March 20th ================================================

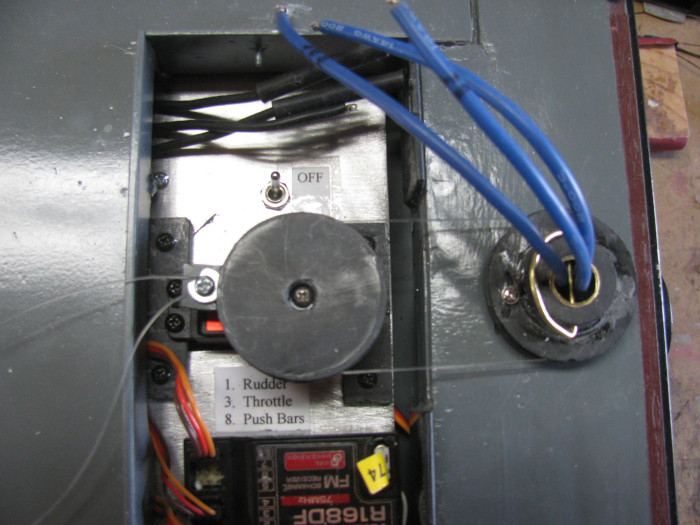

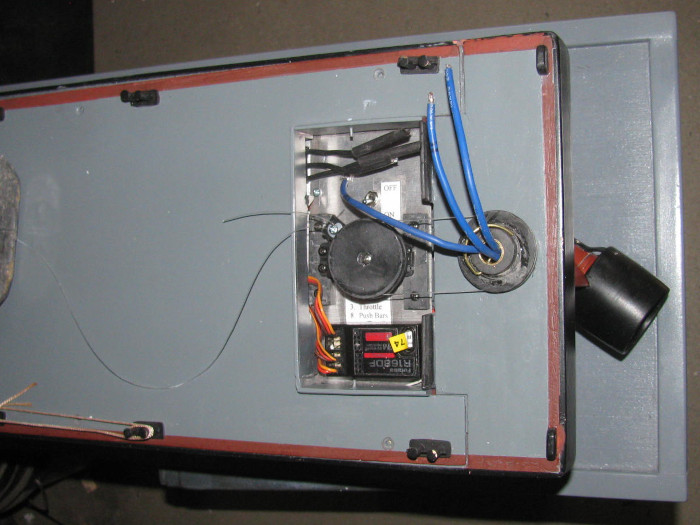

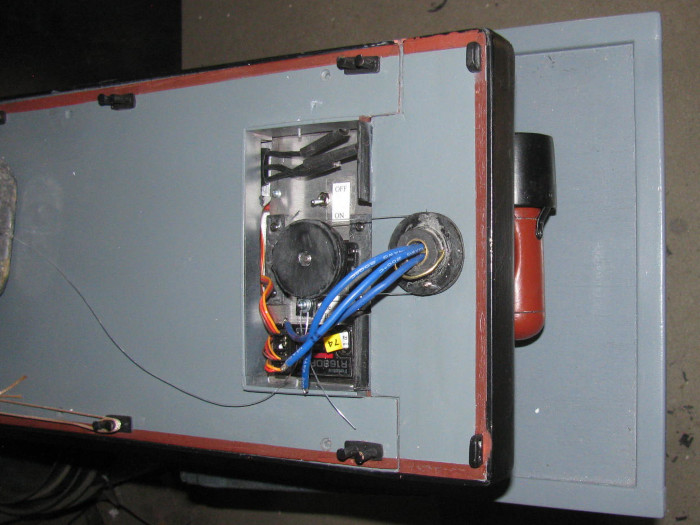

Last start in the shop.

