Hello,

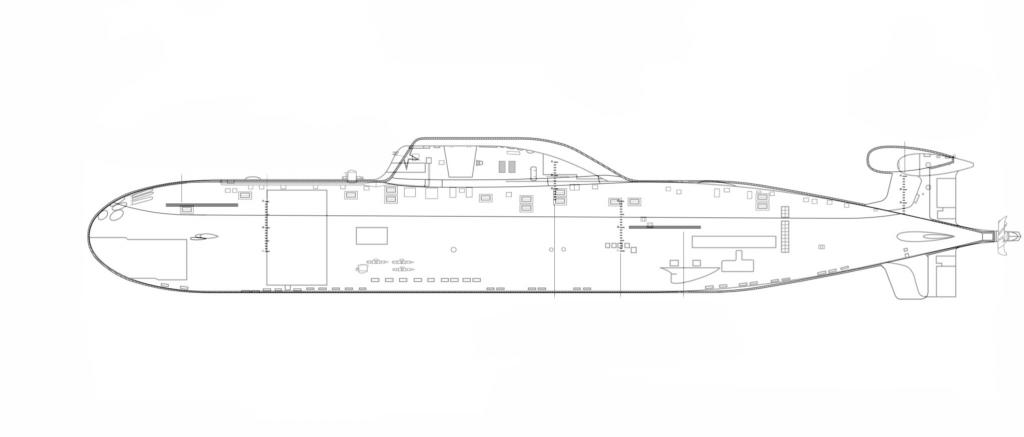

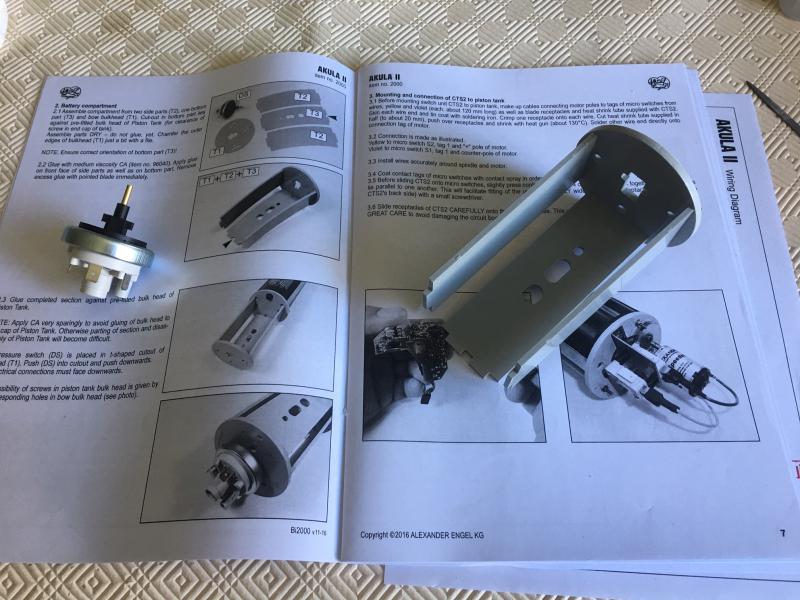

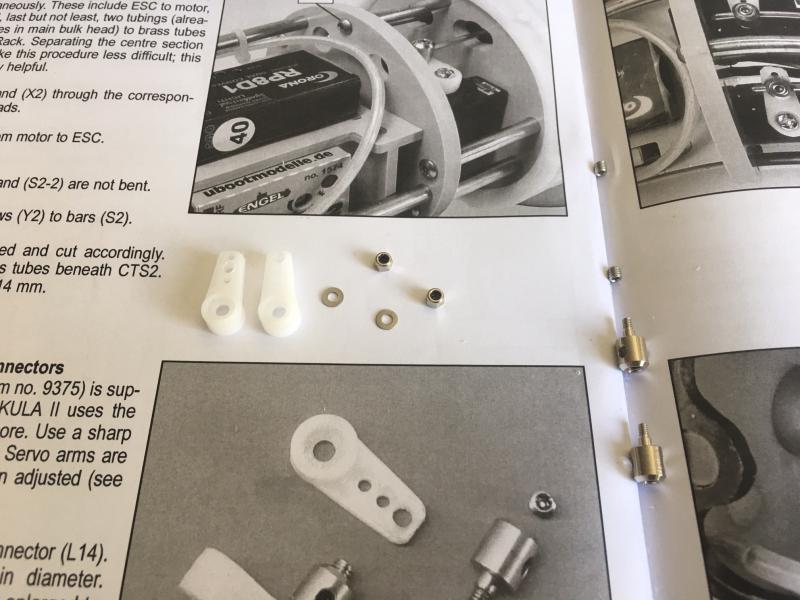

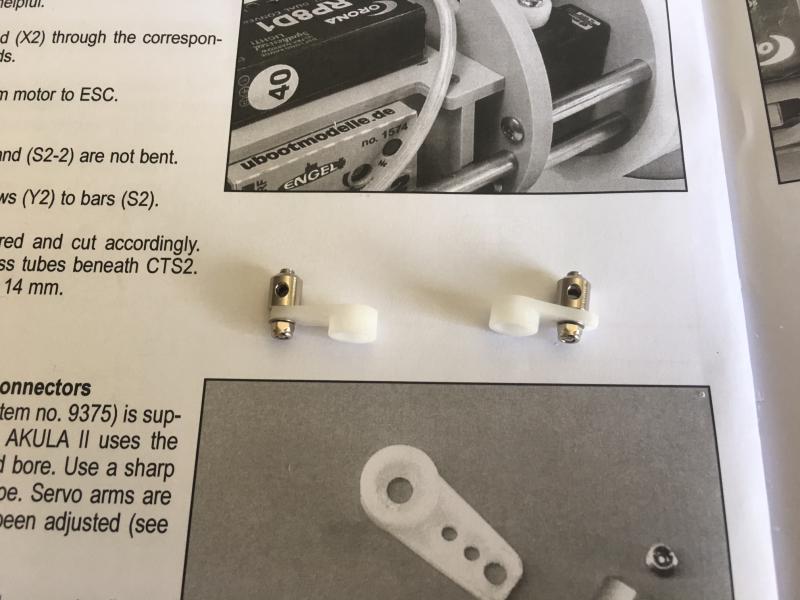

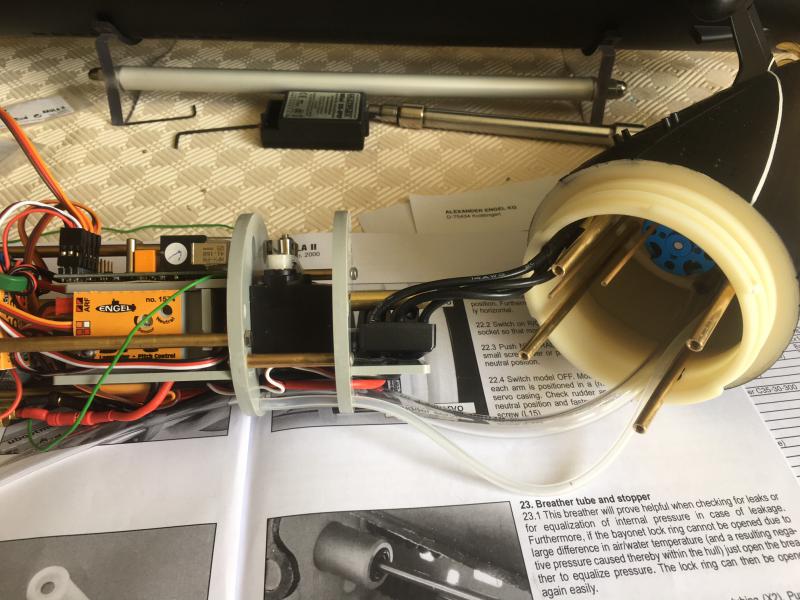

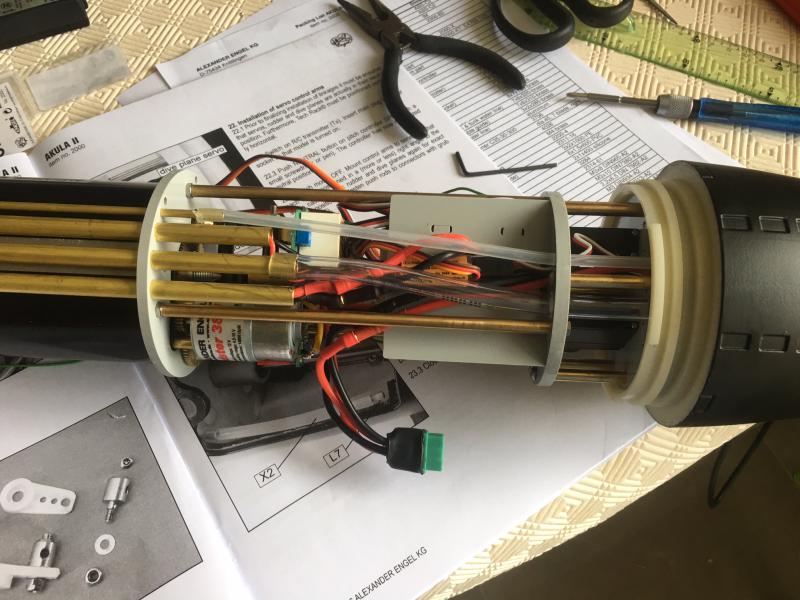

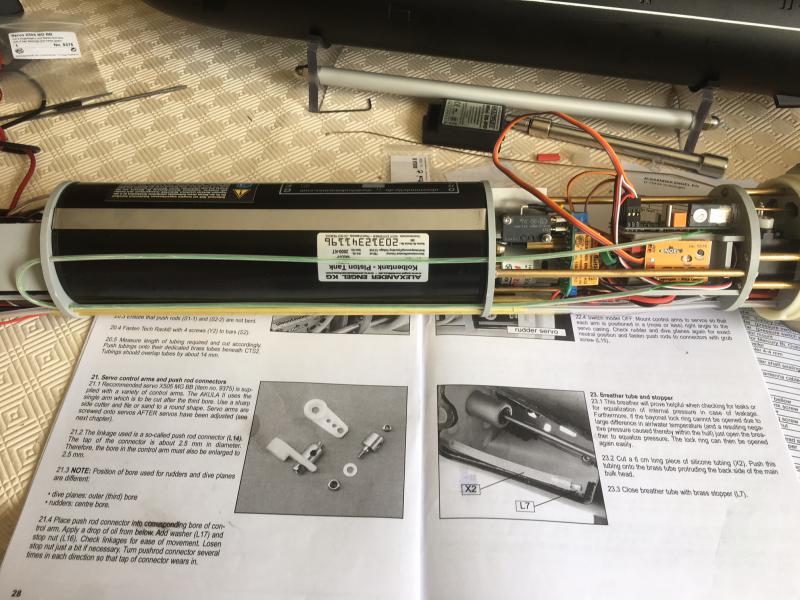

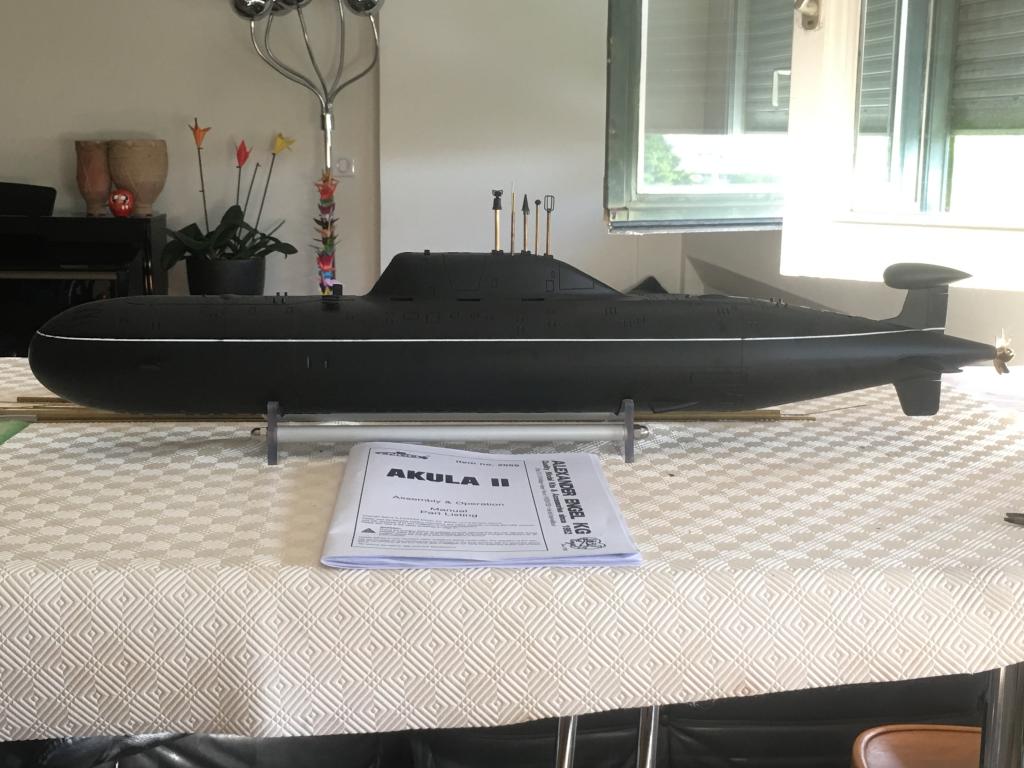

Here is a building report of the newest Engel RC sub kit, the little Akula II in 125th scale.

