Originally posted by salmon

View Post

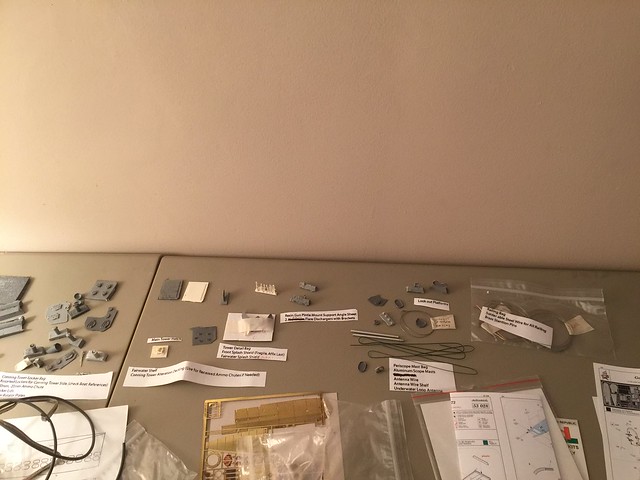

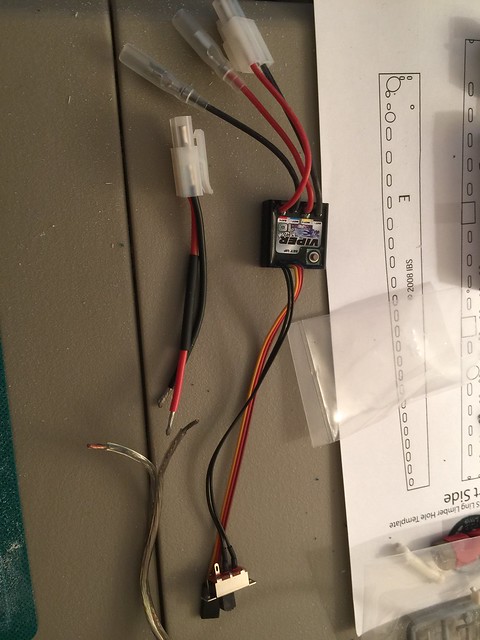

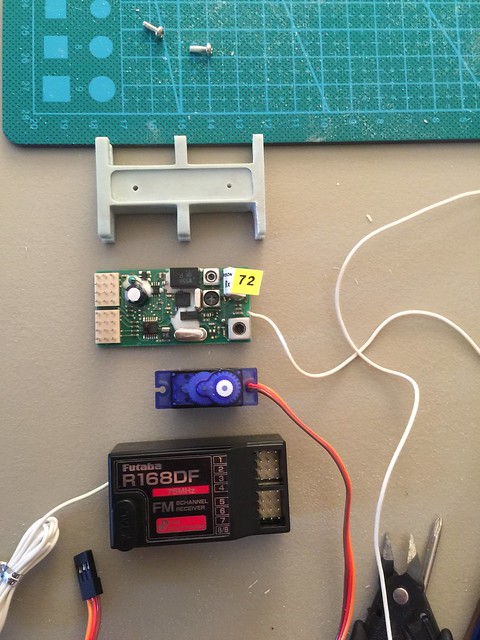

Stencils, replacement gun, and tower all came from Iron Bottom Sound. I can't remember, but I think I got the 'Government Long Balaos' tower. You'll still be using some of the Revell kit parts on it since it isn't a 100% replacement. The Sub-Driver and fittings kit came from Bob at Nautilus Drydocks, but he did announce that they'd stop carrying them so he might not have them anymore, so It'd be something to ask him.

Comment