December 26th =================================================

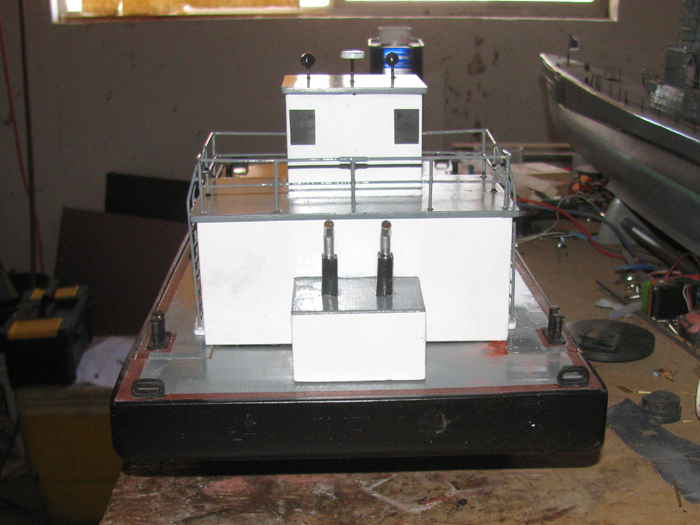

I had about 30 to 45 minutes in the shop this morning.

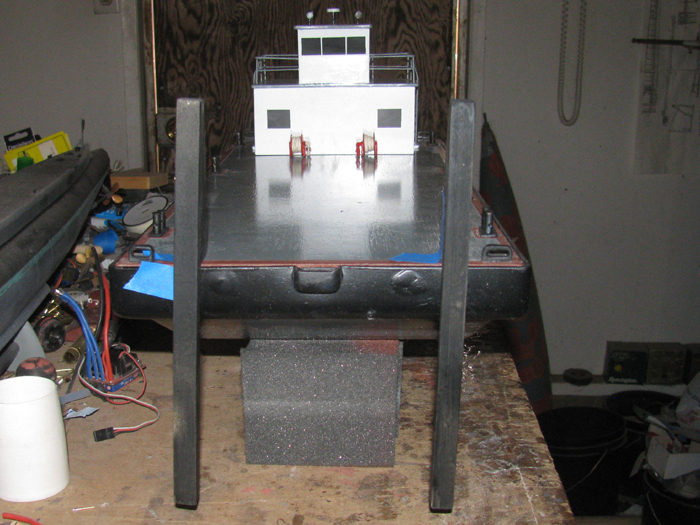

Painted the spotlights black.

I did not like the white.

Worked on the glazing on the stern block.

Sanded and reglazed.

Cleaned the railing with paint thinner.

Files a couple of spots where the solder was sticking out and sharp.

Applied a first coat of gray.

It is going to need a second coat.

The brass shows through in spots.

I will let this paint dry then apply a second coat.

After that, I will move on to touching up the white.

There are some places that are just too much to be considered work related.