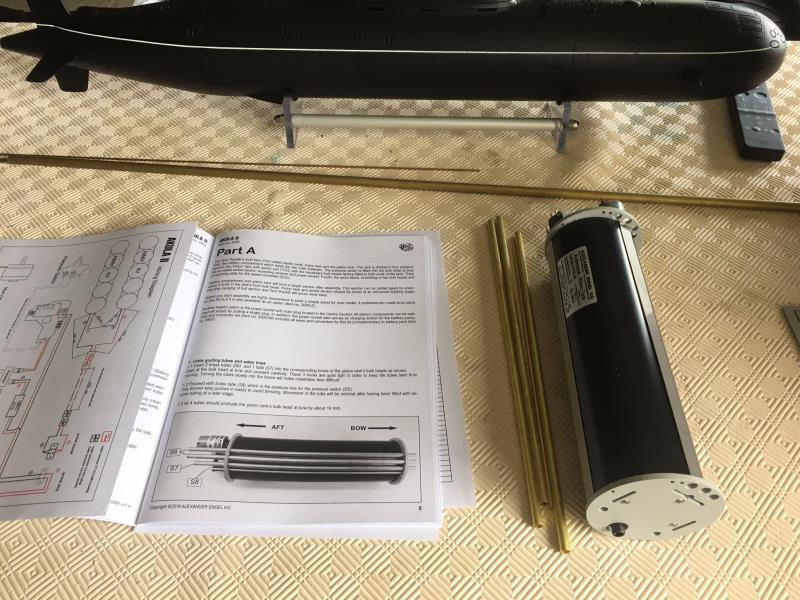

Like the 212A, the hull is made in injected/molded ABS thick plastic. It comes preprinted with control surfaces preinstalled, a real piece of cake !

Sold in two different version, basic and SET, I ordered the second one that includes almost everything to finish it less the Tx and Rx. Ordered last Wednesday, it arrived this Monday.

