Originally posted by scott t

View Post

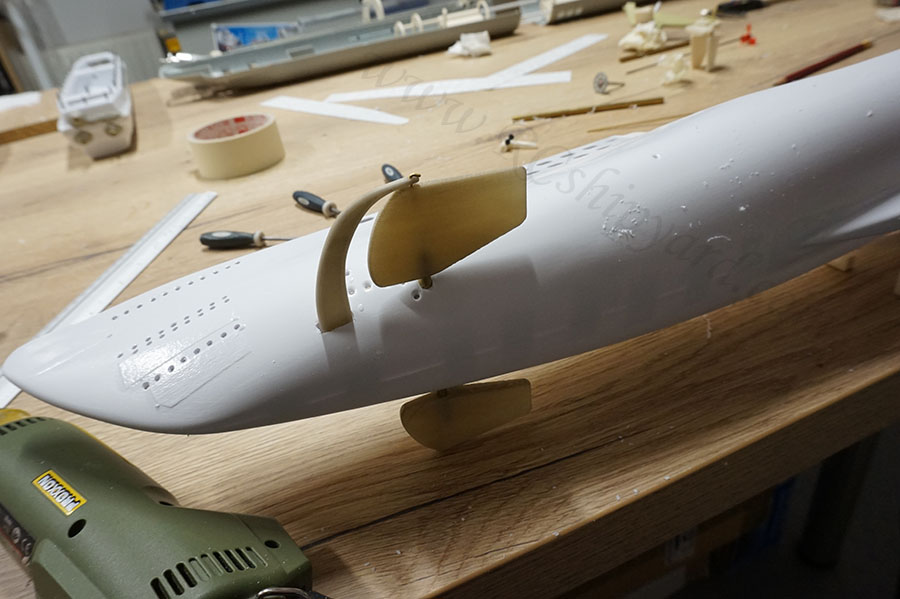

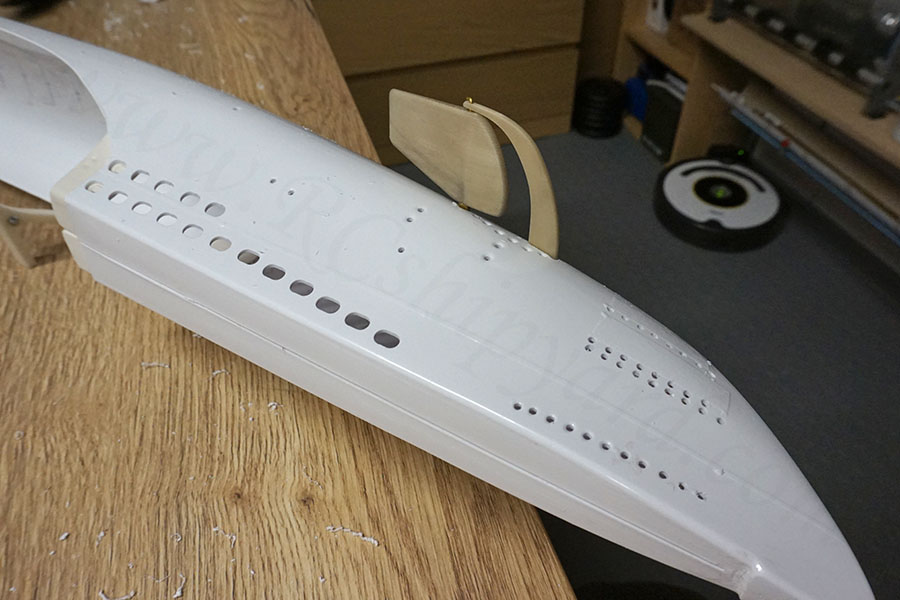

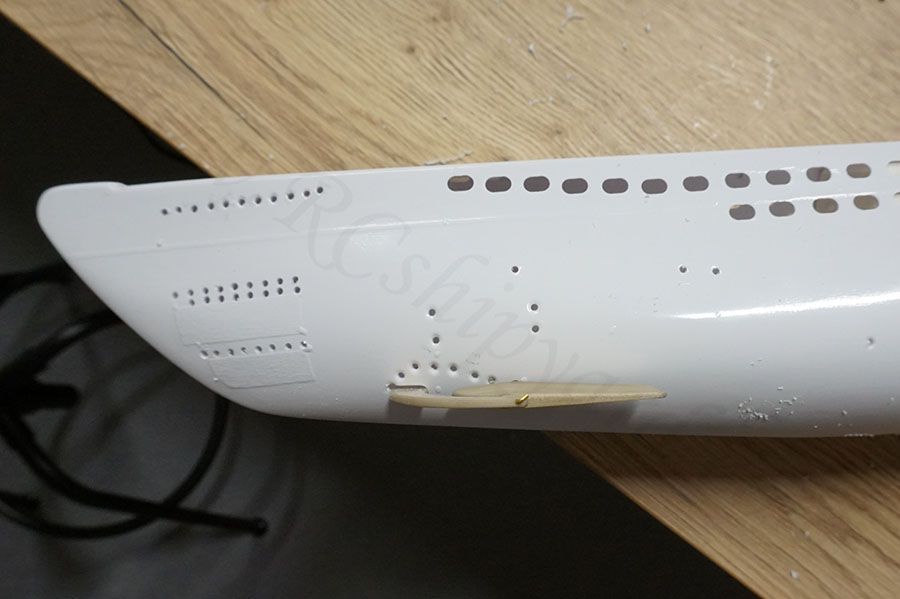

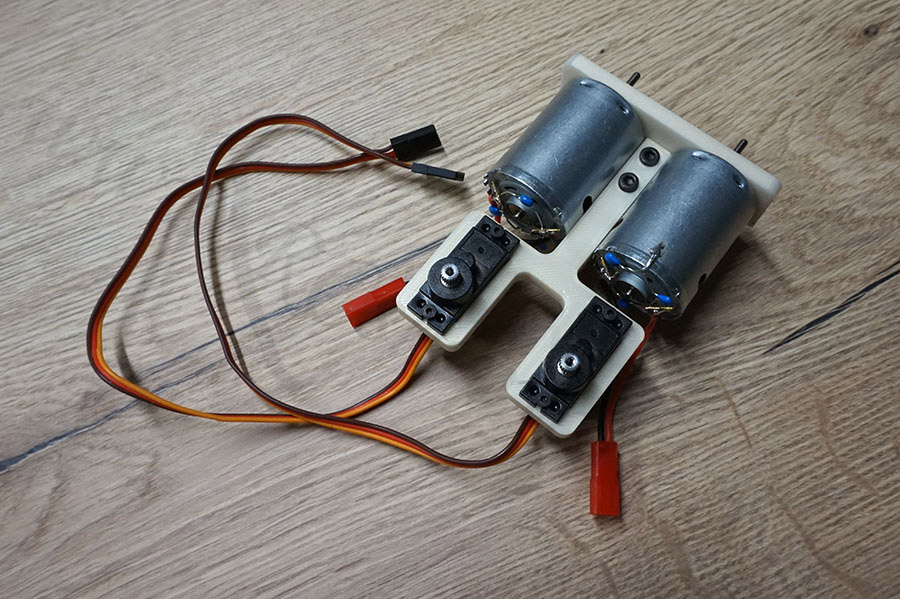