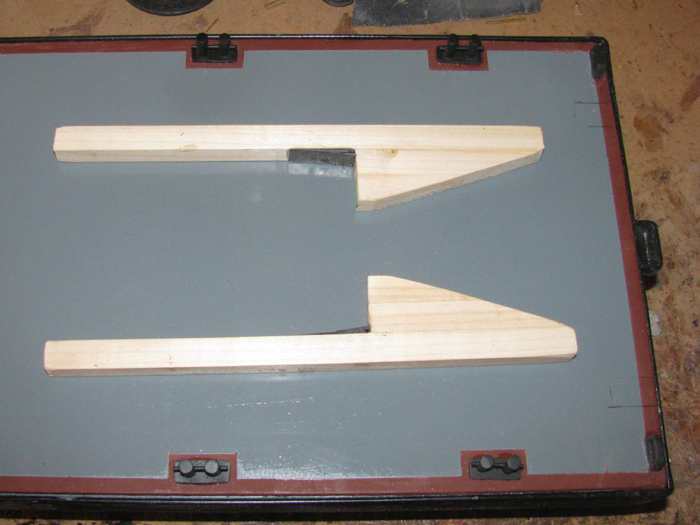

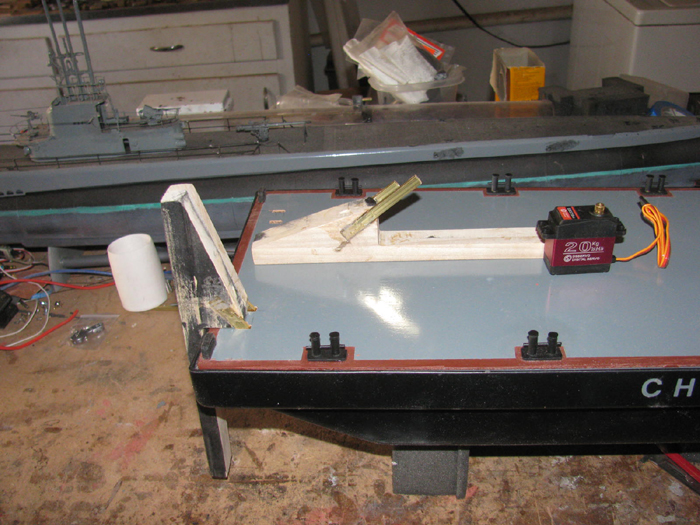

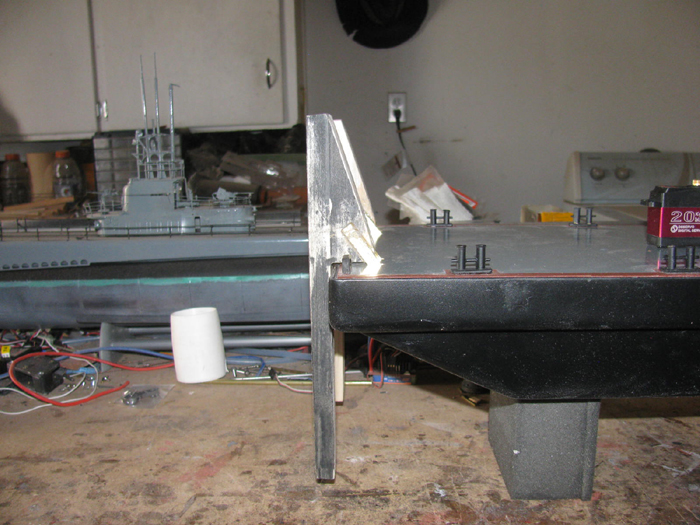

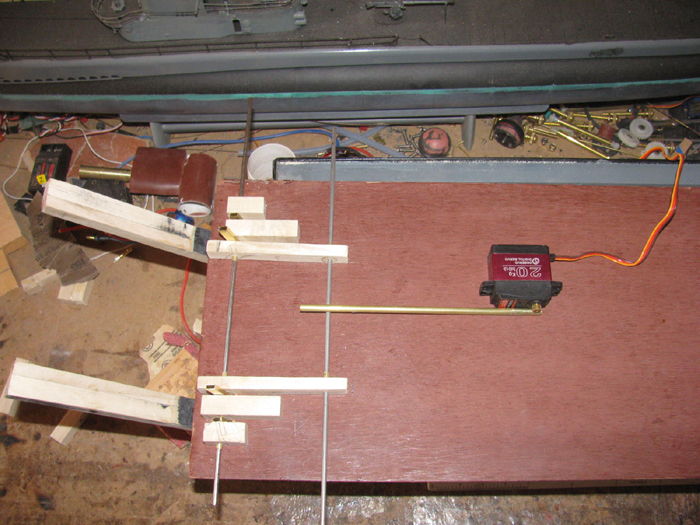

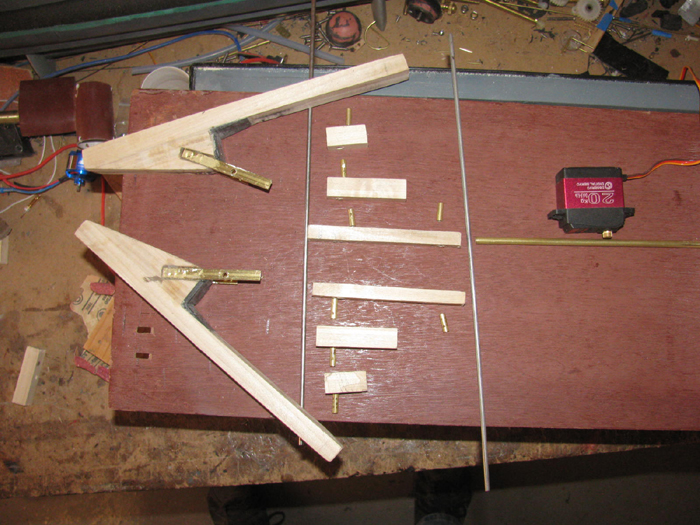

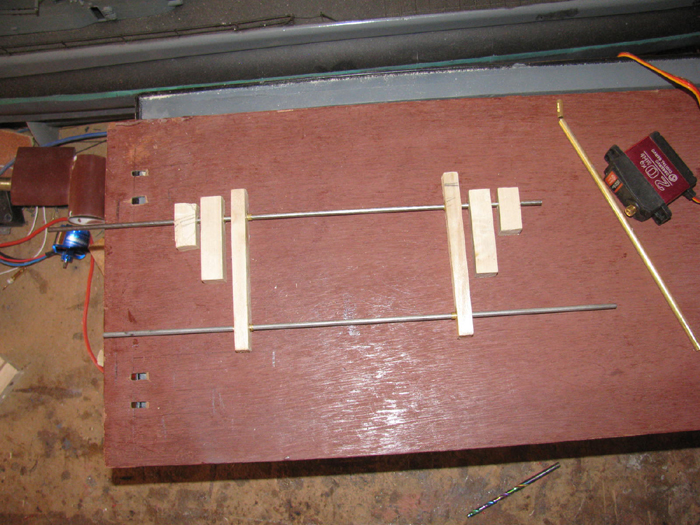

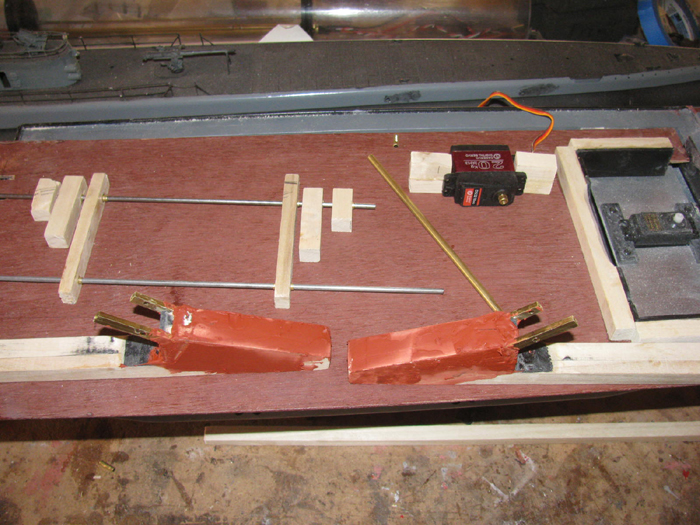

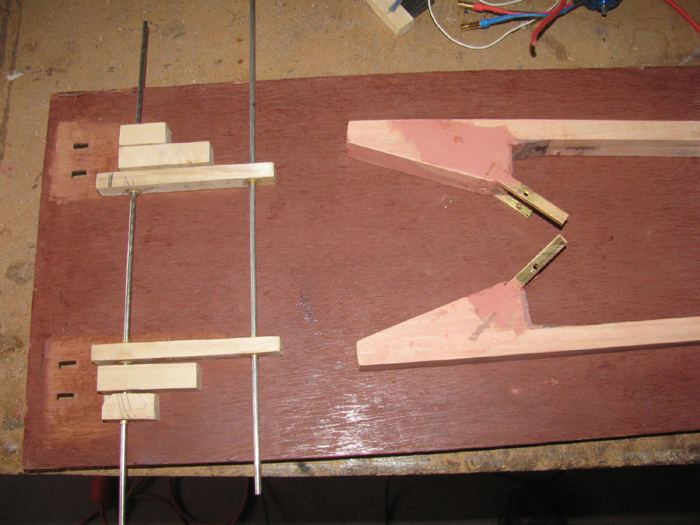

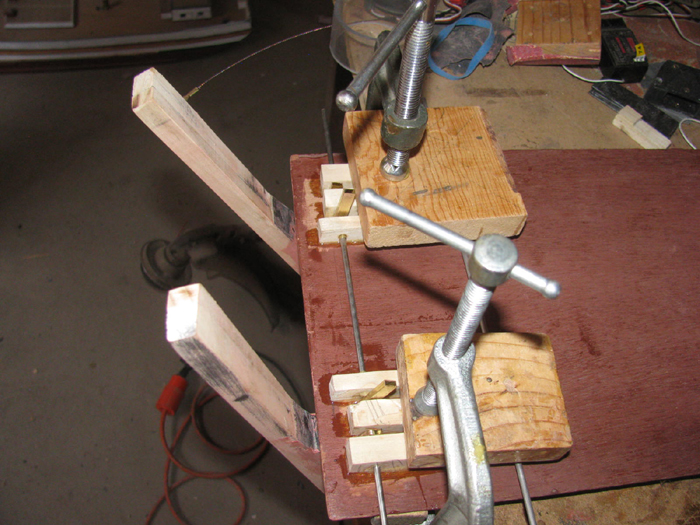

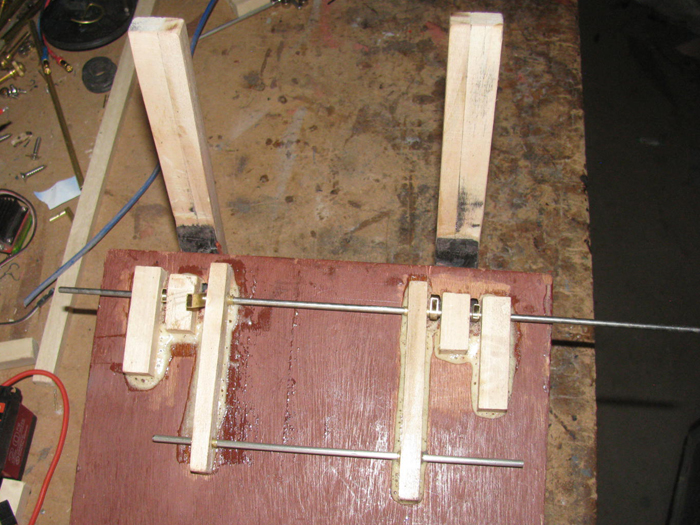

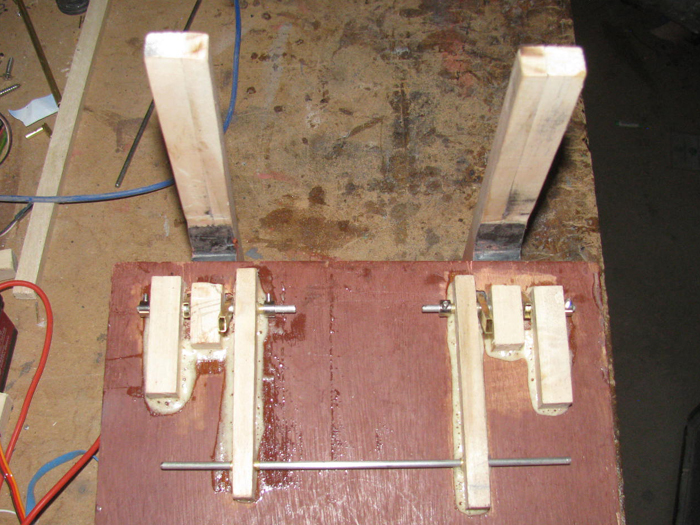

