Hello Everyone!

My name is Jakub (Jacob) and I'm from Poland. This is my first post here and I'm very happy to join Since a while I was a rather silent "read only" fan of this forum, but the time has finally came to write something of my own.

Since a while I was a rather silent "read only" fan of this forum, but the time has finally came to write something of my own.

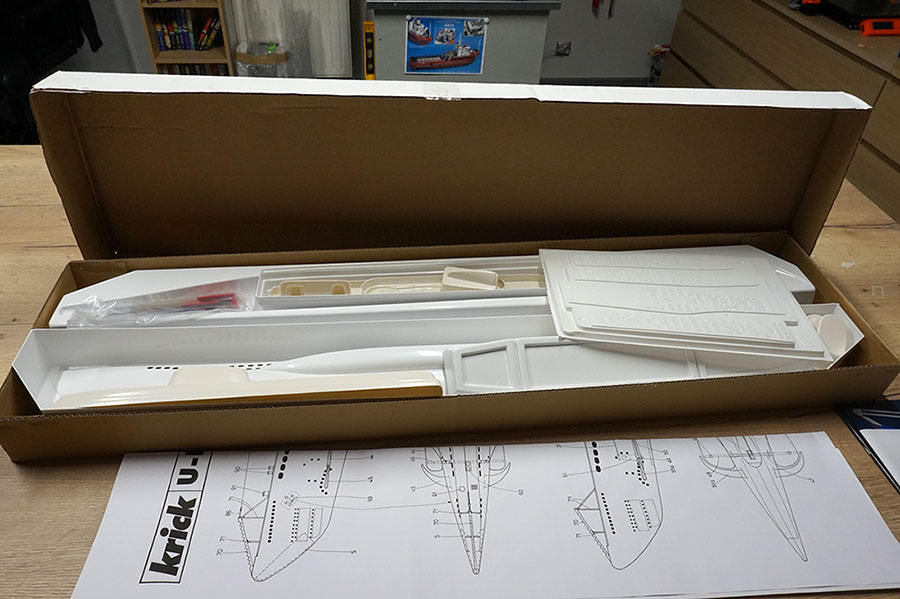

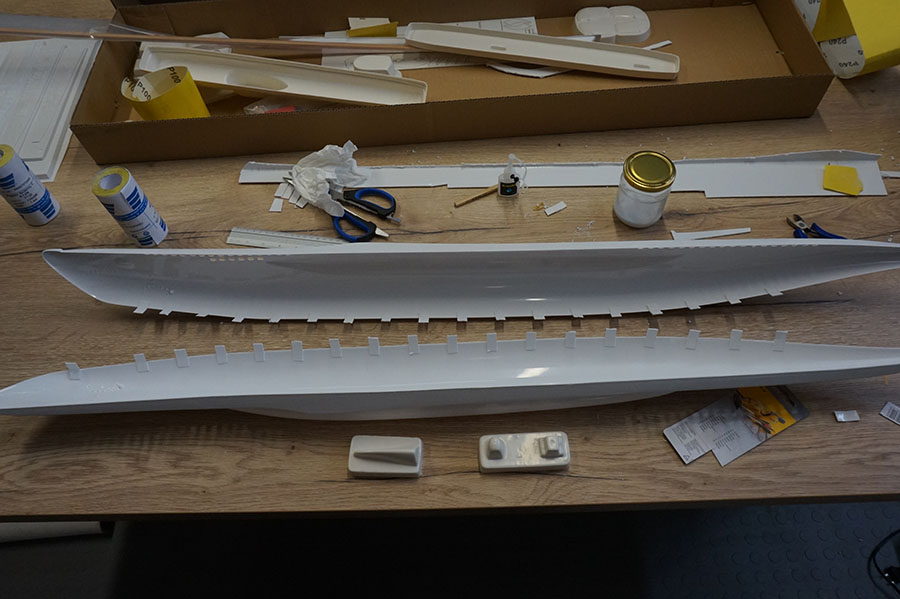

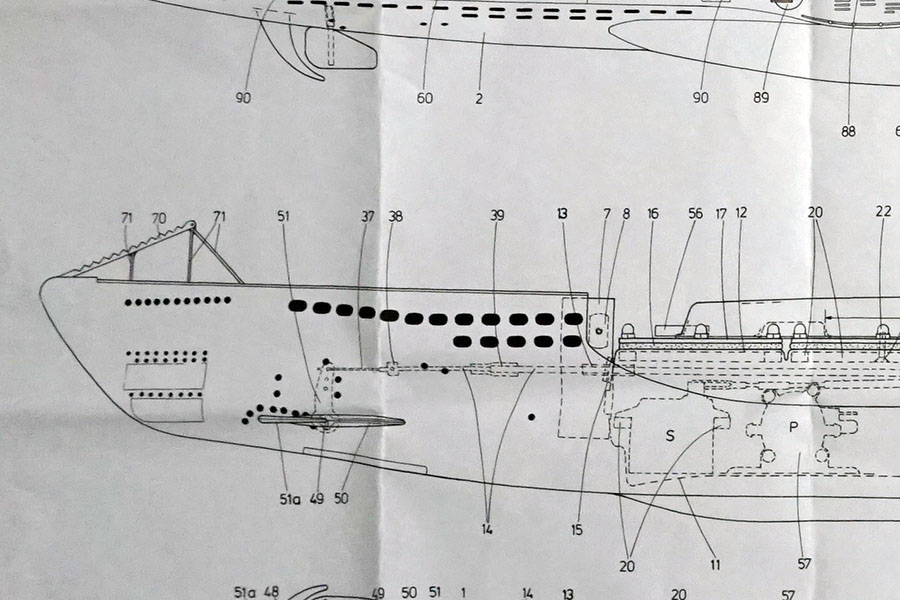

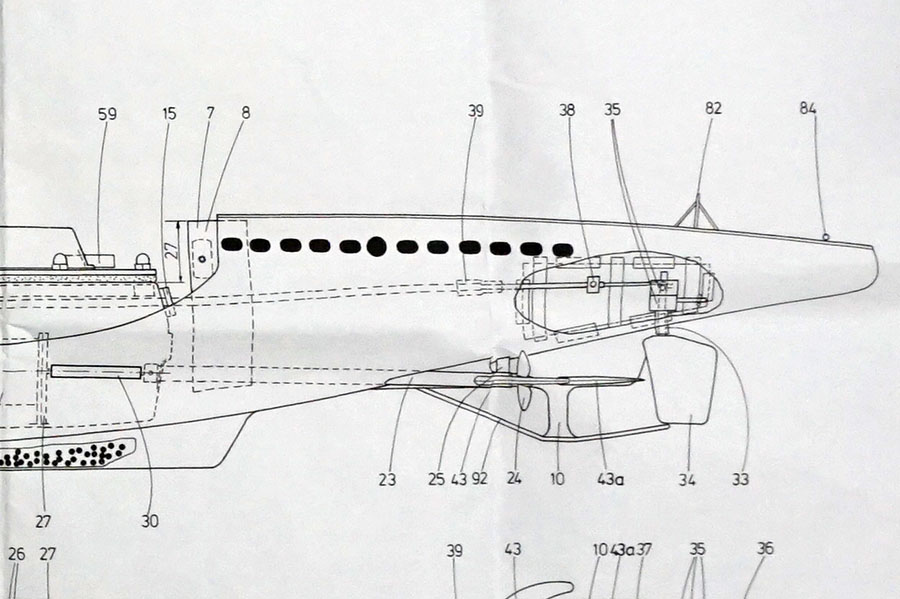

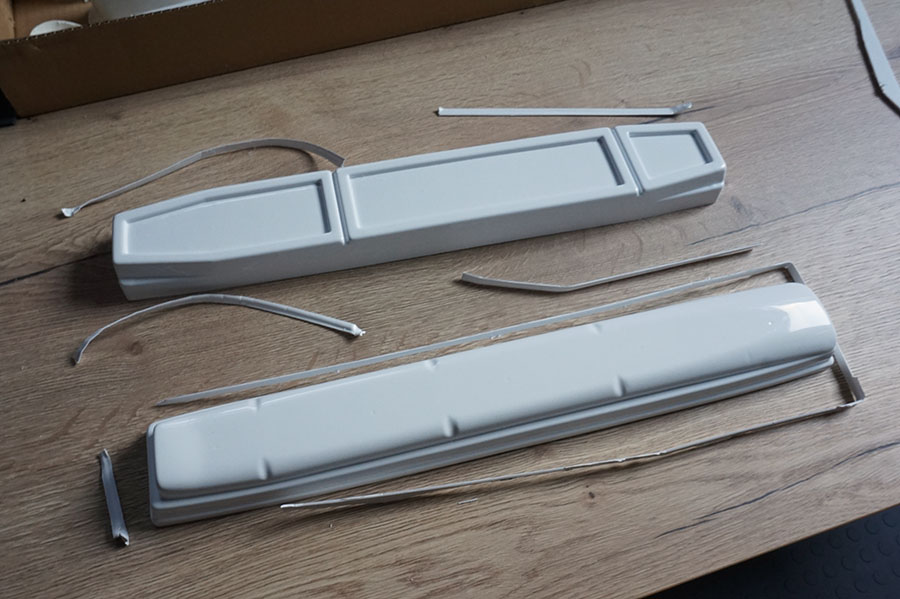

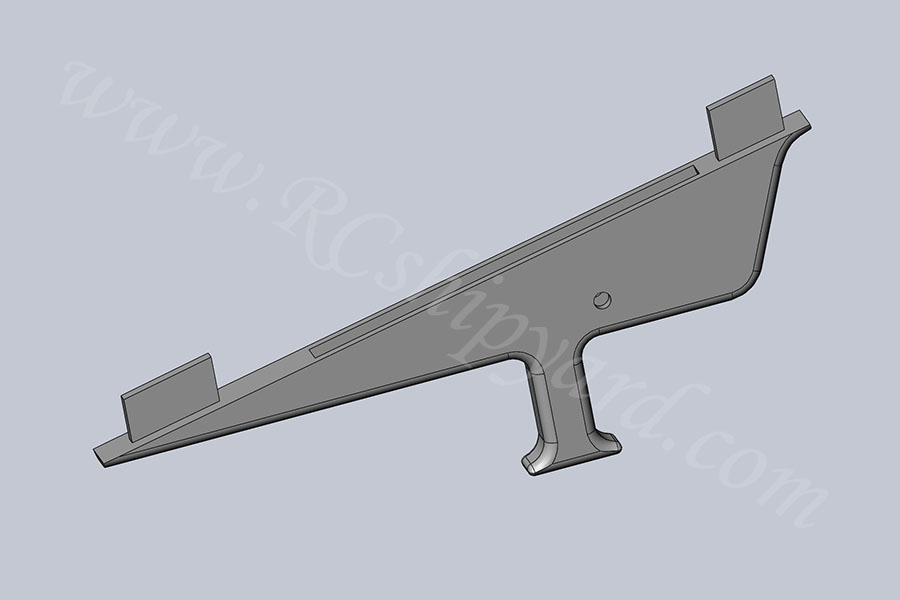

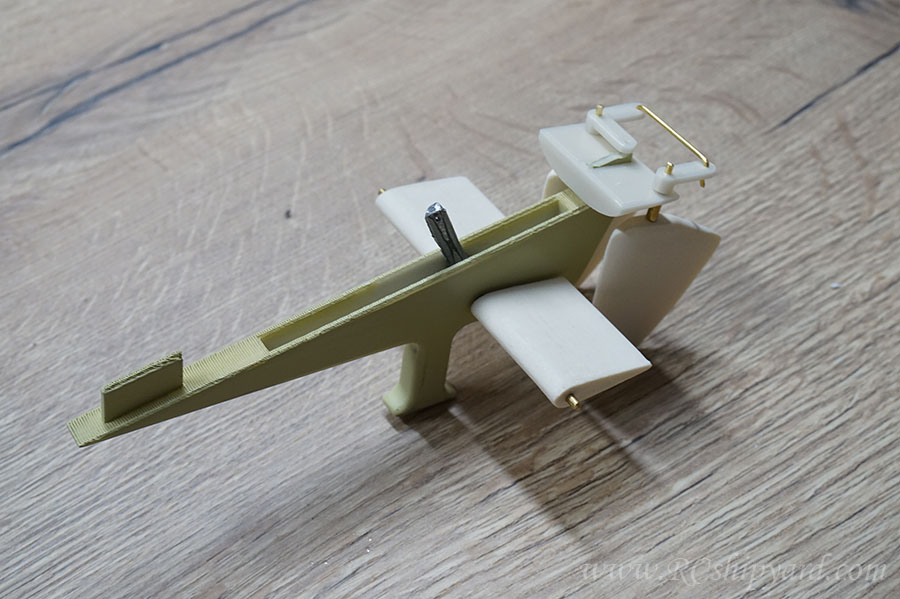

I bought myself the Krick VIIB kit as it was a dusty, cheap thing in my local store. I intend to use it as a learning platform how to work with ABS based hulls, as in the future I would like to assemble something more detailed and complicated, but still ABS based - like the Robbe's type XXI (as a static diver). I also have to learn some weathering as I have never done it before.

