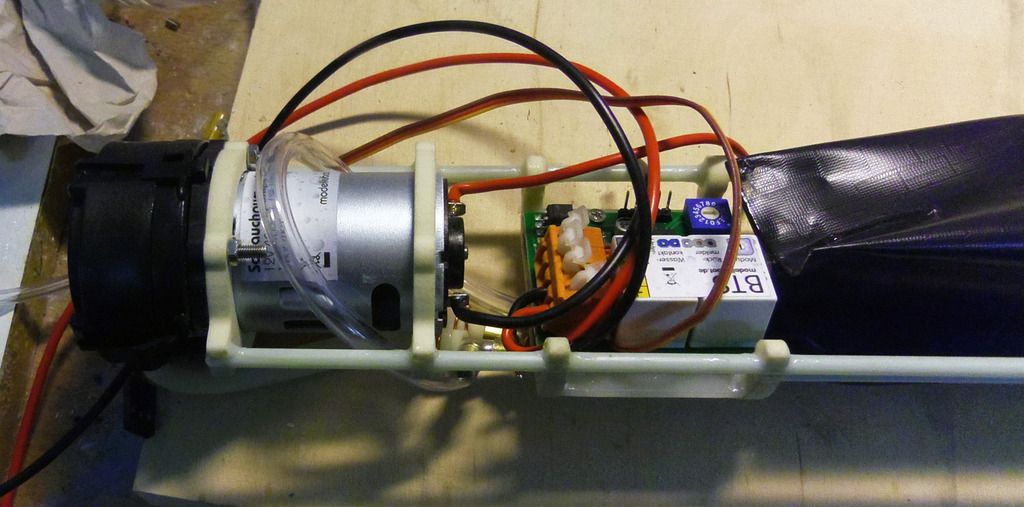

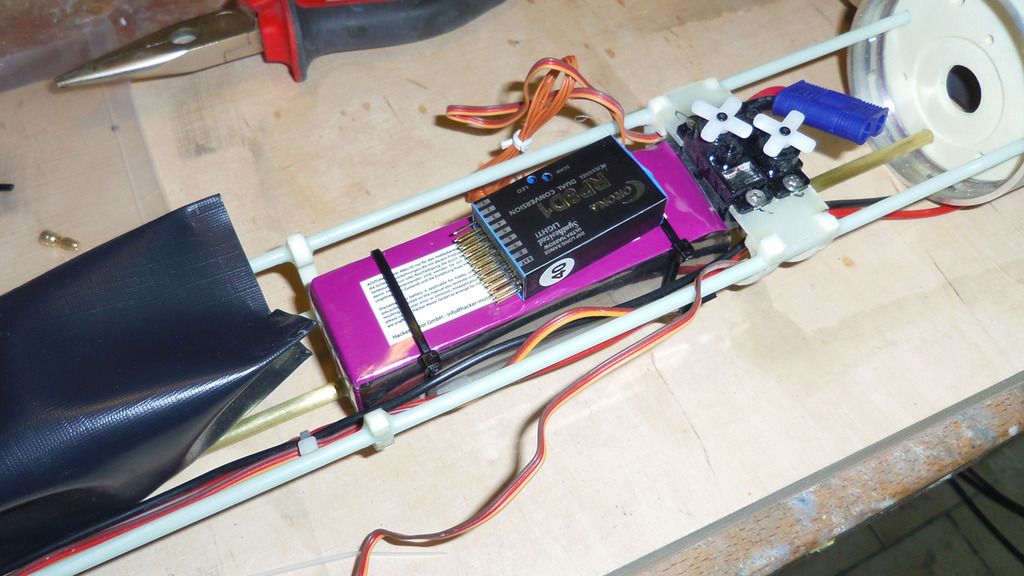

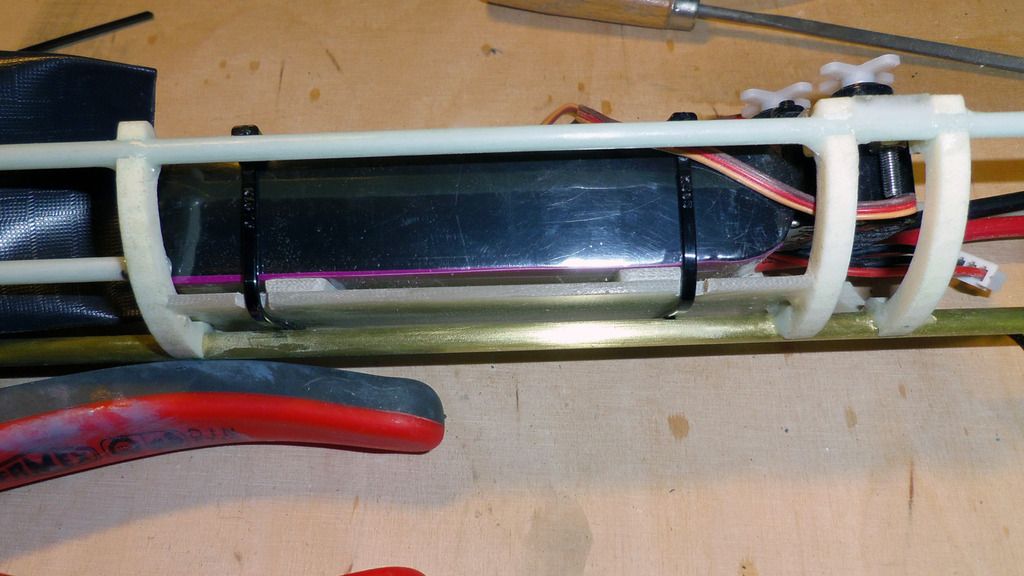

