December 14th =================================================

I did not get much time in the shop.

I got 15 minutes this morning and 30 minutes this afternoon.at the most.

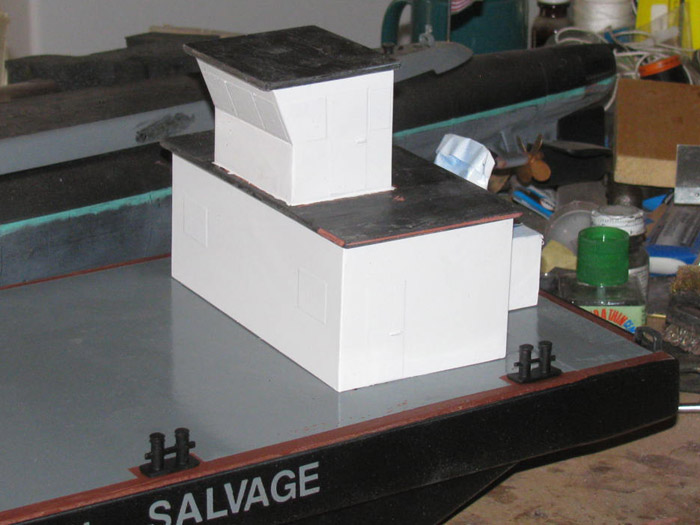

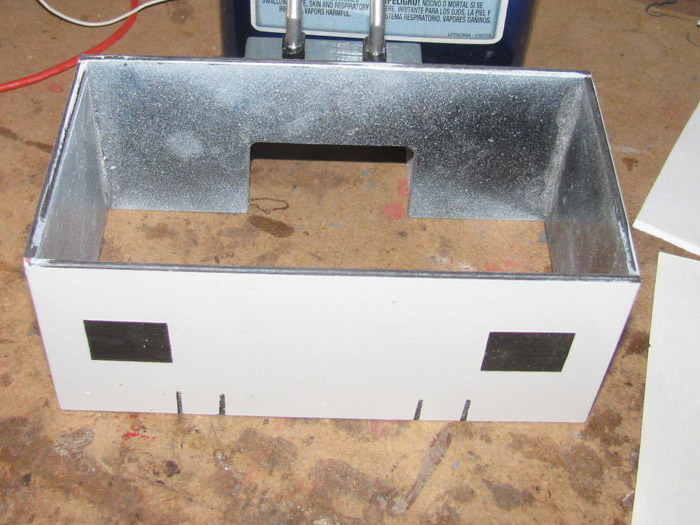

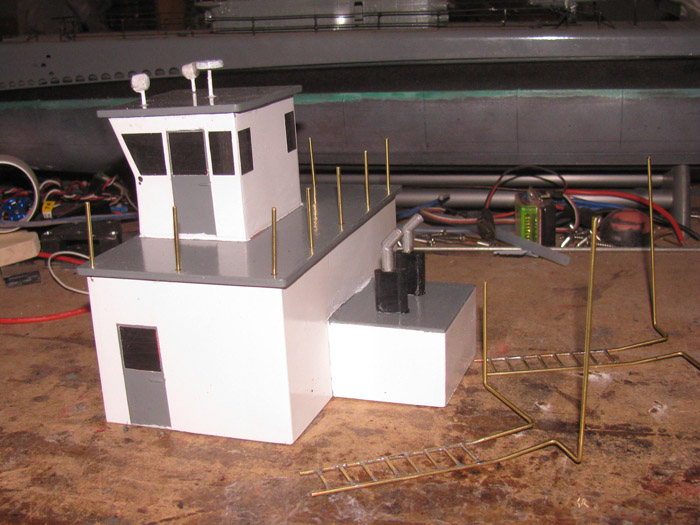

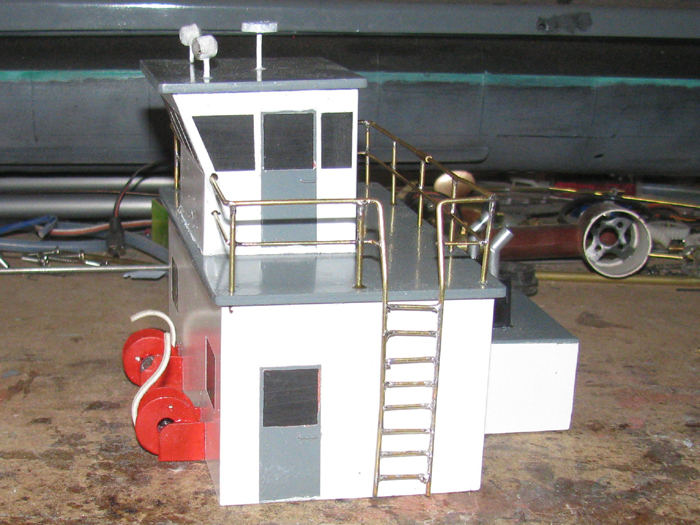

I sanded the glaze on the deck house and wheel house.

