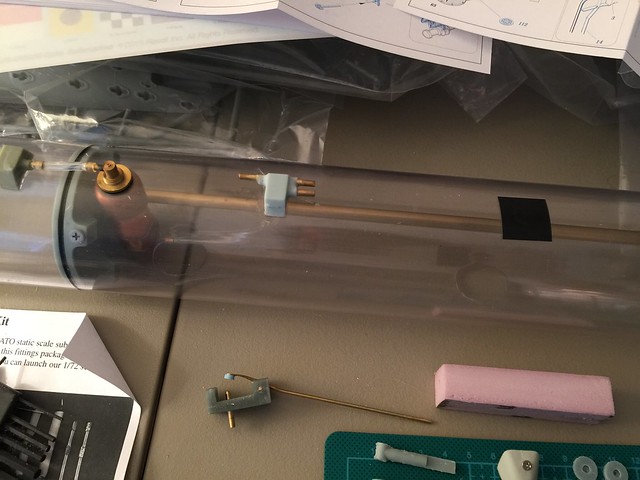

So, I have a sub-driver (finally) for the boat but I'm at a complete loss on how to set it up. I think I need tubing, but I don't know what size or kind, or where to get it, same goes for what I think is a 5mm bucket joint.

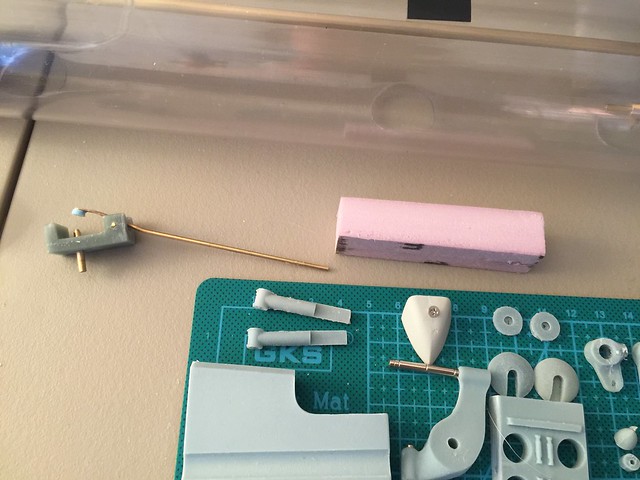

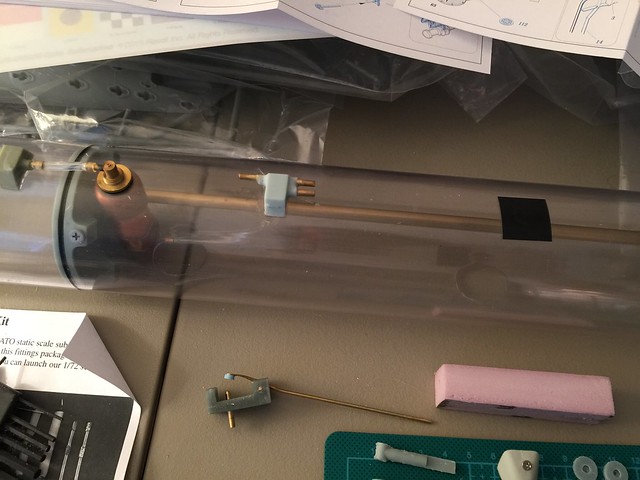

This would be the snorkel, but I don't have any tubing for it and I don't know how to set it up in the tower.

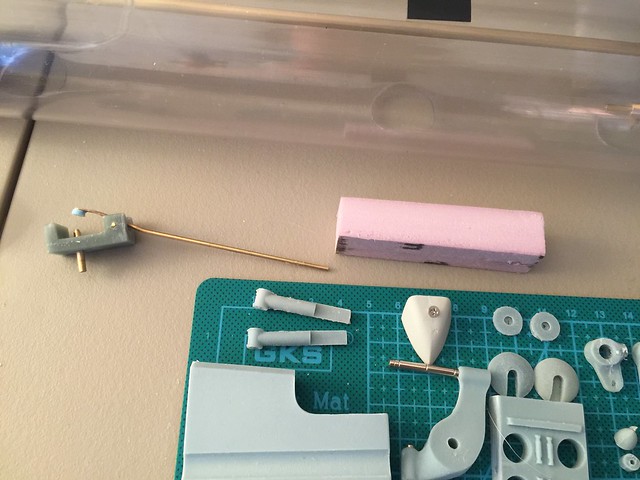

I thing I might be missing something else, but I don't know what it is.

Something that goes to something else.

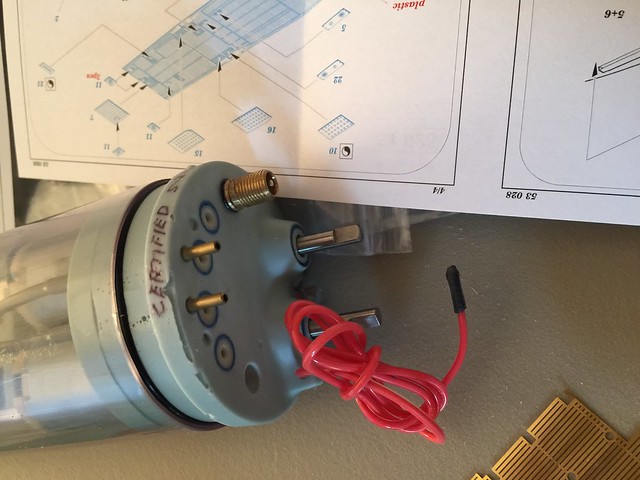

connected ports that I assume go somewhere?

Well, this is what I have and the sub driver forums seem to be down, so any help (or instructions) would be appreciated! Thanks

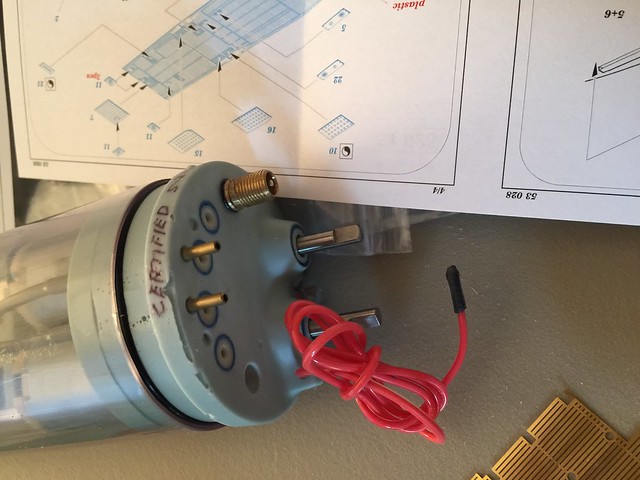

This would be the snorkel, but I don't have any tubing for it and I don't know how to set it up in the tower.

I thing I might be missing something else, but I don't know what it is.

Something that goes to something else.

connected ports that I assume go somewhere?

Well, this is what I have and the sub driver forums seem to be down, so any help (or instructions) would be appreciated! Thanks

Comment