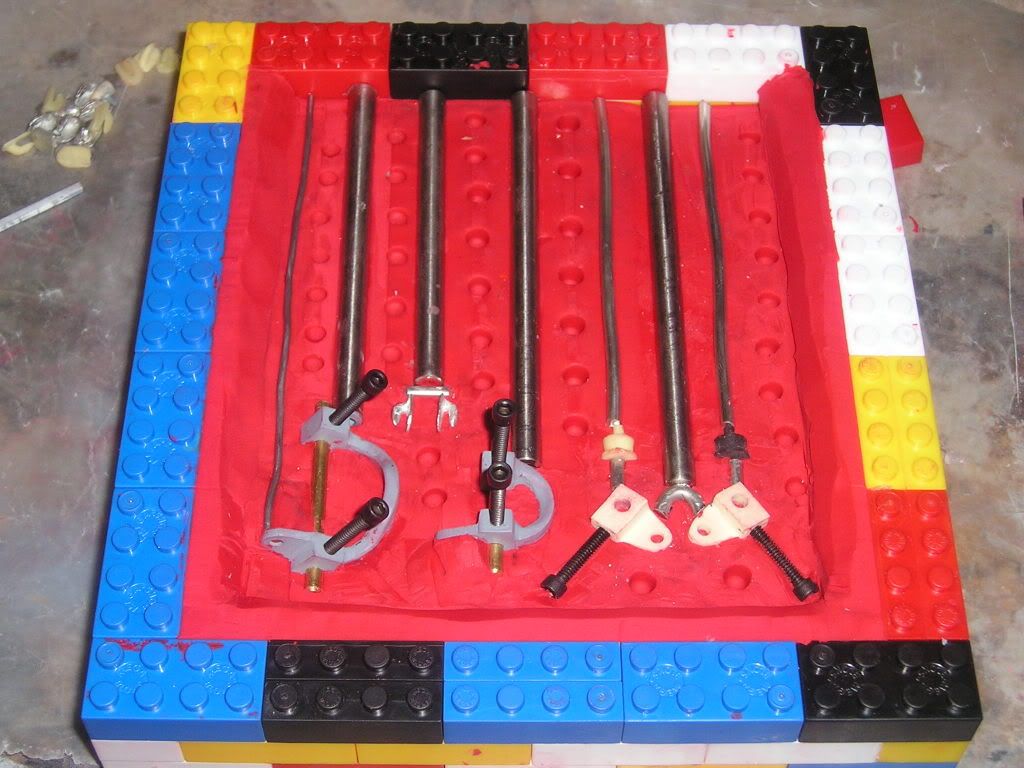

Greenman - All the hardware

Greenman - All the hardware came from Albacore kit inventory which was originally purchased from Stock Drive Products.

The housings consist of much modified ABP pump housings which gave me the output shaft seal, and lexan tubing capped with ABP pump covers. As I said, it all came from inventory.

Skip Asay

Greenman - All the hardware came from Albacore kit inventory which was originally purchased from Stock Drive Products.

The housings consist of much modified ABP pump housings which gave me the output shaft seal, and lexan tubing capped with ABP pump covers. As I said, it all came from inventory.

Skip Asay

Comment