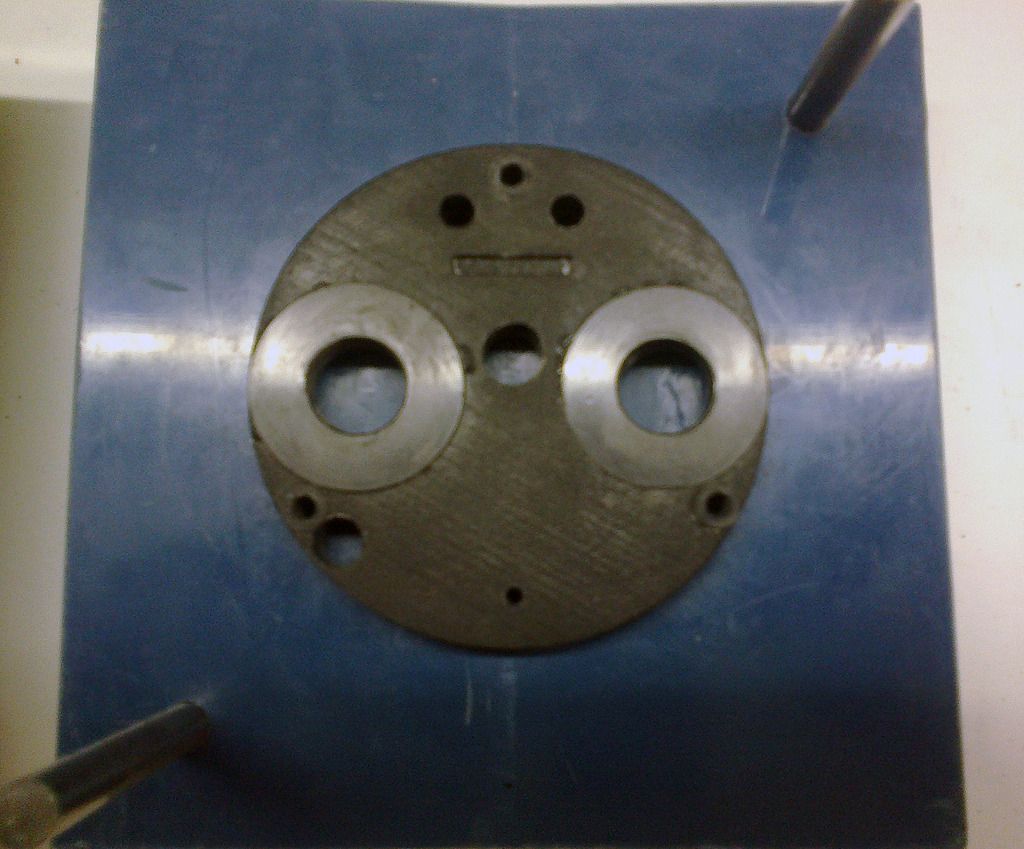

This will be the motor feed through of the Nautilus. Basically it's an advanced version of the ones I have in my U-1. Took a while to find a workshop that is now doing the parts. I guess I'll make some more.... The parts will be made of bronze and brass, it will have a ball bearing and an ID 4 mm rotary shaft seal. It will be attached to the rear bulkhead via a simple M16 fine thread and sealed via an o-ring. Advantage: only one hole in the bulkhead, no additional holes that have to be sealed. And it saves so much space in your boat....

Comment

-

-

Re: New project

HI @ DrSchmidt

OUTSTANDING work as everything You do .

Can You tell me Please what is that "red and light blue" piece and where is situated the ball bearing ? .

Is correct my assumption there are some Simmering/s ?.

THANK YOU .

