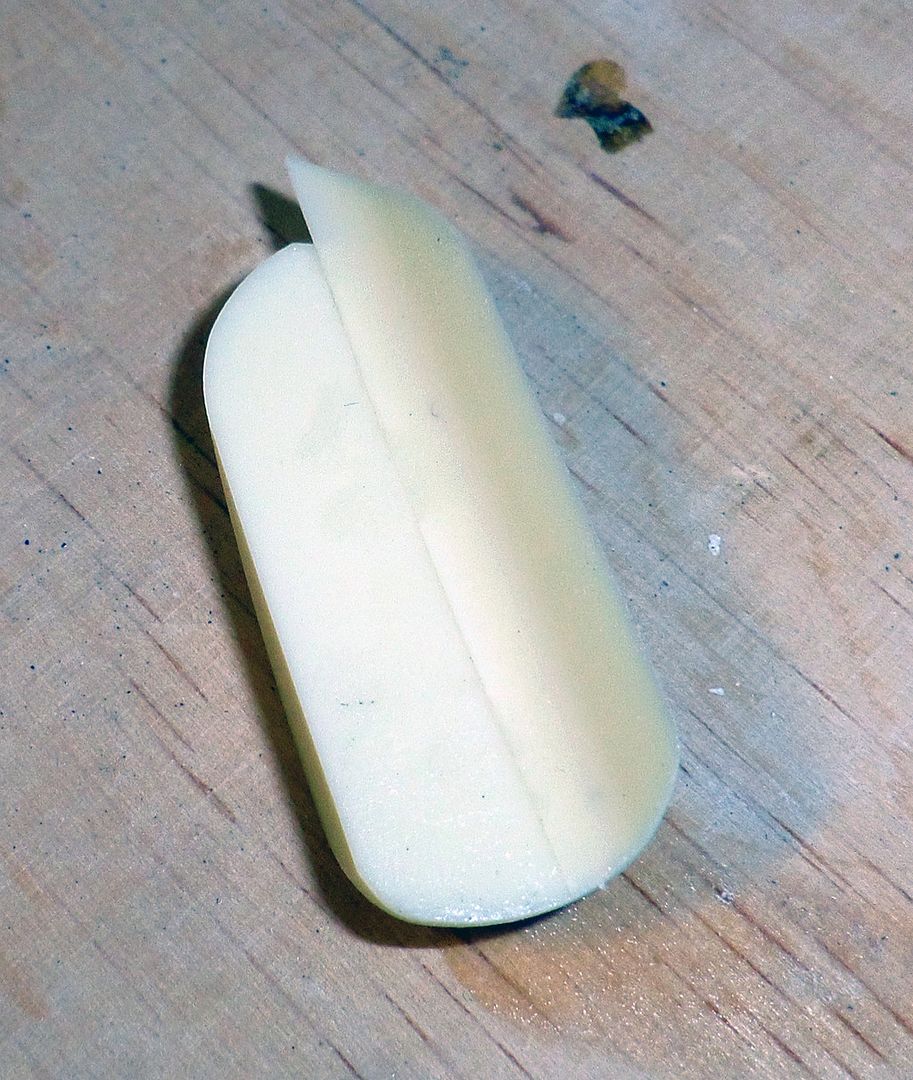

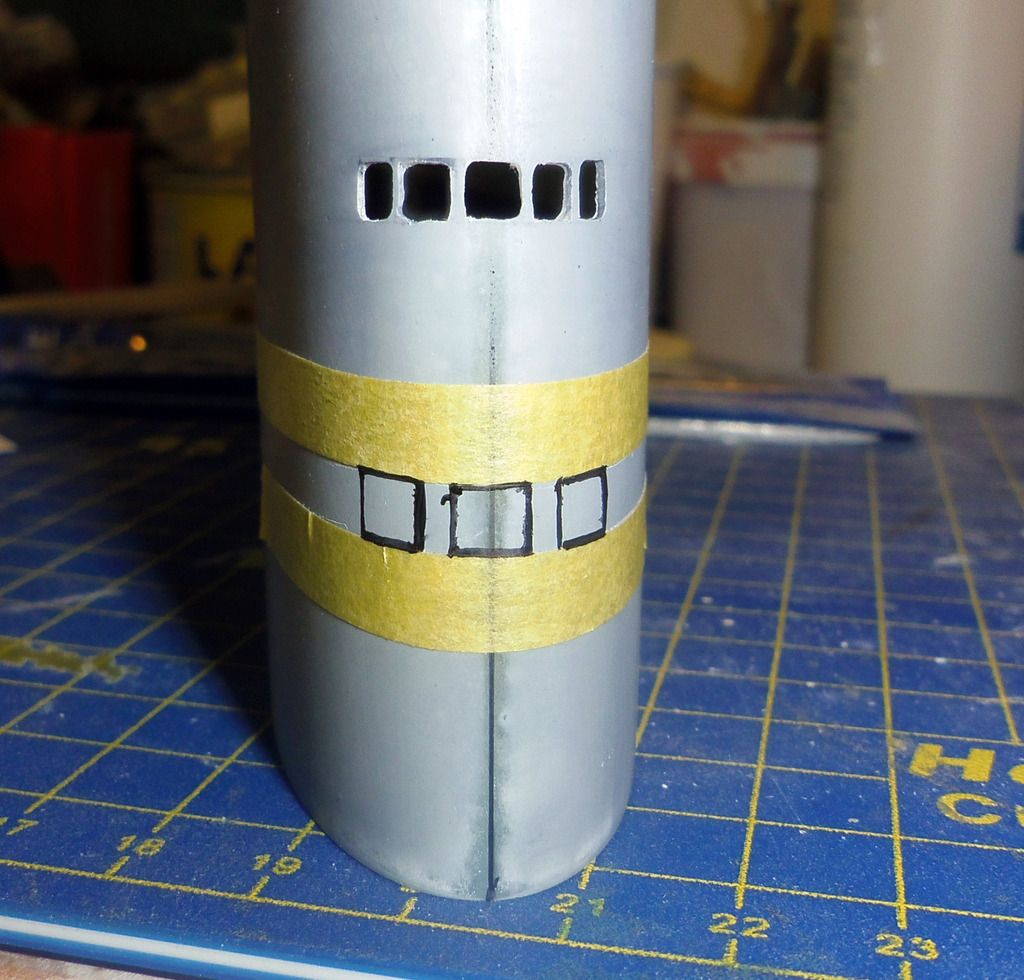

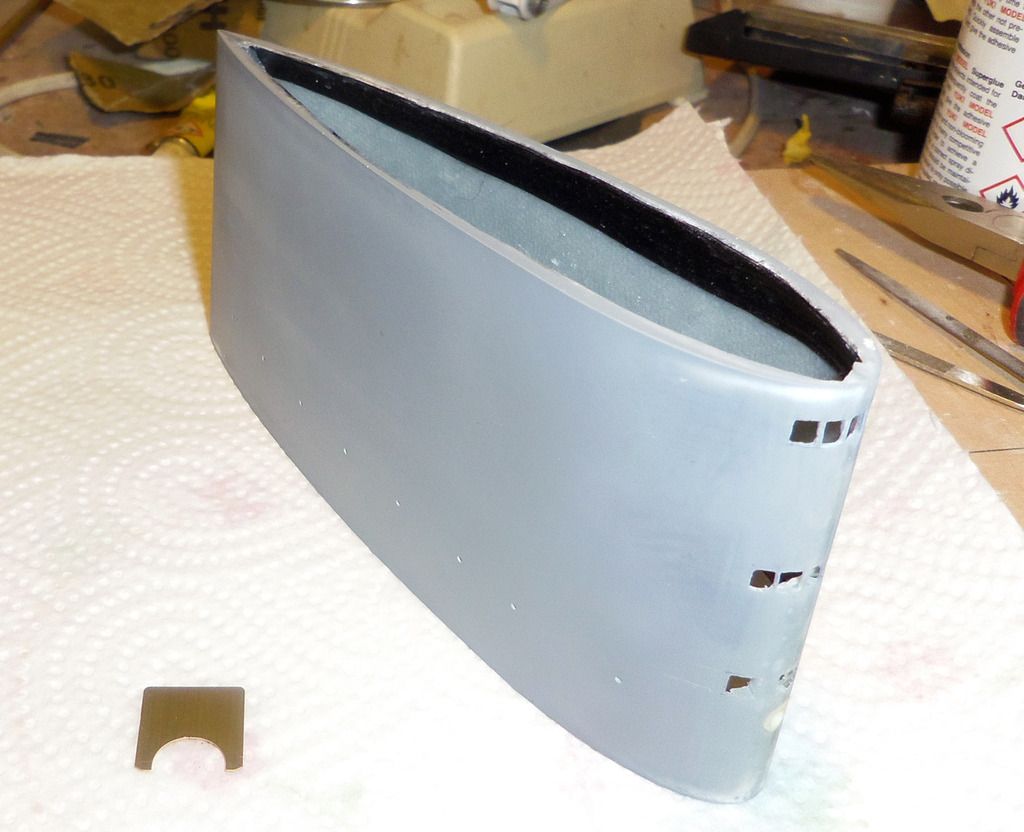

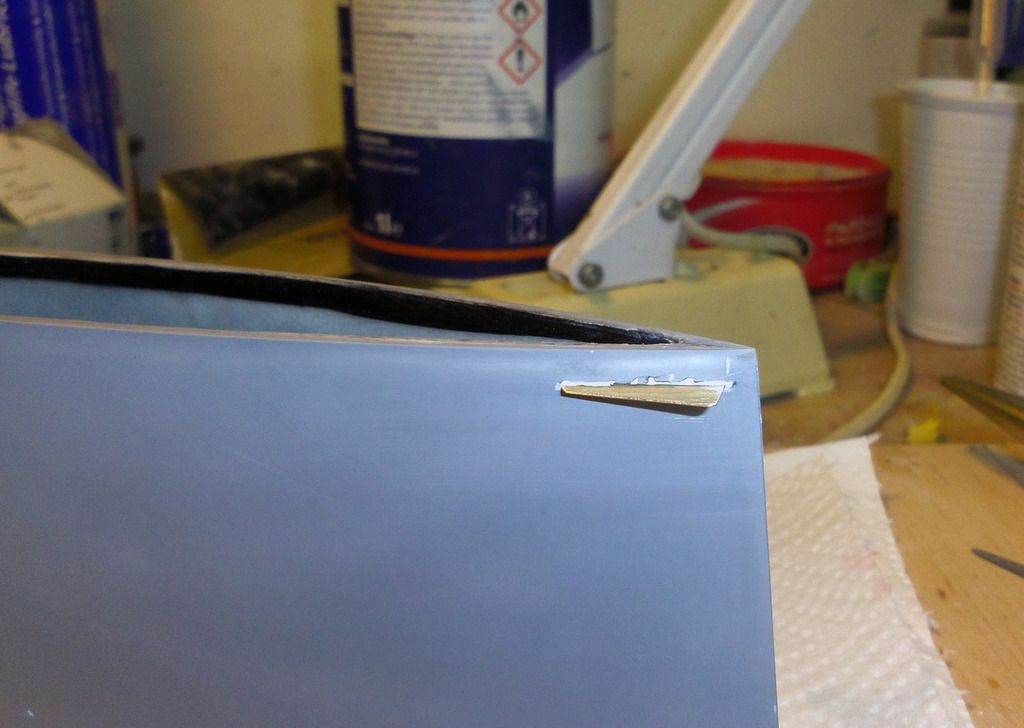

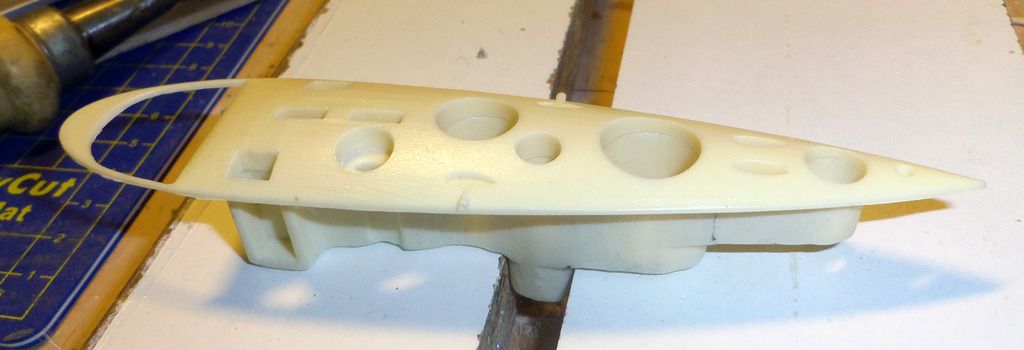

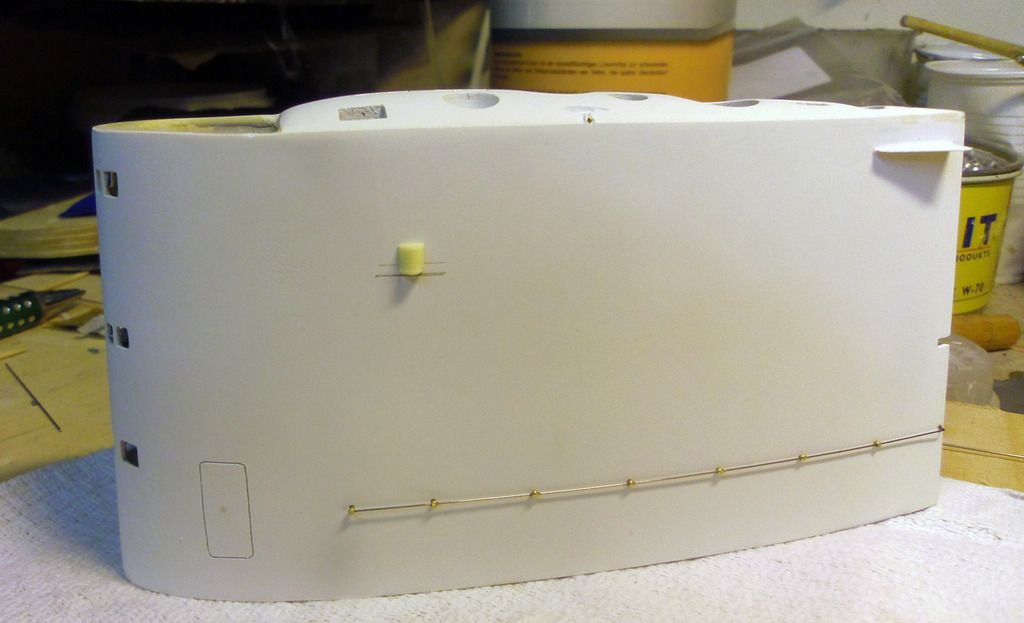

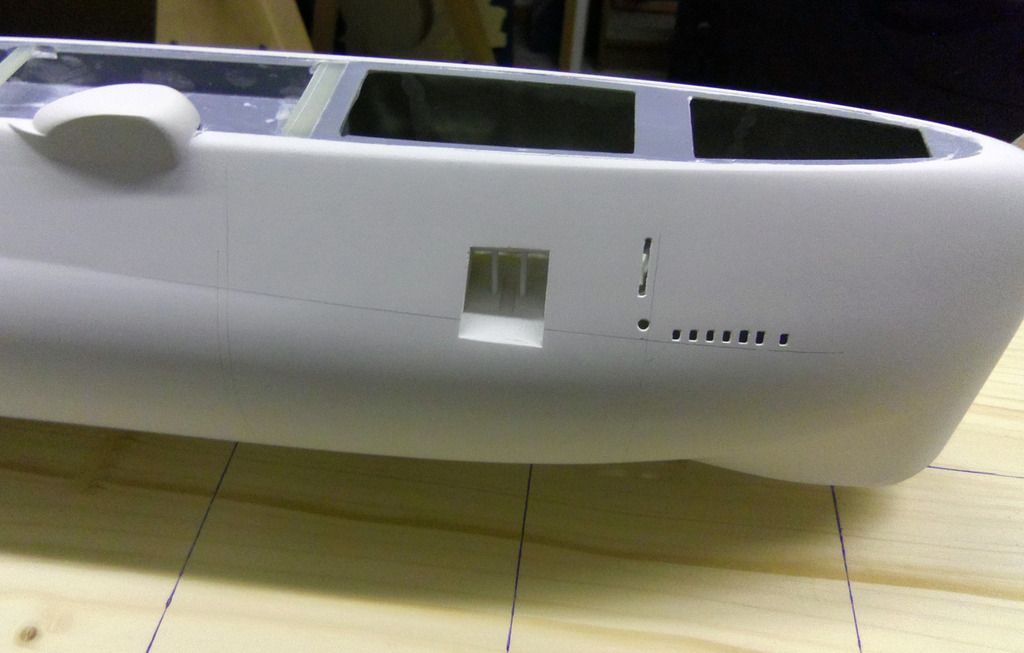

Next, the bow section is glued to the pressure-tight main hull. Sand and clean the adherent and fix both parts using high-strength epoxy. The bow deck is used to align the two sections but mustn’t be glued yet.

