A servo tester.

Why, no I do not have a servo tester.

I do have 2 Tx and a hand full of Rx on the work bench.

Just a matter of tuning the Tx to the Rx of choice and having a charged battery.

The Futaba 9CAP Tx is computer controlled and I can turn any channel from zero to 130 % travel.

I try to not break things, I start at 5% then while everything is on I can turn the percentage up at the Tx to adjust the needed throw.

My other Tx do not have this feature.

So basically it requires a little more work to setup.

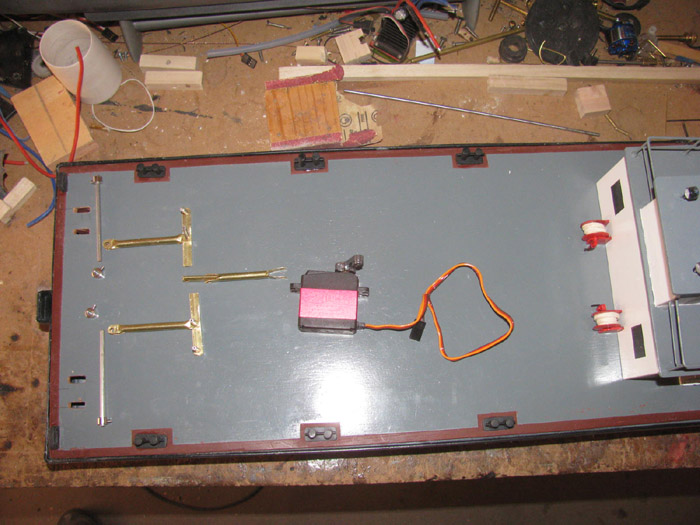

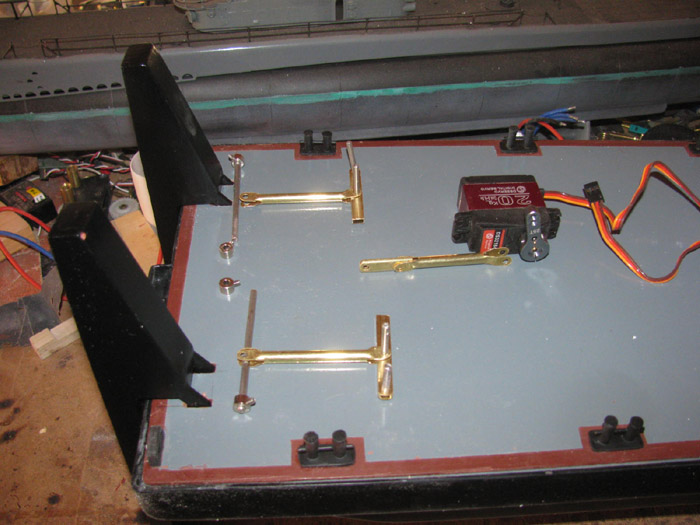

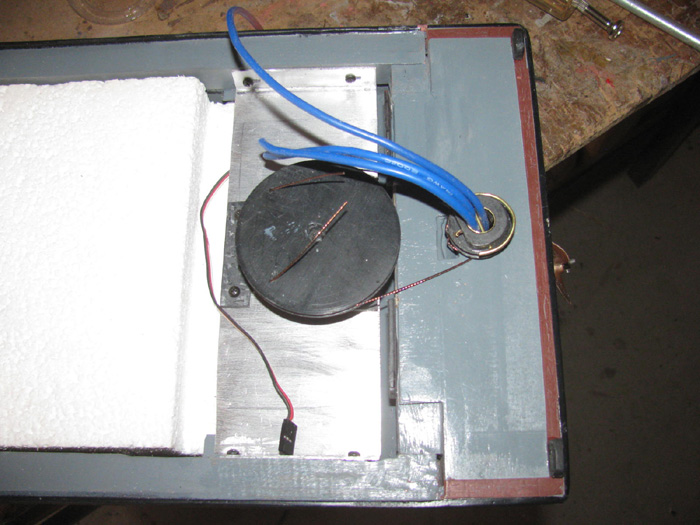

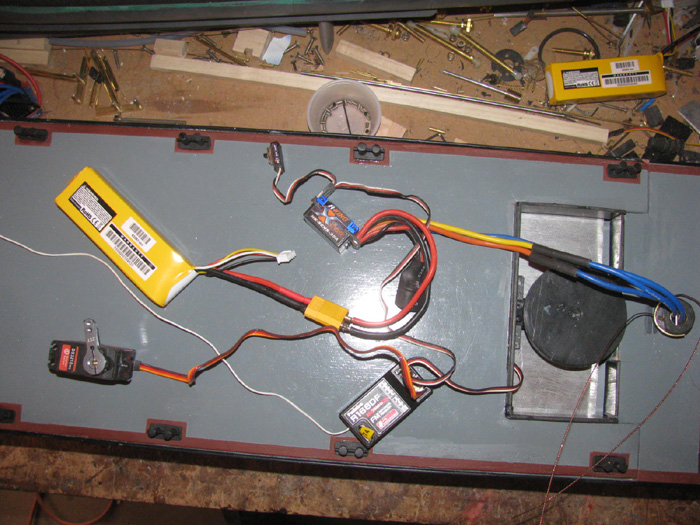

I will also have to adjust the rudder servo and speed controller because I do not want this boat going very fast at full throttle and I need a little more than 90 degree to each side.

I do draw on paper the full size linkage and then see how much servo throw I need and this gives me the location of the holes in the horns.

It is usually close enough with a little adjustment to the Tx.

My Skipjack was a lot of fun because the Tx is shadered with the Aklula II and all linkage adjustment is physical.

The Akula II was setup first to the Tx.

Then I had to match the Skipjack linkage t work on the same Tx.

No computer in that Tx.

If I make it to easy, what fun would that be! <GG>

Why, no I do not have a servo tester.

I do have 2 Tx and a hand full of Rx on the work bench.

Just a matter of tuning the Tx to the Rx of choice and having a charged battery.

The Futaba 9CAP Tx is computer controlled and I can turn any channel from zero to 130 % travel.

I try to not break things, I start at 5% then while everything is on I can turn the percentage up at the Tx to adjust the needed throw.

My other Tx do not have this feature.

So basically it requires a little more work to setup.

I will also have to adjust the rudder servo and speed controller because I do not want this boat going very fast at full throttle and I need a little more than 90 degree to each side.

I do draw on paper the full size linkage and then see how much servo throw I need and this gives me the location of the holes in the horns.

It is usually close enough with a little adjustment to the Tx.

My Skipjack was a lot of fun because the Tx is shadered with the Aklula II and all linkage adjustment is physical.

The Akula II was setup first to the Tx.

Then I had to match the Skipjack linkage t work on the same Tx.

No computer in that Tx.

If I make it to easy, what fun would that be! <GG>

Comment