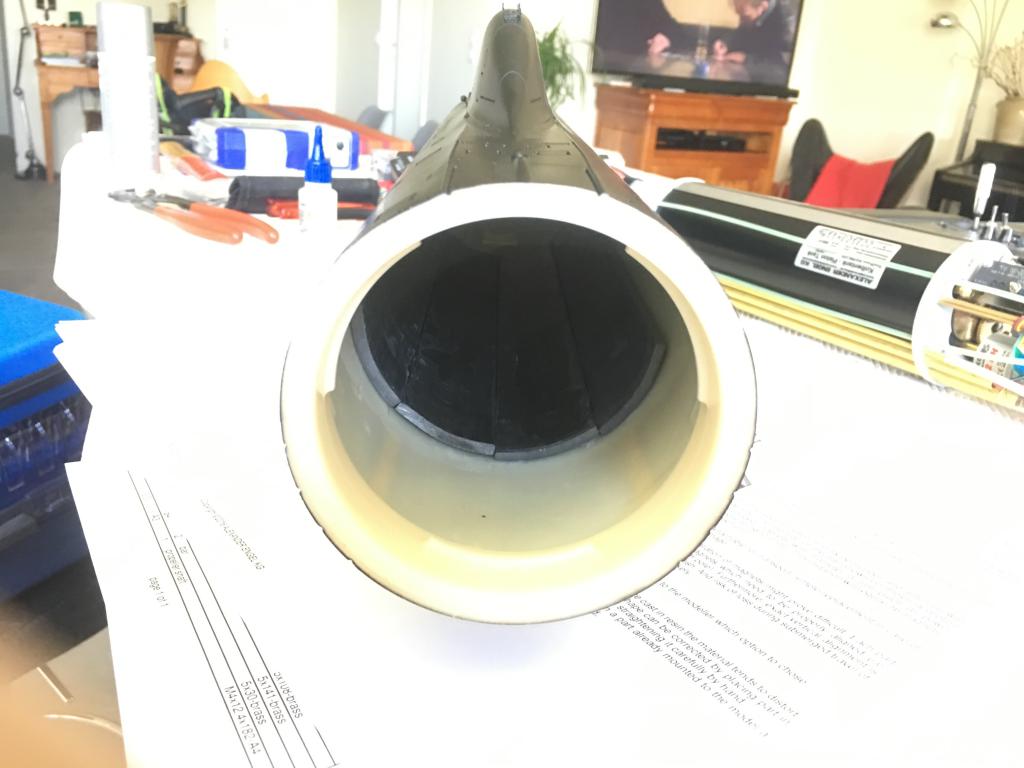

Here is the hull out of the shipping box (that I'll use as a transport crate like I did with my 212A) :

