Hallo,

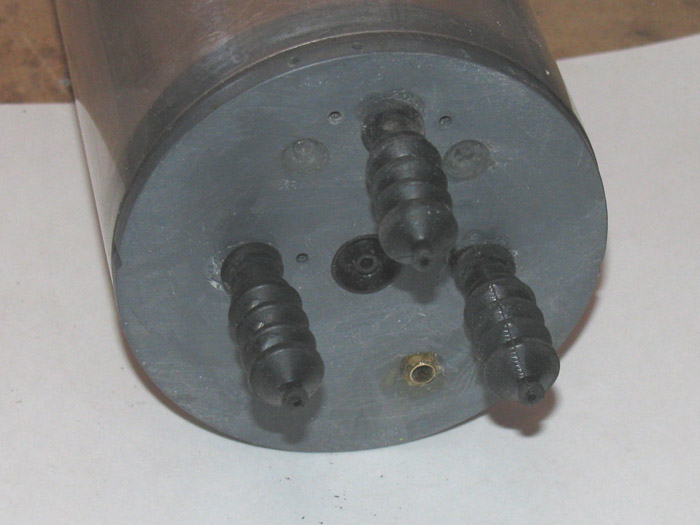

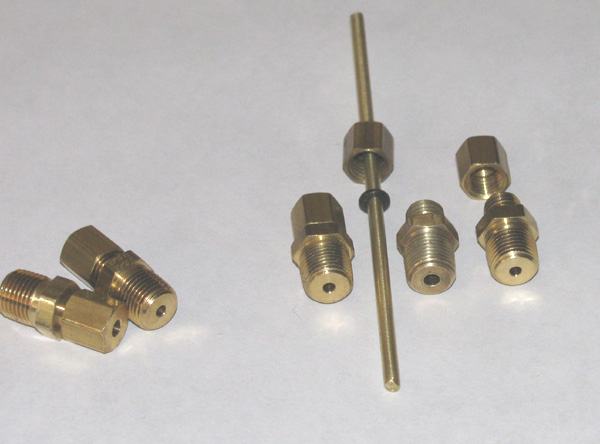

I’m using the RCABS not the RCABS-R System. About the seals I don’t know I hope I made it right otherwise there is a lot of work to do.

I made it like so:

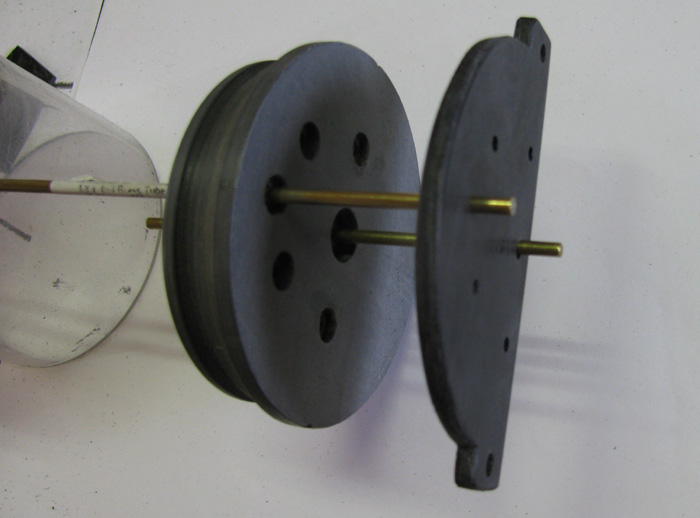

I thought I make two of them in opposite directions one against water and one against vacuum pressure.

Here is visibly the front and backside and the lip.

What would Ralph say about that?

ps. Is it possible to order something from frontiernet again?

THANKS for helping

I’m using the RCABS not the RCABS-R System. About the seals I don’t know I hope I made it right otherwise there is a lot of work to do.

I made it like so:

I thought I make two of them in opposite directions one against water and one against vacuum pressure.

Here is visibly the front and backside and the lip.

What would Ralph say about that?

ps. Is it possible to order something from frontiernet again?

THANKS for helping

Comment