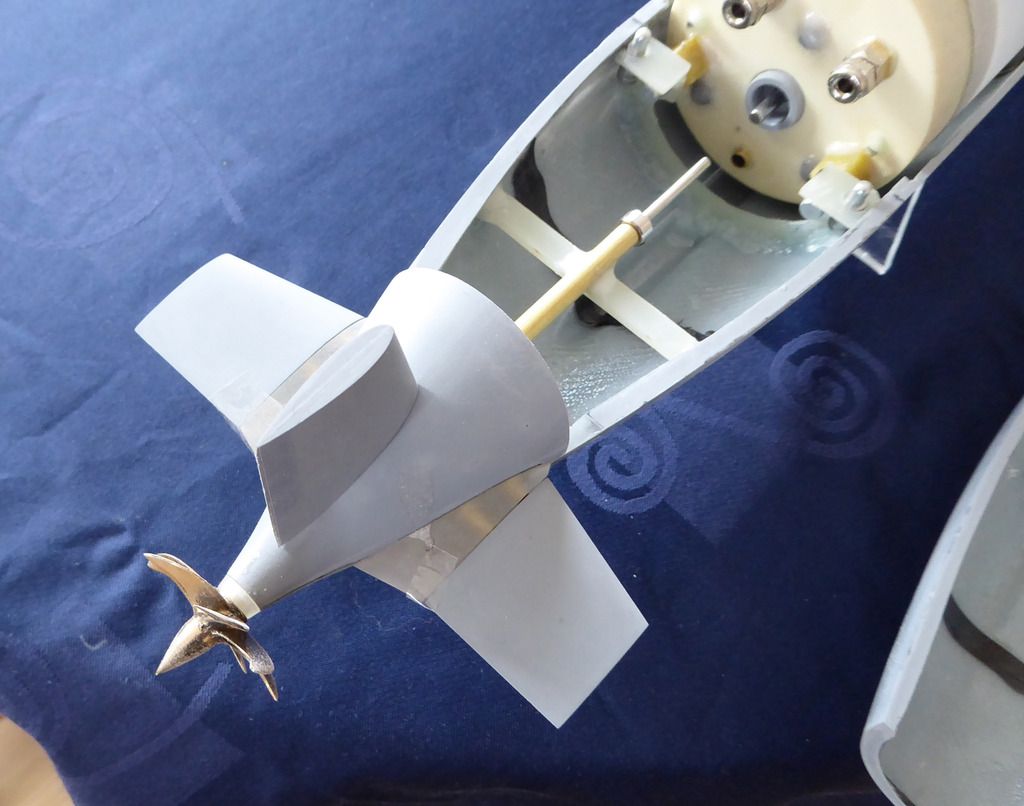

Slowly everything falls into place. The dive controller is screwed in place and I started wiring the whole thing:

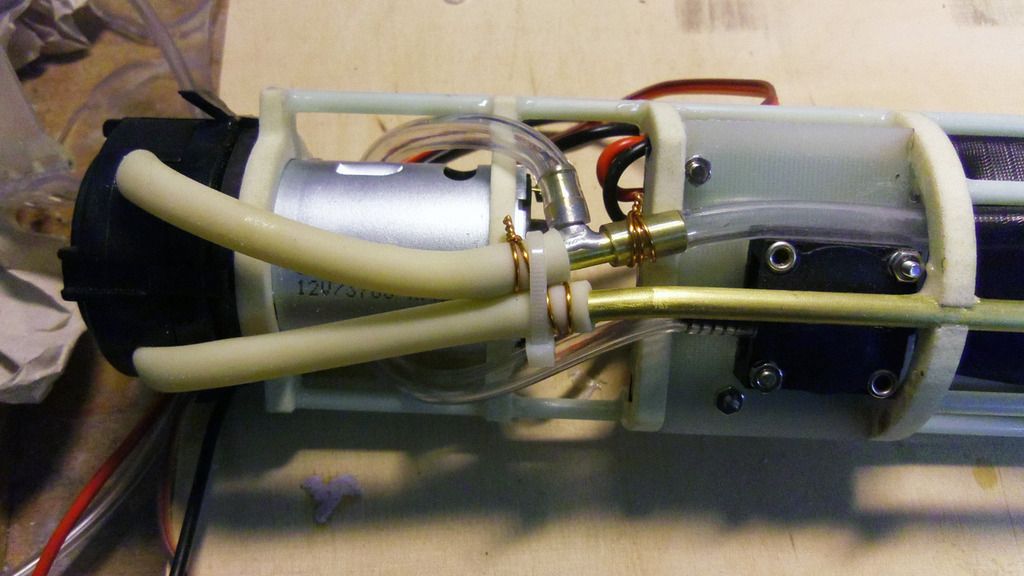

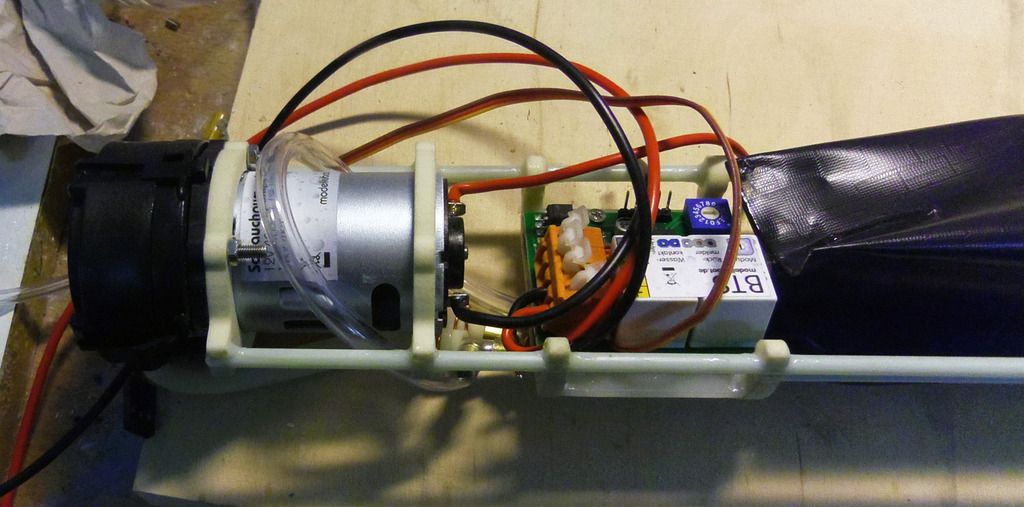

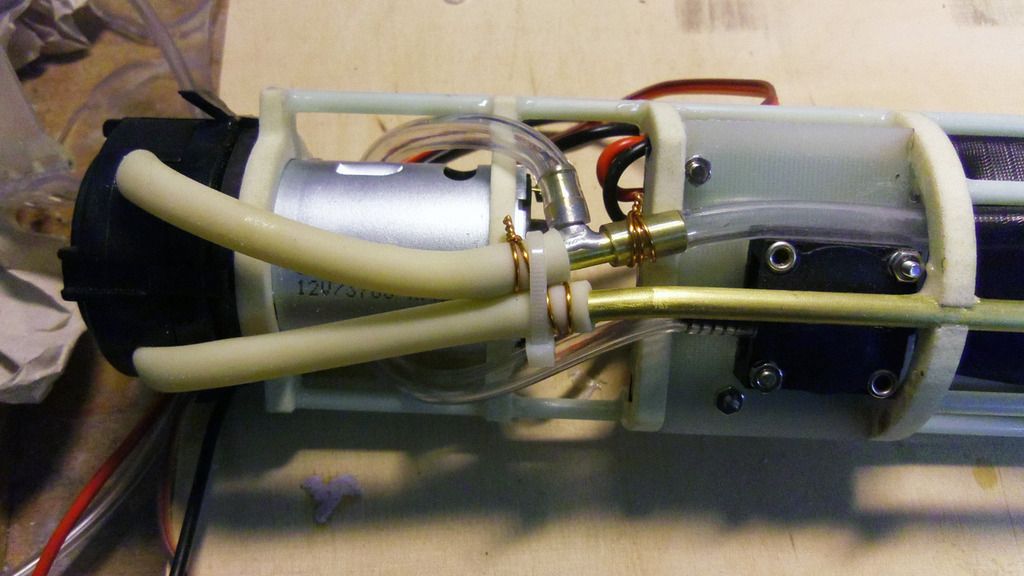

The hoses are hooked up. The overpressure switch is new, not the one I got with the controller, as latter was too big. The new one fits tightly into place below the dive controller. The hose to the pressure switch starts in a T nipple and is routed over the pump motor to ensure that no water reaches the switch. And it looks cool....

