March 1st ================================================

Early this morning I had errands to do.

While out, I picked up some line to try on the steering pulleys.

This afternoon I was able to get in to the shop.

But my plans of a couple hours was not to be.

It seems yesterday when I was in the shop I turned on the heater because of the cold and high winds.

When I went in the shop today, it was 95F because I forgot to turn off the heater.

I thought I could hang in there but I was wrong.

20 minutes or so is all I could take.

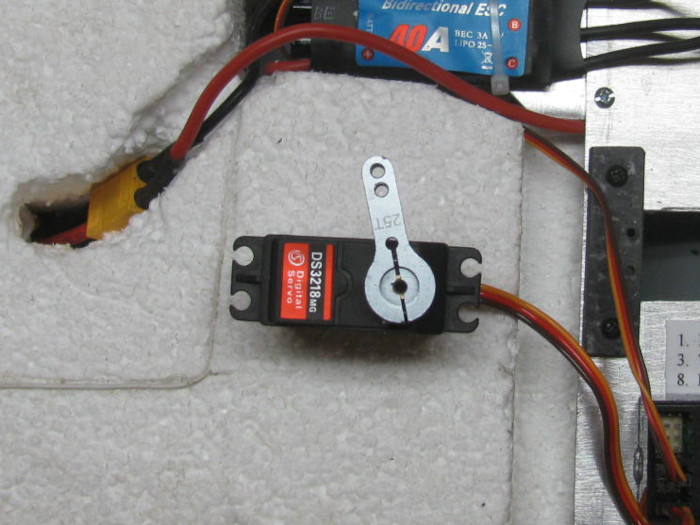

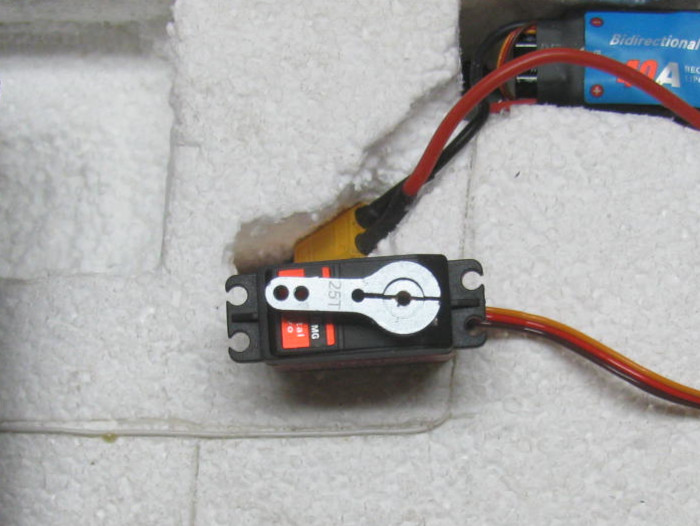

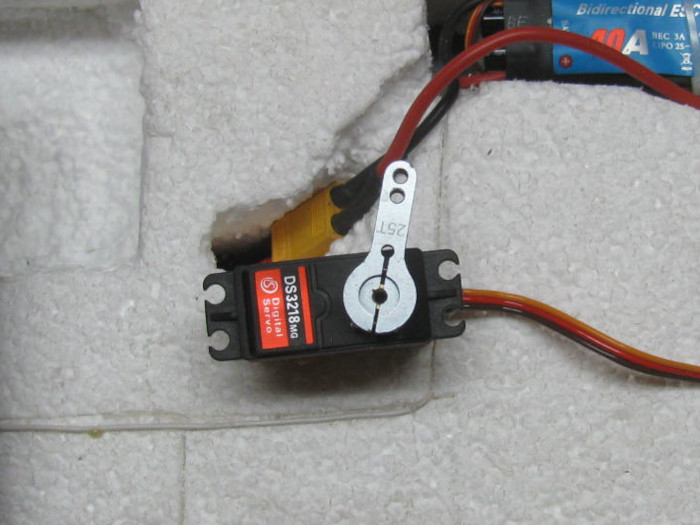

So this is what I got done.

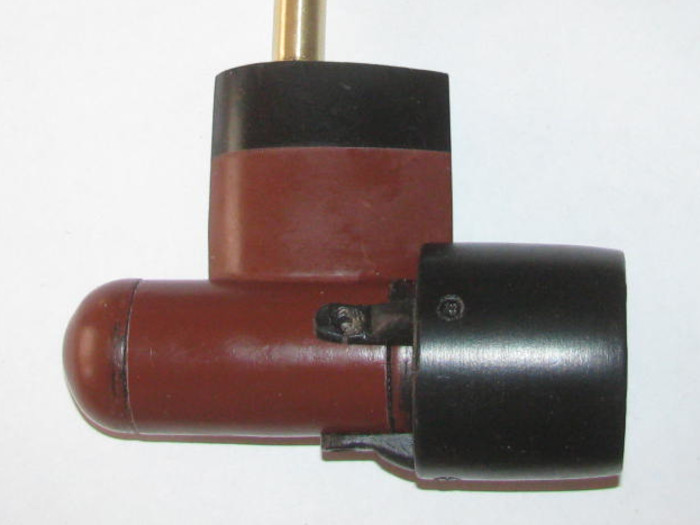

I installed the pod shaft through the rudder shaft.