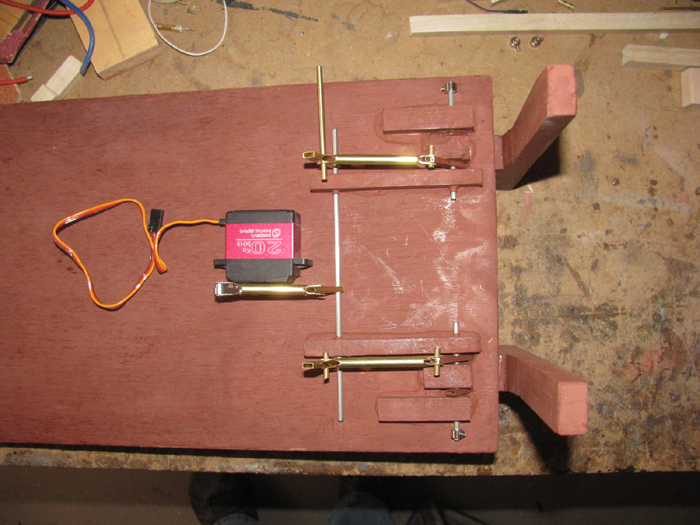

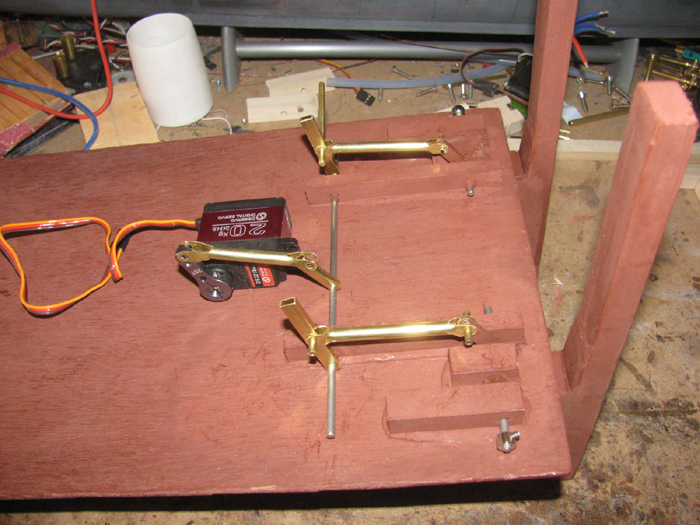

Finished up the shims on the pusher bars.

The hull sides are not 90 degrees tot he bench top.

I had put a 1/16" plastic shim on last week.

Today while fitting, it took another 1/16" to get it square.

In 1" distance I needed to go from zero to 1/8" to get square.

Go that done and sanded for primer.

Photo just before applying primer.

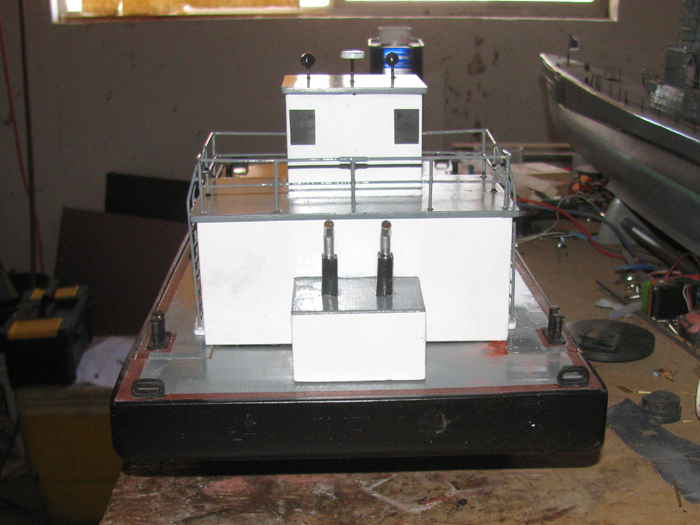