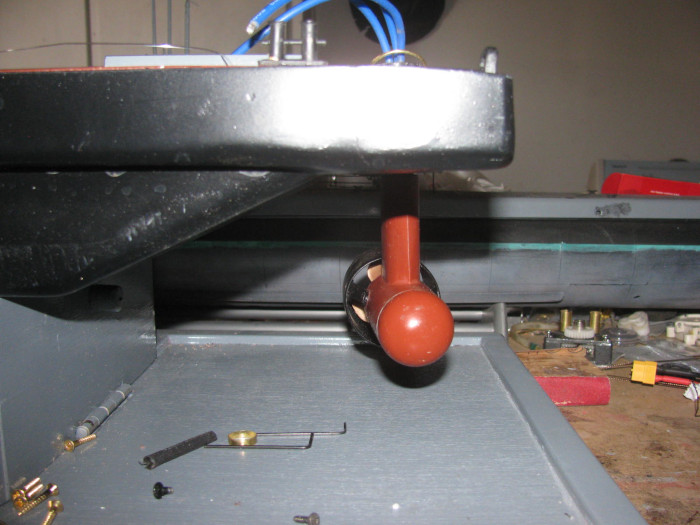

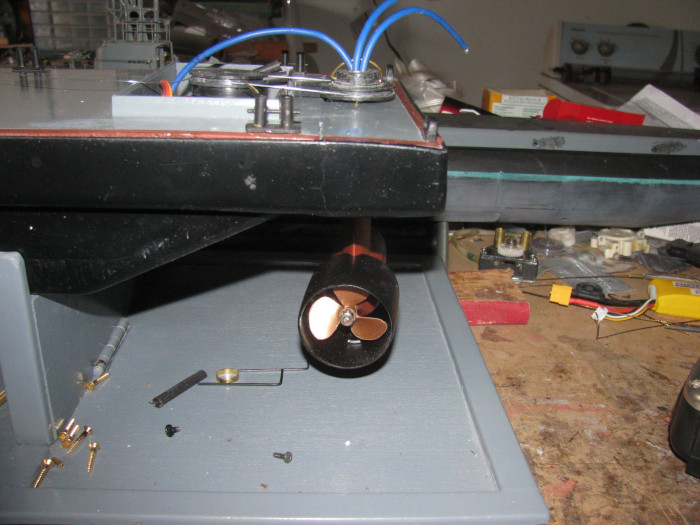

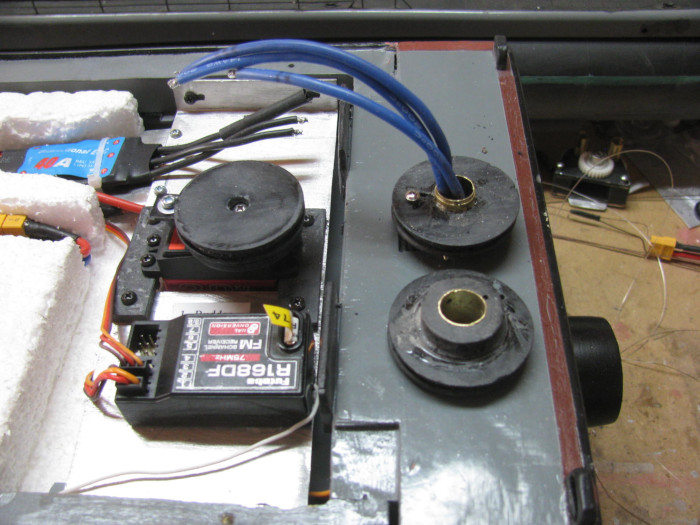

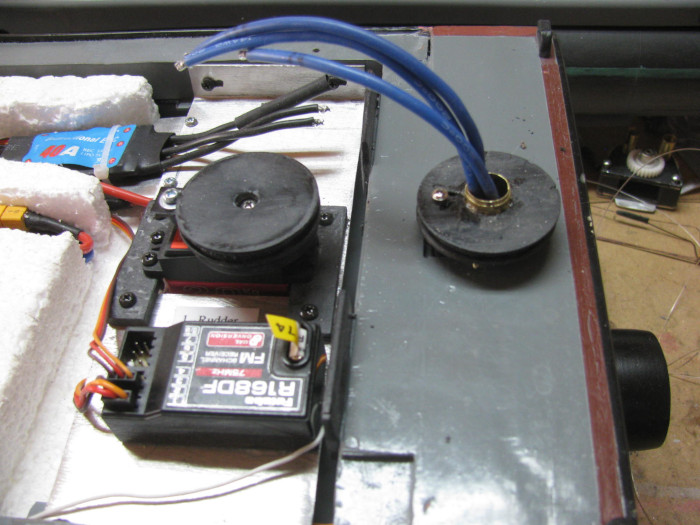

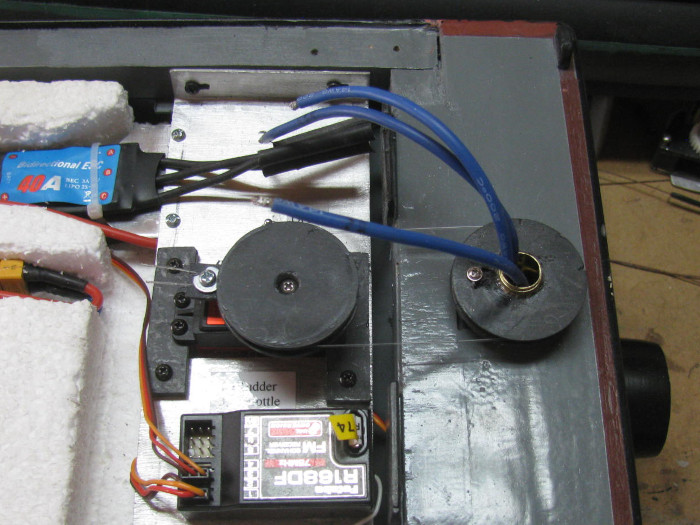

Put the planned steering system on the rudder post and servo.

It works for about 4 minutes.

Then the line used was cut and failed.

Tried it again making sure not to cut the line.

Again the line cut.

It appears to be the clamp I made to hold the 2 end of the line.

Okay, I will try an o-ring.

My o-ring was a little short but I could stretch it to go over the two pulleys.

This did not work.

The o-ring slips.