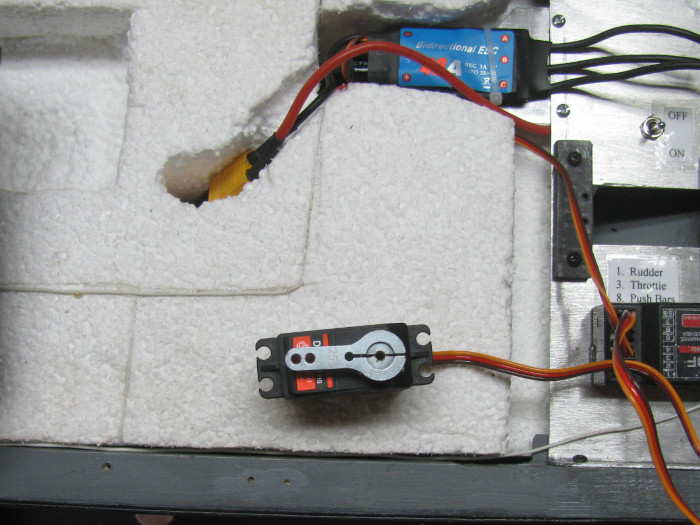

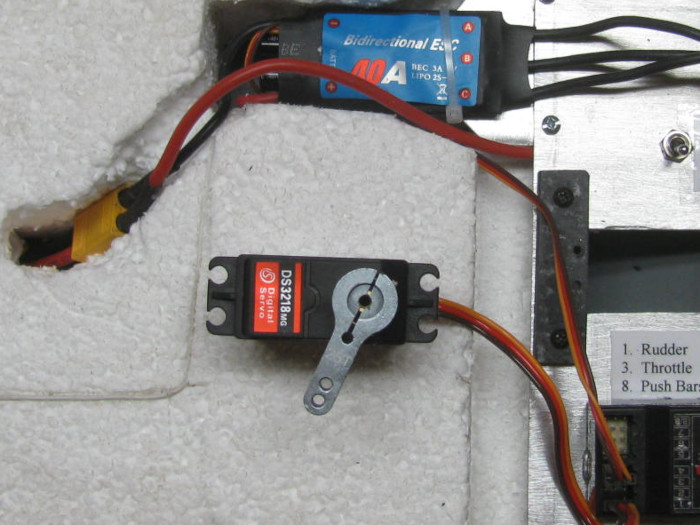

I soldered the 3 motor wires to the speed controller.

Covered the wires so they would not touch and short out.

I turned on the Tx and Rx systems.

Checked the propeller rotation.

I got it right the first time.

Checked the high speed. GOOD.

Check low speed for cogging.

There is but it is at the end of very slow rotation.

The slow rotation is more than acceptable.

I checked the solder joints to make sure I had got attachment.

Let them cool and slipped the heat shrink tube over the soldered joints.

I have not shrunk the tube yet.

I did more cutting in the foam for a better point to point for the battery wires.

This gets rid of the 6" extension wires.