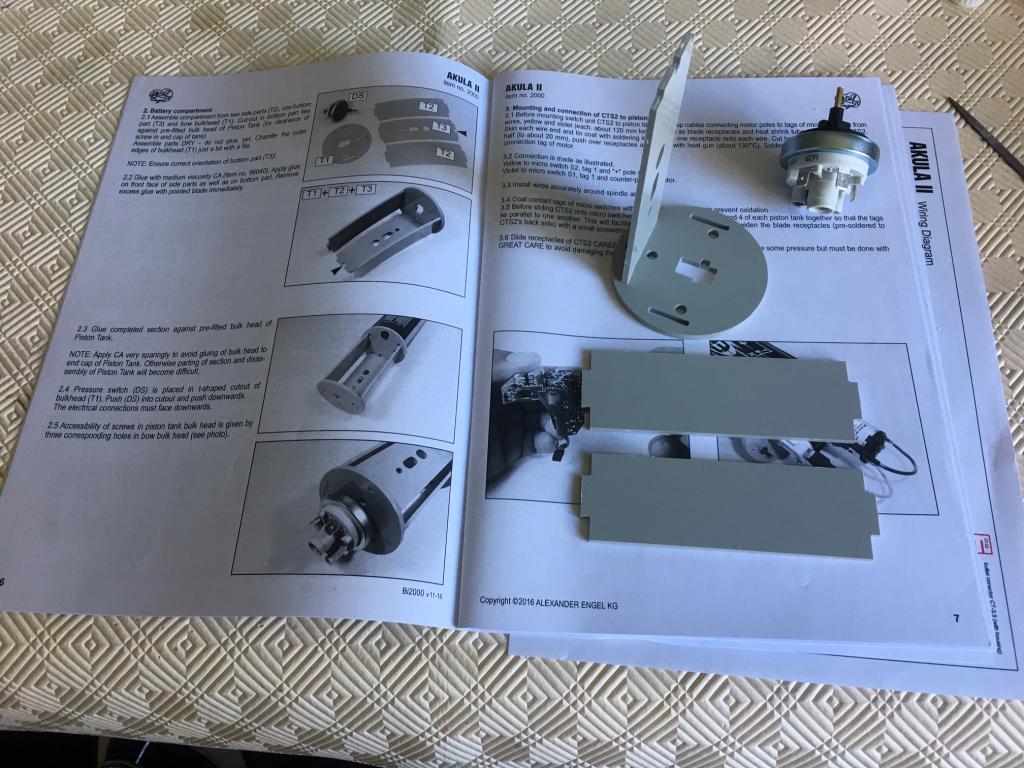

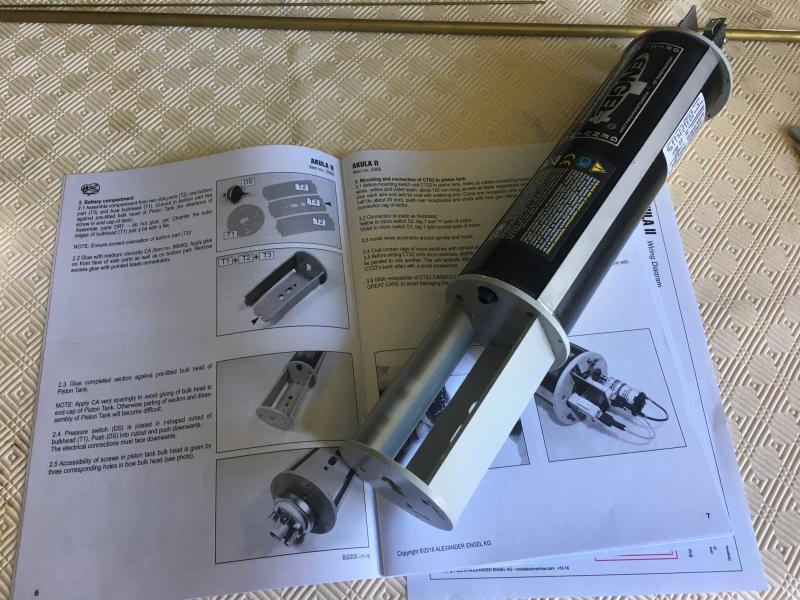

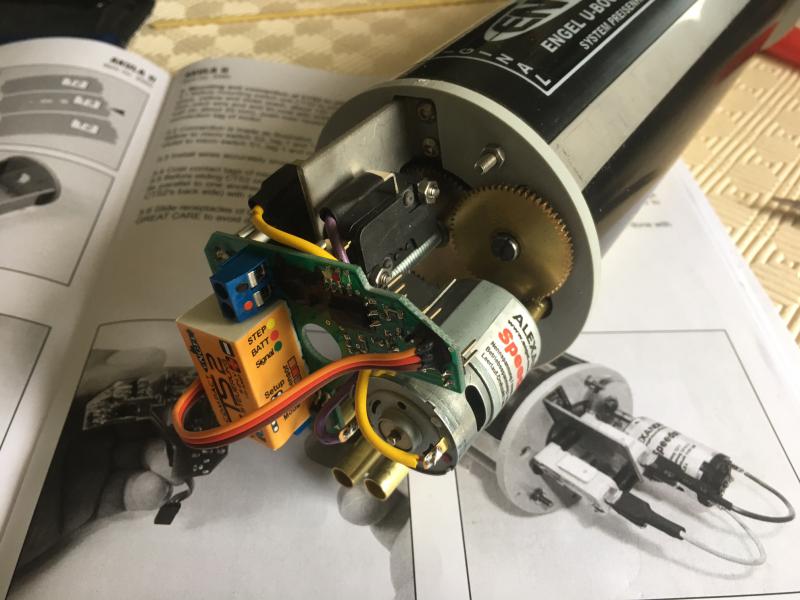

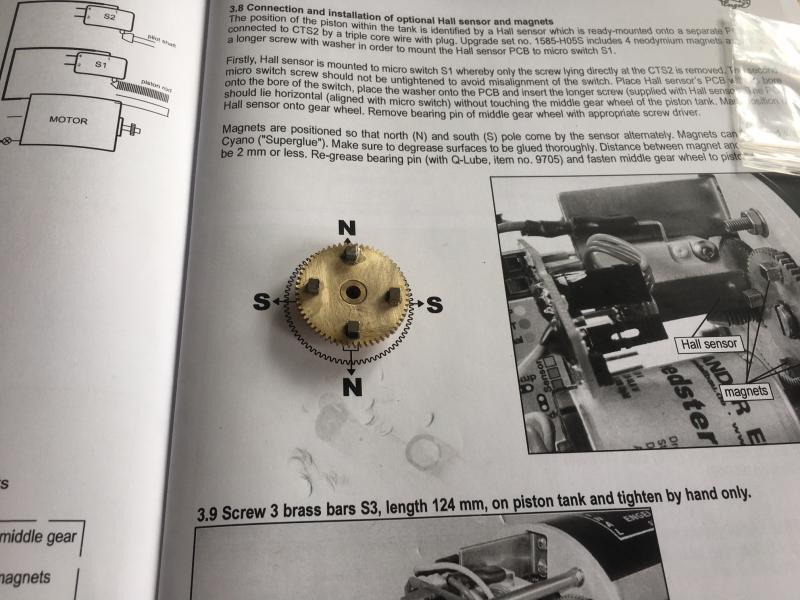

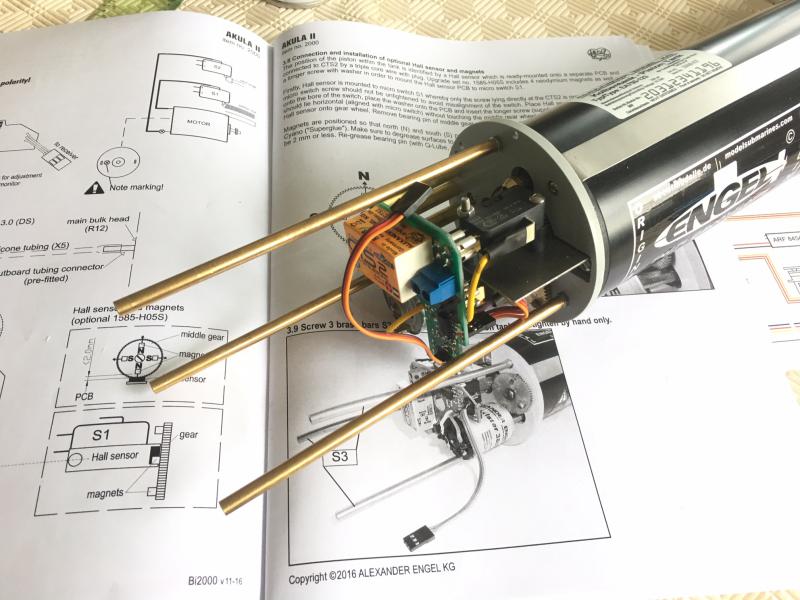

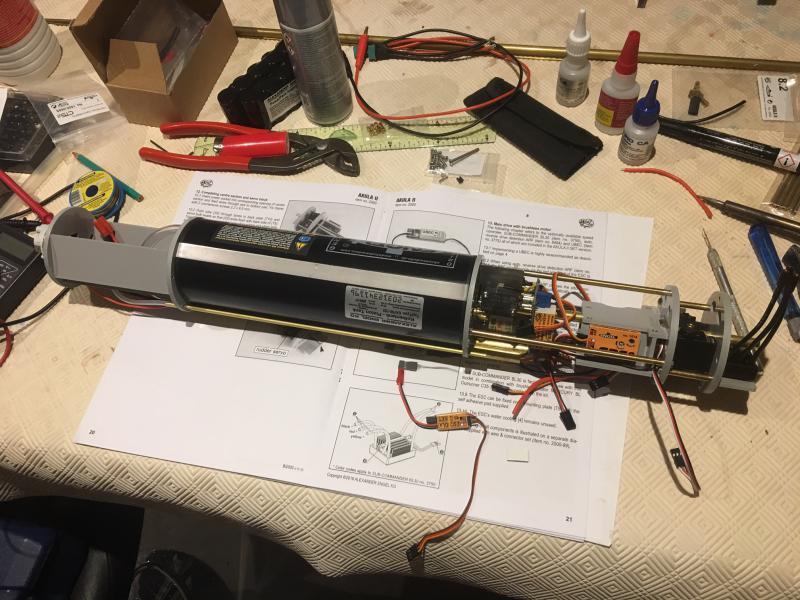

Inside the parcel, there are two boxes with the rest of the kit. I strongly recommend to buy the stand and the Hall sensor option (to convert the piston control into a proportional command). Everything was inside these boxes, even the options...

What's inside ? From left to right :