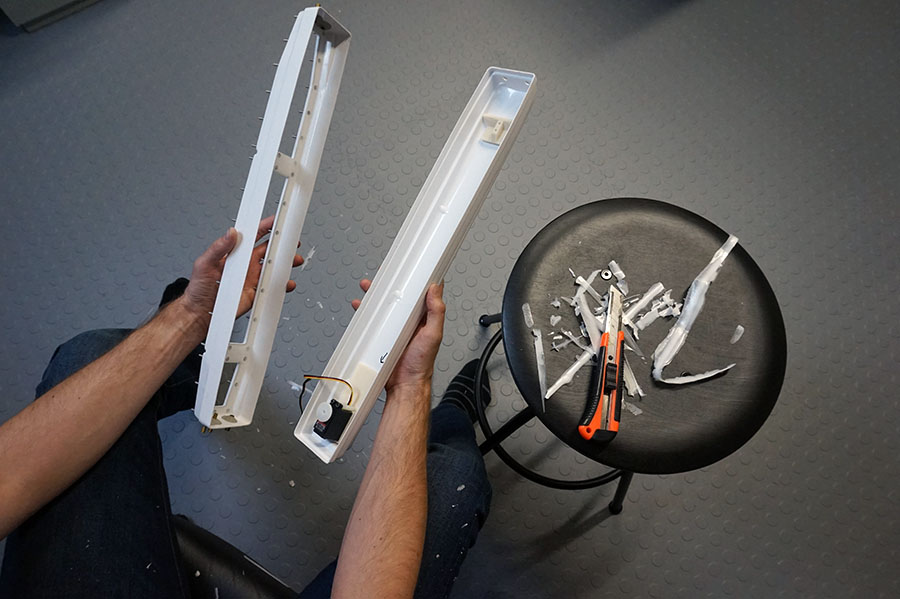

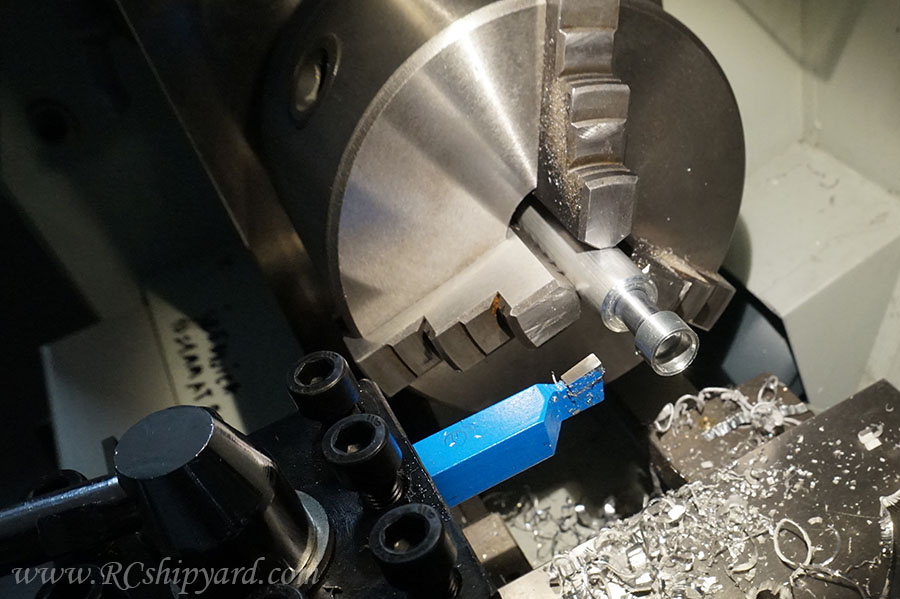

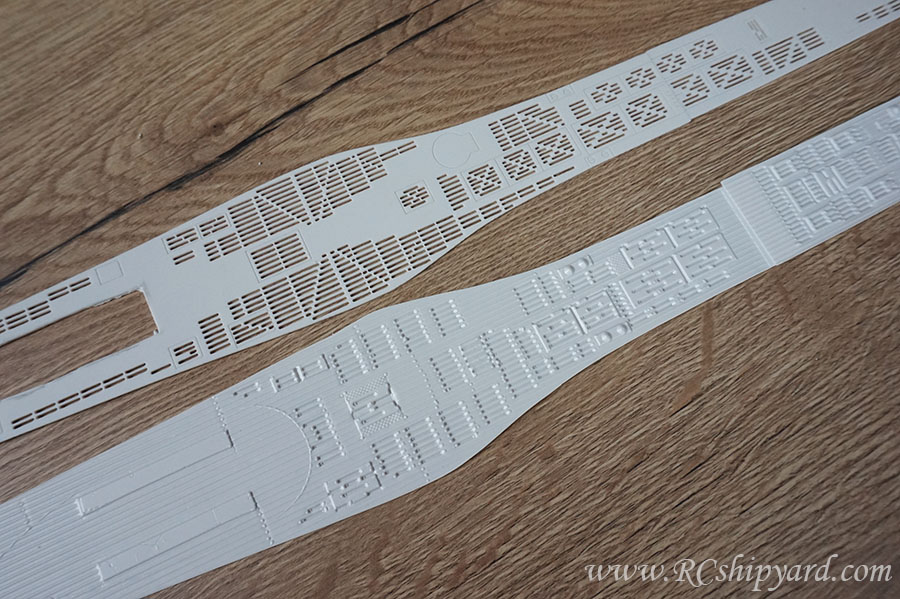

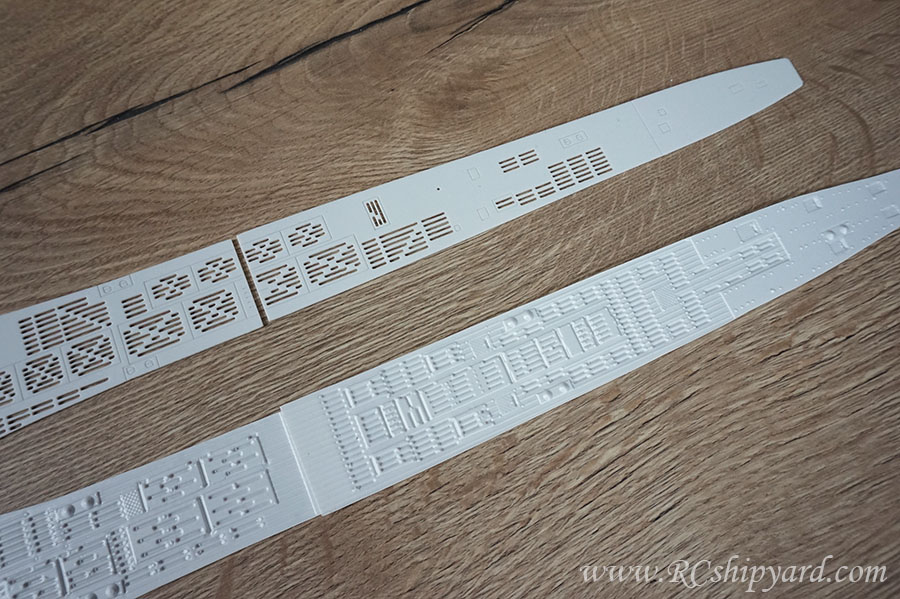

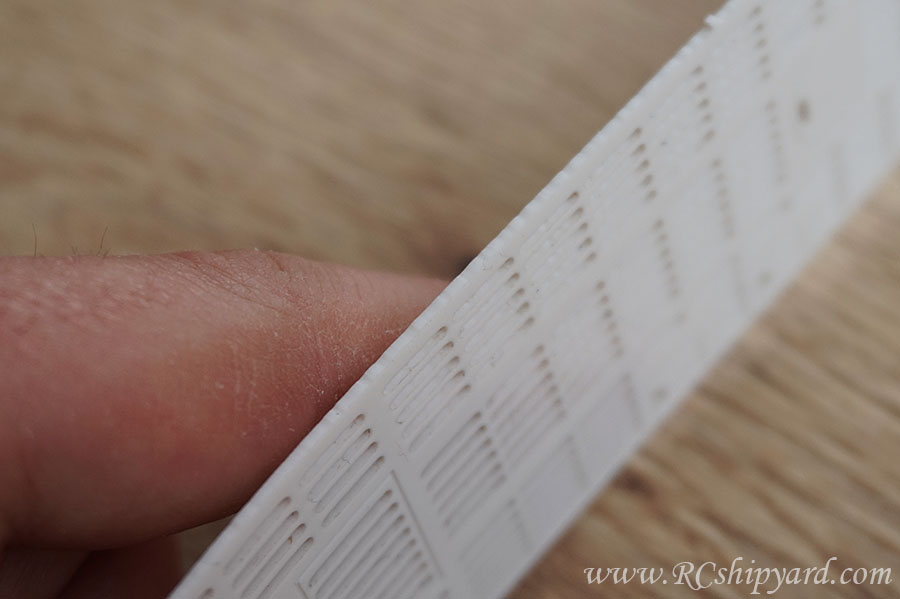

