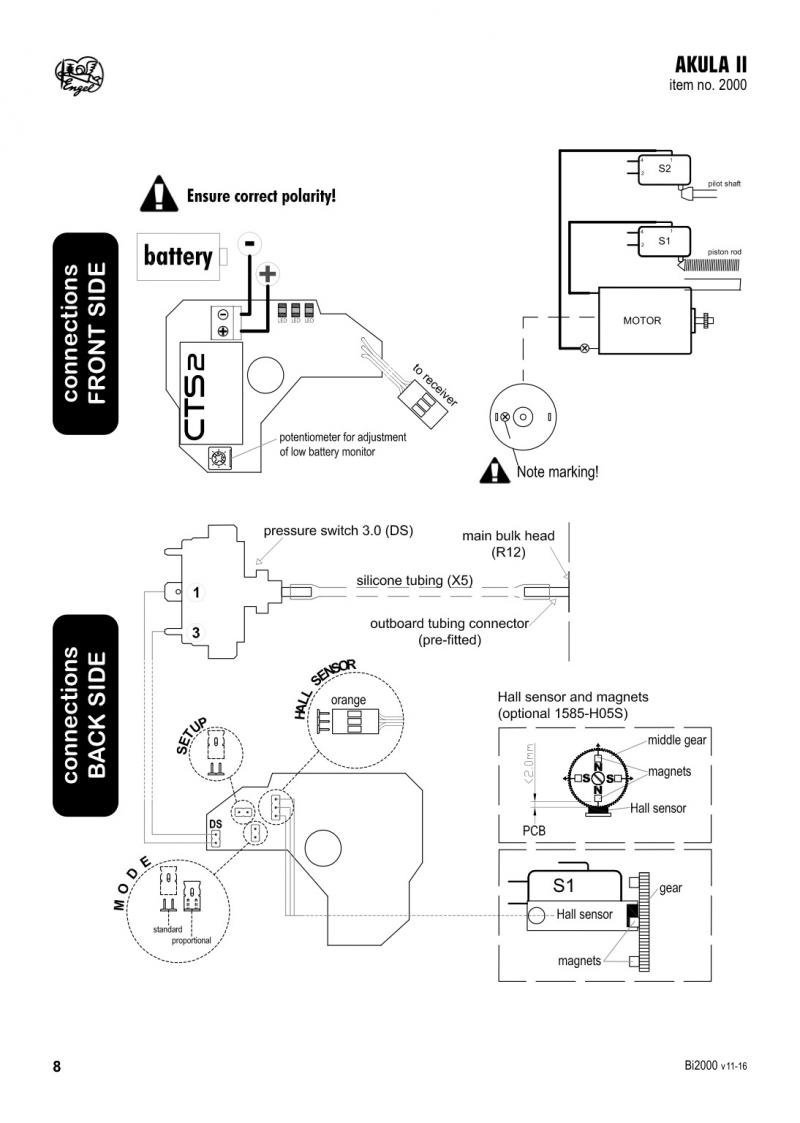

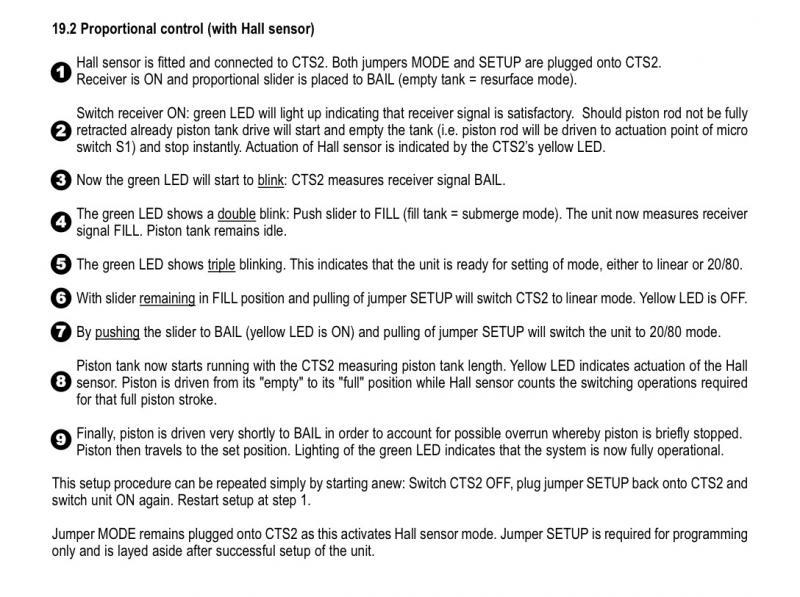

So I have started an Engel/Akula II kit and hit my first “interesting” problem. I opted for the Hall Sensor upgrade so the ballast tank fill can be proportional. The kit involves installing 4 small 4mm cube Neodymium magnets by “super gluing” the magnets at four places symmetrically around the perimeter of the ballast tank’s drive gear.

The magnets are arranged 2 mm from the edge of the gear 90 degrees apart in an alternating N-S-N-S orientation around the perimeter.

Simple, right? Wrong!

Placing a drop of CA at the first magnet location and carefully placing the small cube magnet in the CA, I watched as the magnet slooowly rotated its position in the drying glue to magnetic North…hmmm, that’s not going to work (time to bust out the bottle of CA Undo!).

After removing the magnet, I oriented the gear and magnet to magnetic North and re-glued the magnet 2 mm from the edge of the gear without it rotating again…success!

Next I rotated the gear 180 degrees and repeated the process for the opposing magnet, which was also oriented with the North side of the magnet toward the gear teeth. Placed the cube magnet in the CA, let go and POOF it was gone, right before my eyes! Where did it go? It shot directly across the gear, attracted to the first magnet and its momentum carried it across the gear and directly under the first magnet…hmmm, that’s not going to work either!

Next tried holding it with wooden clothes pins, hobby clamps & etc. but it is just too small and too strong.

Finally made a fixture from a piece of the scrap PVC of the bulkheads that came with the kit; however, if you do this, the u-shaped opening must be a snug fit or the opposing magnet will cause the magnet to rotate within the fixture due to the N-S attraction of the opposing magnet already on the gear!

The magnets are arranged 2 mm from the edge of the gear 90 degrees apart in an alternating N-S-N-S orientation around the perimeter.

Simple, right? Wrong!

Placing a drop of CA at the first magnet location and carefully placing the small cube magnet in the CA, I watched as the magnet slooowly rotated its position in the drying glue to magnetic North…hmmm, that’s not going to work (time to bust out the bottle of CA Undo!).

After removing the magnet, I oriented the gear and magnet to magnetic North and re-glued the magnet 2 mm from the edge of the gear without it rotating again…success!

Next I rotated the gear 180 degrees and repeated the process for the opposing magnet, which was also oriented with the North side of the magnet toward the gear teeth. Placed the cube magnet in the CA, let go and POOF it was gone, right before my eyes! Where did it go? It shot directly across the gear, attracted to the first magnet and its momentum carried it across the gear and directly under the first magnet…hmmm, that’s not going to work either!

Next tried holding it with wooden clothes pins, hobby clamps & etc. but it is just too small and too strong.

Finally made a fixture from a piece of the scrap PVC of the bulkheads that came with the kit; however, if you do this, the u-shaped opening must be a snug fit or the opposing magnet will cause the magnet to rotate within the fixture due to the N-S attraction of the opposing magnet already on the gear!

Comment