Okay, tomorrow I will go back to the cable instead of the 20 pound line.

As a last resort, I can use brass rod linkage and not have the 180 degree turning of the motor pod.

-----------------------------

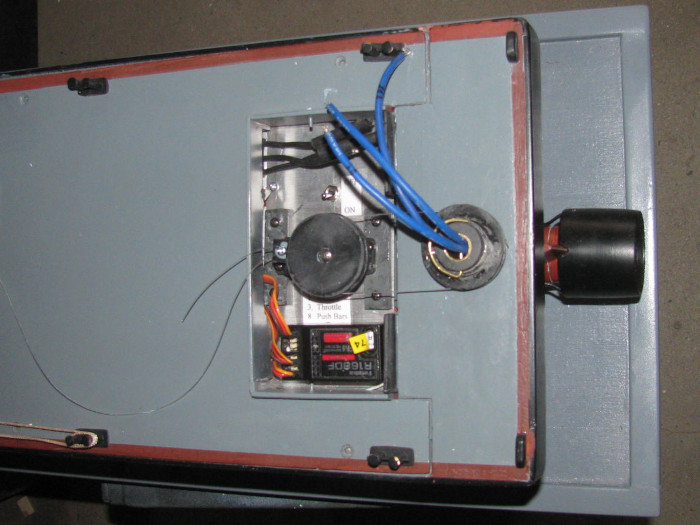

I may make a paper drawing of the steering post and servo.

I can draw a 3/4" and 1" pulley over the centers and see how long a gear belt would be.

Convert it all to metric and then maybe I can find a belt and gear drive that might work.

==================

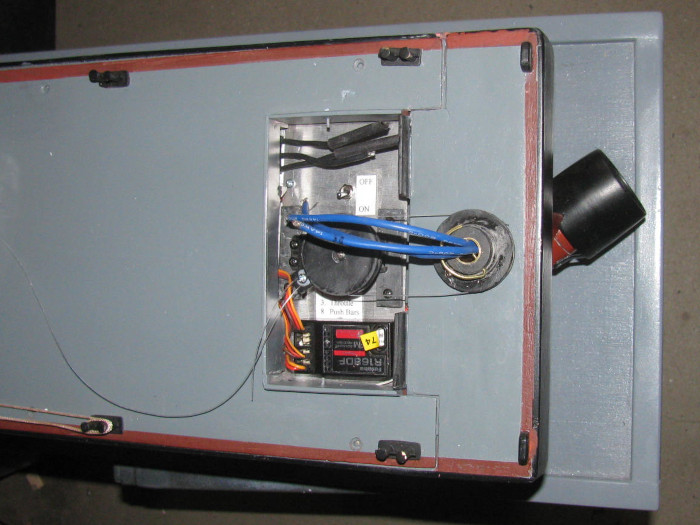

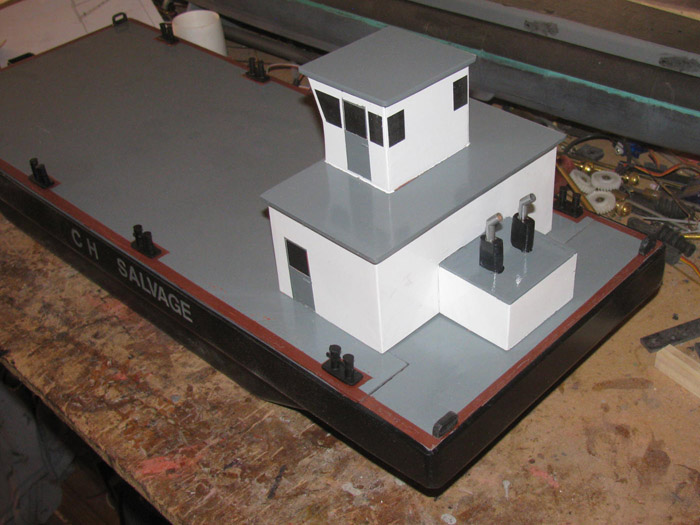

Tomorrow if I can not get the cable to work, I will make up the brass rod linkage parts so at least I h ave a working boat.

Last start in the shop.

Put the planned steering system on the rudder post and servo.

It works for about 4 minutes.

Then the line used was cut and failed.

Tried it again making sure not to cut the line.

Again the line cut.

It appears to be the clamp I made to hold the 2 end of the line.

Okay, I will try an o-ring.

My o-ring was a little short but I could stretch it to go over the two pulleys.

This did not work.

The o-ring slips.

Okay, tomorrow I will go back to the cable instead of the 20 pound line.

As a last resort, I can use brass rod linkage and not have the 180 degree turning of the motor pod.

-----------------------------

I may make a paper drawing of the steering post and servo.

I can draw a 3/4" and 1" pulley over the centers and see how long a gear belt would be.

Convert it all to metric and then maybe I can find a belt and gear drive that might work.

==================

Tomorrow if I can not get the cable to work, I will make up the brass rod linkage parts so at least I h ave a working boat.

...

...

Comment