http://www.subcommittee.com/forum/icon_question.gif Dear Crazy:

I noticed that

Dear Crazy:

Dear Crazy:

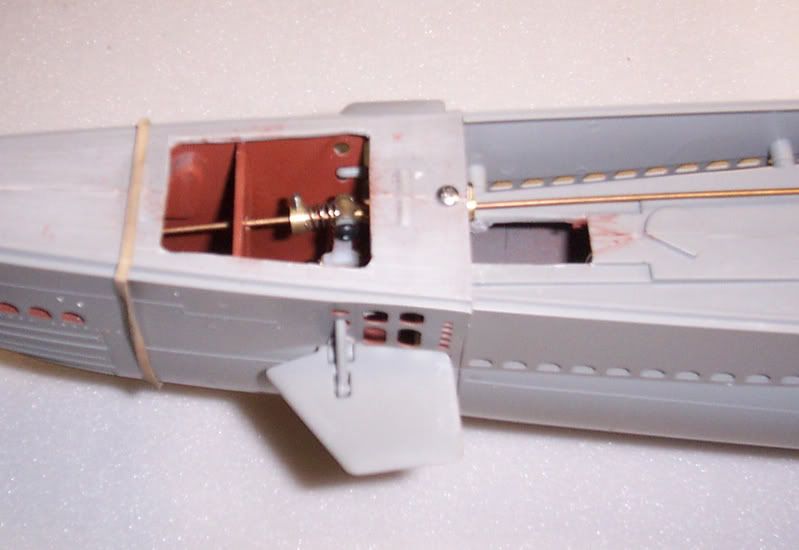

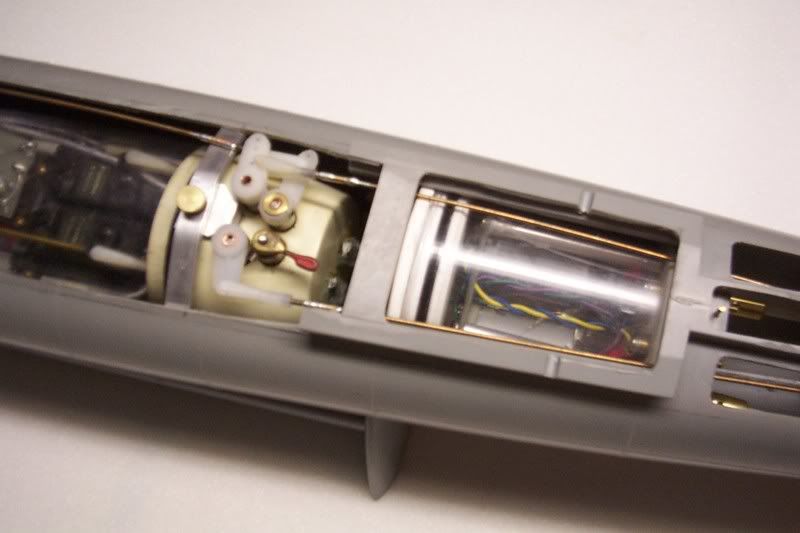

I noticed that you are using direct drive. From what I can see you are using 300 series motors. I'm wondering whether the motors will be able to turn 30mm four bladed props on direct without lugging. What voltage do you plan to run them on?

I noticed that

I noticed that you are using direct drive. From what I can see you are using 300 series motors. I'm wondering whether the motors will be able to turn 30mm four bladed props on direct without lugging. What voltage do you plan to run them on?

Comment