MARIUS

Comment

-

-

Re: New project

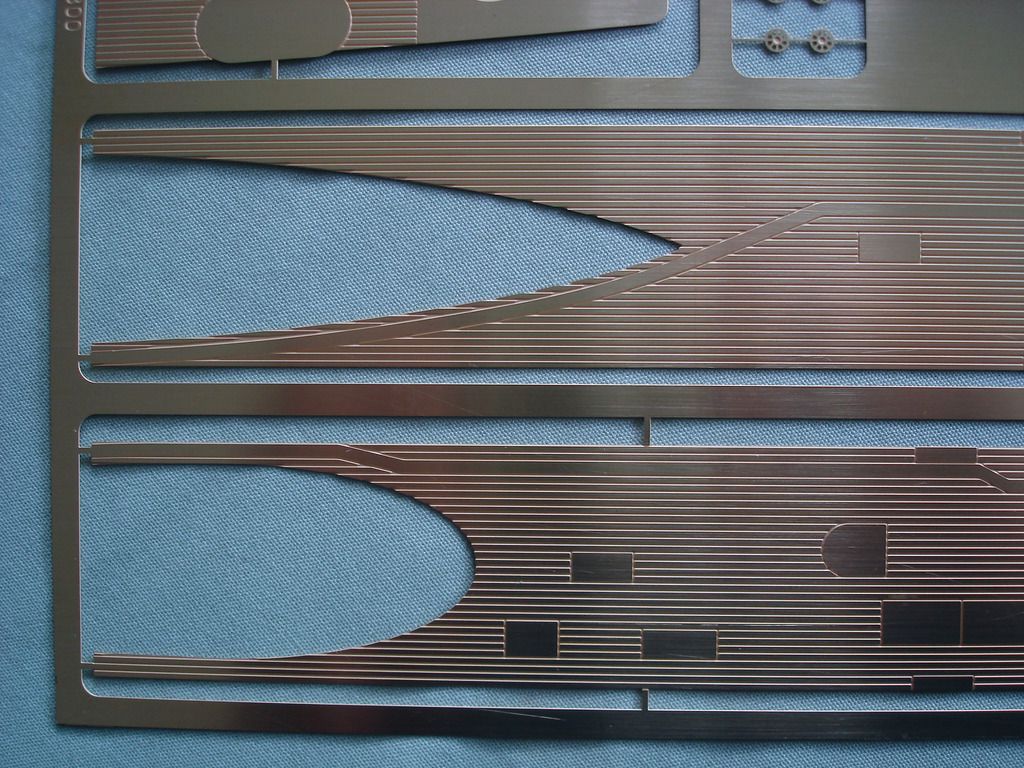

I've decided to make the watertight main section out of glass fiber, too. Attaching the deck to a plexiglas tube works, I've tried it successfully. But one has to fill the transition with filler and that is a) an annoying work and b) the result is, compared to the exact and sharp lines of the bow and stern, sub standard. So I have prepared the respective CAD files and ordered the milling of the preforms......

