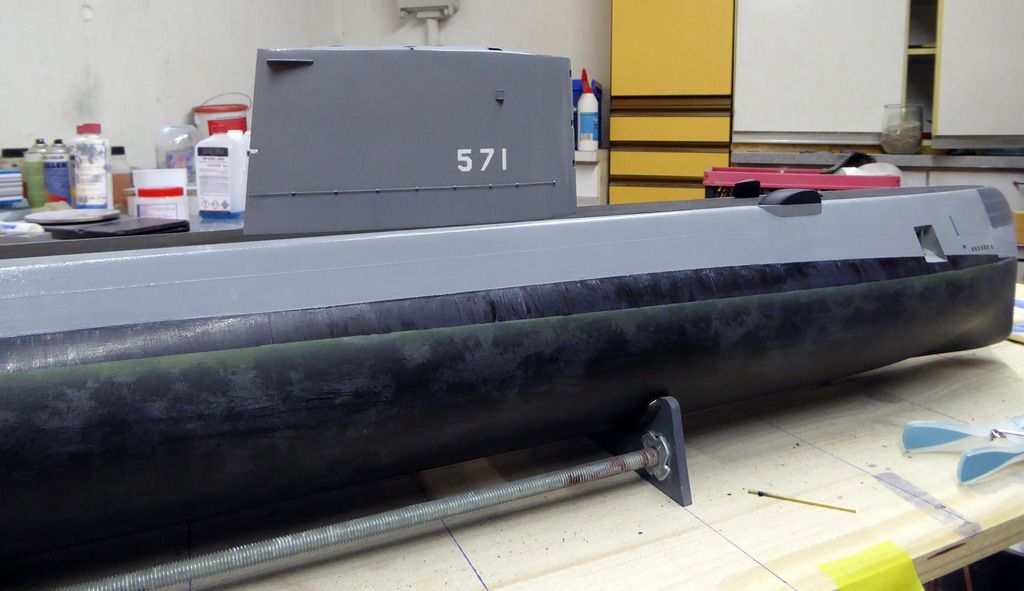

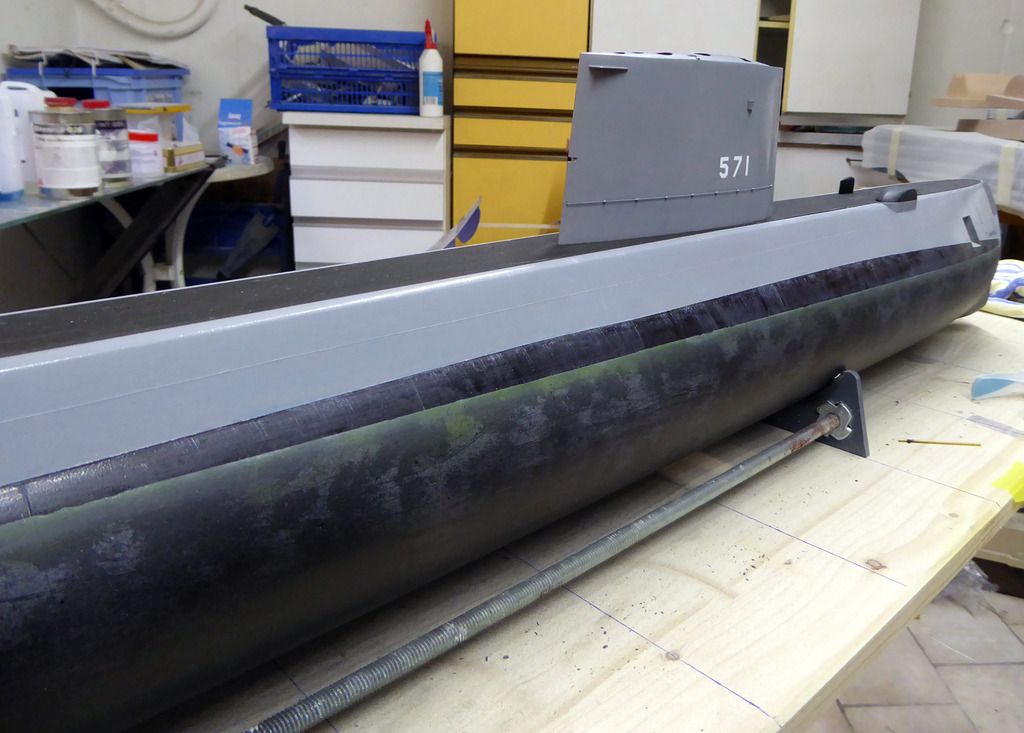

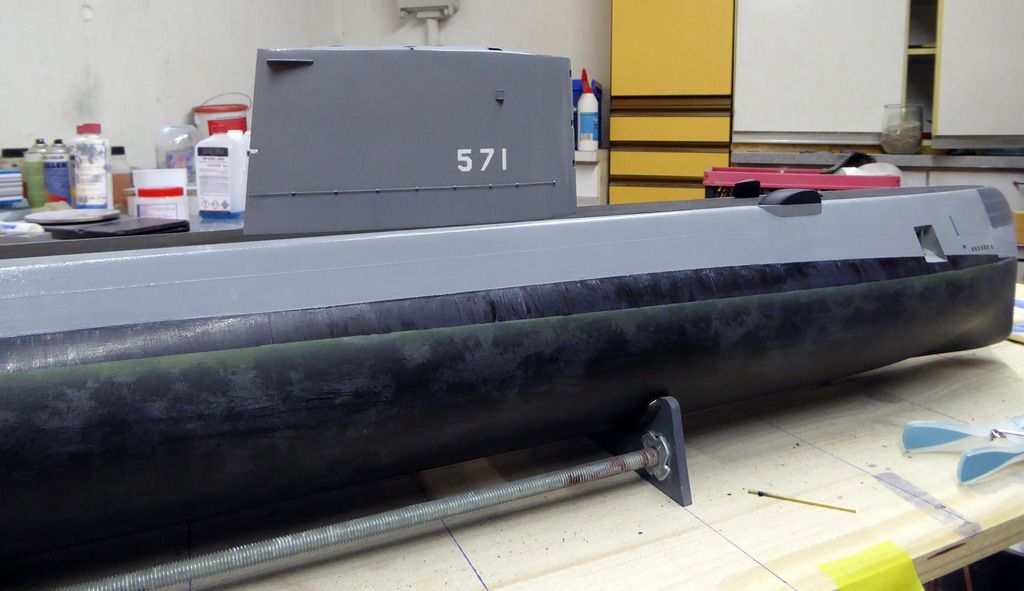

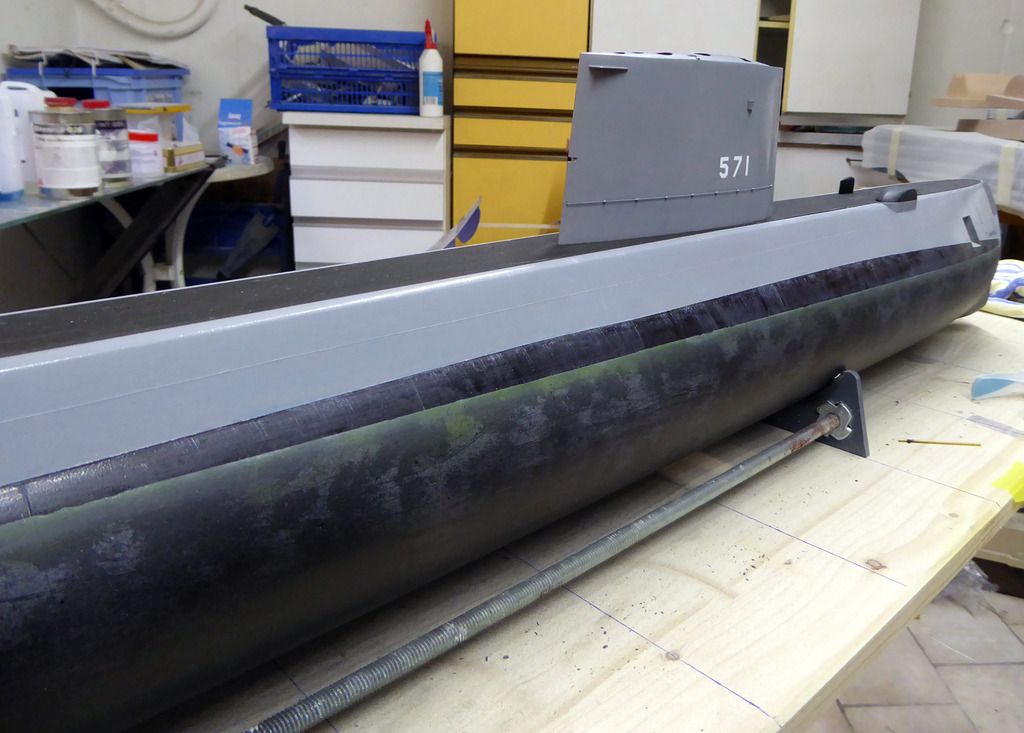

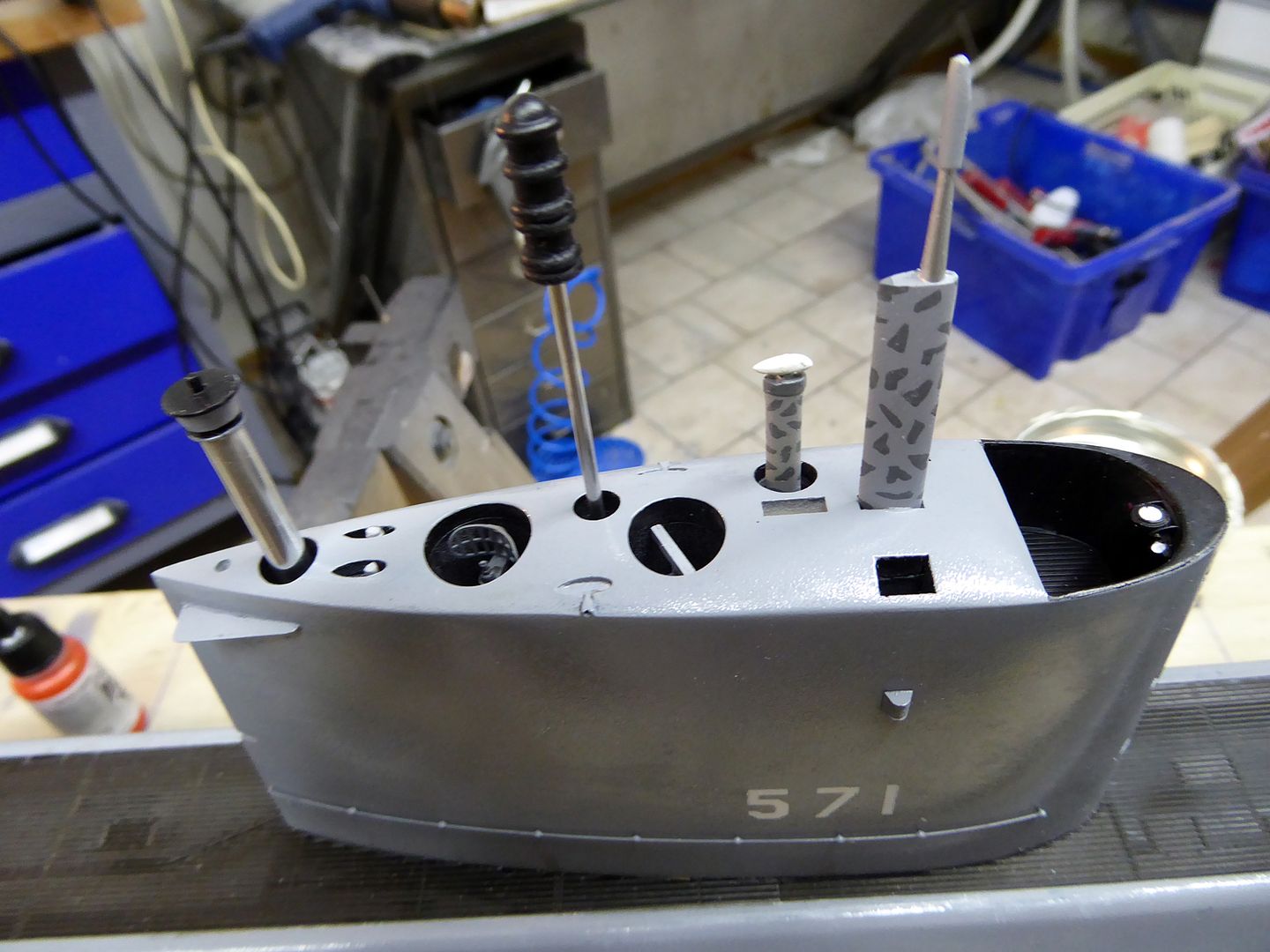