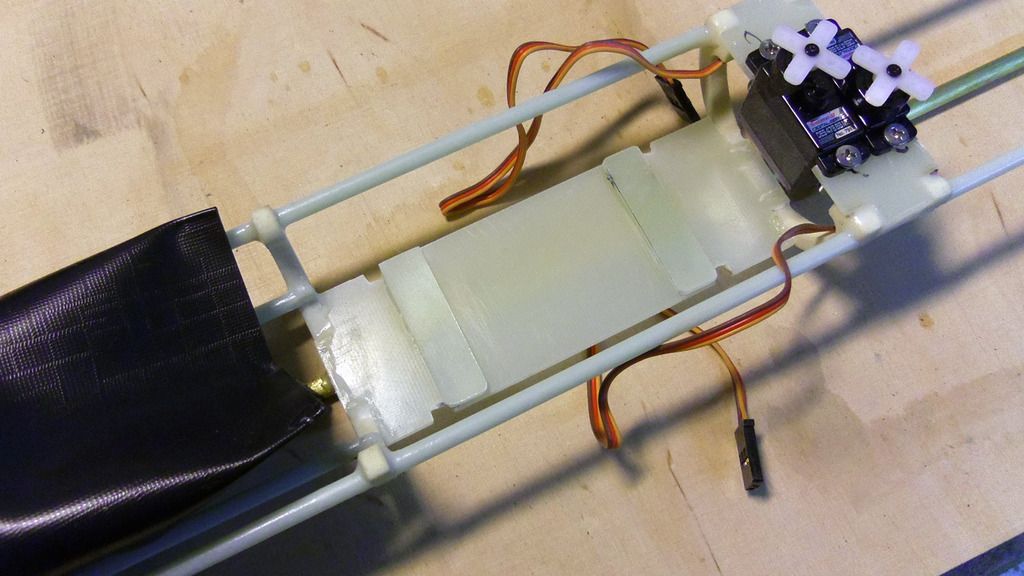

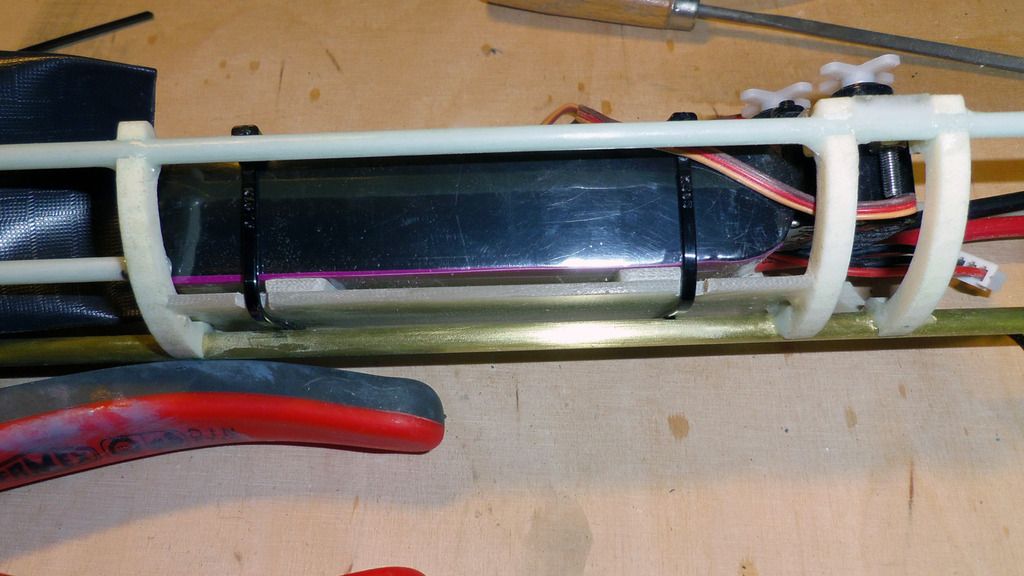

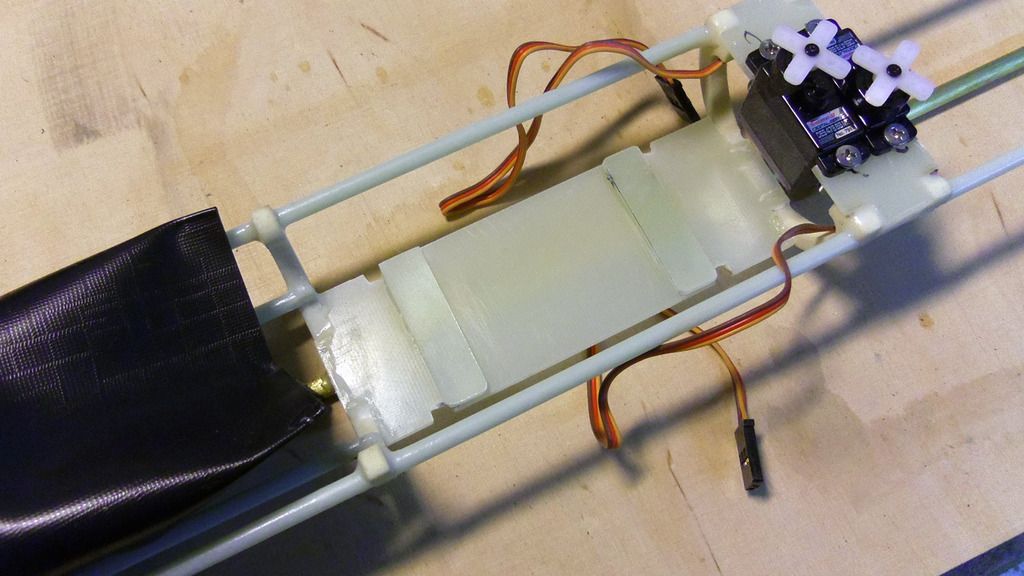

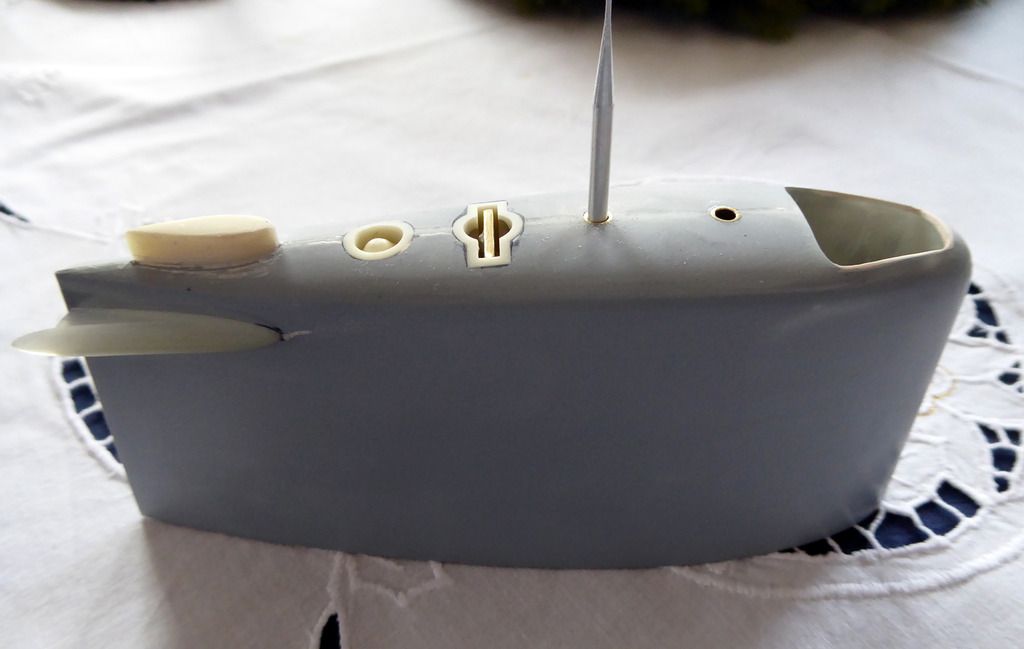

The battery rest on two 2 mm thick GRP planks:

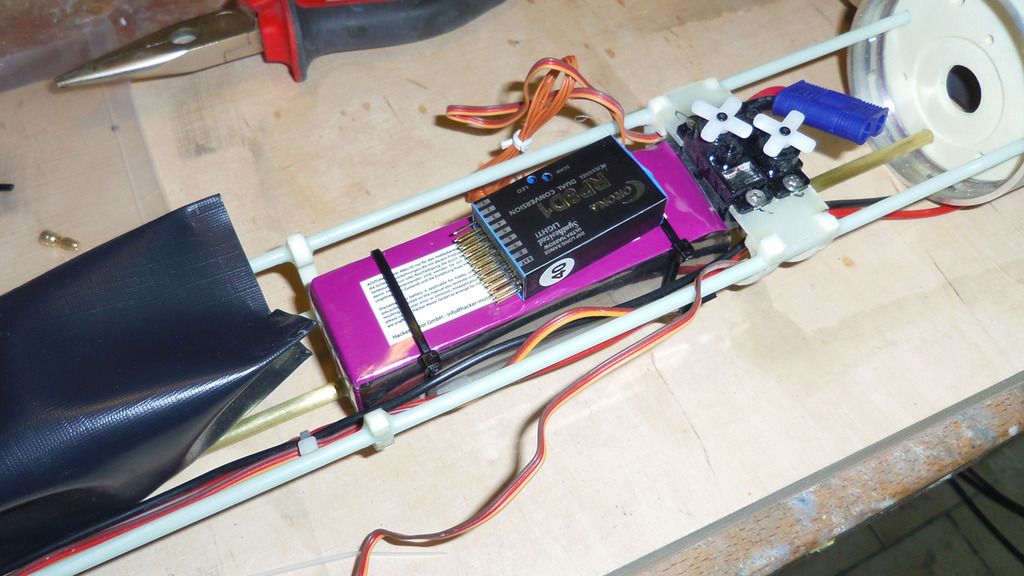

This way the battery can easily be fixed with cable ties:

The gap between battery the GRP deck has the advantage, that in case anything gets wet, the battery can easily dry. And the gap is well suited to route cable ties to fix additional gear:

e.g. the receiver. It will simply sit on top of the battery:

The hoses are hooked up. The overpressure switch is new, not the one I got with the controller, as latter was too big. The new one fits tightly into place below the dive controller. The hose to the pressure switch starts in a T nipple and is routed over the pump motor to ensure that no water reaches the switch. And it looks cool....

The battery rest on two 2 mm thick GRP planks:

This way the battery can easily be fixed with cable ties:

The gap between battery the GRP deck has the advantage, that in case anything gets wet, the battery can easily dry. And the gap is well suited to route cable ties to fix additional gear:

e.g. the receiver. It will simply sit on top of the battery:

Comment