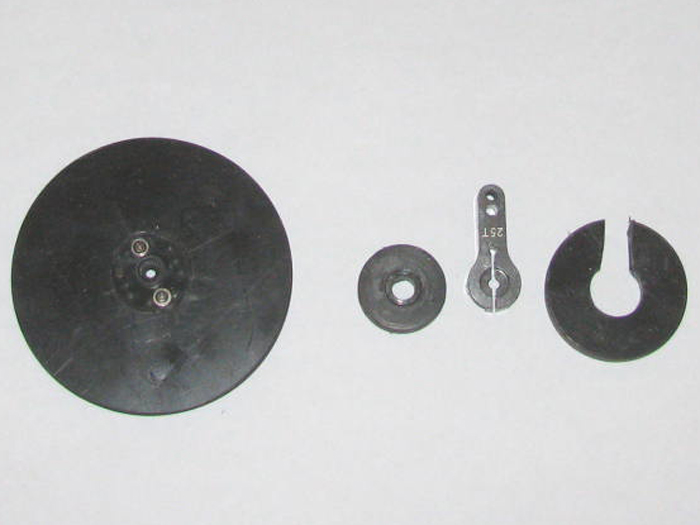

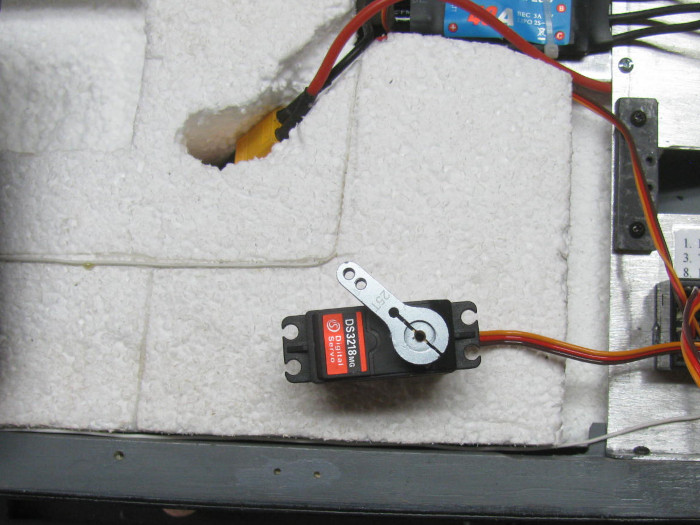

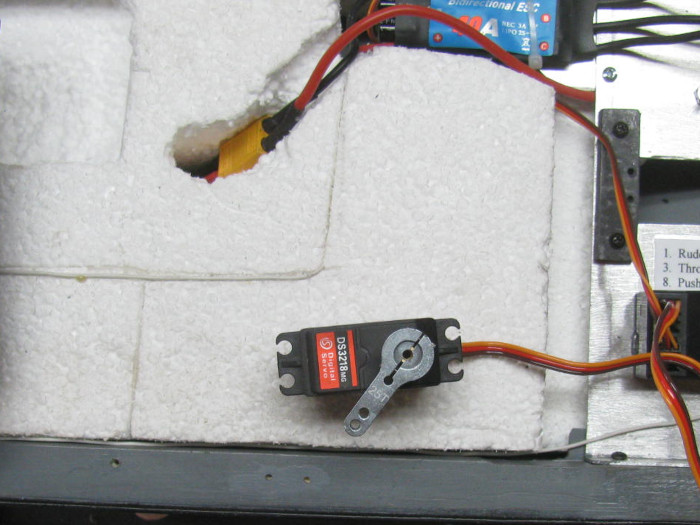

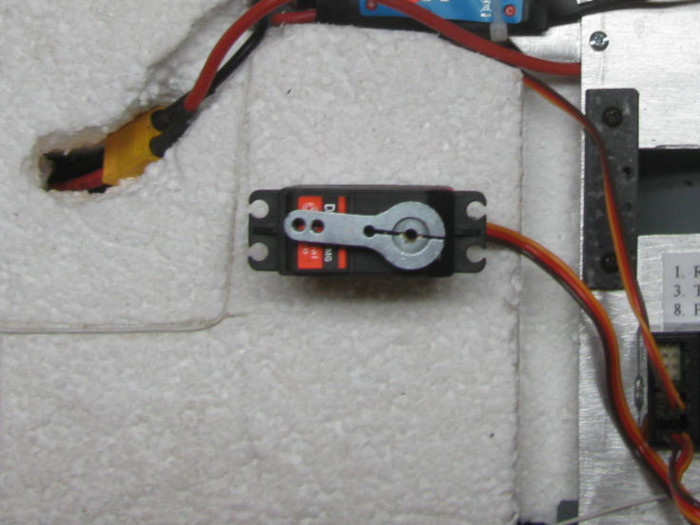

I moved on to the deck pusher bar linkage.

With the wheel collar set screws tight, the pusher bars slip on the connecting shaft.

I marked the shaft for the set screw locations and removed the shaft to grind flats on the shaft.

Should not slip any more.

I started to put the motor shroud on the pod but it has been long enough in the hot house.

I am done in the shop for today.

Tomorrow is more VA surgery.

2 appointments for 2 surgeries.

It will all be good.

Early this morning I had errands to do.

While out, I picked up some line to try on the steering pulleys.

This afternoon I was able to get in to the shop.

But my plans of a couple hours was not to be.

It seems yesterday when I was in the shop I turned on the heater because of the cold and high winds.

When I went in the shop today, it was 95F because I forgot to turn off the heater.

I thought I could hang in there but I was wrong.

20 minutes or so is all I could take.

So this is what I got done.

I installed the pod shaft through the rudder shaft.

I soldered the 3 motor wires to the speed controller.

Covered the wires so they would not touch and short out.

I turned on the Tx and Rx systems.

Checked the propeller rotation.

I got it right the first time.

Checked the high speed. GOOD.

Check low speed for cogging.

There is but it is at the end of very slow rotation.

The slow rotation is more than acceptable.

I checked the solder joints to make sure I had got attachment.

Let them cool and slipped the heat shrink tube over the soldered joints.

I have not shrunk the tube yet.

I did more cutting in the foam for a better point to point for the battery wires.

This gets rid of the 6" extension wires.

I moved on to the deck pusher bar linkage.

With the wheel collar set screws tight, the pusher bars slip on the connecting shaft.

I marked the shaft for the set screw locations and removed the shaft to grind flats on the shaft.

Should not slip any more.

I started to put the motor shroud on the pod but it has been long enough in the hot house.

I am done in the shop for today.

Tomorrow is more VA surgery.

2 appointments for 2 surgeries.

It will all be good.

Comment