Comment

-

Re: New project

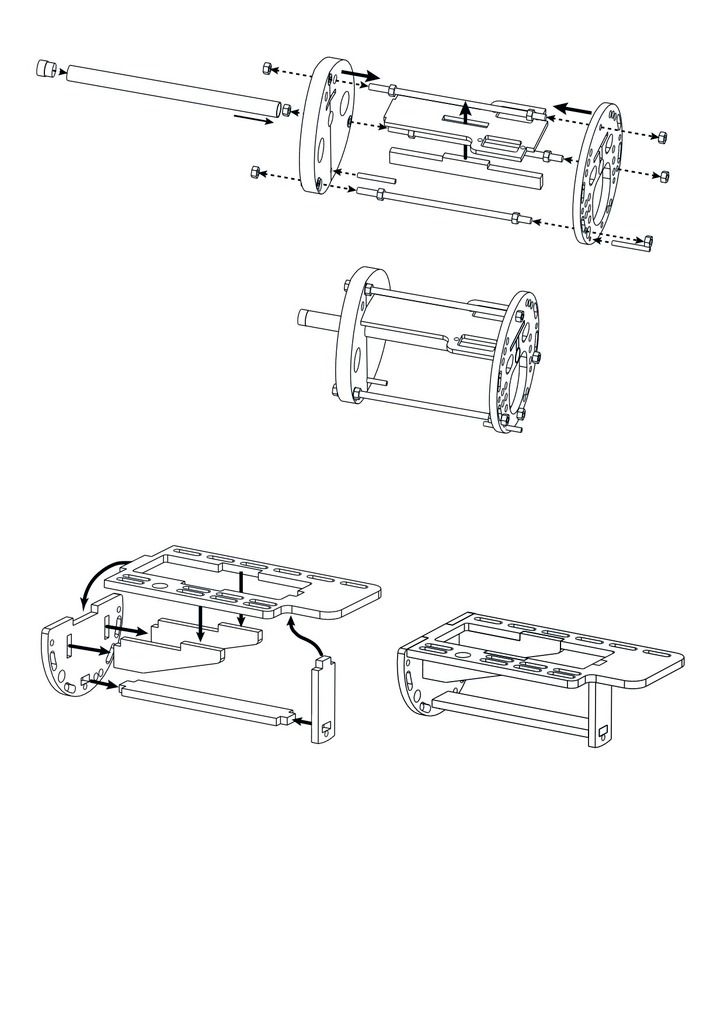

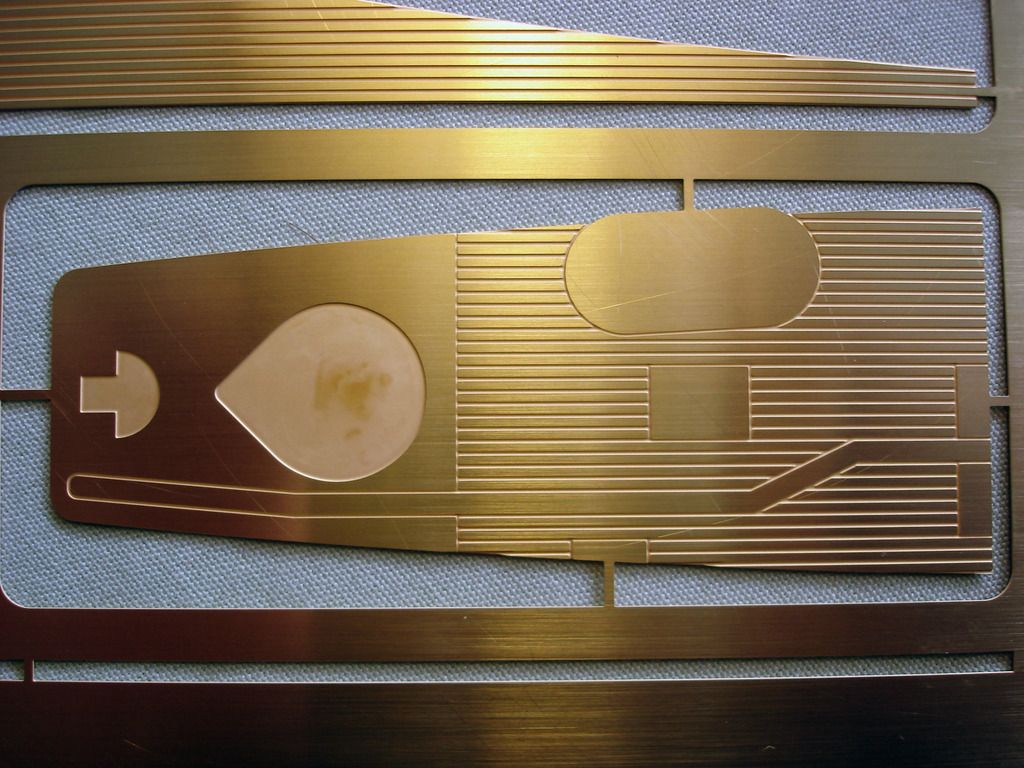

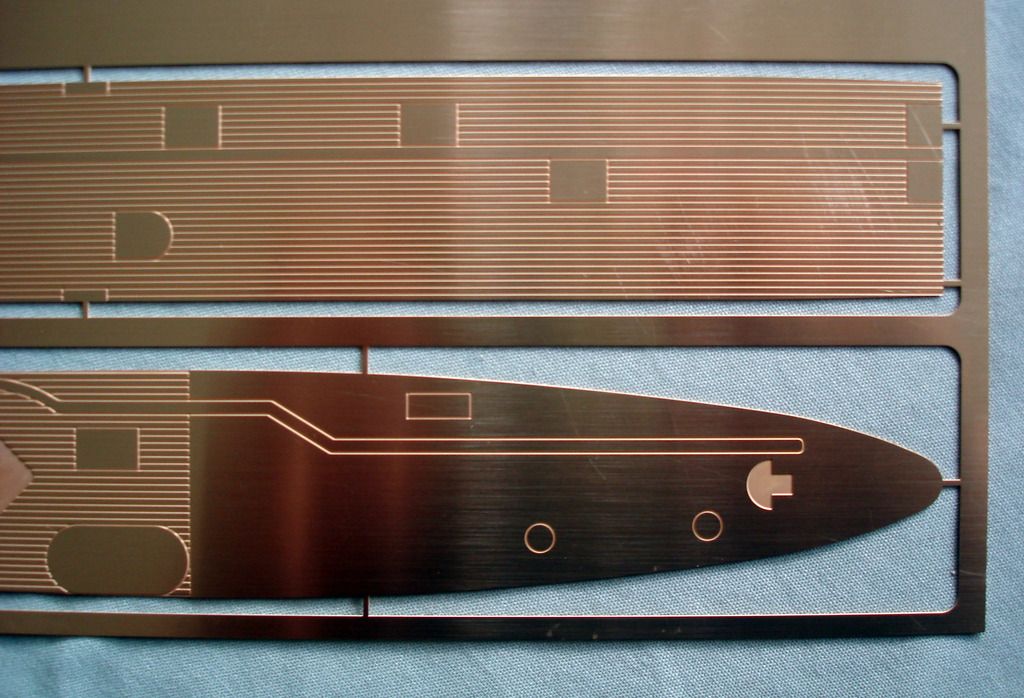

I thought a bit more about how to make the hull of gpr without losing the advantages of having a tube shaped pressure hull and to minimize the additional volume by the deck. This is how it's going to be. I can minimize the additional volume of the deck by making a trench in the structure that will be free flooding. The trench will also enable the flooding of the sail and it will connect the free flooding stern and bow sections. The photo-etched brass deck will get cuts that help venting the trench. The bridge structures help to ensure that the deck does not bend. The remaining left and right bump of the deck superstructure will be filled e.g. with resin and microballoons. This makes it possible to lay down the glass fiber in an almost perfect circular shape, restoring the full strength of a tube structure.

Comment

[/url]

[/url]

Comment