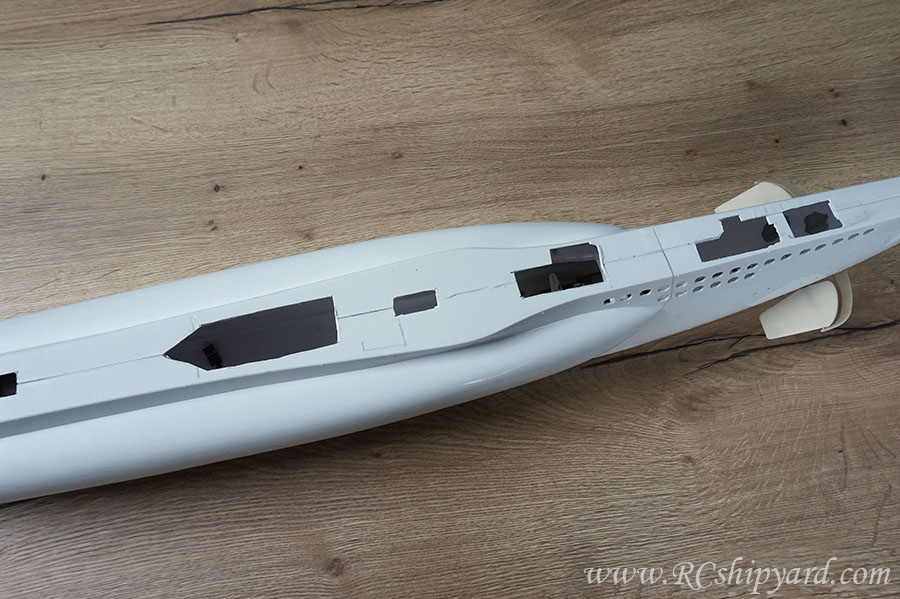

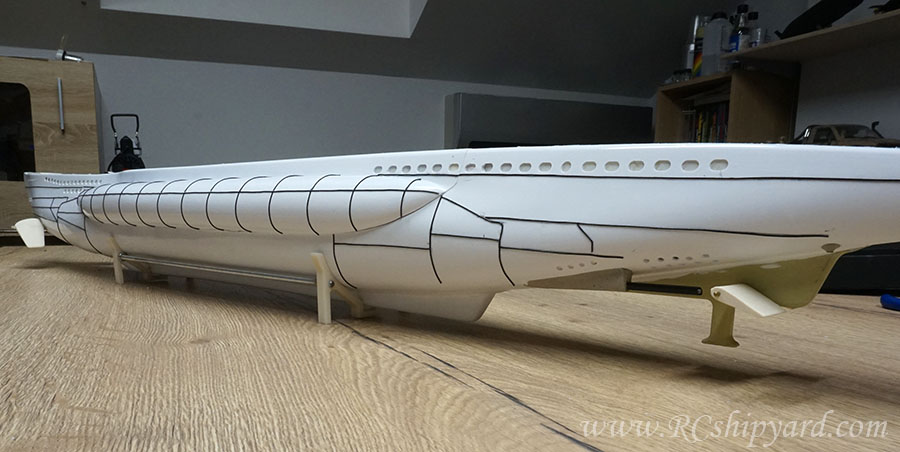

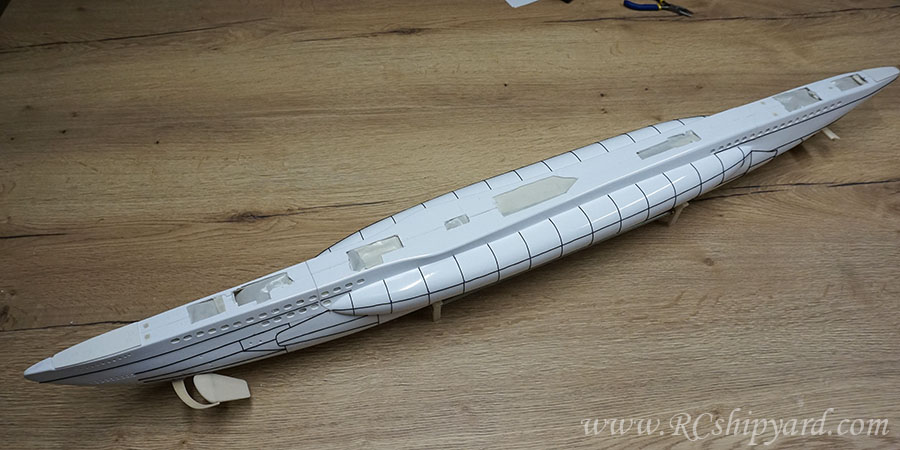

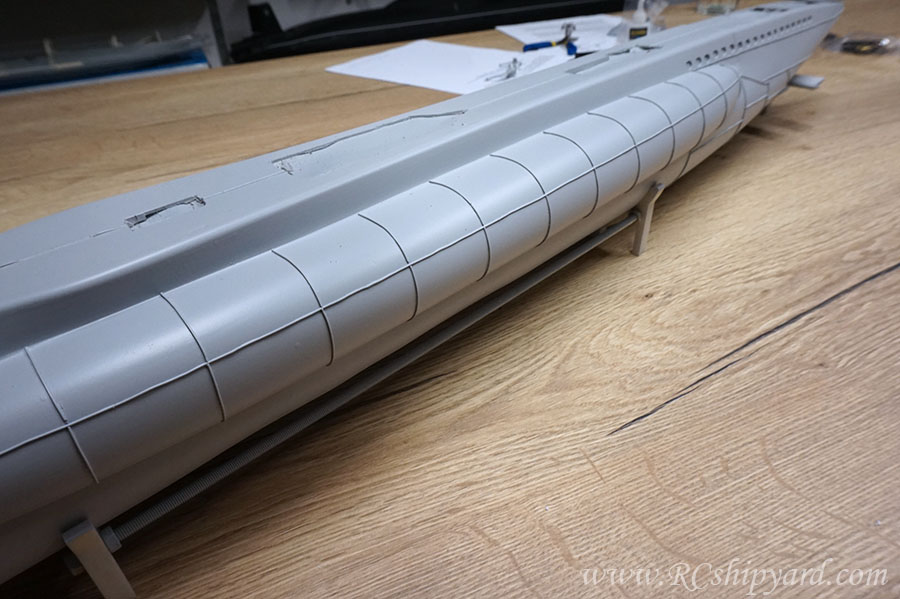

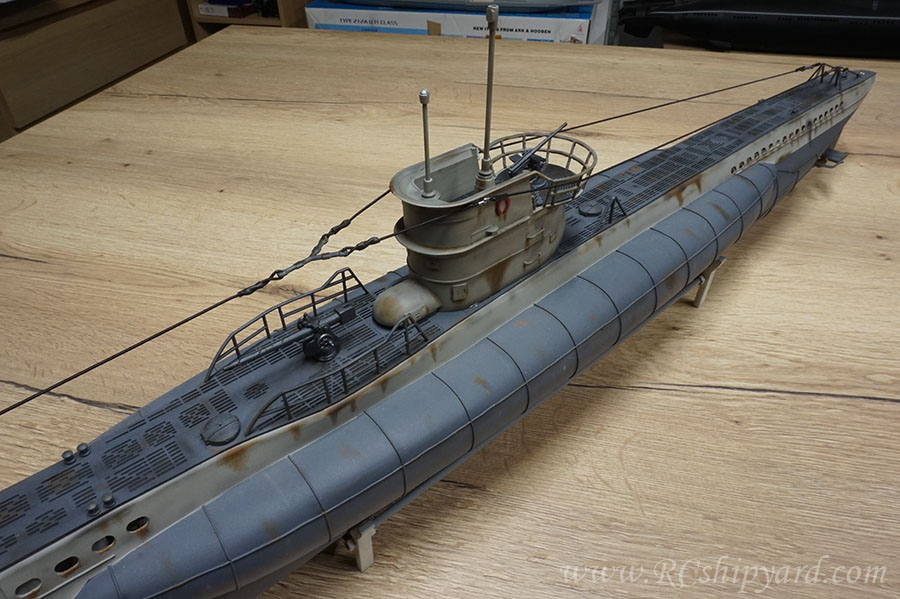

And some further progress. With the bow planes it's a similar situation as with the stern planes - the ones provided by the manufacturer are simply to primitive for me, so I'll make myself a new set