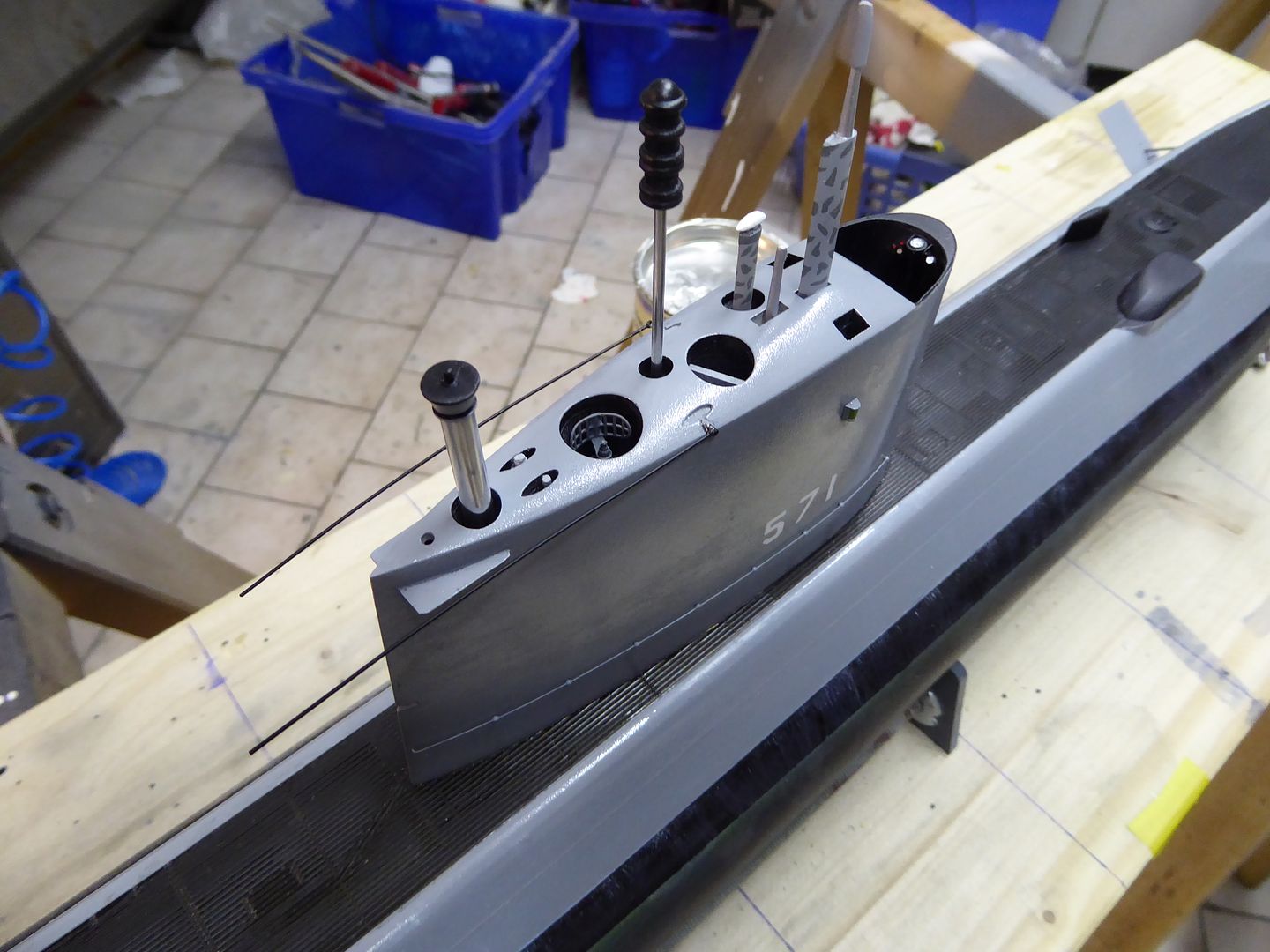

On it goes with the aging of the base coors. I mainly use filters and washes by the company M.I.G.. A slow process where one applies alternate coats of ultra-thinned colors. The curing times between the cotes takes quite some time, but it’s worth the effort. In addition the ship numbers are airbrushed using the photo-etched stencil.

