November 29th =================================================

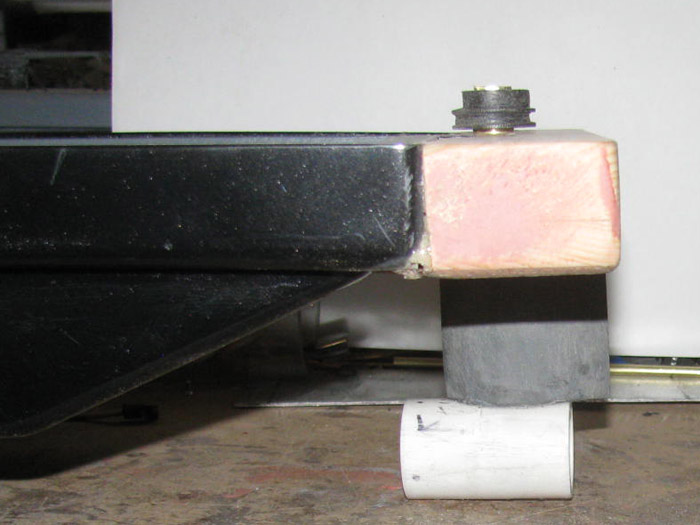

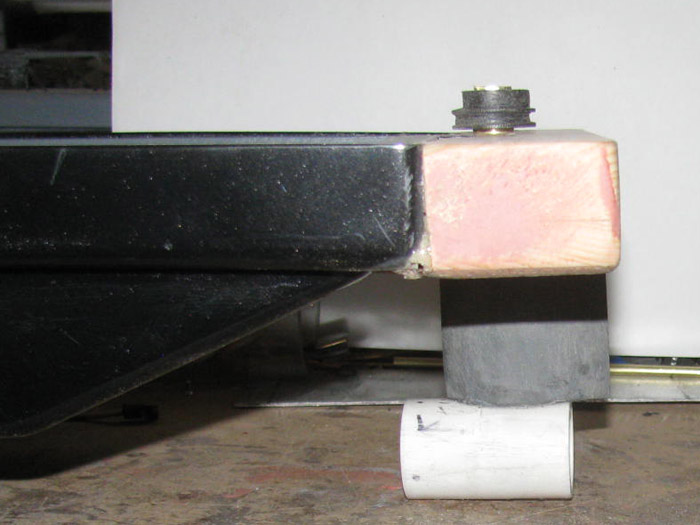

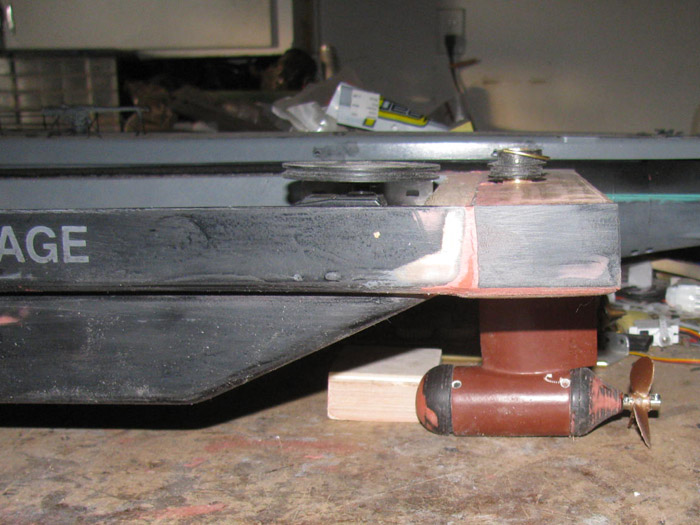

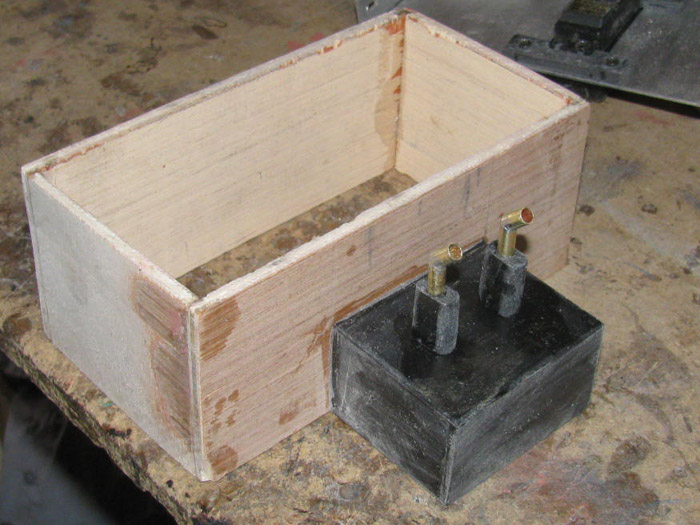

Today, I fitted the rudder post in to the stern rudder through tube.

The glue I use to install the rudder through tube, expands.