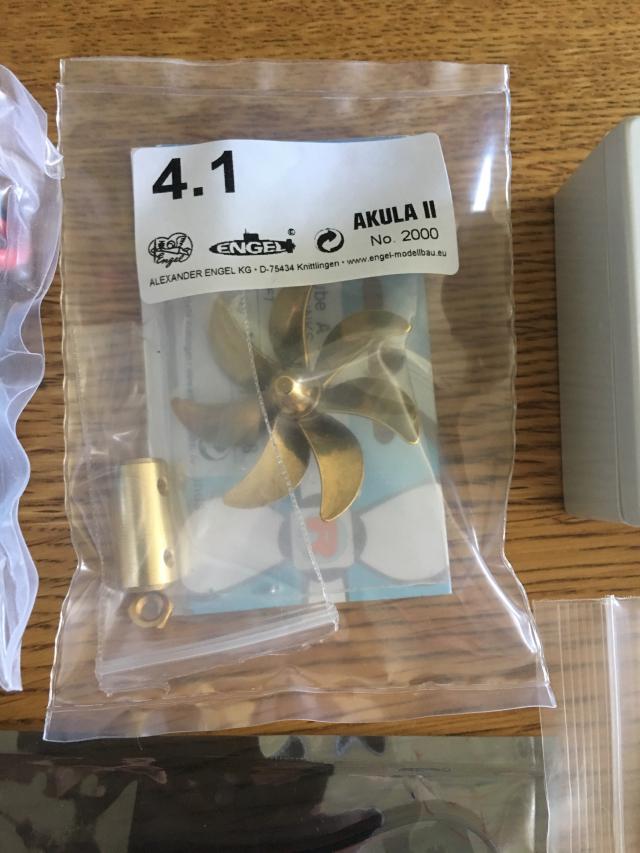

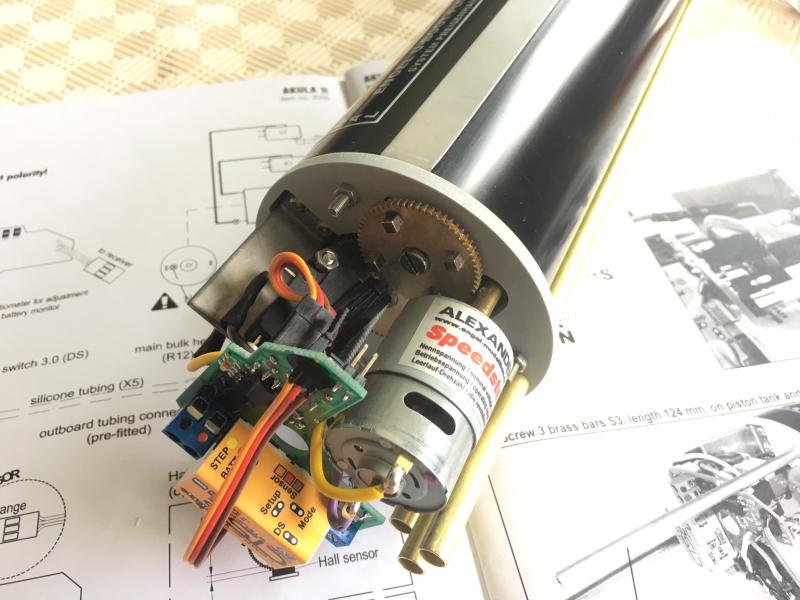

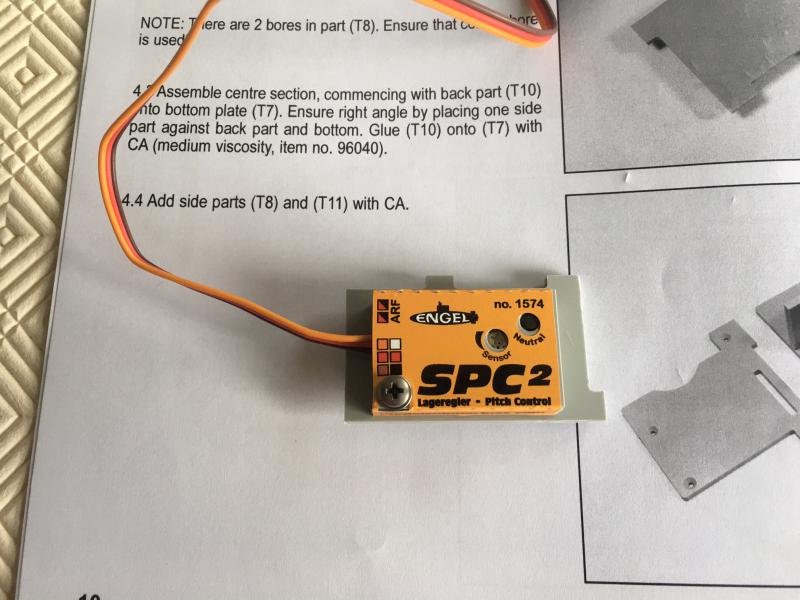

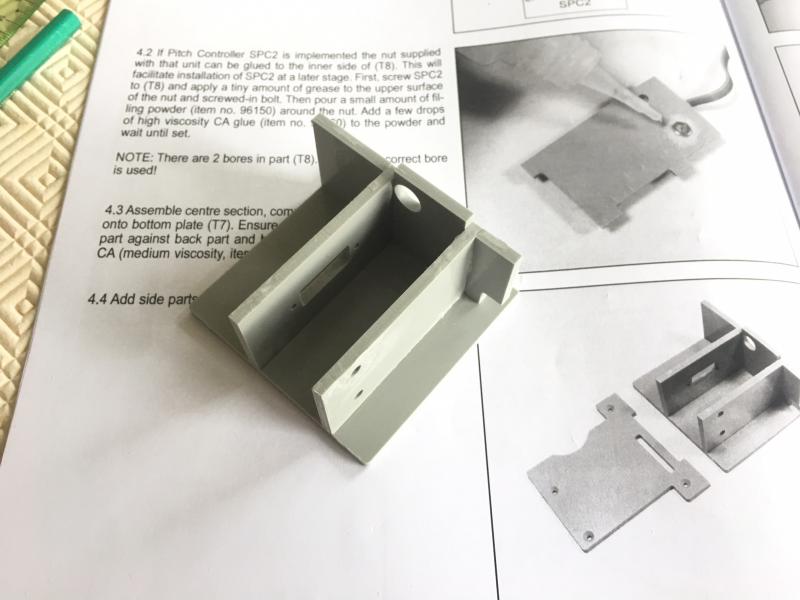

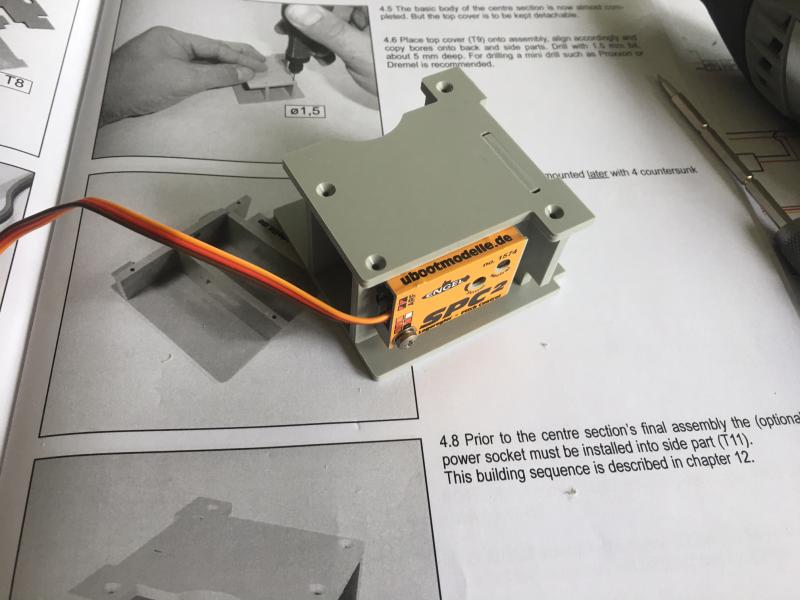

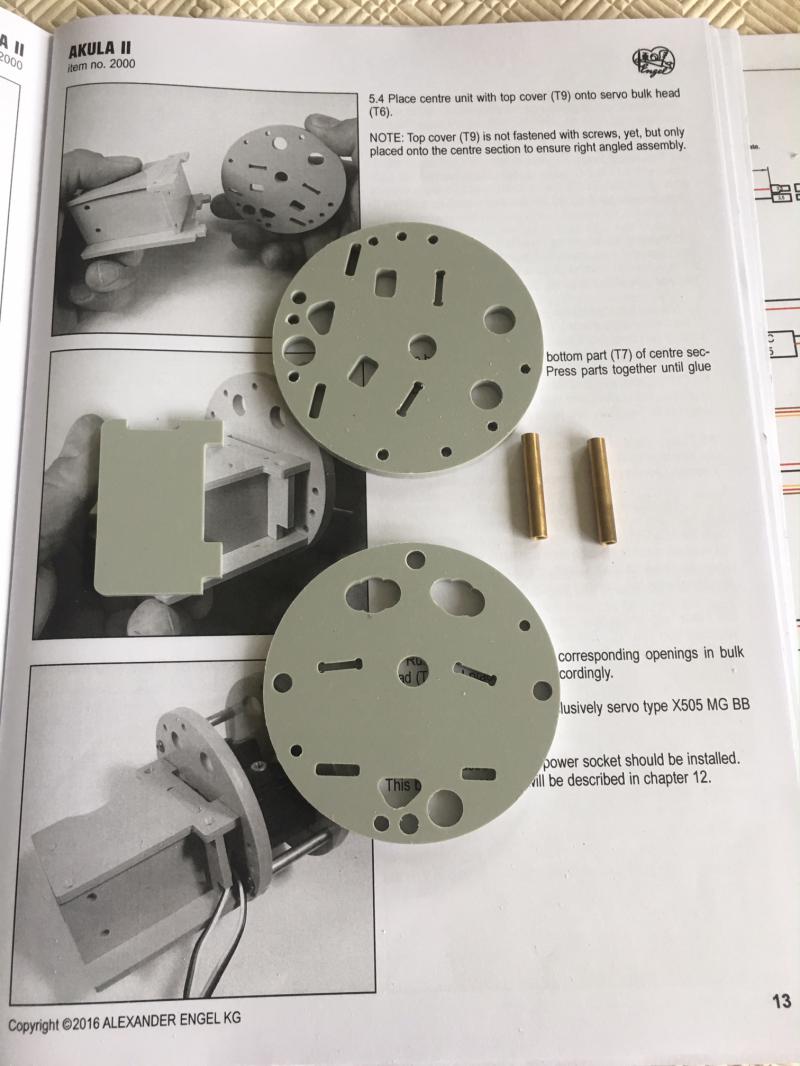

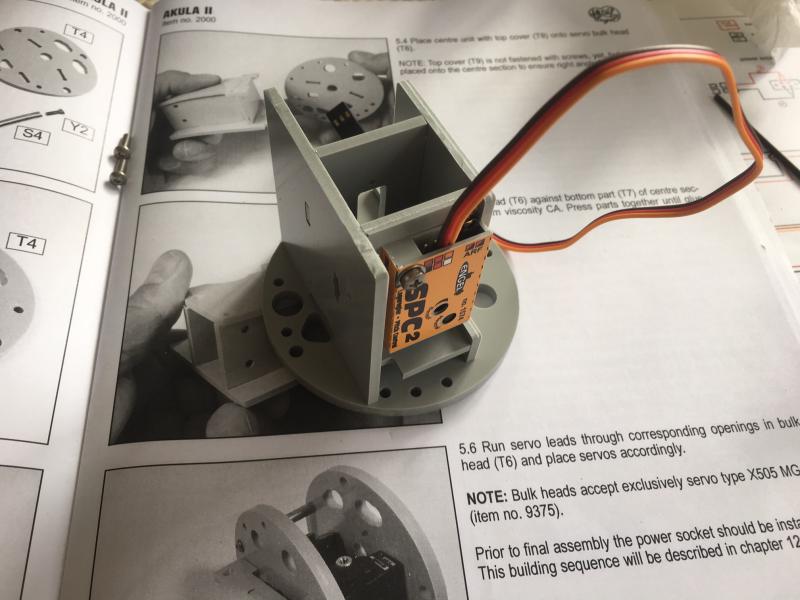

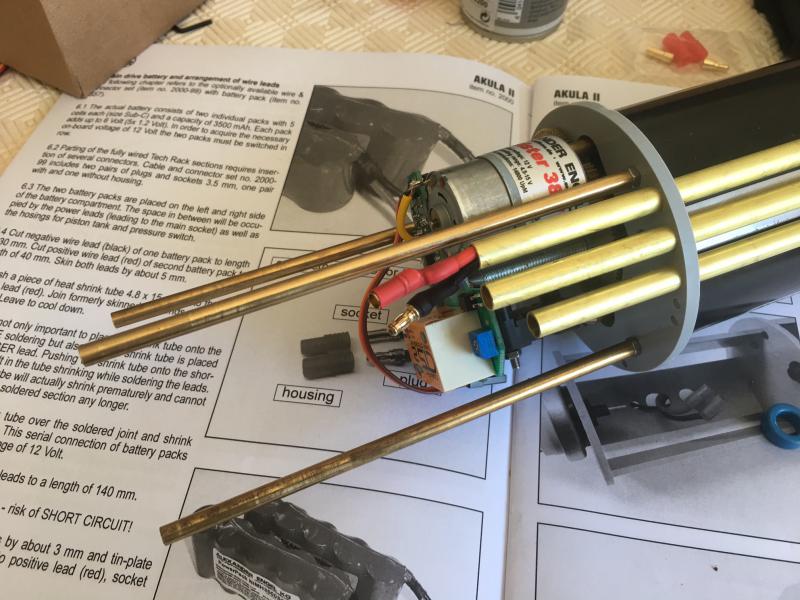

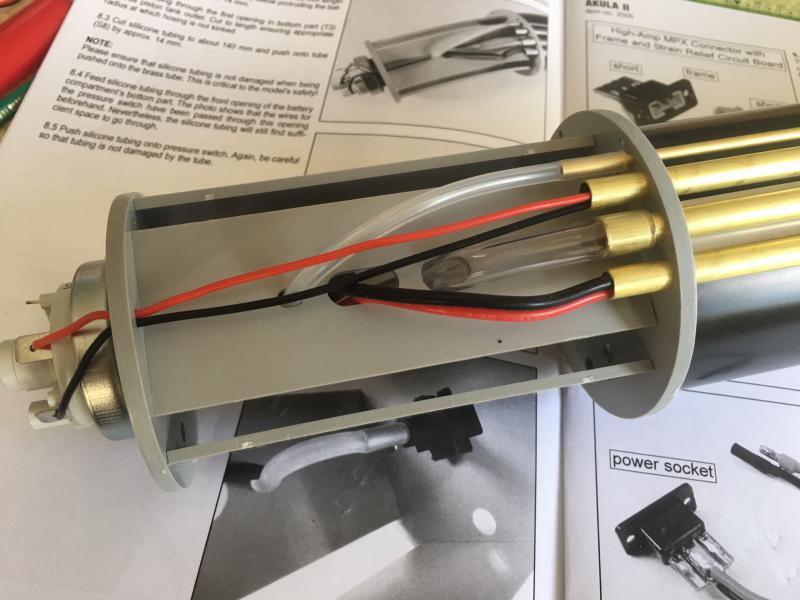

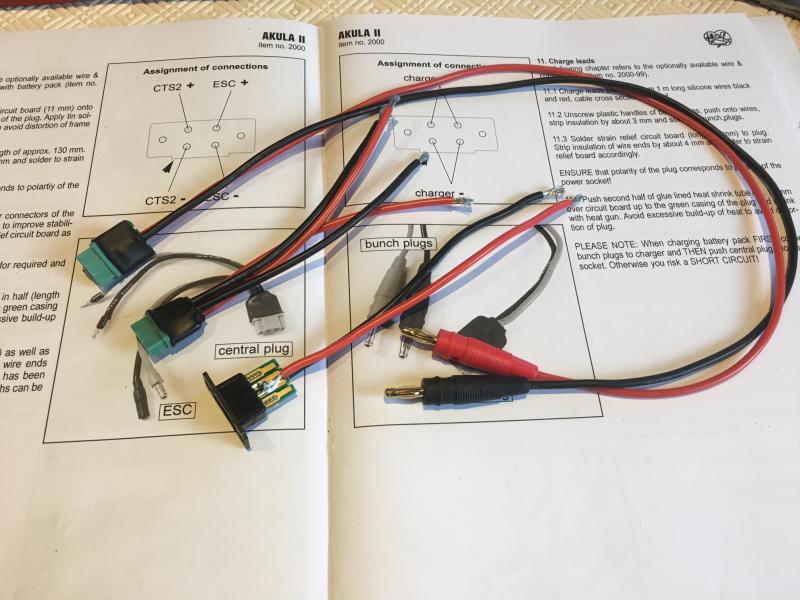

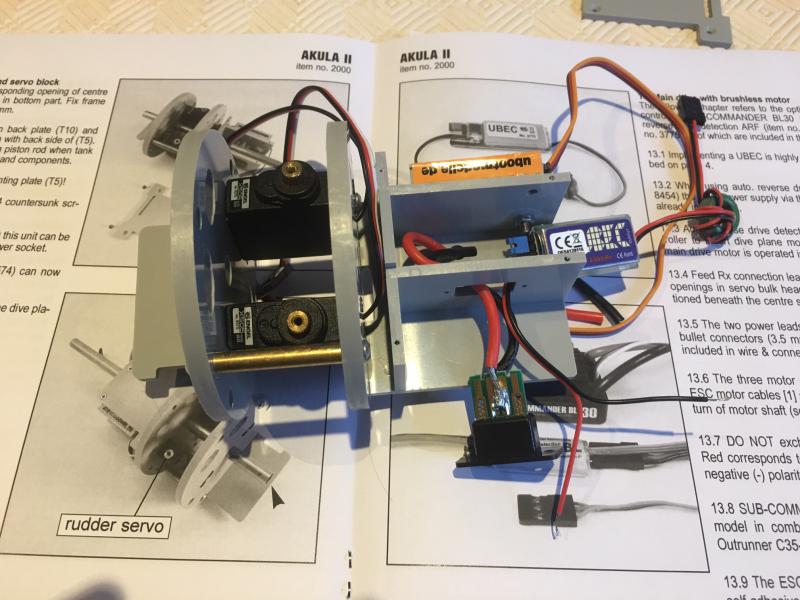

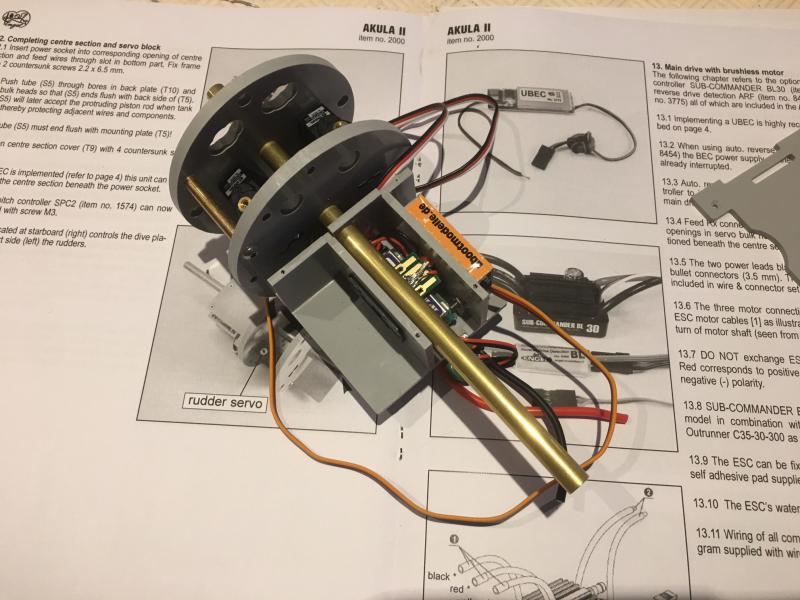

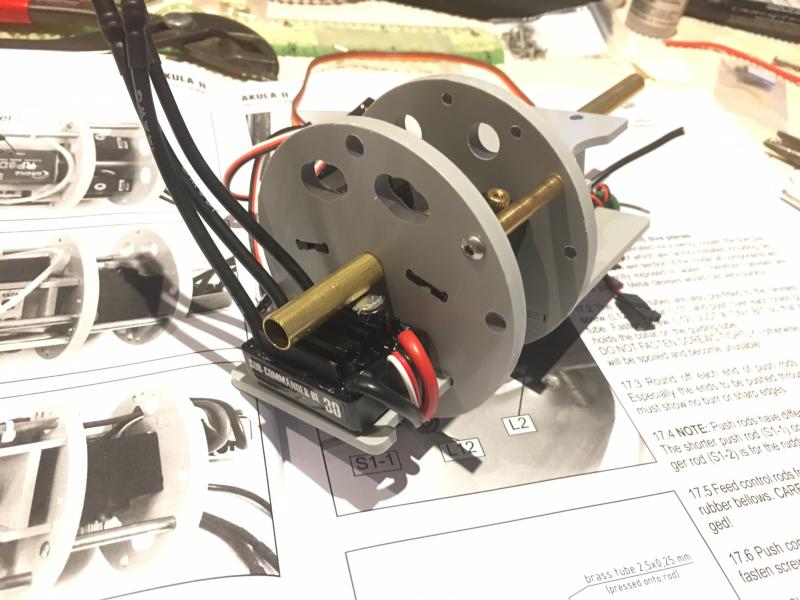

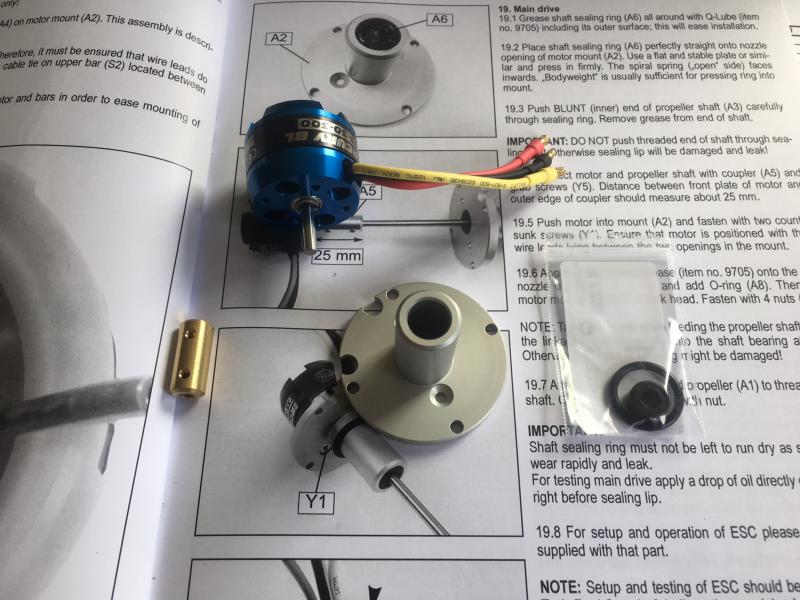