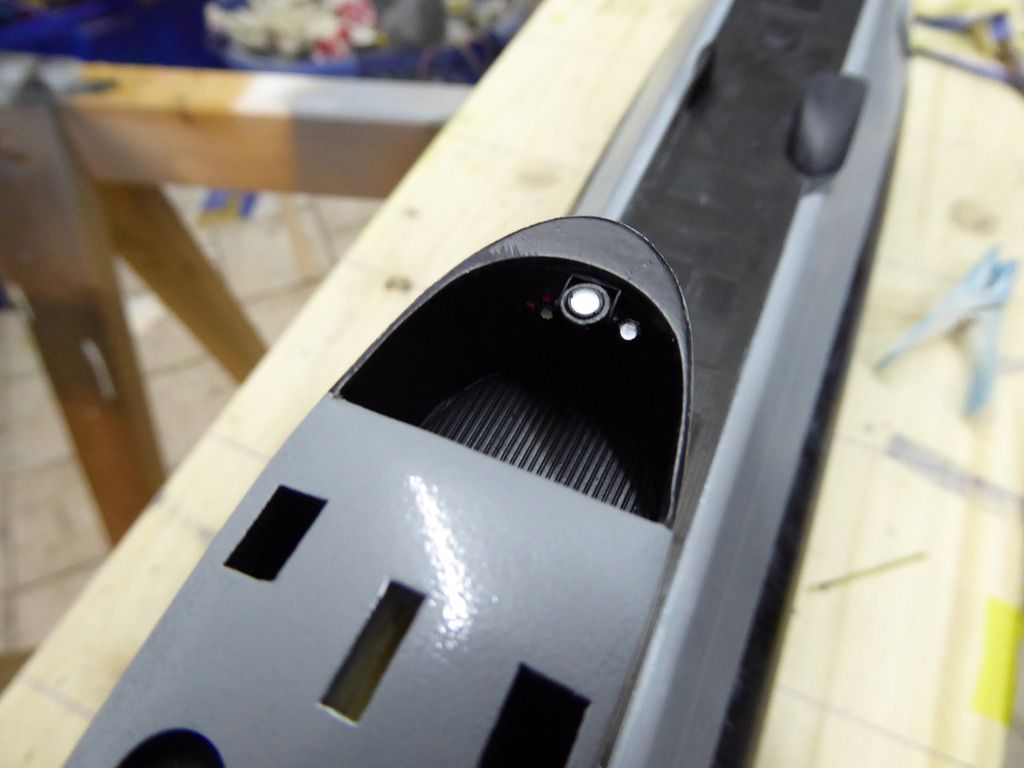

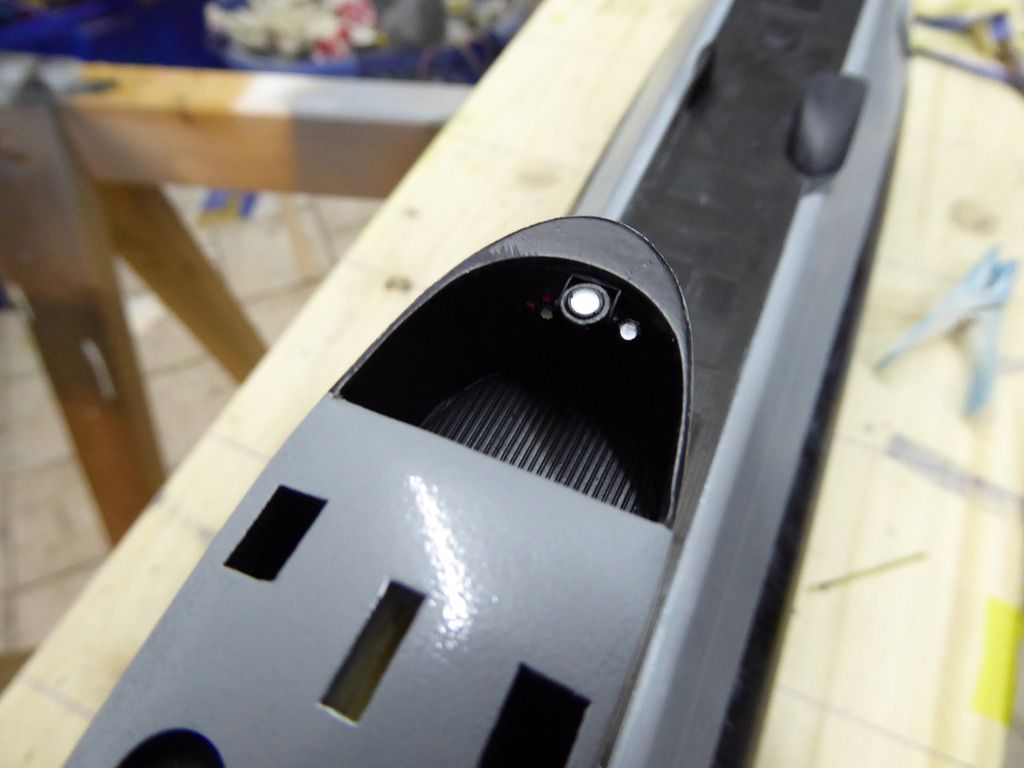

