January 30th =================================================

A bit chilly outside but warm enough to get some sanding done.

No wind makes even better.

Weather says 41F but looking at my thermometer on the shop wall says it is about 54F.

Out to the steel work bench I do.

Sanded the transportation box and the lid.

I see a few more spots to glaze.

Not much.

Just seams that need more filling after the glaze shrank when it cured.

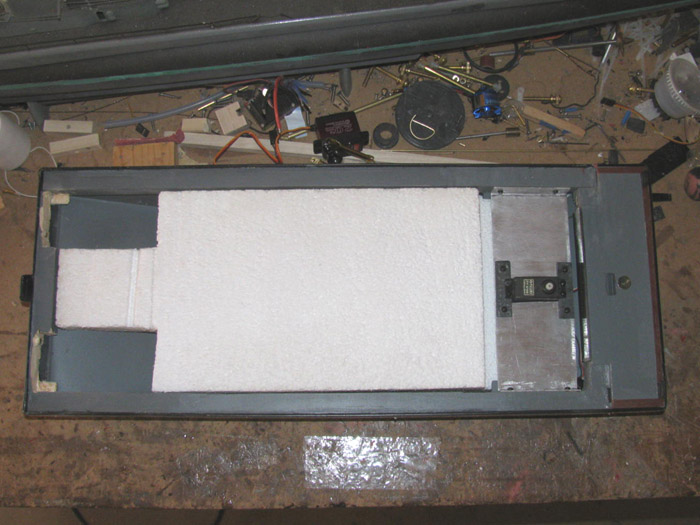

Back in the shop I installed the 4 trim boards that the lid frame sits on to take any weight that might come it's way.

The lid trim sits on the box top edge but is not very strong should there be weight on the lids.

These 4 trim boards are down inside the box and the lid frame will sit on them taking the load off the lid trim boards.

Glazed the few spots.

I will probably hand sand them tomorrow with a wooded block.

Maybe 5 minutes to do it all.

If the weather is like today, I should be able to get the tack coat of paint on the box and lid.

Might even get the first full coat on the box.

After lunch, I think I will go out to the shop and paint the Tx case and mount the small badge.

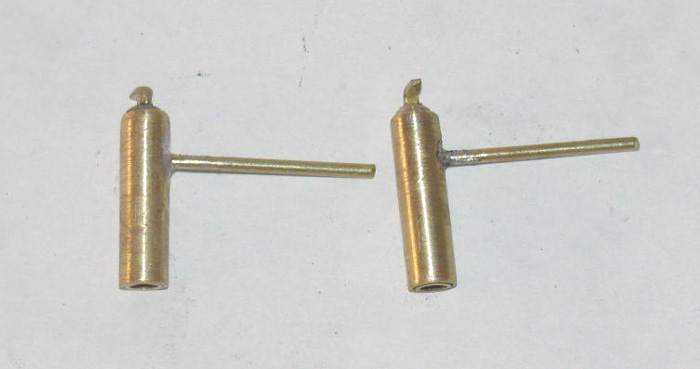

Here are 2 Tx cases with their badges.

Old photo. There are now 3 badges on the left case and 2 on the right case.

(left case has B-boat, Skipjack and Akula II)

(Right case has Gato and George Washington)

The Rescue Barge has it's own Tx so there will be only 1 badge on the case at this point.

(this is because if I need to rescue a boat I can not have the Rescue Barge on the same Tx)

----------------------------

Tx case measured and taped off.

Tack coat applied.

The front has been done.

3 coats of paint on top of that.

This is the back with it's tack coat.

I did the 3 coats of paint but did not take photo.

I will pull the tape tomorrow or tonight.

I brought the case and the badge in the house where it is warmer to dry.

.

.

A bit chilly outside but warm enough to get some sanding done.

No wind makes even better.

Weather says 41F but looking at my thermometer on the shop wall says it is about 54F.

Out to the steel work bench I do.

Sanded the transportation box and the lid.

I see a few more spots to glaze.

Not much.

Just seams that need more filling after the glaze shrank when it cured.

Back in the shop I installed the 4 trim boards that the lid frame sits on to take any weight that might come it's way.

The lid trim sits on the box top edge but is not very strong should there be weight on the lids.

These 4 trim boards are down inside the box and the lid frame will sit on them taking the load off the lid trim boards.

Glazed the few spots.

I will probably hand sand them tomorrow with a wooded block.

Maybe 5 minutes to do it all.

If the weather is like today, I should be able to get the tack coat of paint on the box and lid.

Might even get the first full coat on the box.

After lunch, I think I will go out to the shop and paint the Tx case and mount the small badge.

Here are 2 Tx cases with their badges.

Old photo. There are now 3 badges on the left case and 2 on the right case.

(left case has B-boat, Skipjack and Akula II)

(Right case has Gato and George Washington)

The Rescue Barge has it's own Tx so there will be only 1 badge on the case at this point.

(this is because if I need to rescue a boat I can not have the Rescue Barge on the same Tx)

----------------------------

Tx case measured and taped off.

Tack coat applied.

The front has been done.

3 coats of paint on top of that.

This is the back with it's tack coat.

I did the 3 coats of paint but did not take photo.

I will pull the tape tomorrow or tonight.

I brought the case and the badge in the house where it is warmer to dry.

.

.

Comment