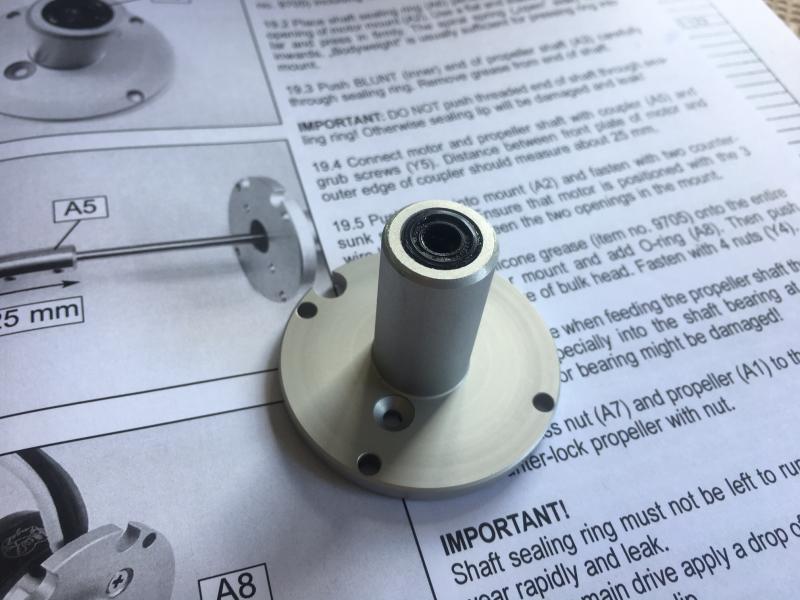

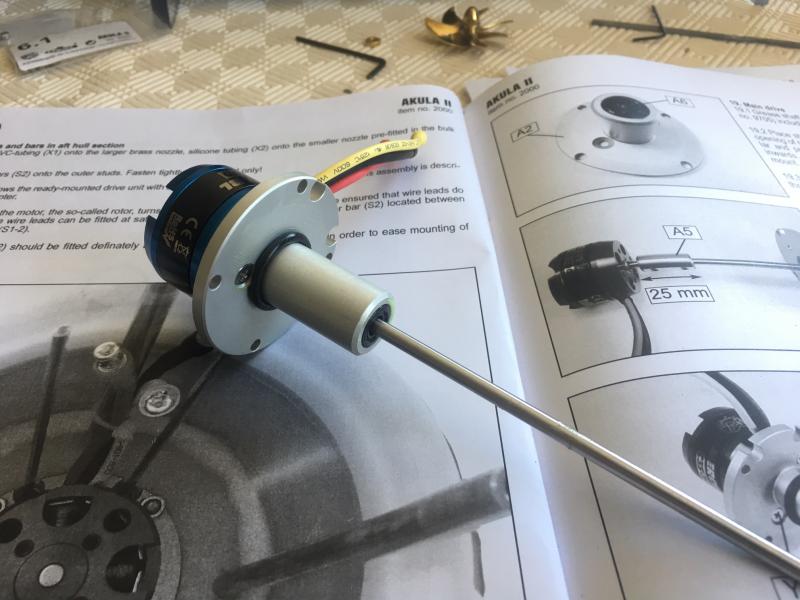

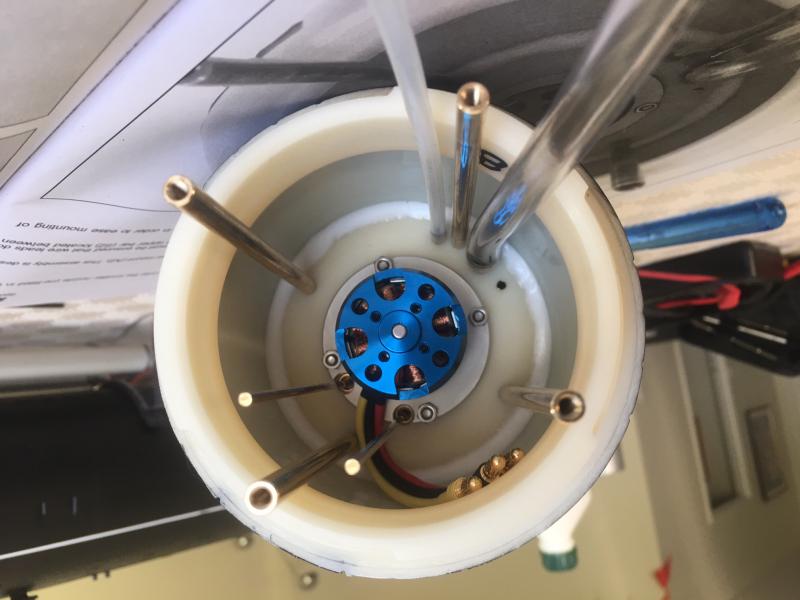

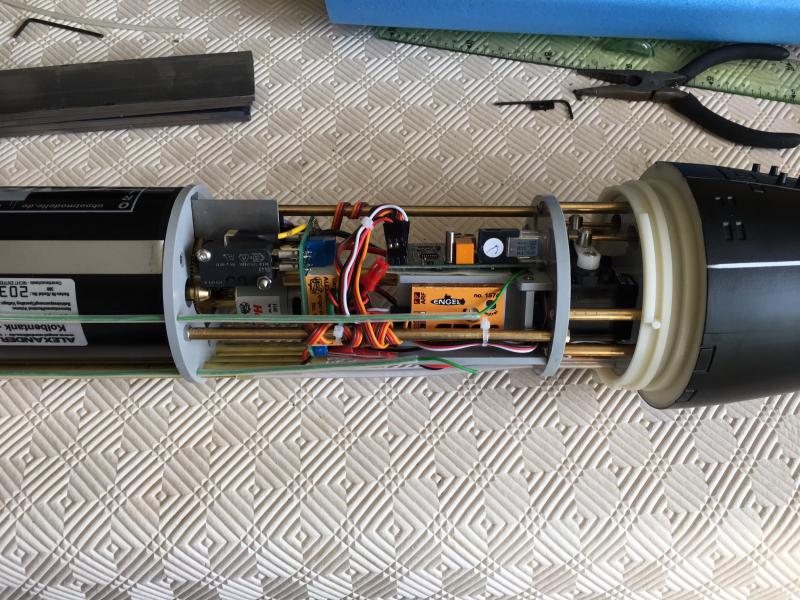

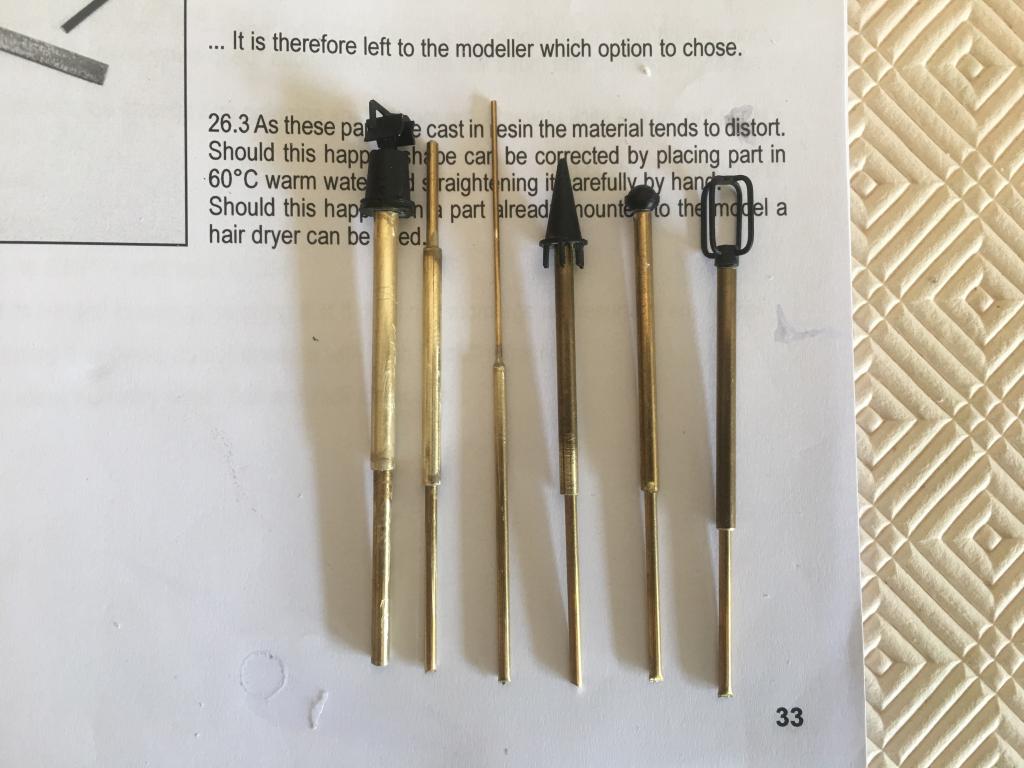

Wires/connectors set, Tech Rack parts, motor mount + BL motor, pressure sensor and the CS2 electronic board, NiMH batteries, ESC, tubings and bellow, 7 blades prop, UBEC, auto Reverse Drive Detection device, Hall sensor + magnets, SPC2 pitch controller, 2 mini servos, Oring + masts and periscopes, Tech Rack PVC parts, 750ml Engel piston, foam and lead ballast.

Here is a building report of the newest Engel RC sub kit, the little Akula II in 125th scale.

Like the 212A, the hull is made in injected/molded ABS thick plastic. It comes preprinted with control surfaces preinstalled, a real piece of cake !

Sold in two different version, basic and SET, I ordered the second one that includes almost everything to finish it less the Tx and Rx. Ordered last Wednesday, it arrived this Monday.

Here is the hull out of the shipping box (that I'll use as a transport crate like I did with my 212A) :

Inside the parcel, there are two boxes with the rest of the kit. I strongly recommend to buy the stand and the Hall sensor option (to convert the piston control into a proportional command). Everything was inside these boxes, even the options...

What's inside ? From left to right :

Wires/connectors set, Tech Rack parts, motor mount + BL motor, pressure sensor and the CS2 electronic board, NiMH batteries, ESC, tubings and bellow, 7 blades prop, UBEC, auto Reverse Drive Detection device, Hall sensor + magnets, SPC2 pitch controller, 2 mini servos, Oring + masts and periscopes, Tech Rack PVC parts, 750ml Engel piston, foam and lead ballast.

Comment