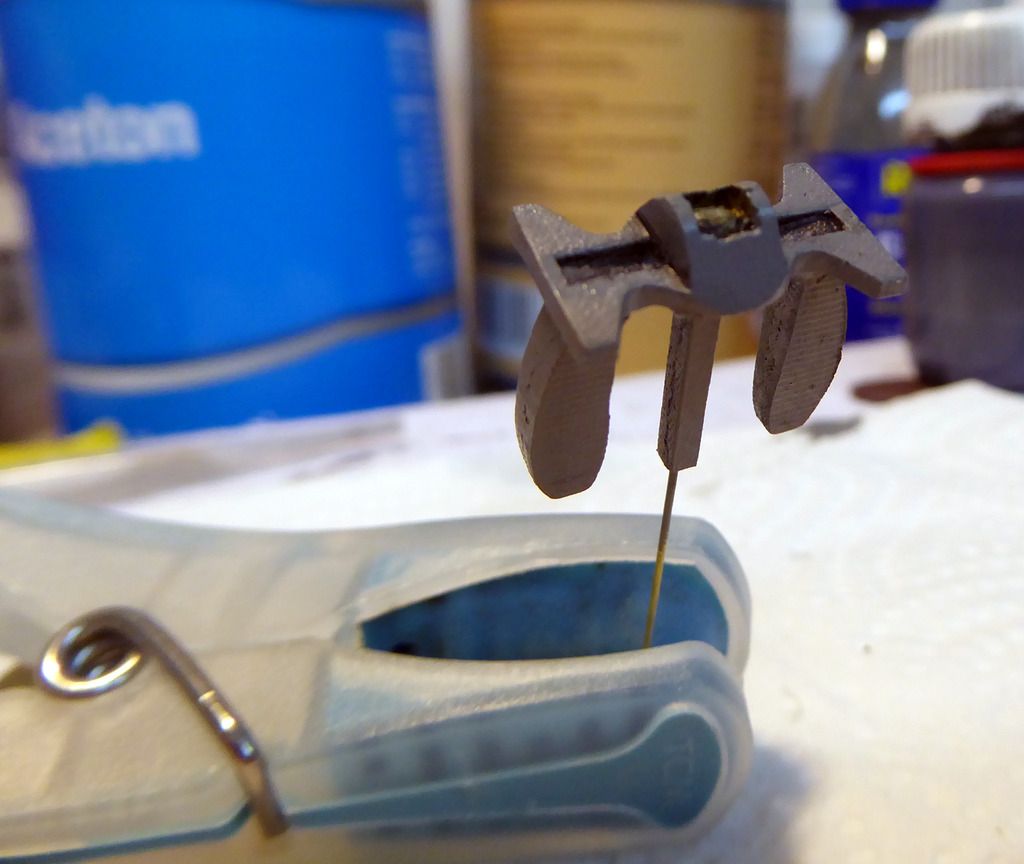

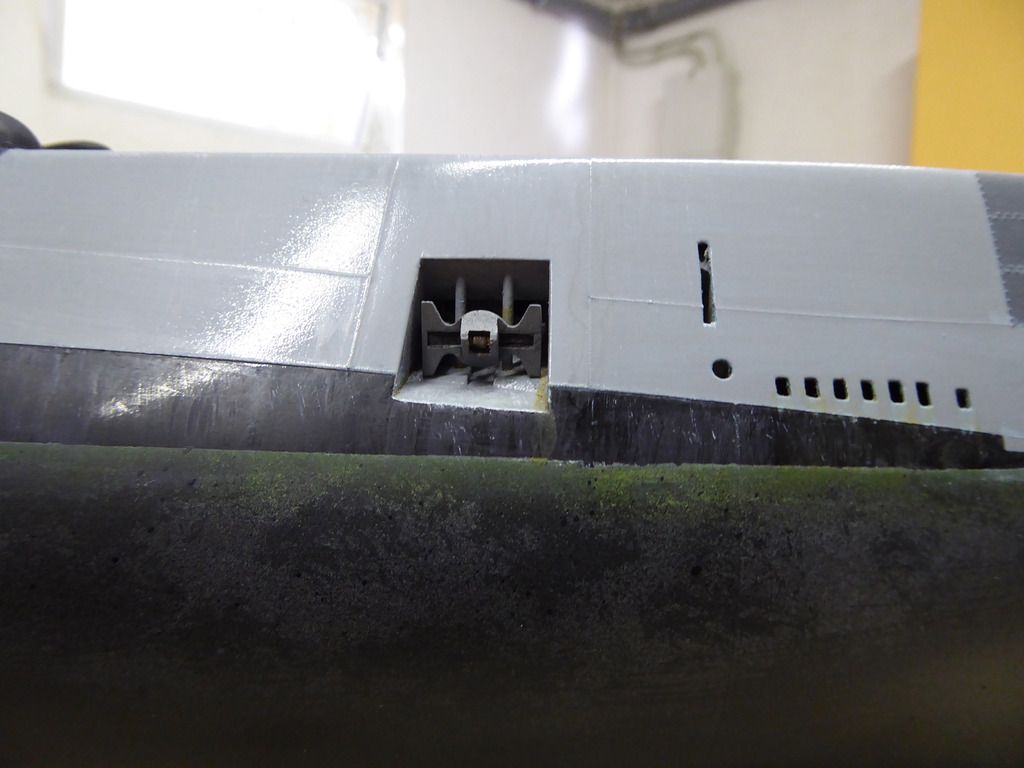

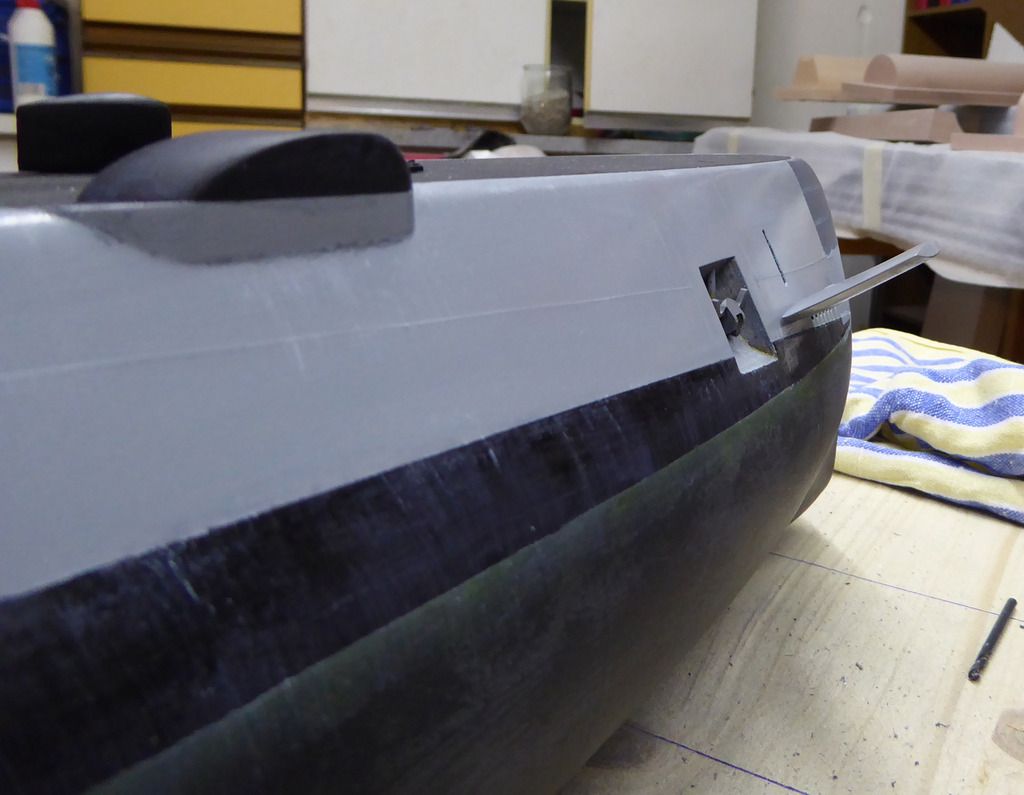