I had been thinking on how to make door details.

I looked last night for my 1/64" wide tape to do an outline of the door frame that I woud paint over.

I did not find the tape.

When I got out to the shop, the first thing I did was fire up the heater.

It was 45 F in the shop at 2pm.

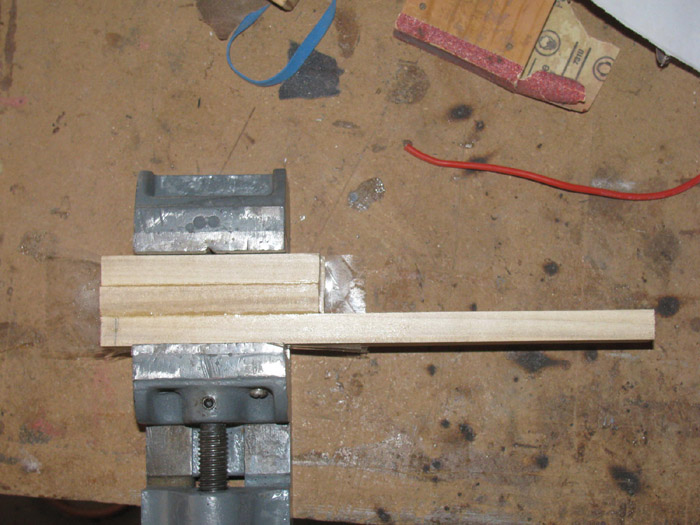

While doing that, I looked down at a test board.

On it are various test I have done to check if something looked good or the glue would hold two different materials together.

An on one edge there was the weld line test I did to reconstruct the weld lines on the Gato hull.

I used 2 pieces of tape with a gap between for the weld line that I had glazed over.

Then sanded down to the tape and removed the tape leaving a nice weld line.

Thought. . . . Why wouldn't that work to make doors and frames?

So I taped off the door locations and glazed them this morning.

I sanded and pulled tape this afternoon.

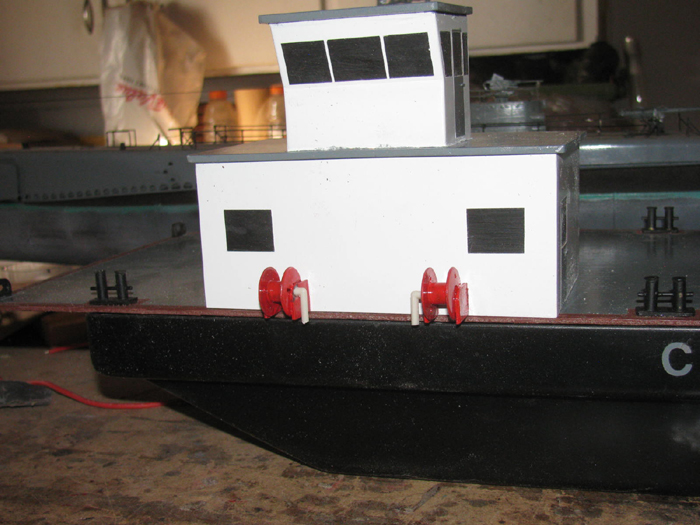

The doors are raised slightly.

The windows are still taped until I paint the white.