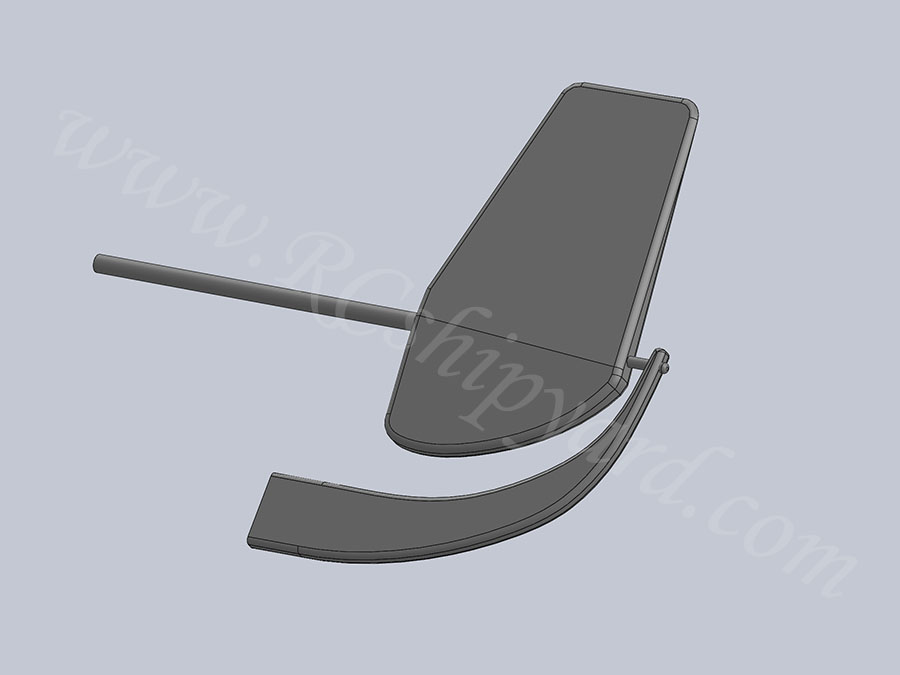

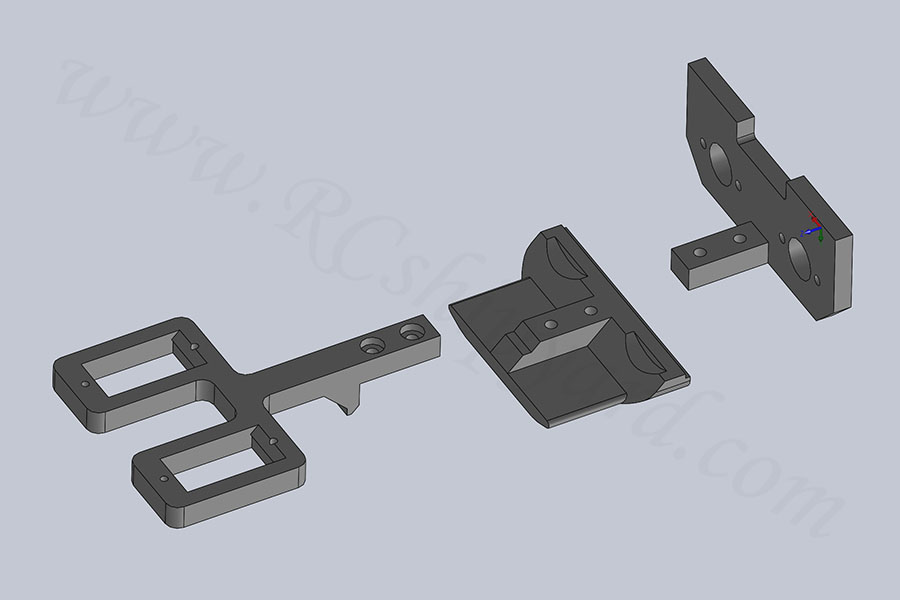

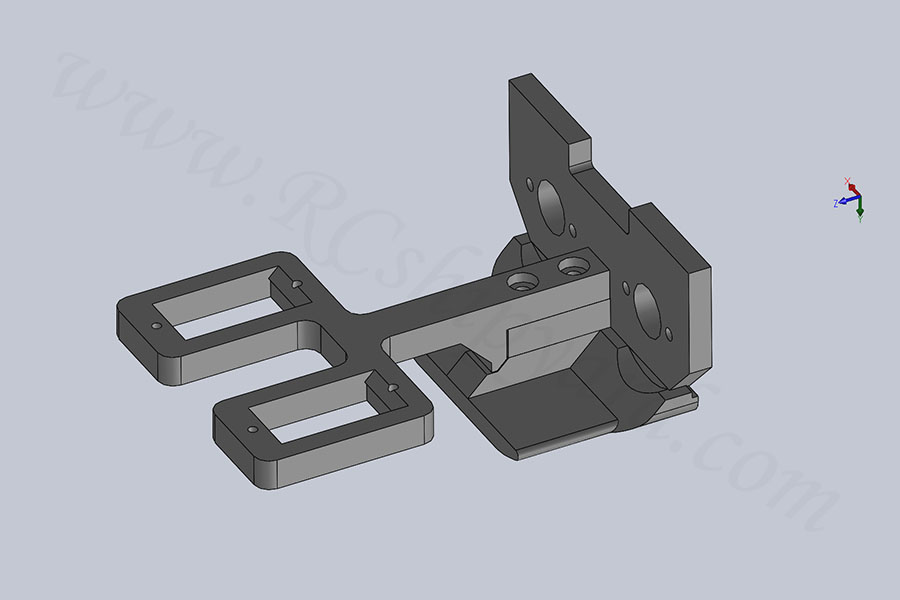

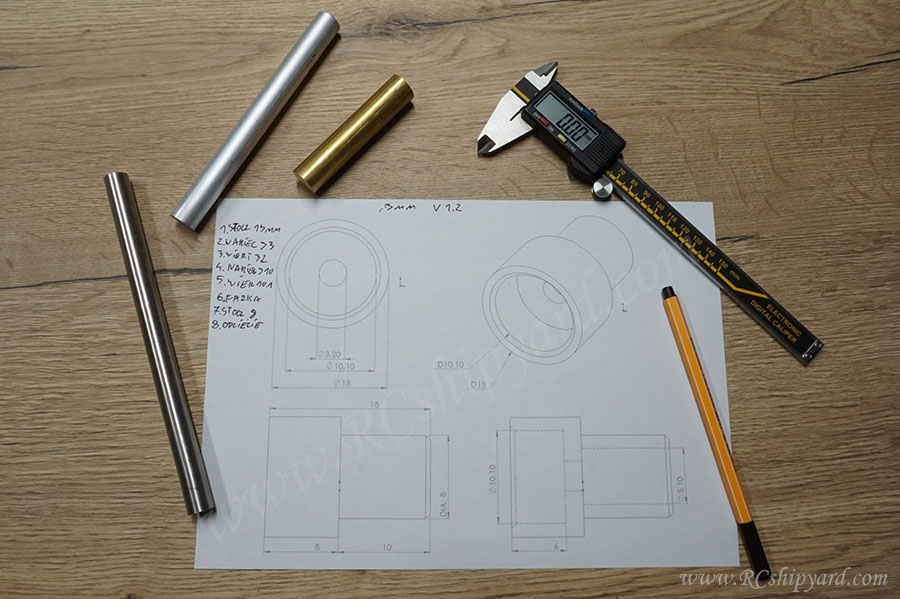