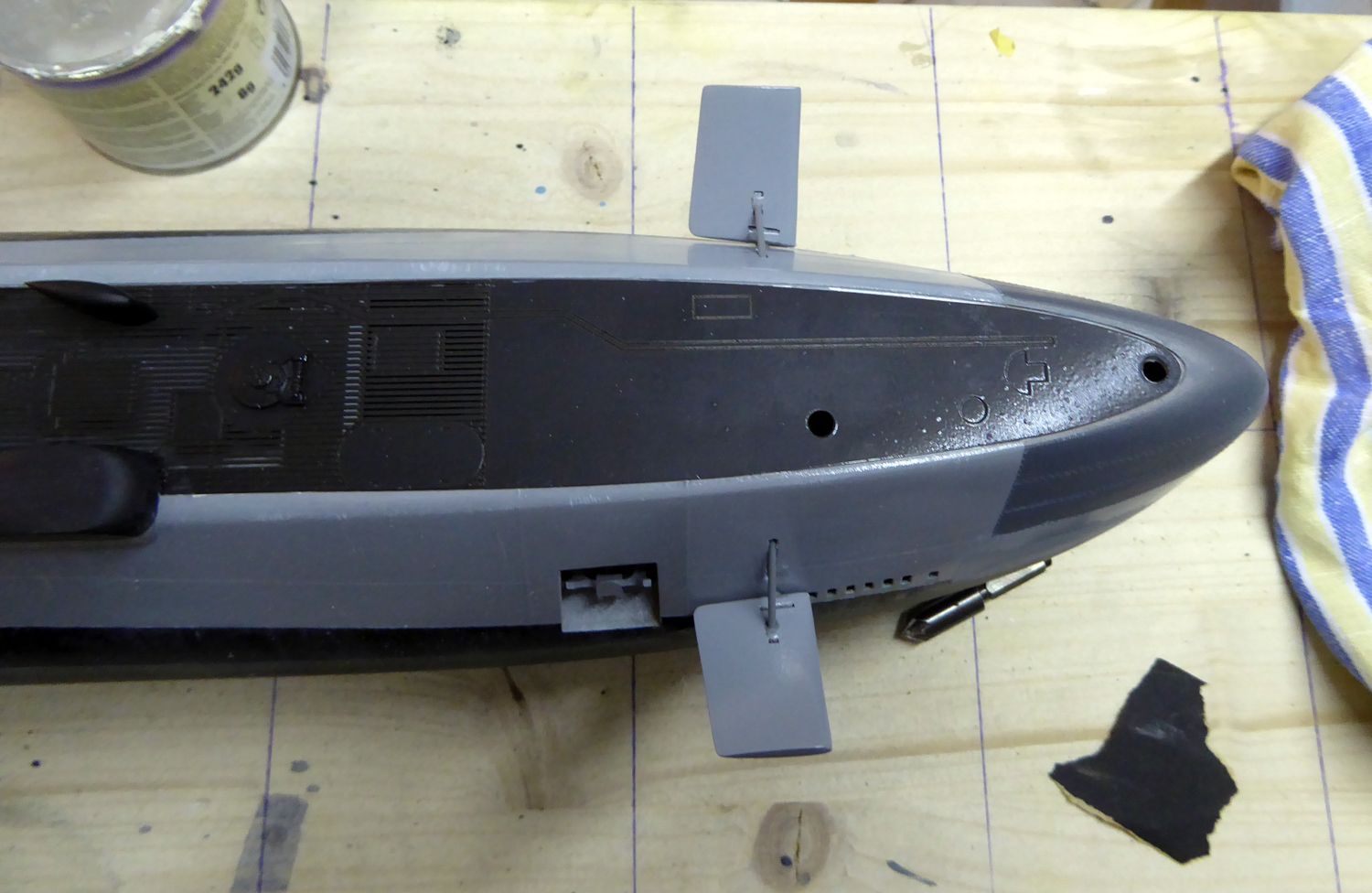

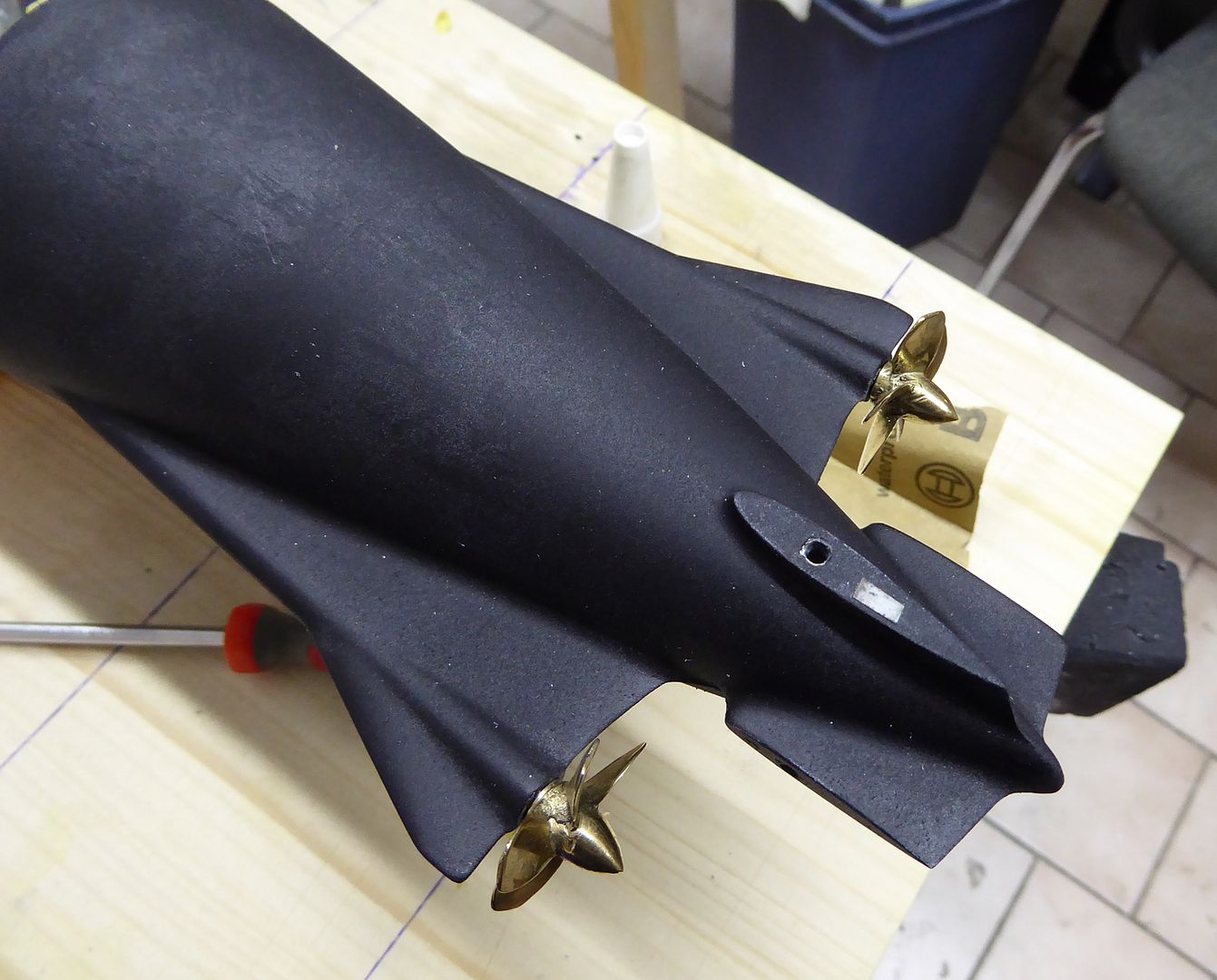

