Originally posted by Charlotte514

View Post

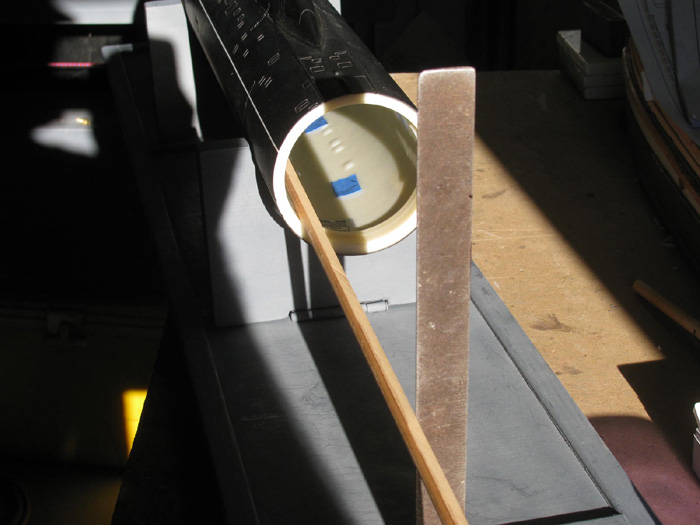

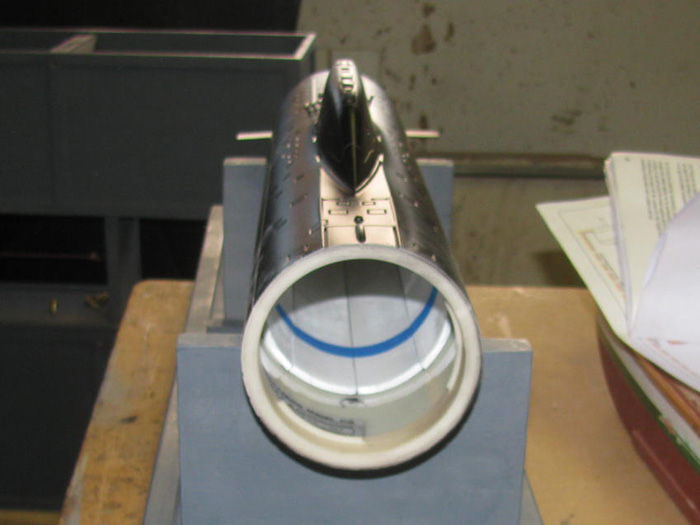

The longer answer is: I have found for both the Engel Type 212a and Akula II that it's best to bend the brass pushrod a little bit at a time until you get a reasonably free servo-to-stern plane/rudder movement. If I recall, on the Akula you'll end up with about 10-15 degree bend? (I'd want to verify that at our next SubRun this Sunday)

-Jeff

Comment