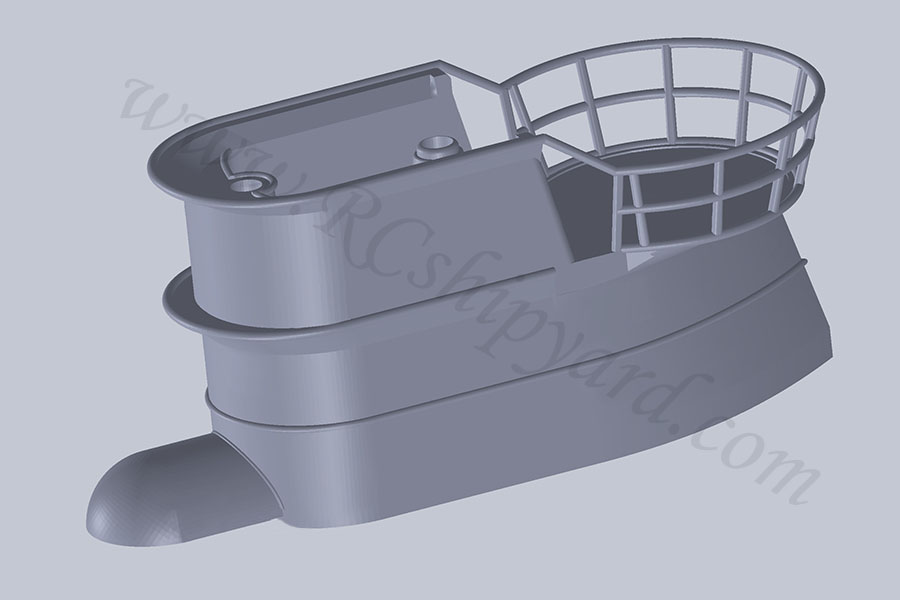

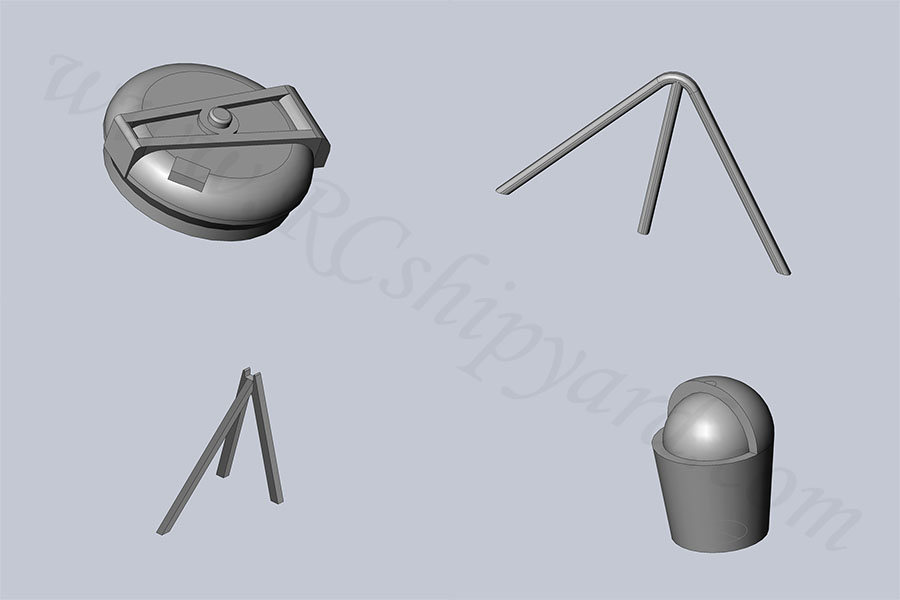

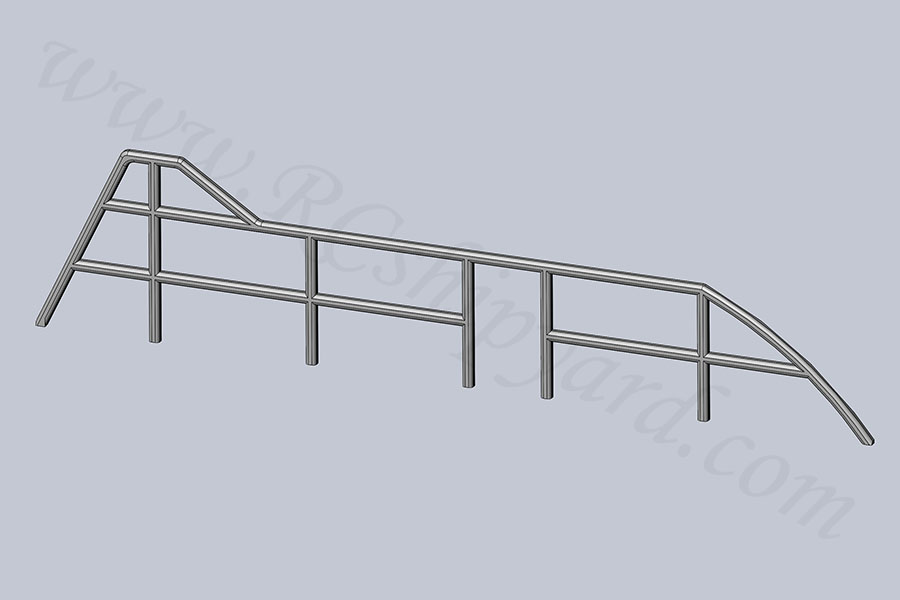

A quick design:

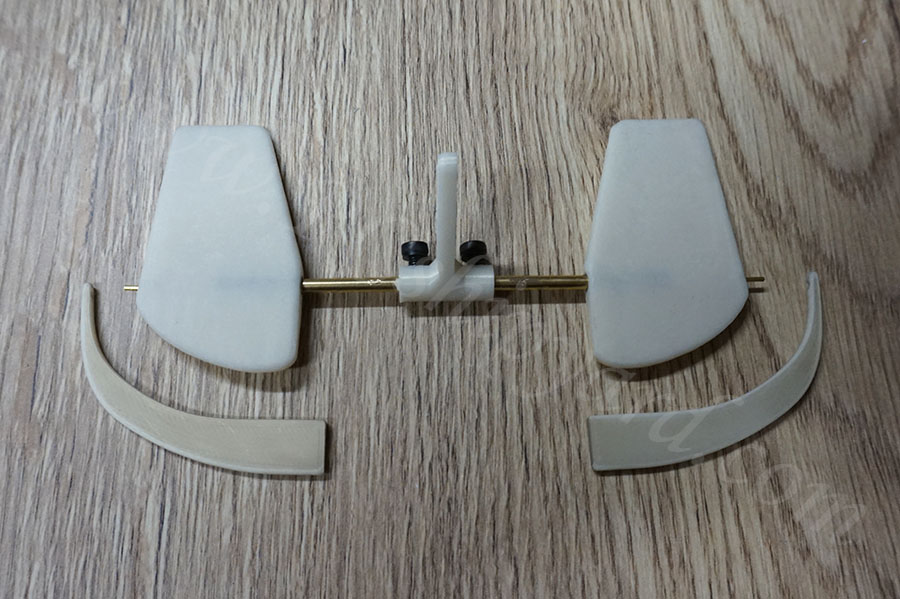

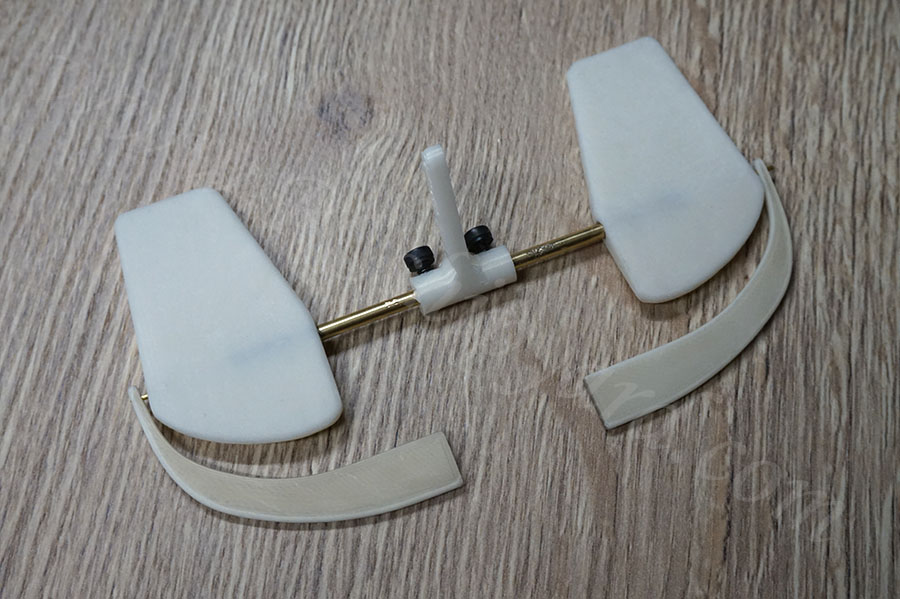

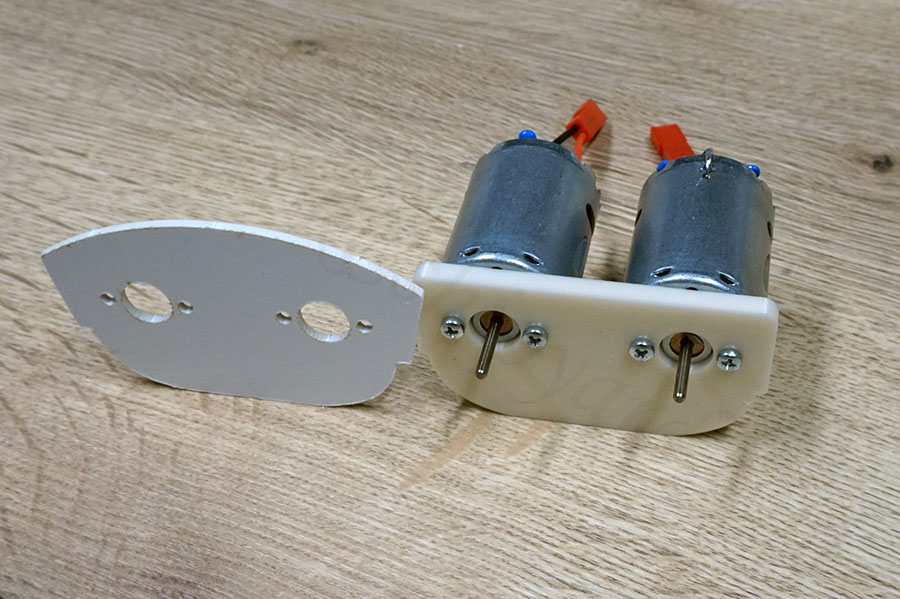

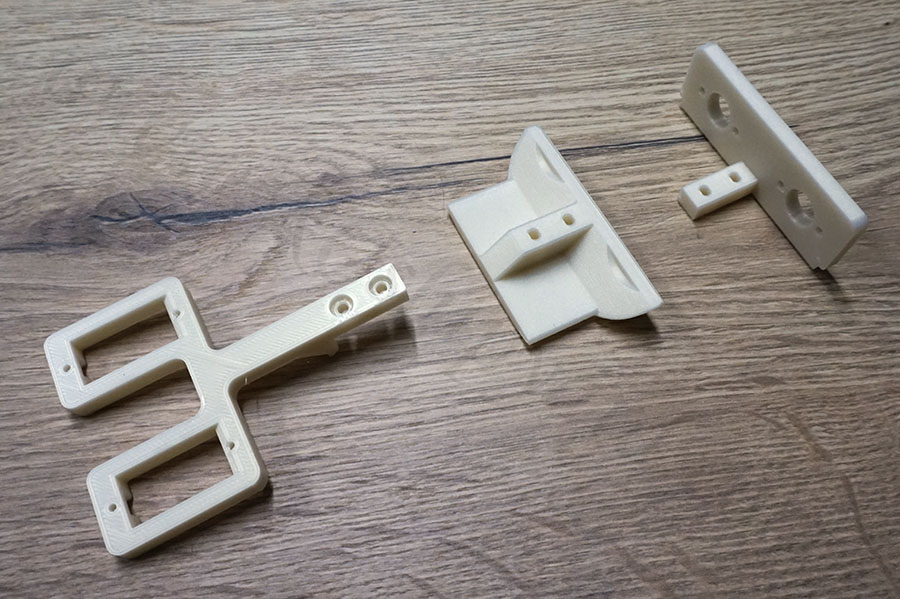

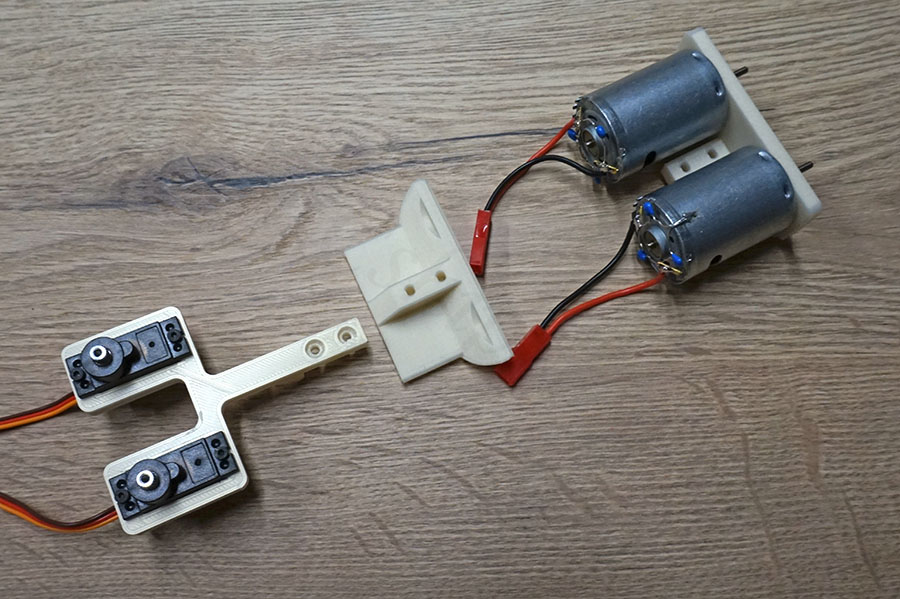

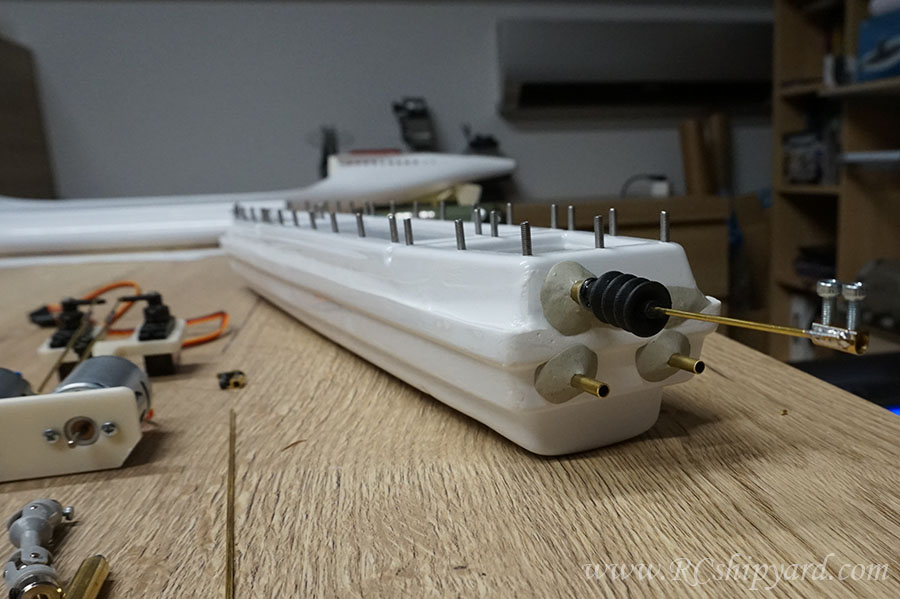

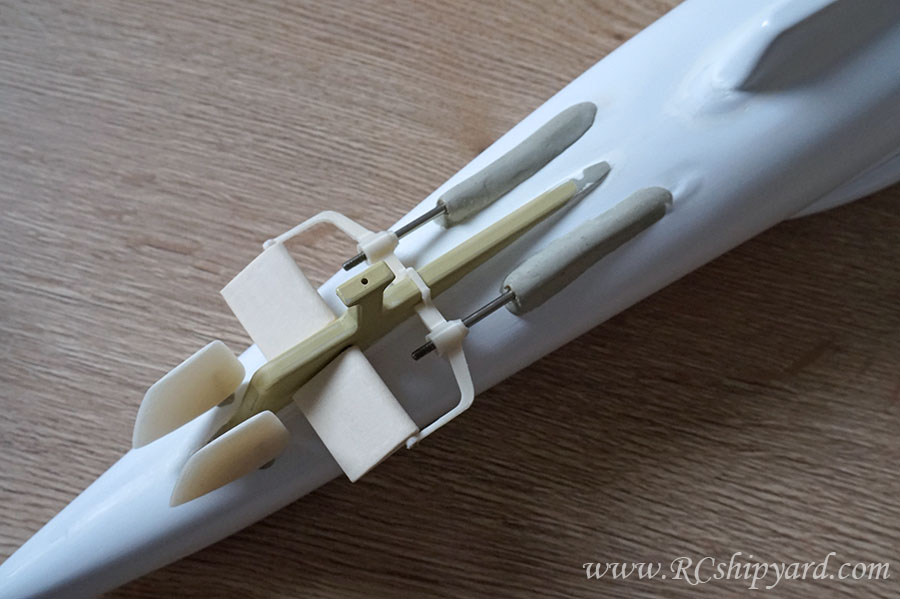

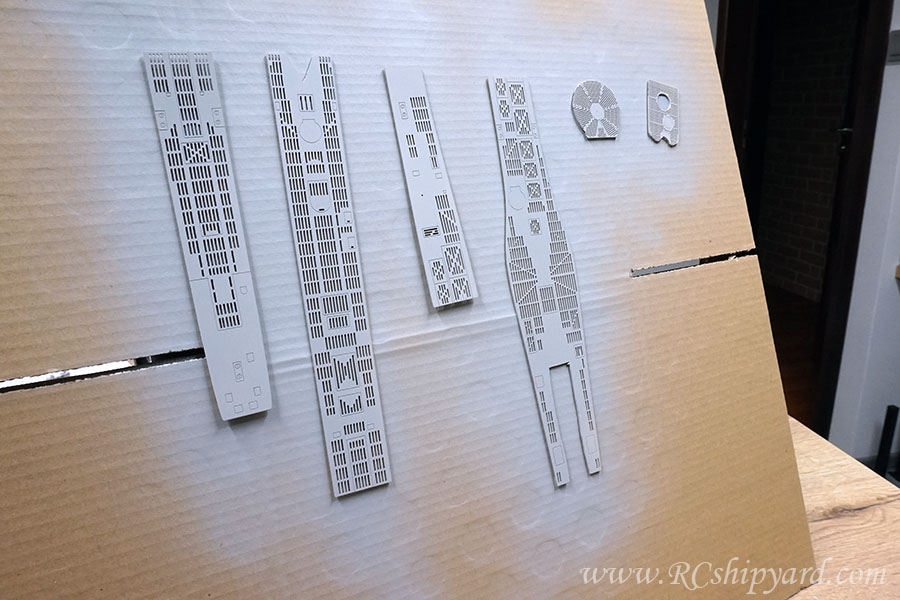