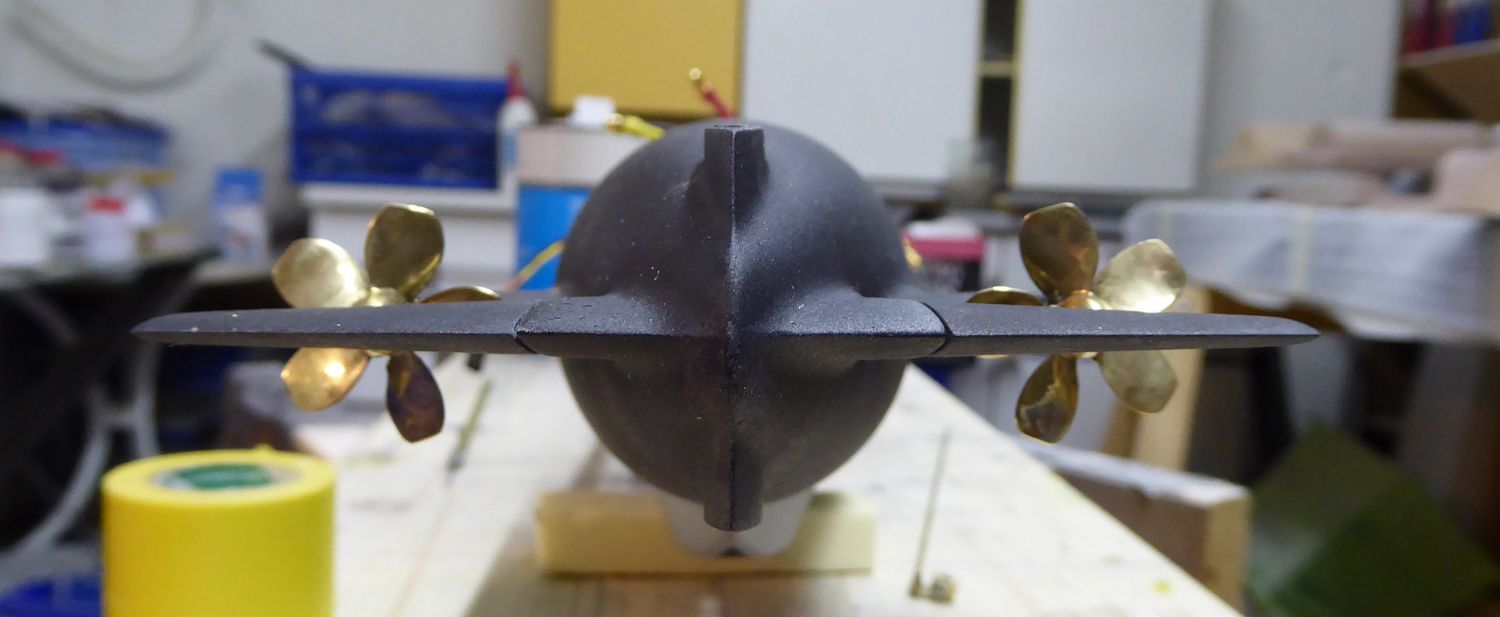

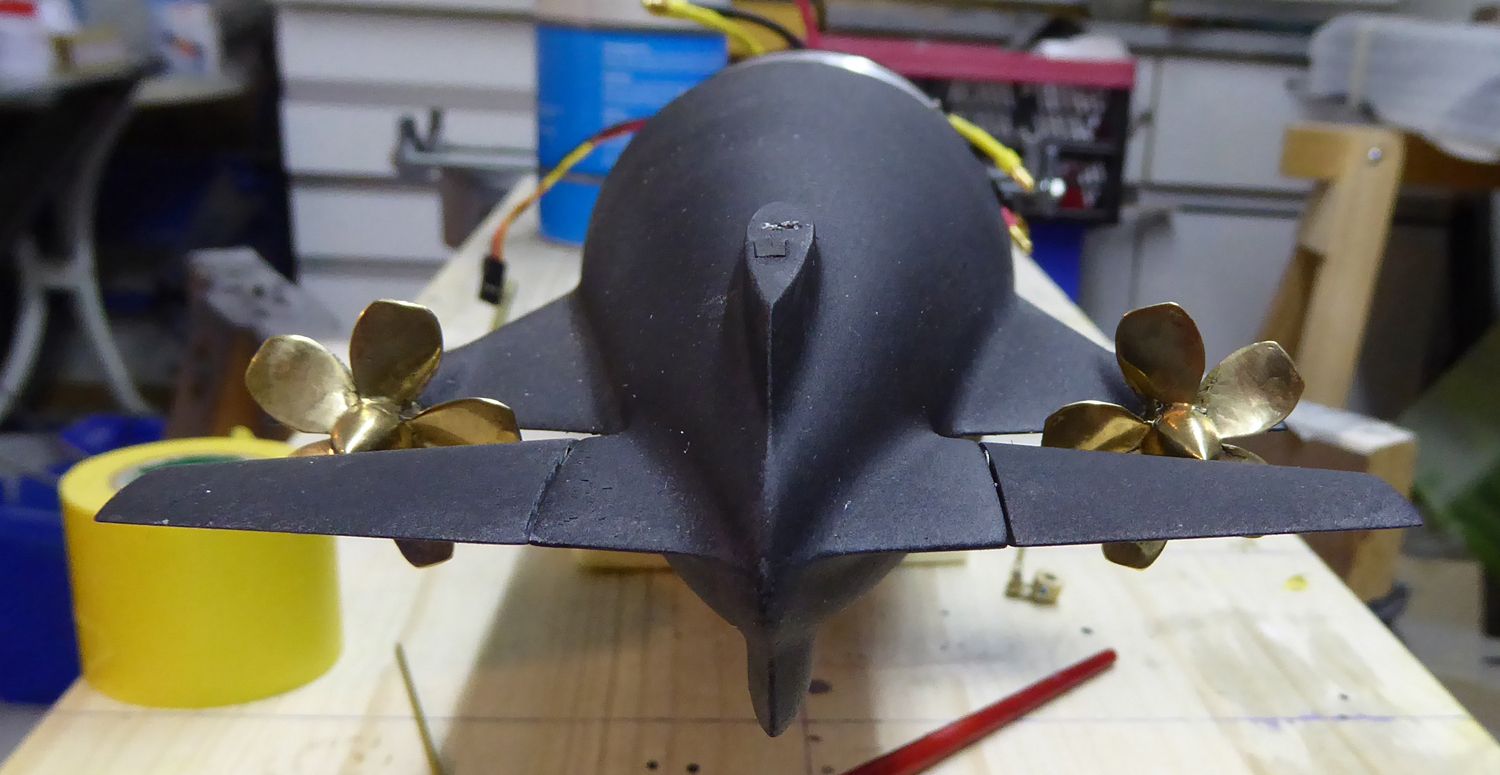

The bridge and the bow planes are painted as well:

The bridge and the bow planes are painted as well:

#

#

Comment