It apparently expands enough to change the shape of the 1/2" brass tube.

I had to use a Dremel 1/4" sanding drum and a couple of files.

Round and half round to get the tube back to round.

Polished it and the rudder post, several times until the rudder turned easily.

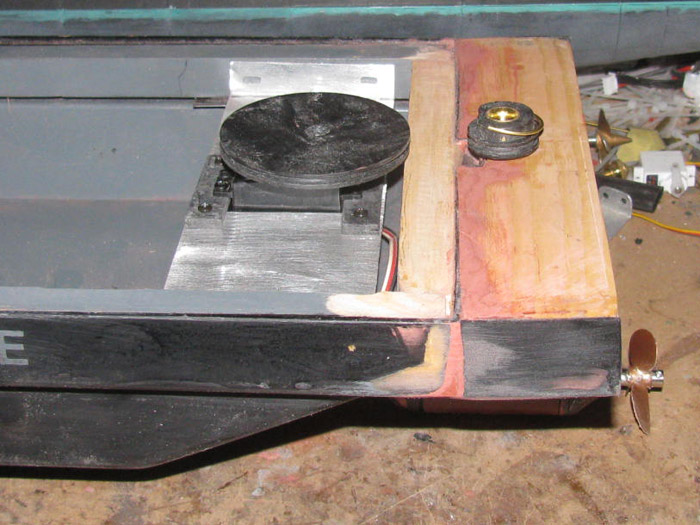

Cleaned up the 2 spacer brass rings that go between the hull and the rudder and between the hull and pulley.