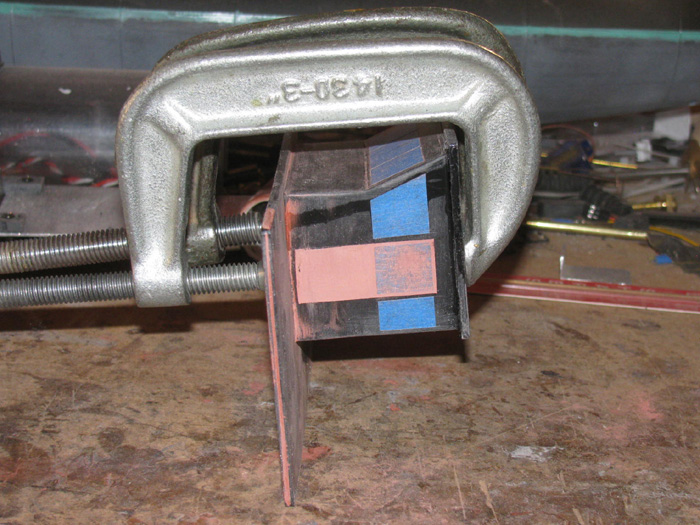

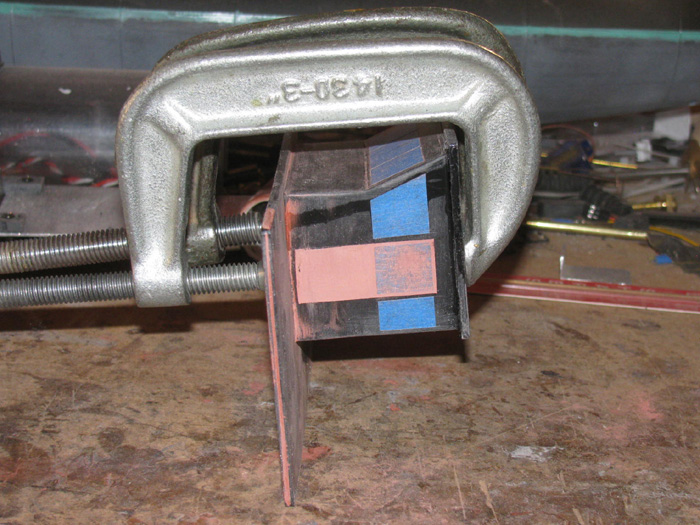

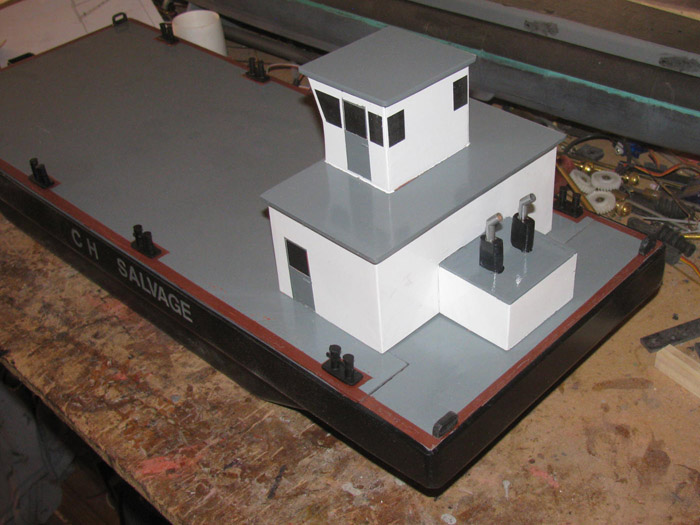

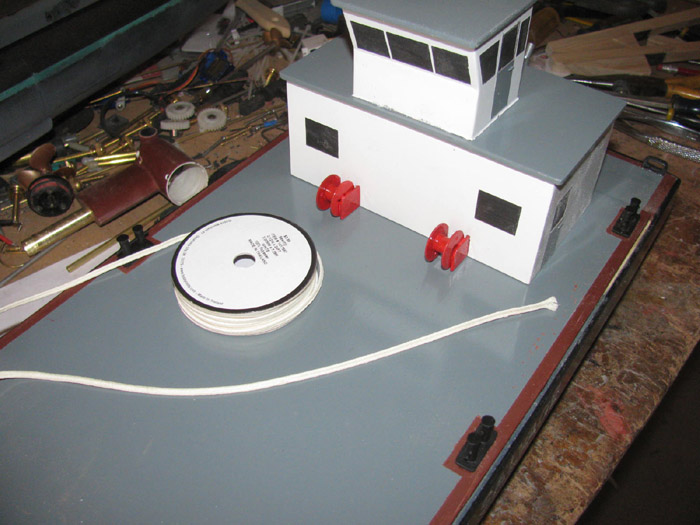

Photo . . Roof being clamped after gluing.

I did not get much time in the shop.

I got 15 minutes this morning and 30 minutes this afternoon.at the most.

I sanded the glaze on the deck house and wheel house.

I had been thinking on how to make door details.

I looked last night for my 1/64" wide tape to do an outline of the door frame that I woud paint over.

I did not find the tape.

When I got out to the shop, the first thing I did was fire up the heater.

It was 45 F in the shop at 2pm.

While doing that, I looked down at a test board.

On it are various test I have done to check if something looked good or the glue would hold two different materials together.

An on one edge there was the weld line test I did to reconstruct the weld lines on the Gato hull.

I used 2 pieces of tape with a gap between for the weld line that I had glazed over.

Then sanded down to the tape and removed the tape leaving a nice weld line.

Thought. . . . Why wouldn't that work to make doors and frames?

So I taped off the door locations and glazed them this morning.

I sanded and pulled tape this afternoon.

The doors are raised slightly.

The windows are still taped until I paint the white.

Photo . . Roof being clamped after gluing.

Comment