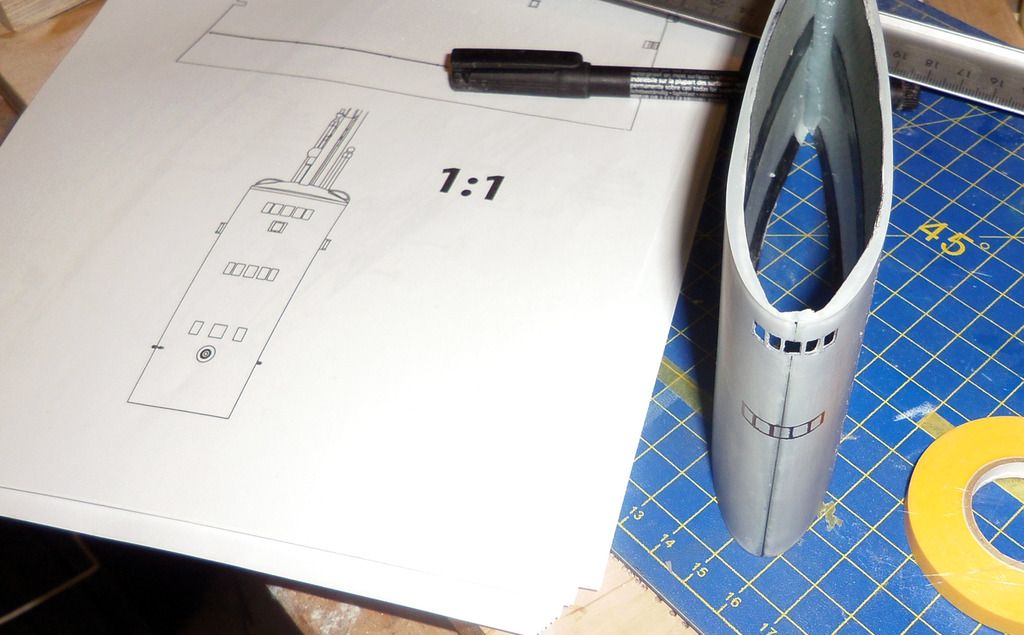

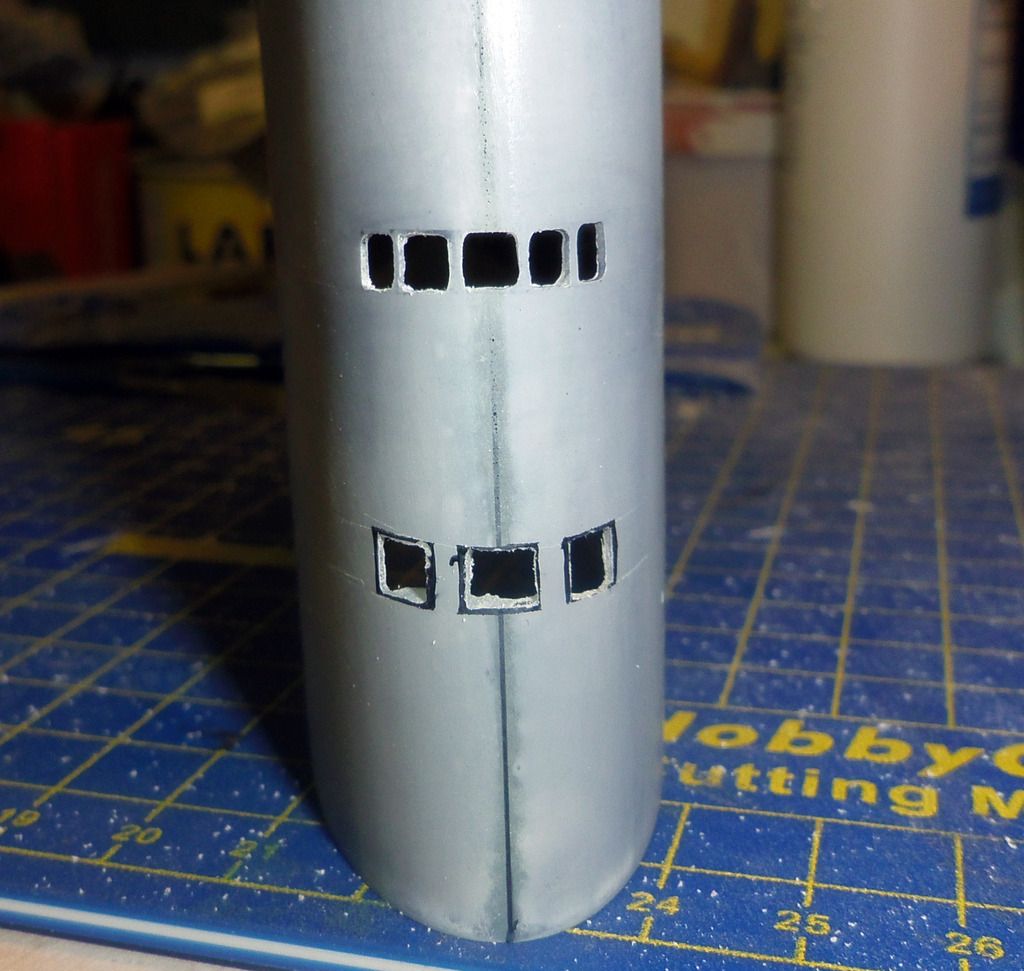

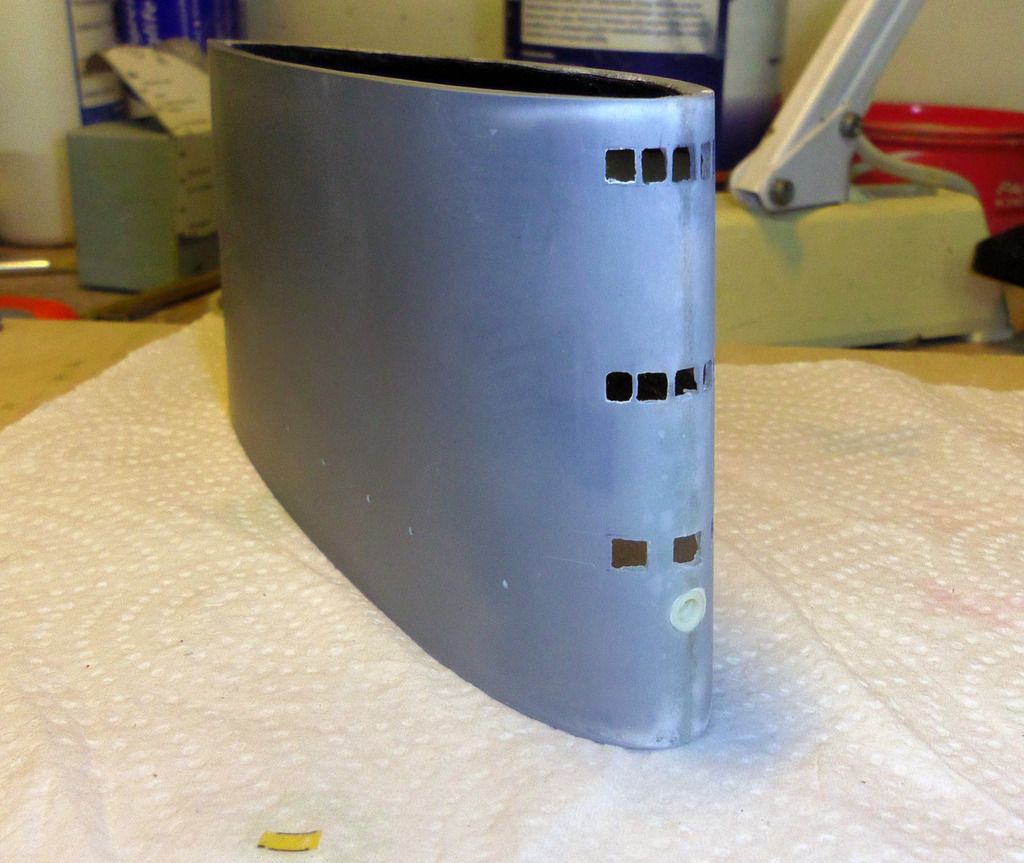

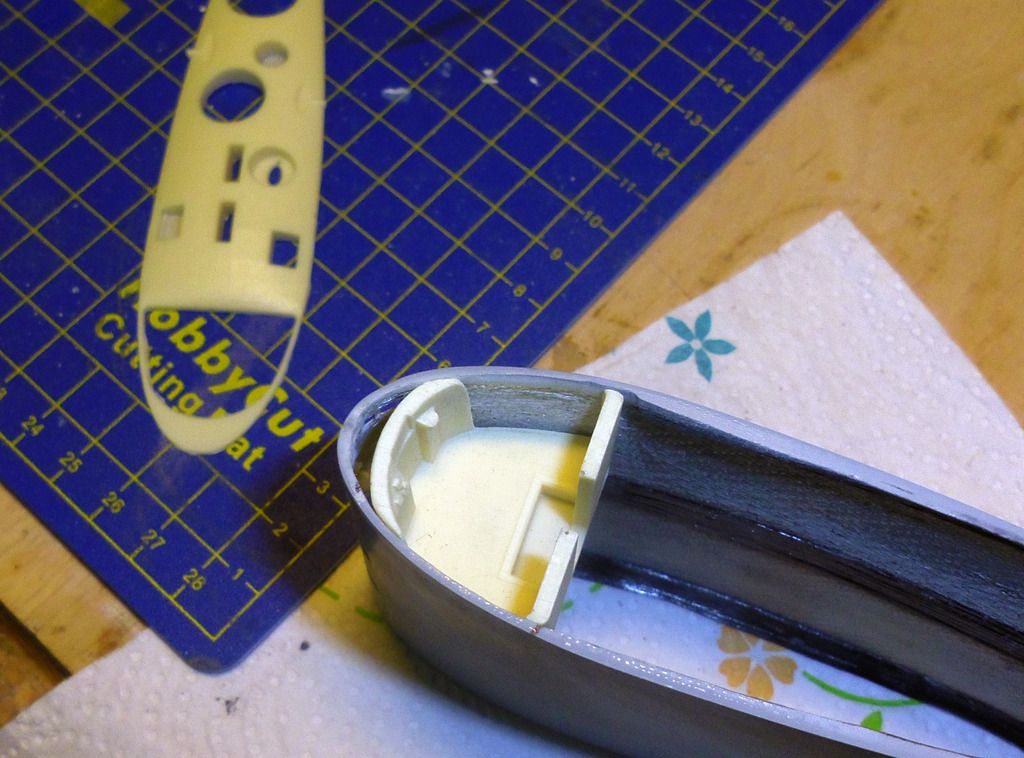

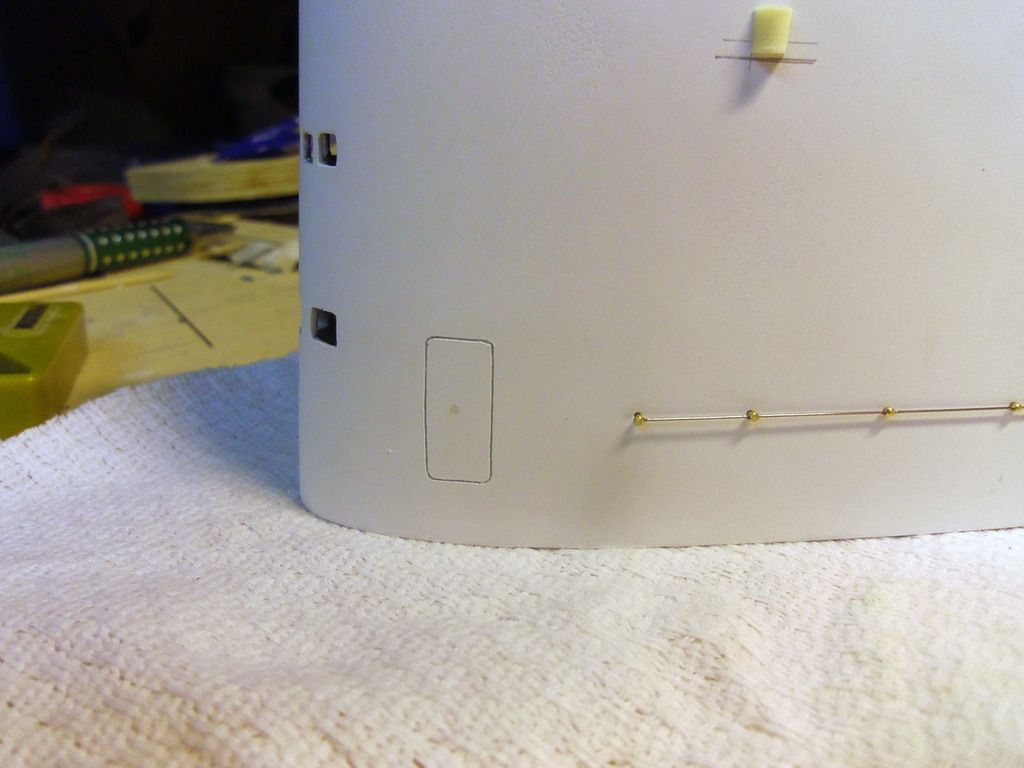

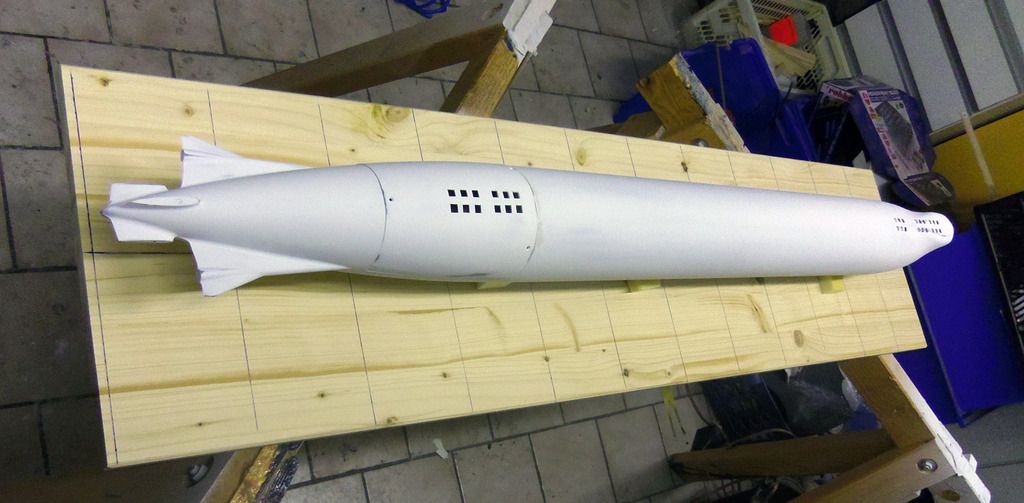

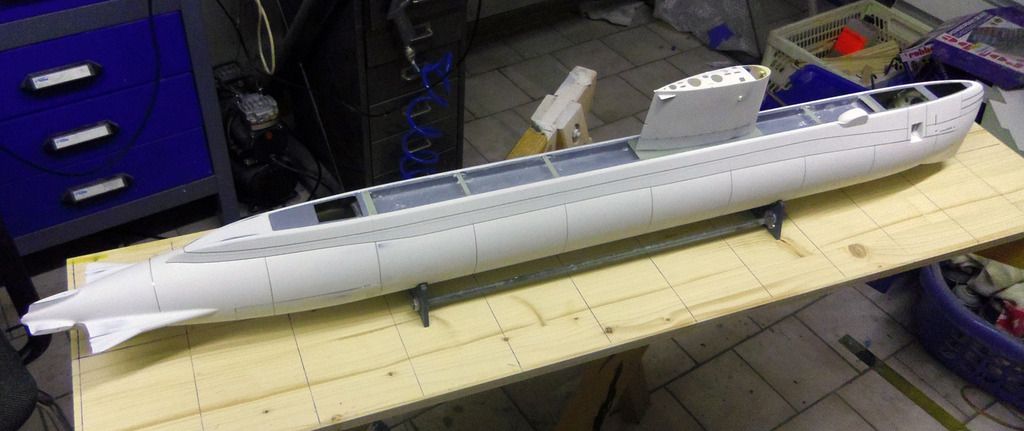

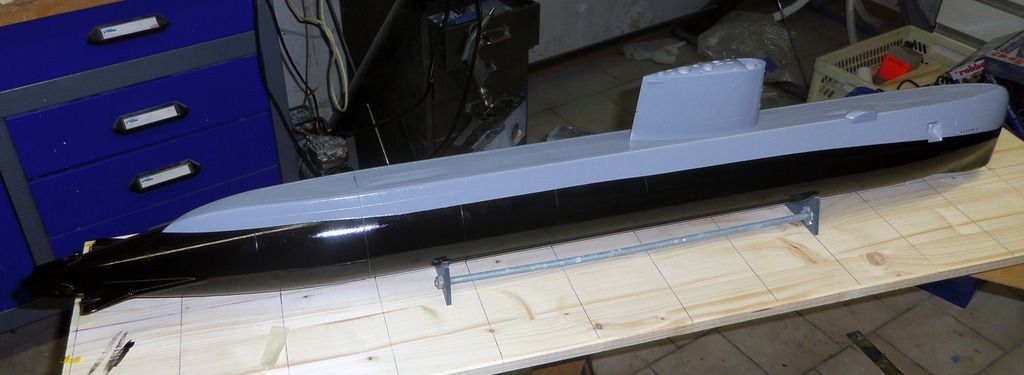

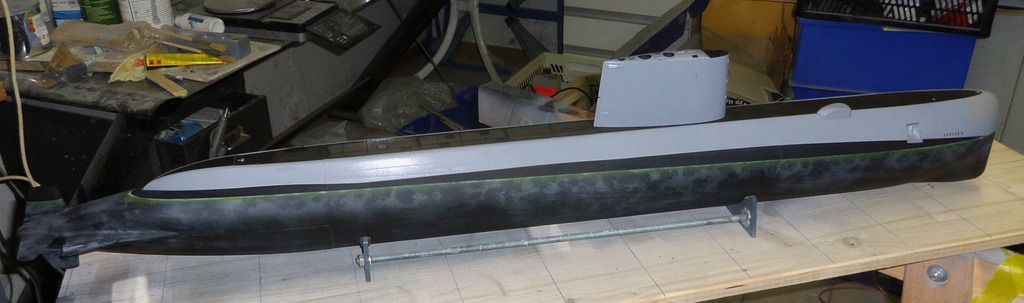

With that the main hull is complete:

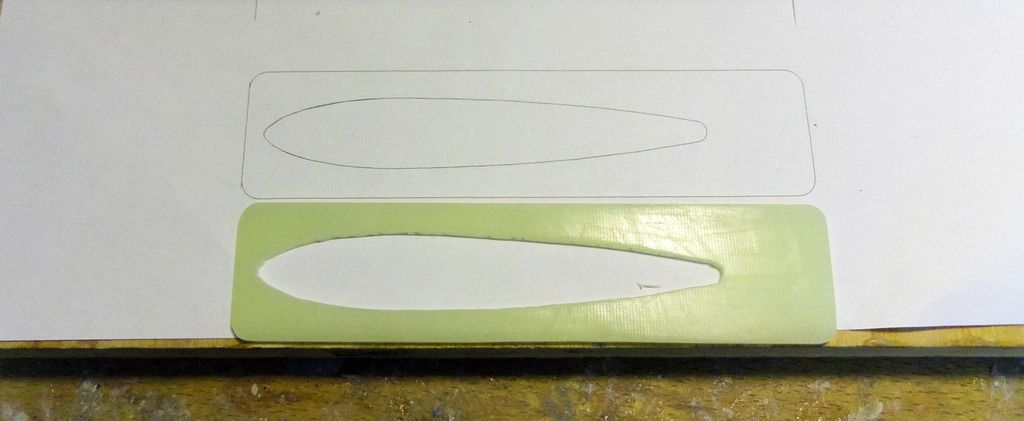

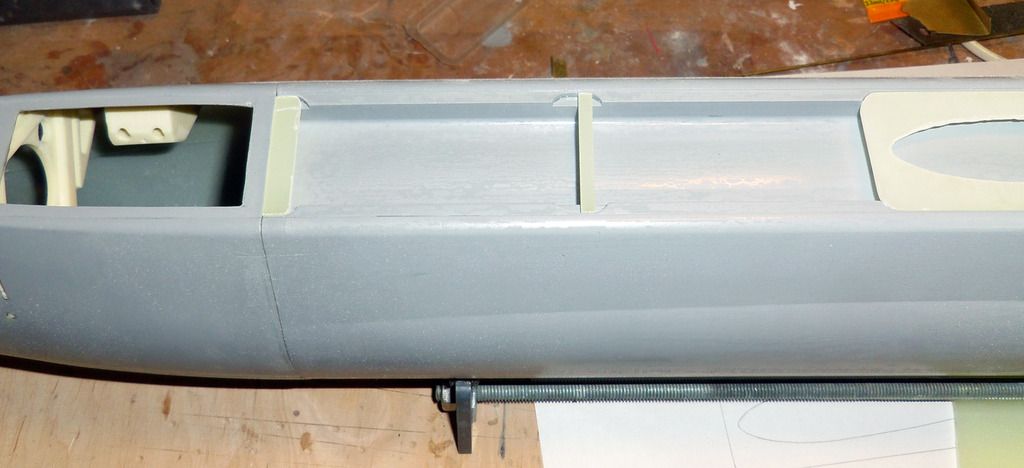

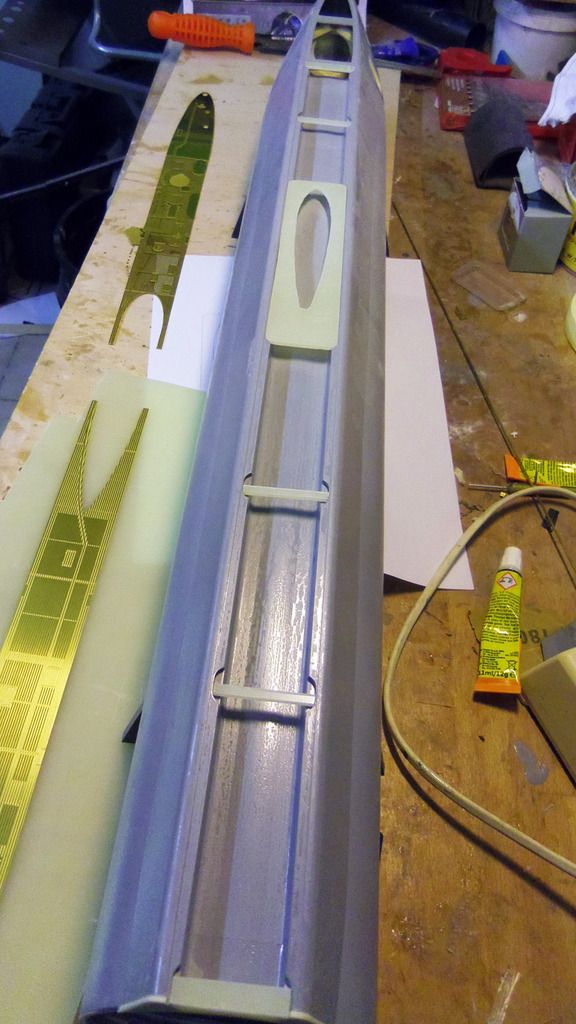

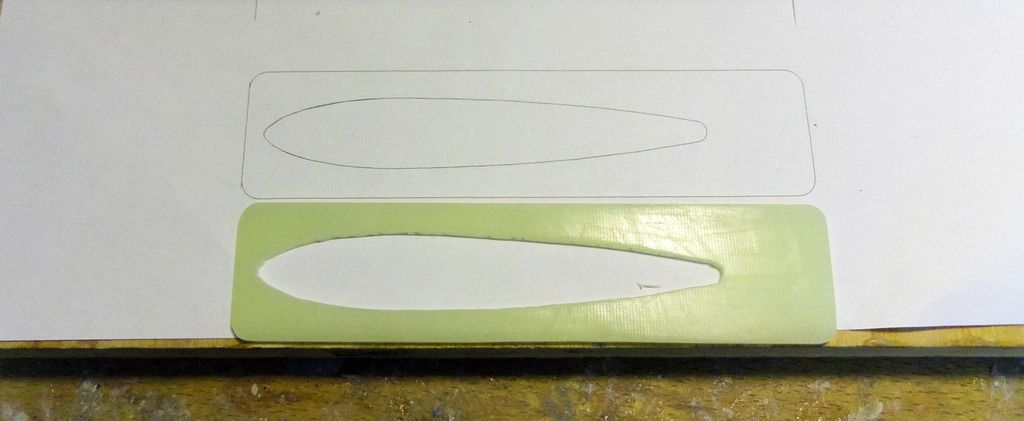

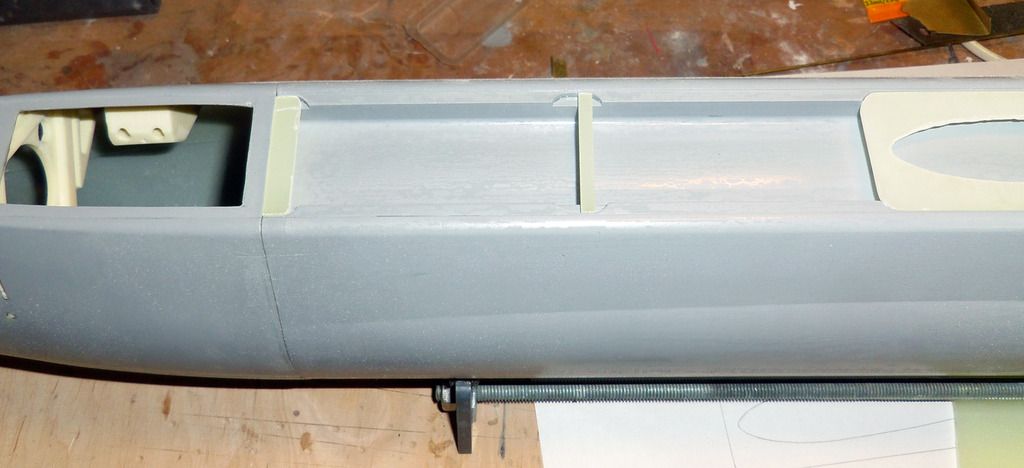

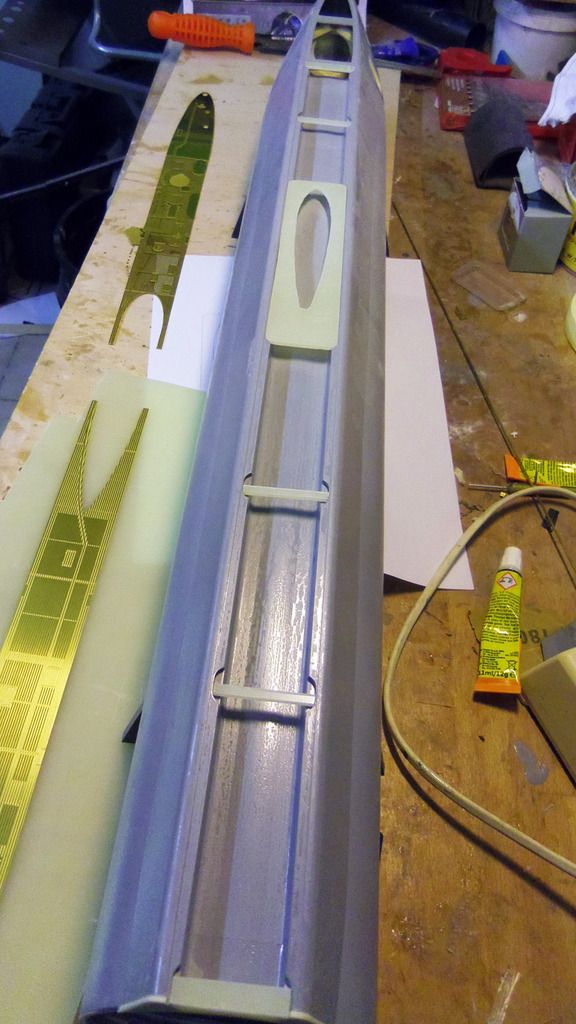

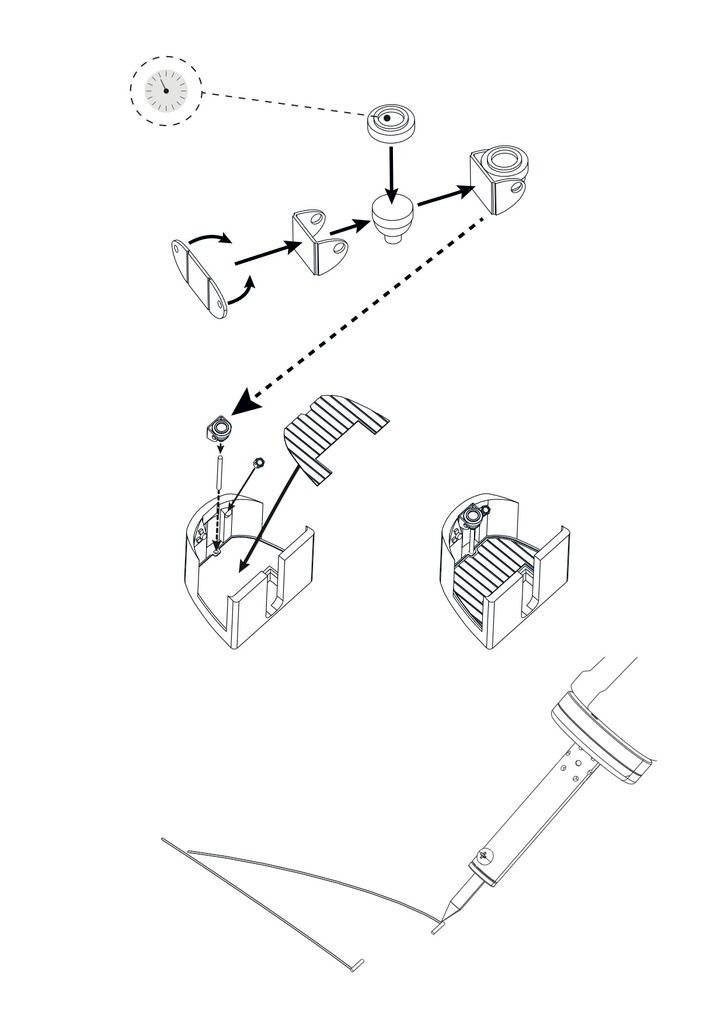