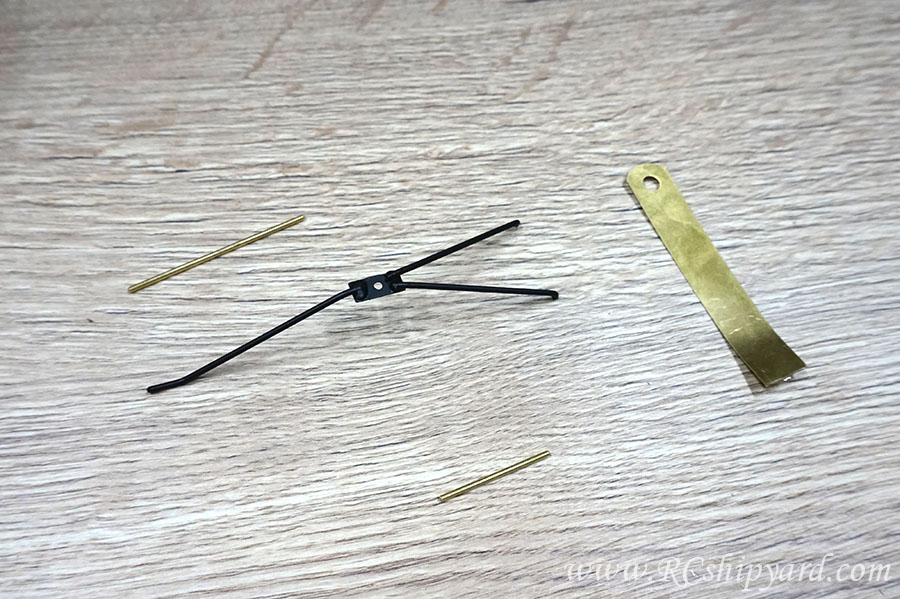

and the final part ready for assembly, this time I used a rotary tumbler to smooth the parts out. The only disadvantage of that is that the parts have to be cleaned quite thorough:

The planes are slightly larger then they should be, as I want some decent manoeuvrability, which type VII models usually lack.

Comment