I had about 30 to 45 minutes in the shop this morning.

Painted the spotlights black.

I did not like the white.

Worked on the glazing on the stern block.

Sanded and reglazed.

Cleaned the railing with paint thinner.

Files a couple of spots where the solder was sticking out and sharp.

Applied a first coat of gray.

It is going to need a second coat.

The brass shows through in spots.

I will let this paint dry then apply a second coat.

After that, I will move on to touching up the white.

There are some places that are just too much to be considered work related.

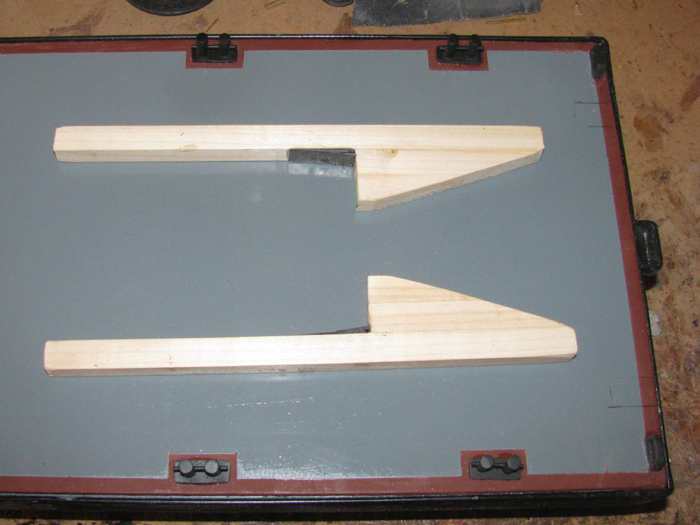

Finished up the shims on the pusher bars.

The hull sides are not 90 degrees tot he bench top.

I had put a 1/16" plastic shim on last week.

Today while fitting, it took another 1/16" to get it square.

In 1" distance I needed to go from zero to 1/8" to get square.

Go that done and sanded for primer.

Photo just before applying primer.

Comment