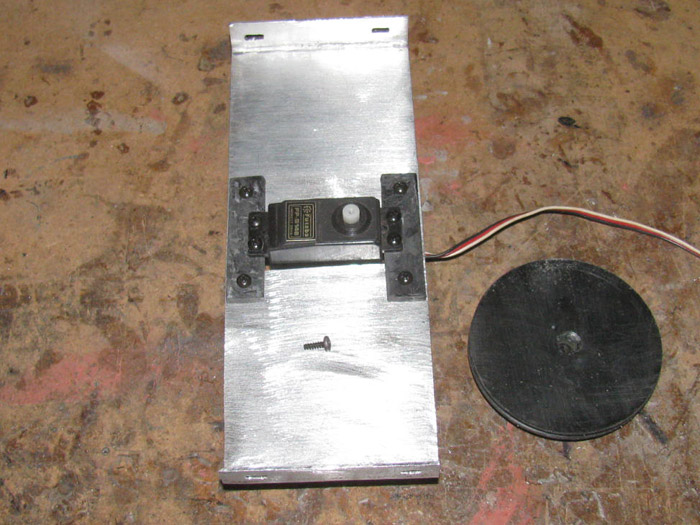

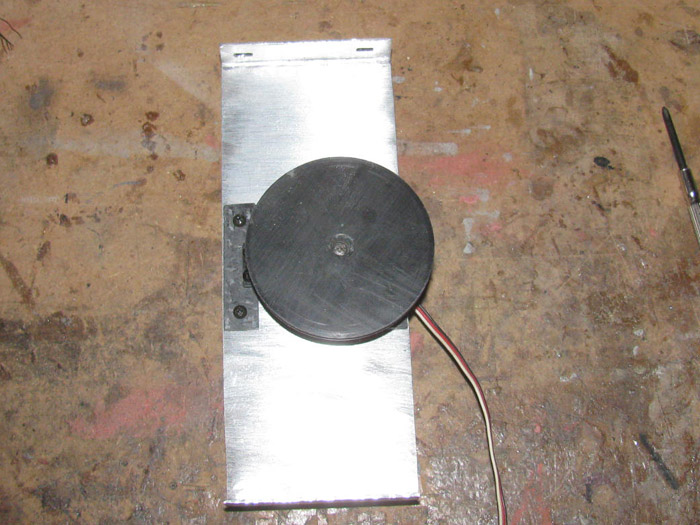

Drilled the pulley and rudder post for a through pin of 1/16" rod.

Also drilled the pulley for the cables but it is on the front side.

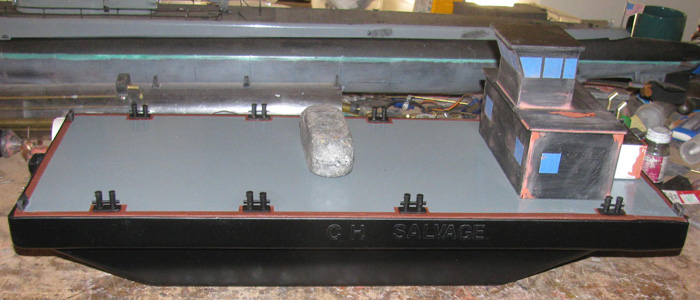

Sat down on my milk crate and with Exacto knife, I removed the vinyl letters.

I am actually surprised how well they came out.

The vinyl letters are 1/2" tall.