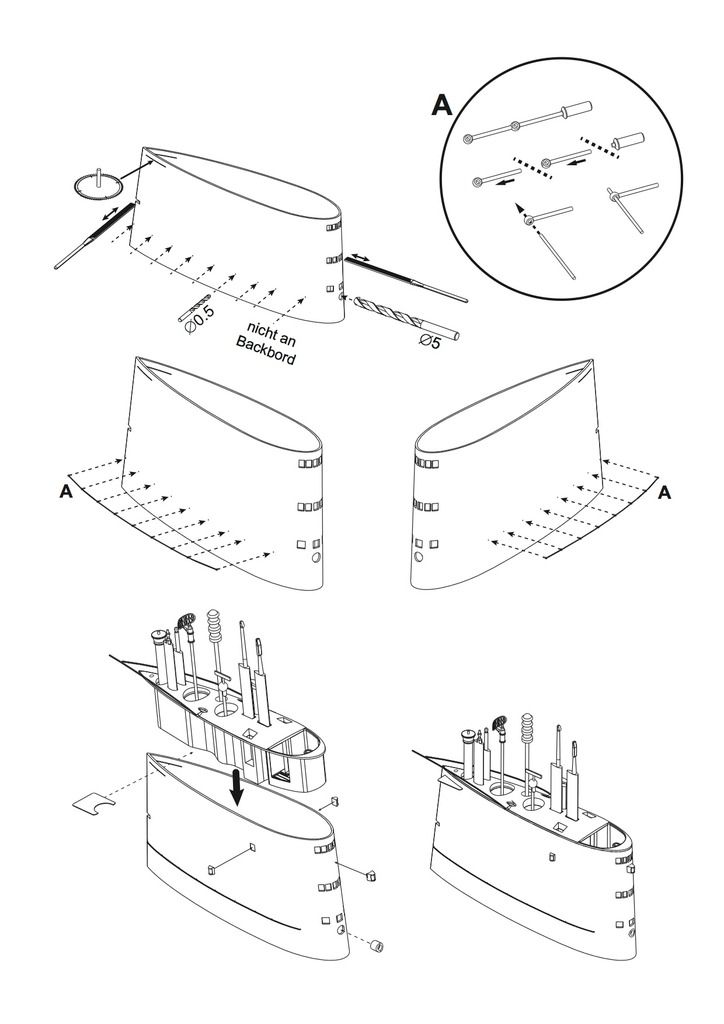

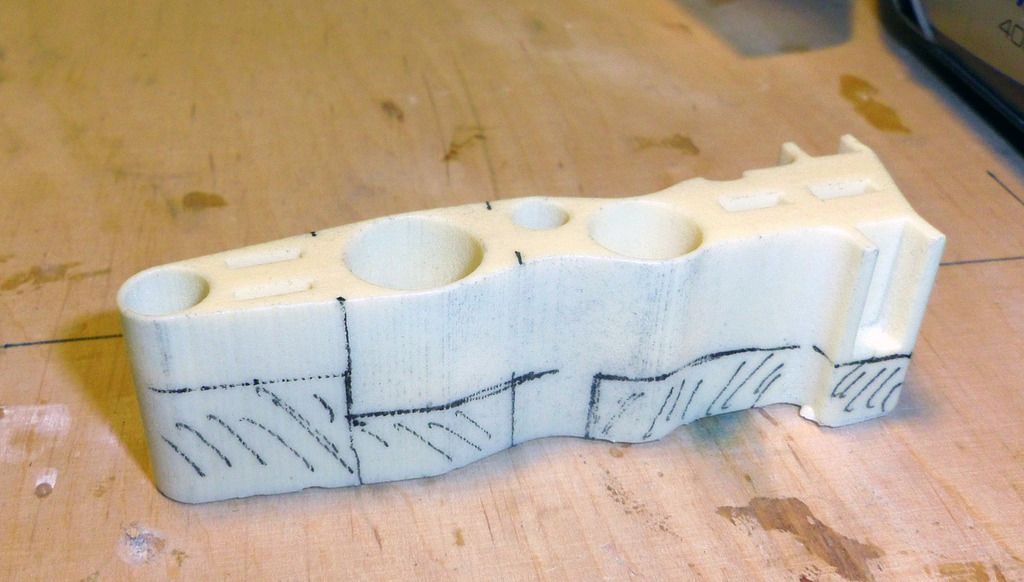

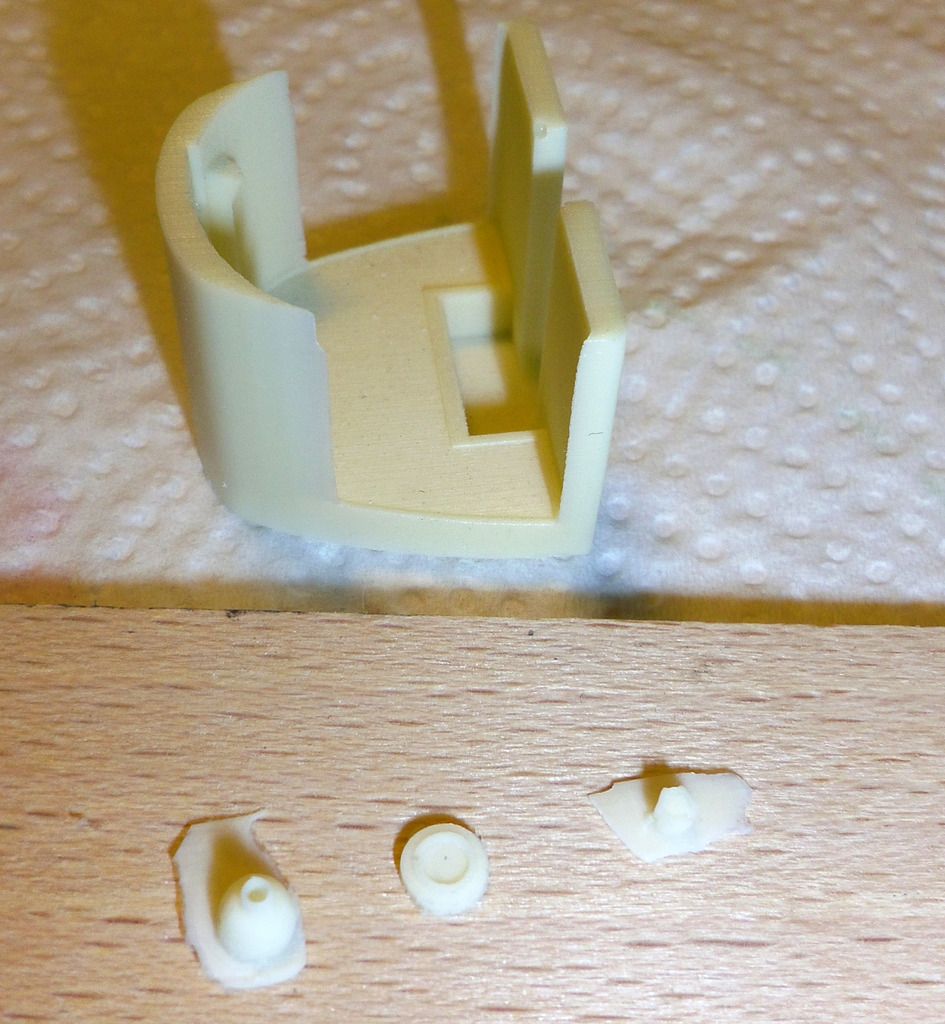

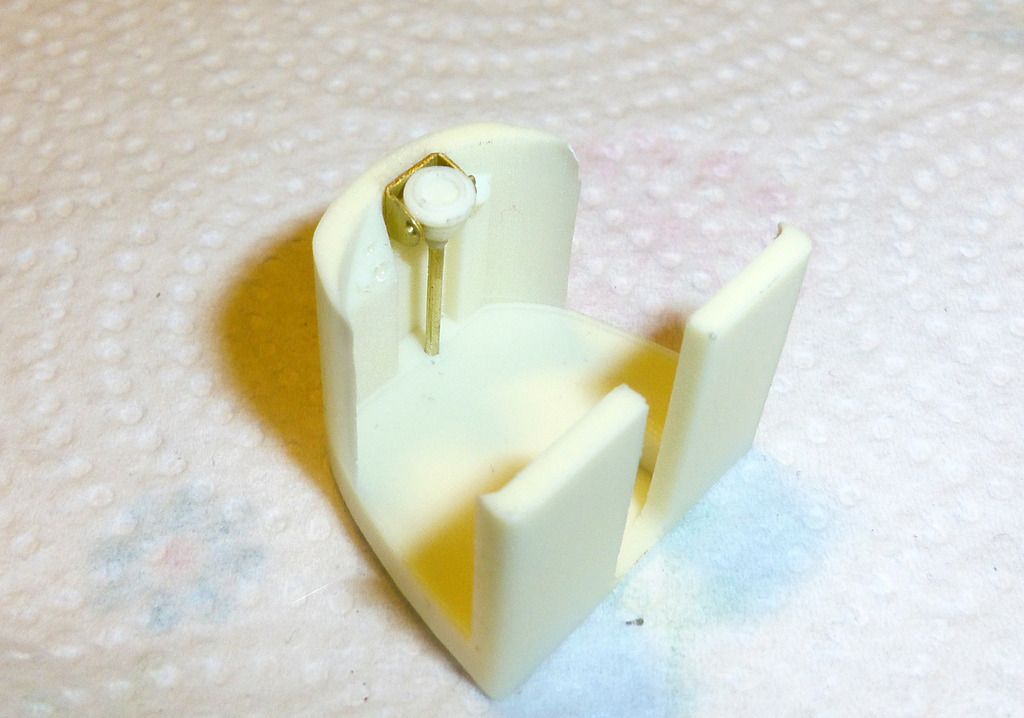

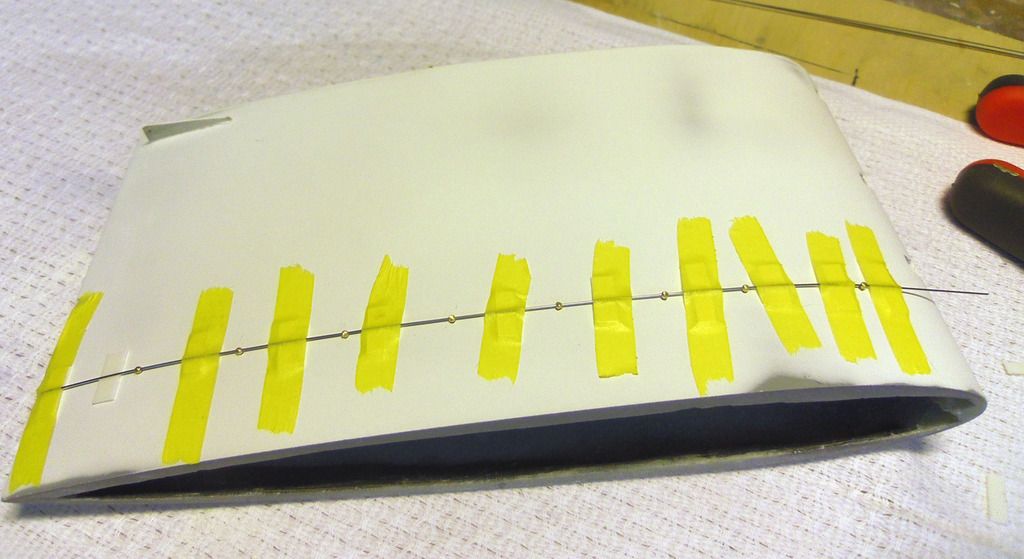

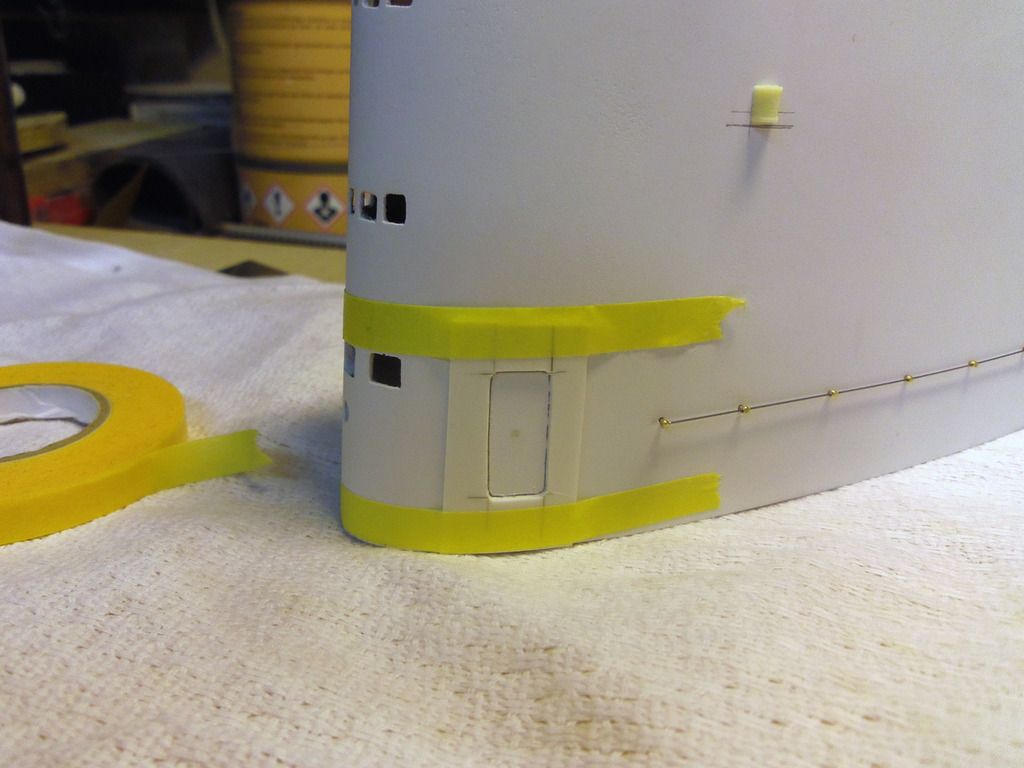

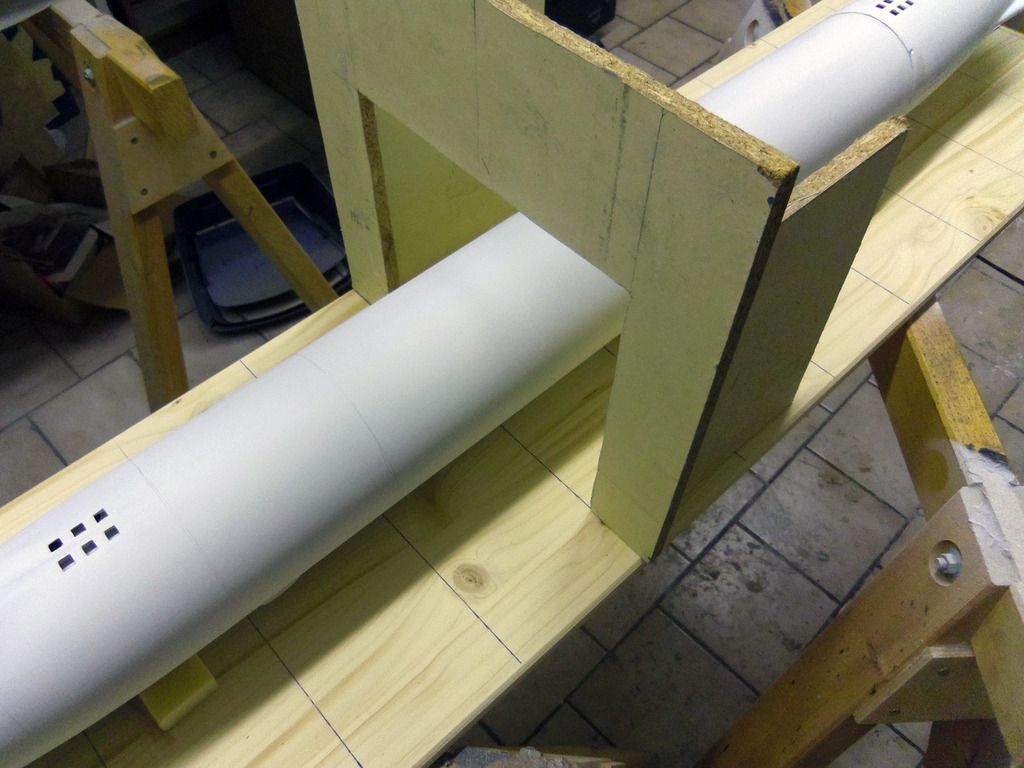