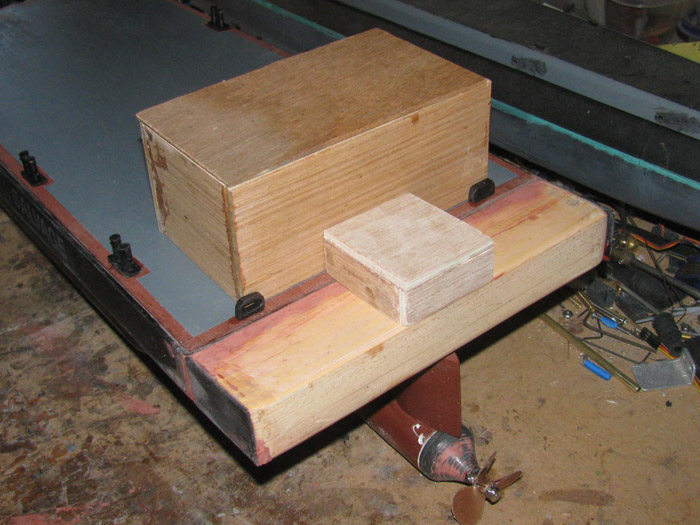

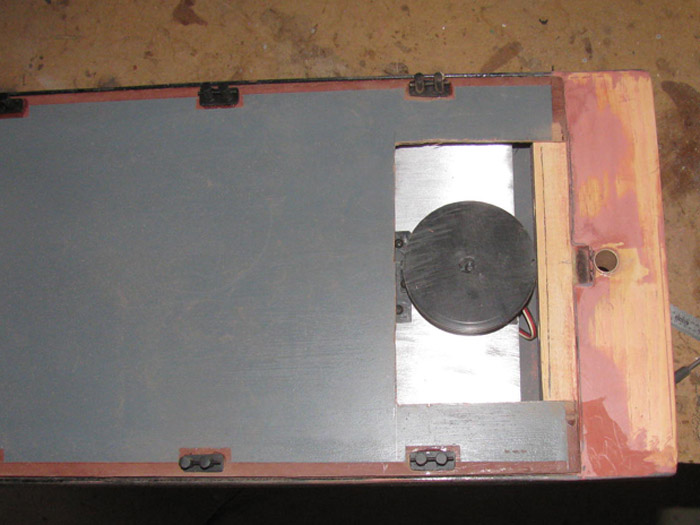

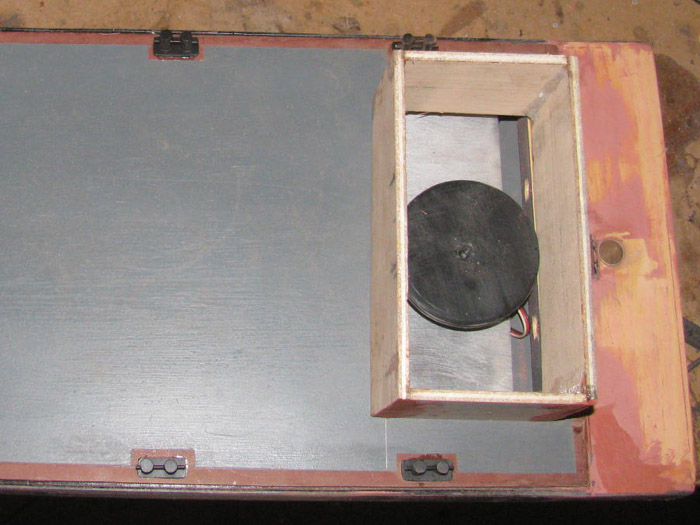

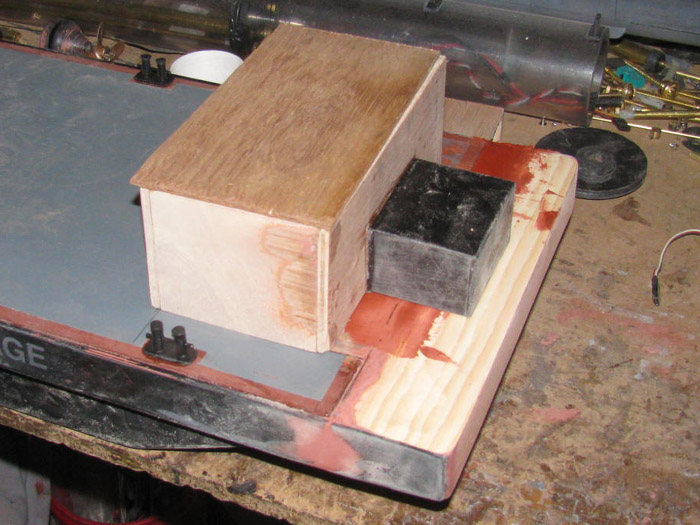

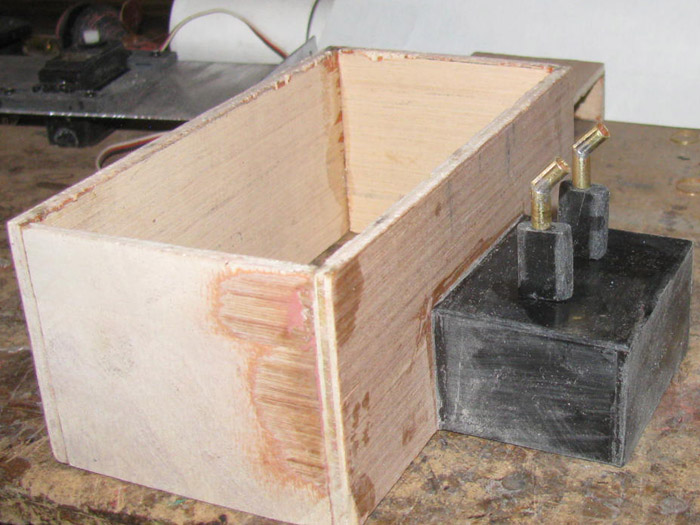

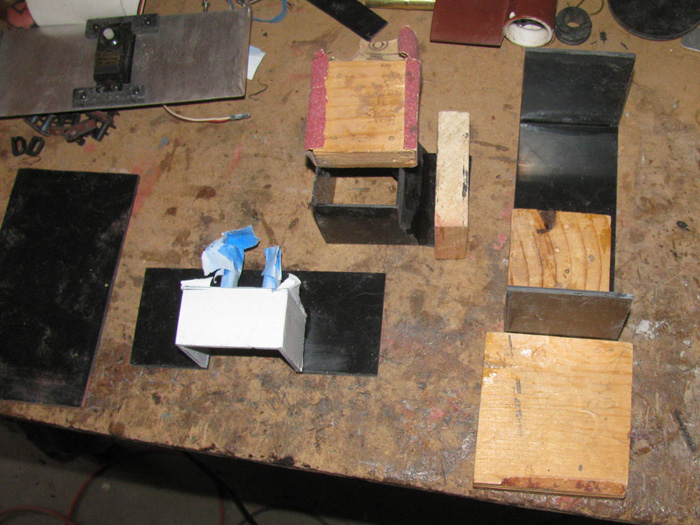

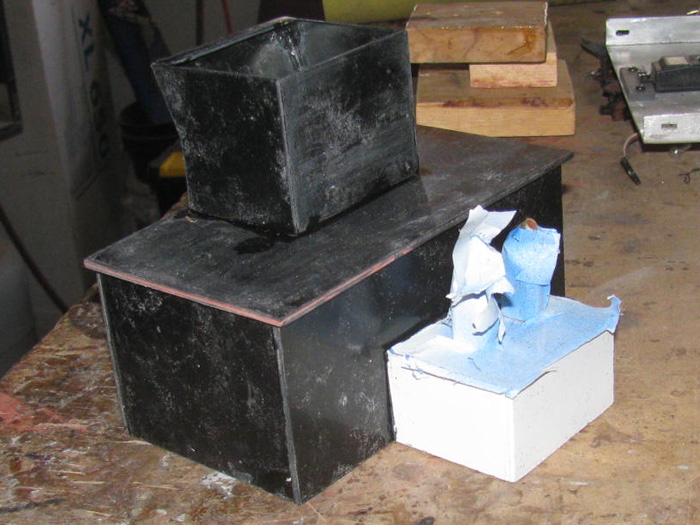

I have removed the rudder and I am preparing the stern block for priming and painting.

There is some glazing to do.

I have jury duty tomorrow, so I plan to put the glazing on today and let it dry until I get done with jury duty.

Today, I fitted the rudder post in to the stern rudder through tube.

The glue I use to install the rudder through tube, expands.

It apparently expands enough to change the shape of the 1/2" brass tube.

I had to use a Dremel 1/4" sanding drum and a couple of files.

Round and half round to get the tube back to round.

Polished it and the rudder post, several times until the rudder turned easily.

Cleaned up the 2 spacer brass rings that go between the hull and the rudder and between the hull and pulley.

Drilled the pulley and rudder post for a through pin of 1/16" rod.

Also drilled the pulley for the cables but it is on the front side.

Sat down on my milk crate and with Exacto knife, I removed the vinyl letters.

I am actually surprised how well they came out.

The vinyl letters are 1/2" tall.

I have removed the rudder and I am preparing the stern block for priming and painting.

There is some glazing to do.

I have jury duty tomorrow, so I plan to put the glazing on today and let it dry until I get done with jury duty.

Comment