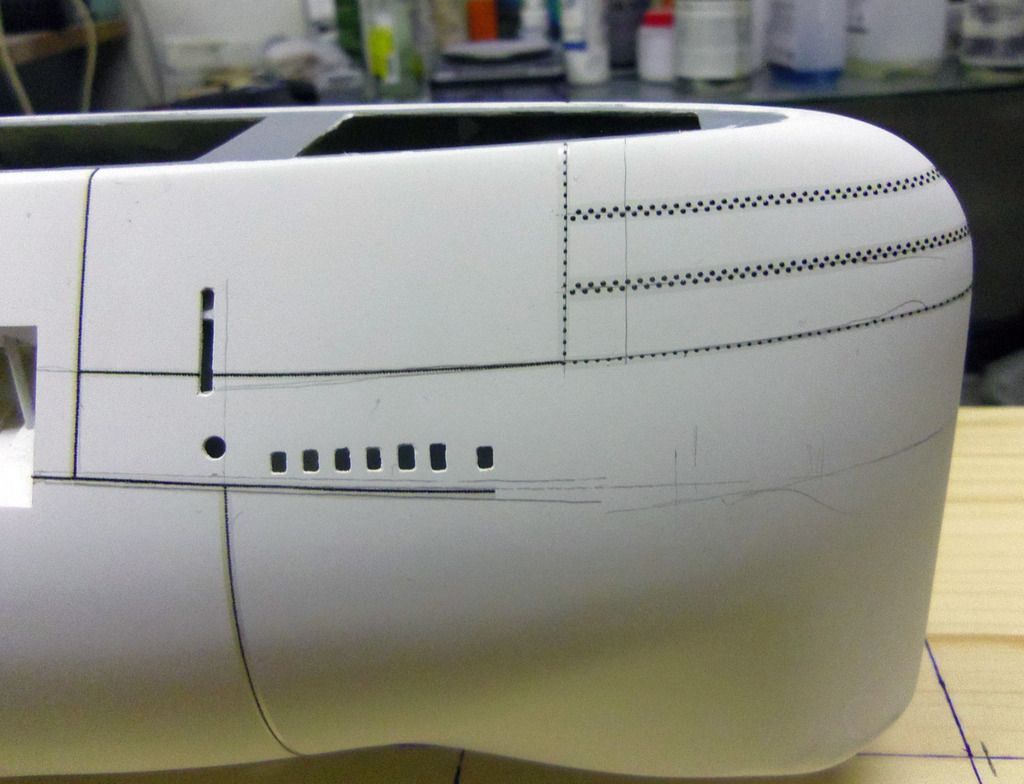

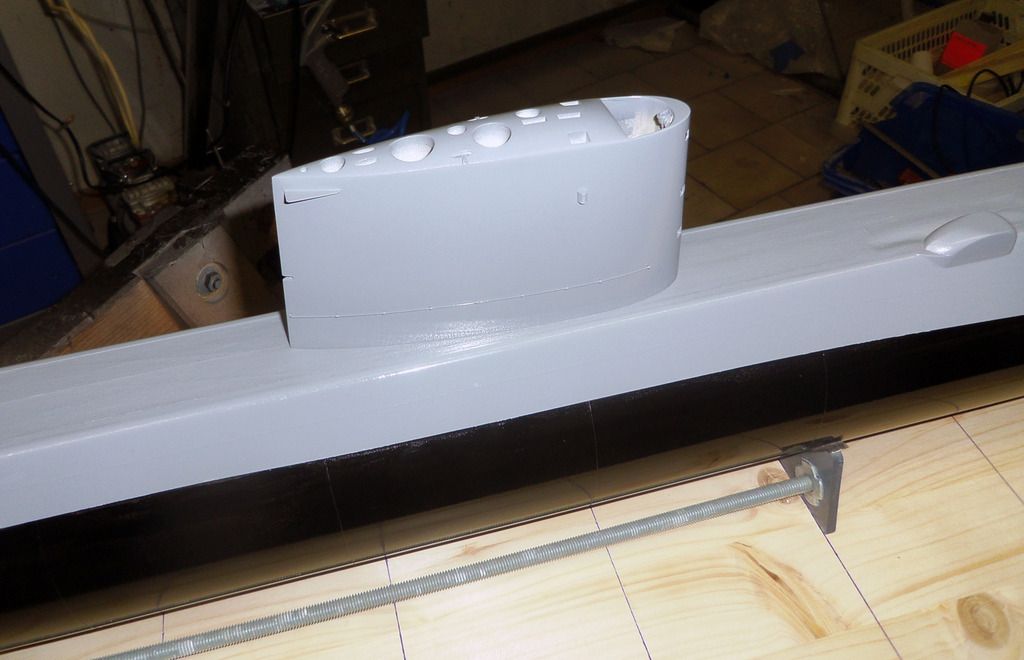

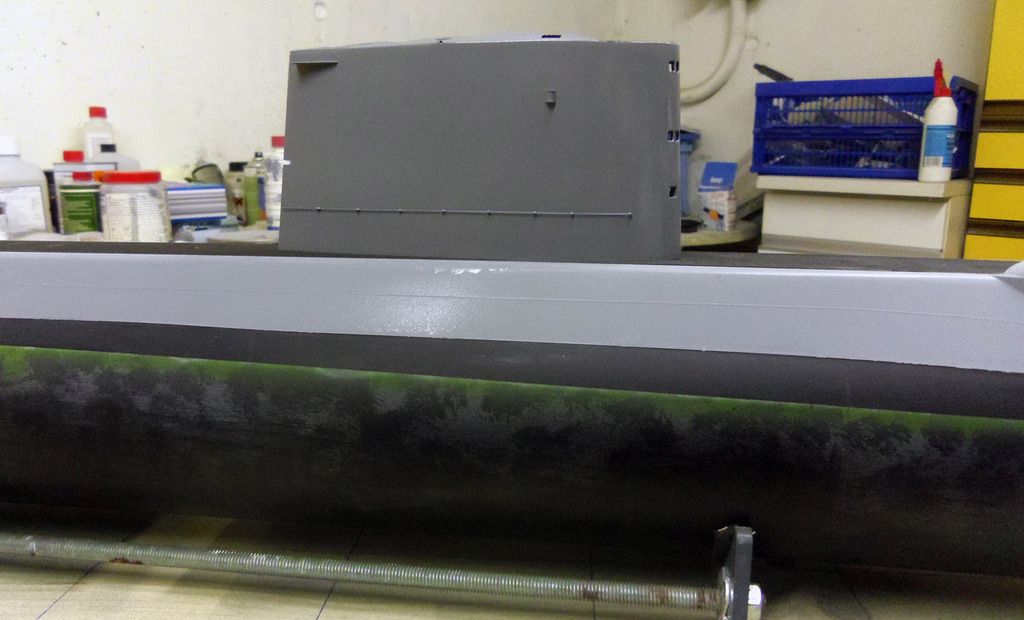

To support the photo-etched deck and to mount the sail, struts, fabricated from 2 mm GRP sheet material, are fabricated and glued into the associated recesses in the main hull:

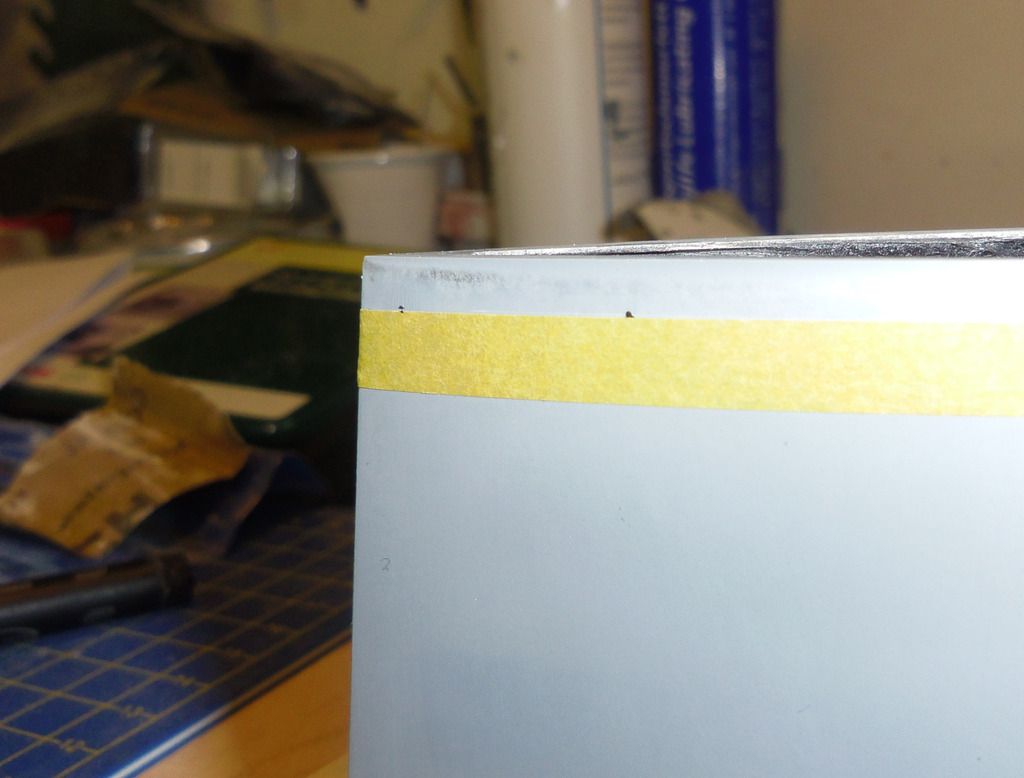

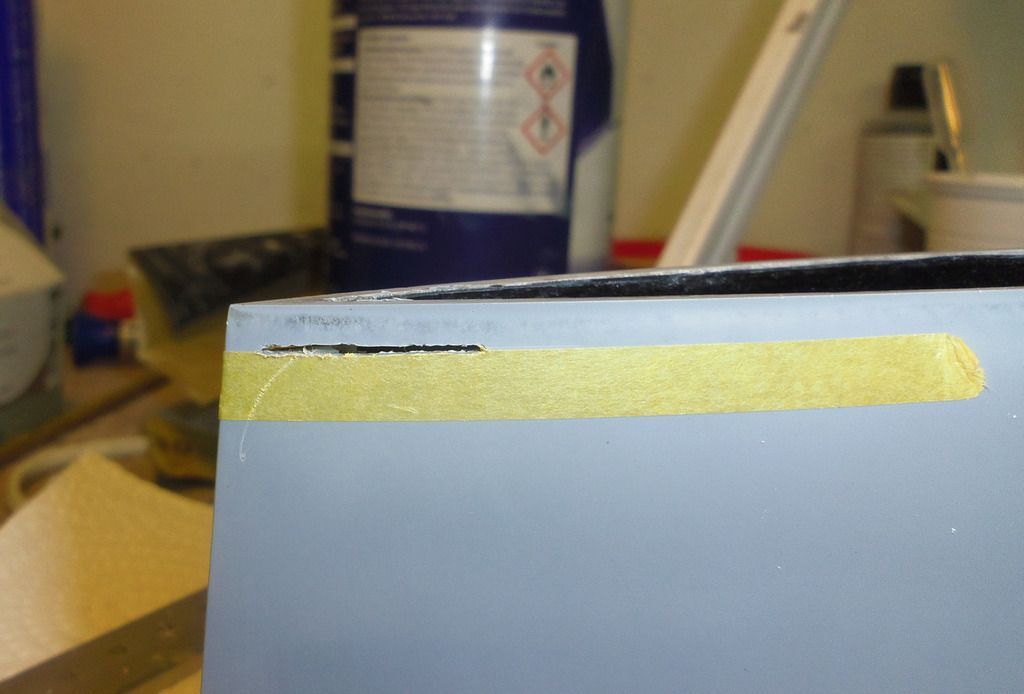

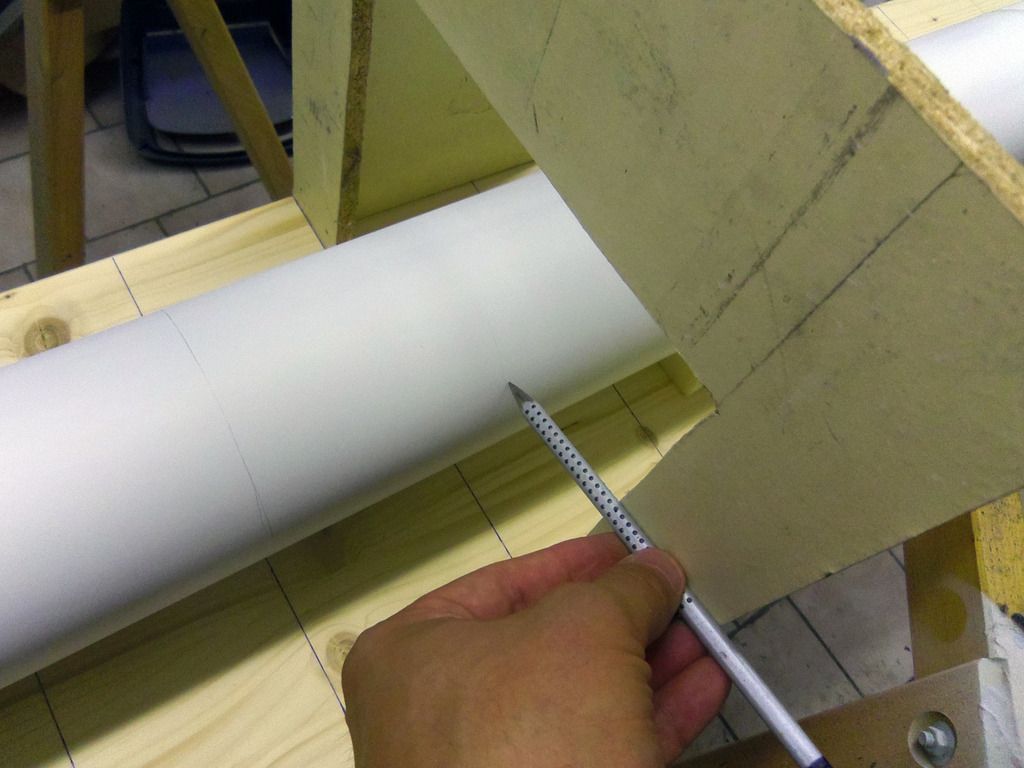

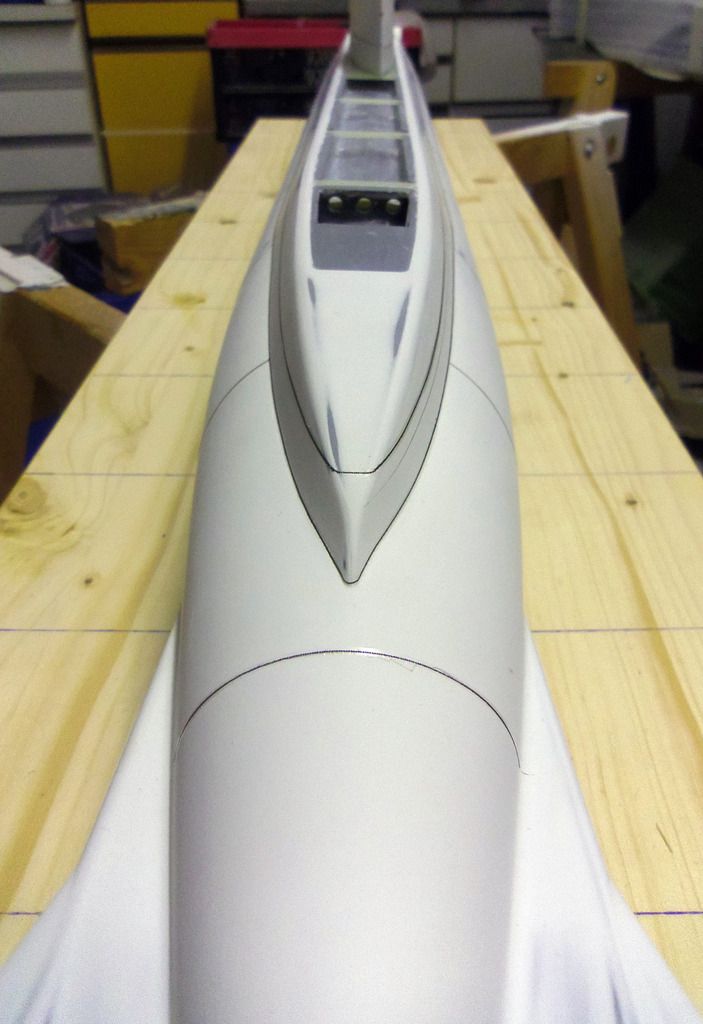

Again remove epoxy residues using a soft cloth and acetone. The deck is put onto the hull to check for the correct position f the struts but mustn’t be glued yet.

Side remark:

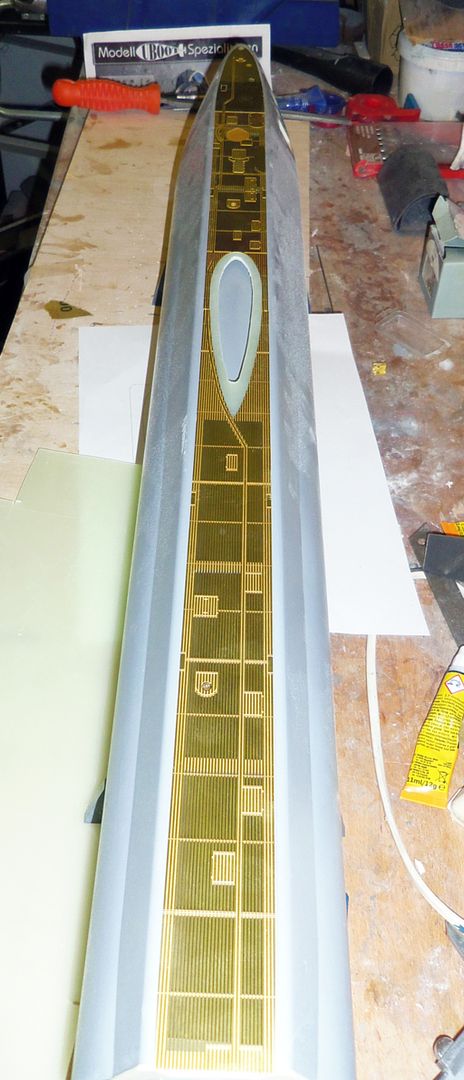

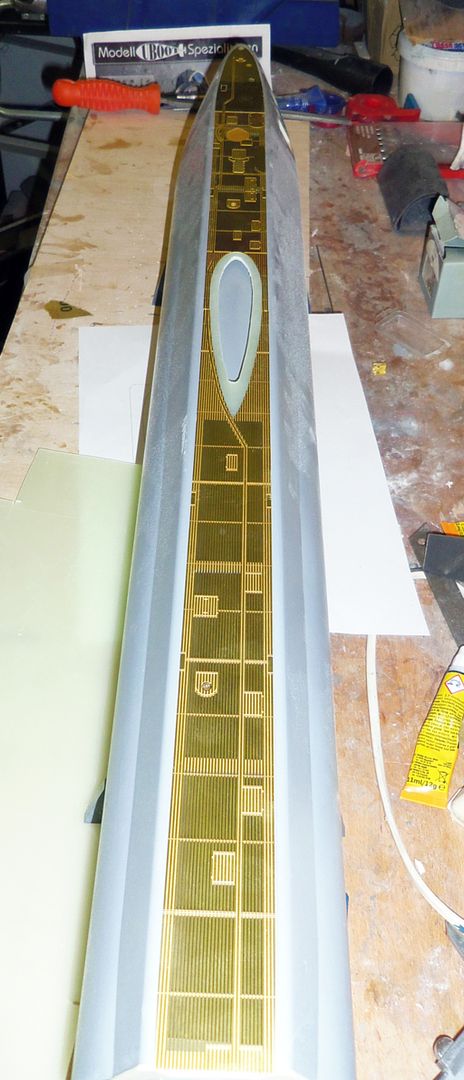

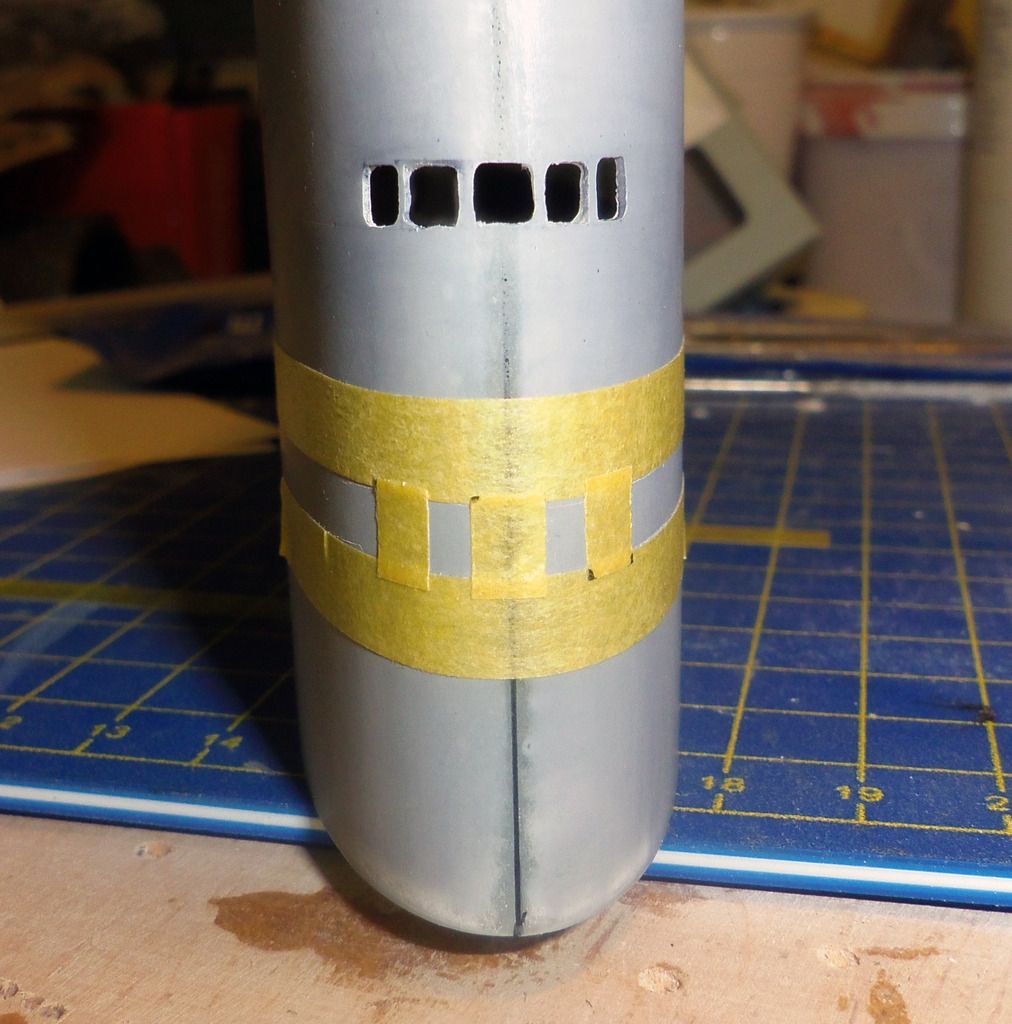

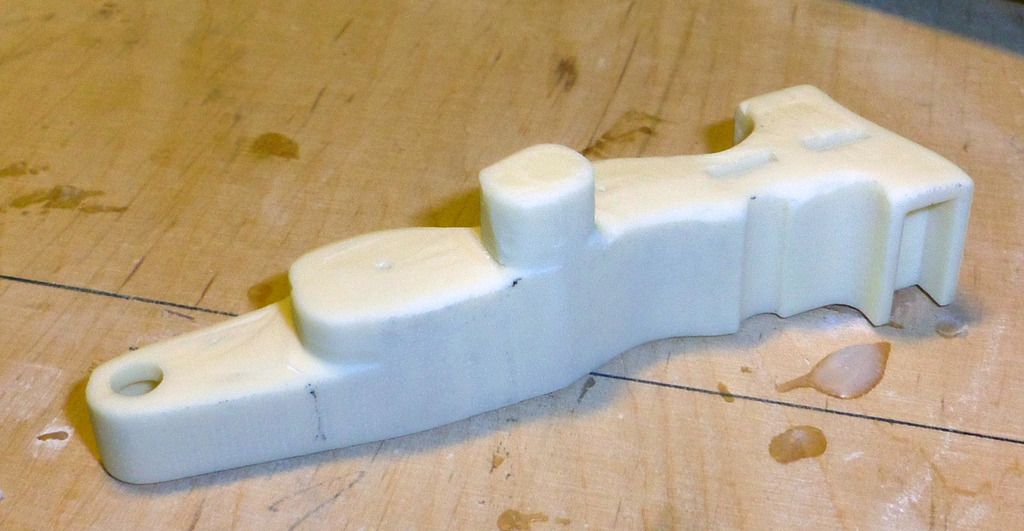

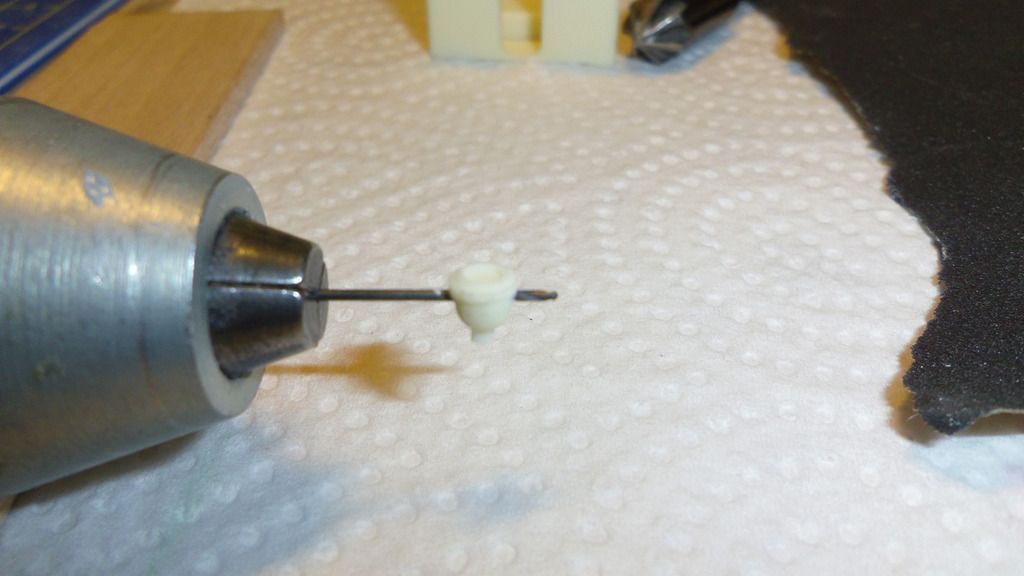

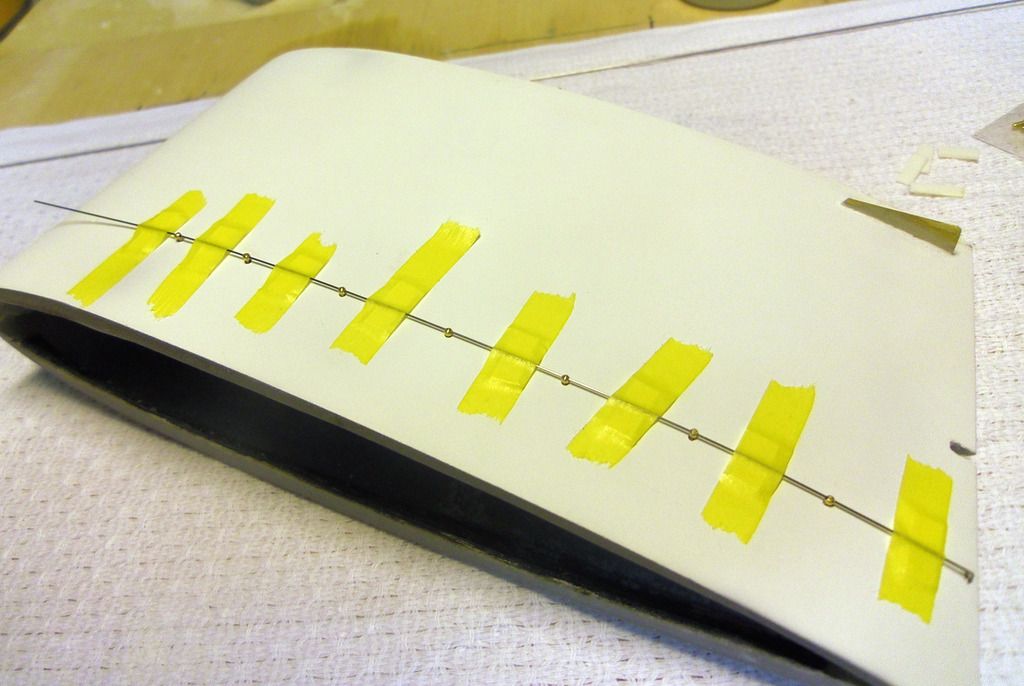

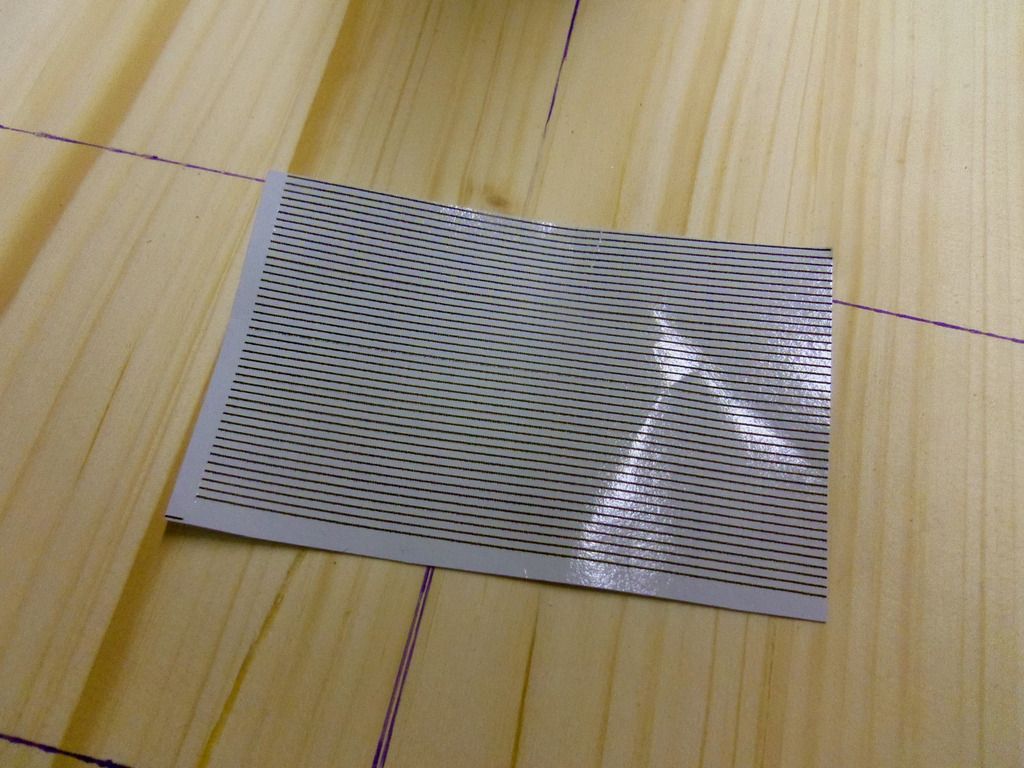

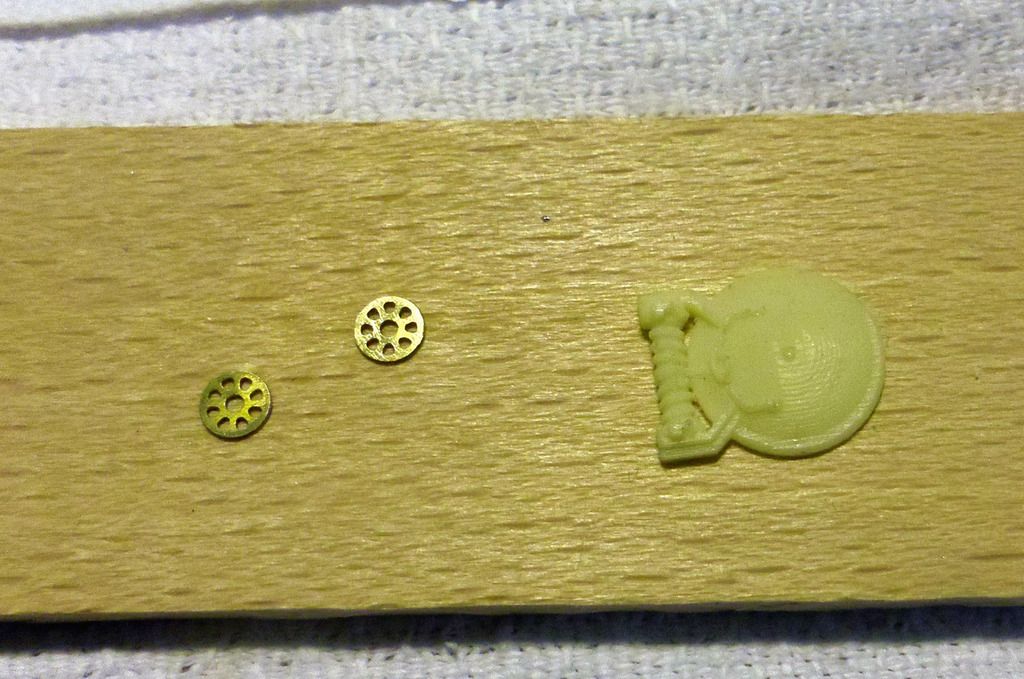

The photo-etched deck is best removed from its sheet using a Dremel drill with a small cutting disk. Carefully clean the edges using fine grade sandpaper.

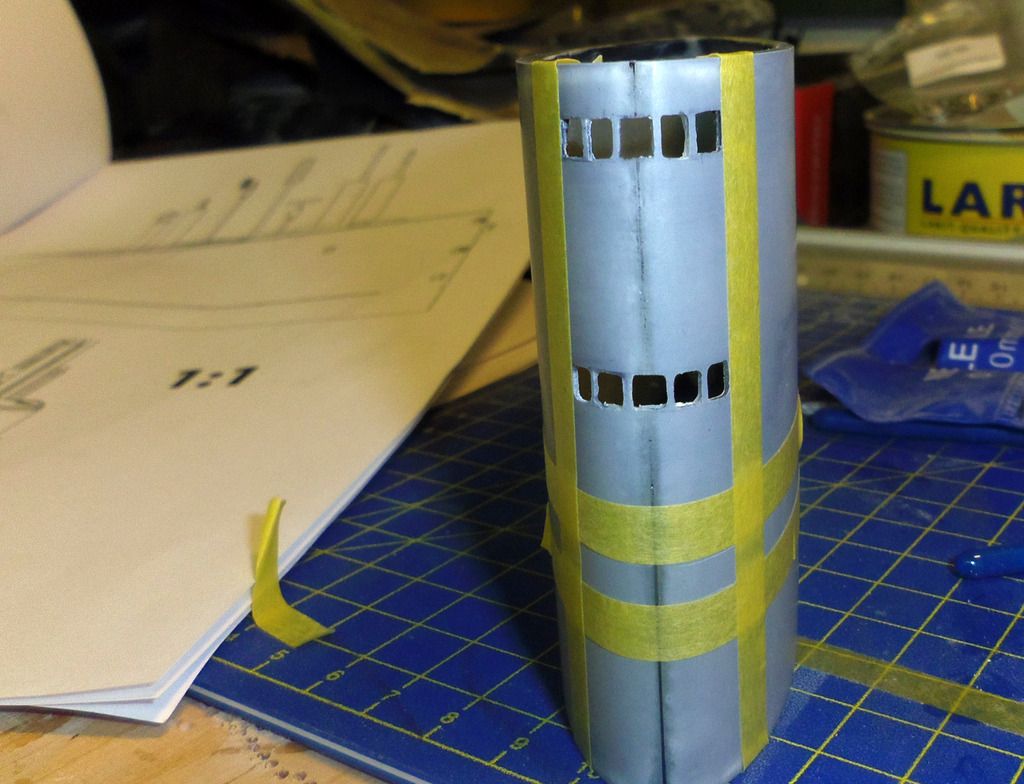

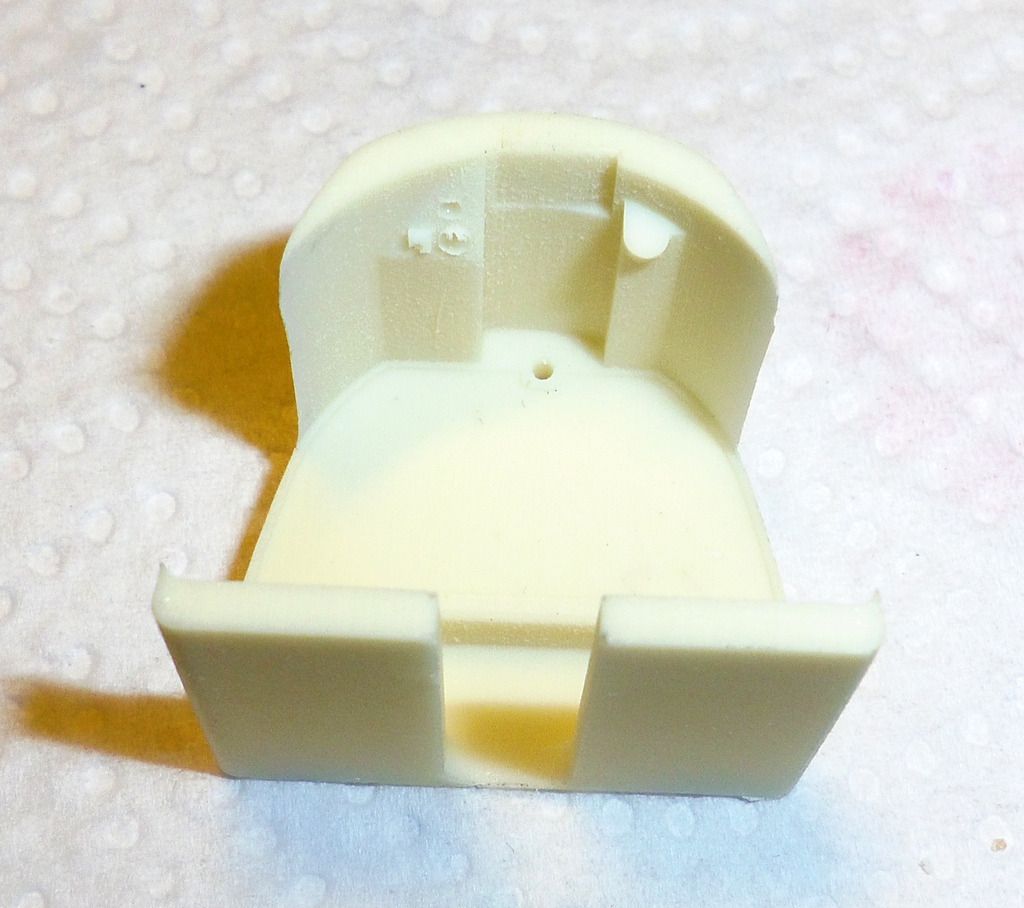

With that the main hull is complete:

To support the photo-etched deck and to mount the sail, struts, fabricated from 2 mm GRP sheet material, are fabricated and glued into the associated recesses in the main hull:

Again remove epoxy residues using a soft cloth and acetone. The deck is put onto the hull to check for the correct position f the struts but mustn’t be glued yet.

Side remark:

The photo-etched deck is best removed from its sheet using a Dremel drill with a small cutting disk. Carefully clean the edges using fine grade sandpaper.

Comment