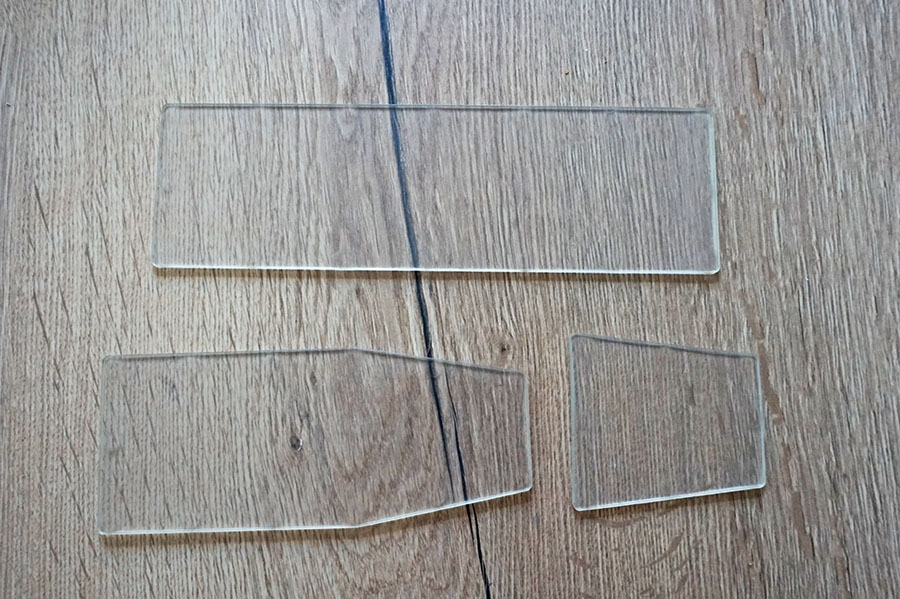

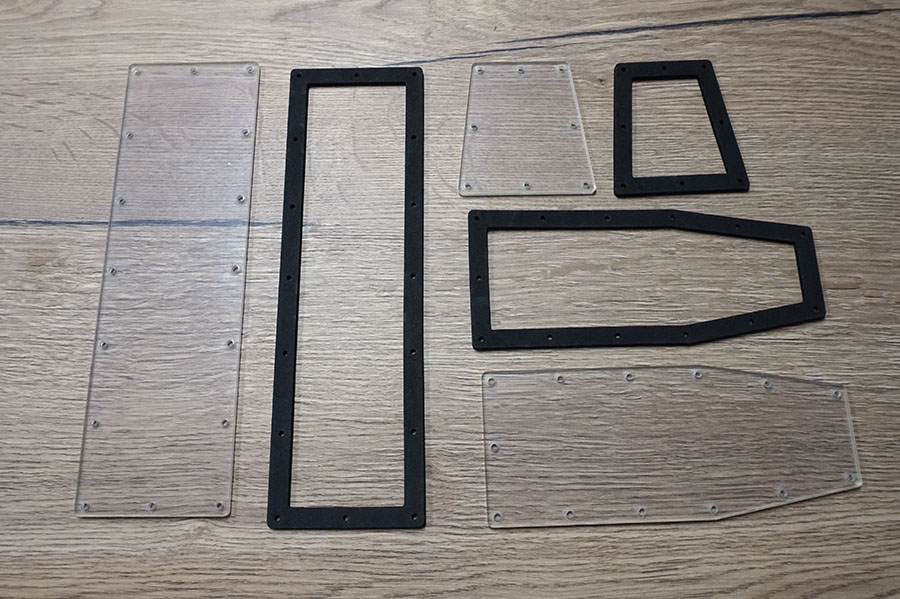

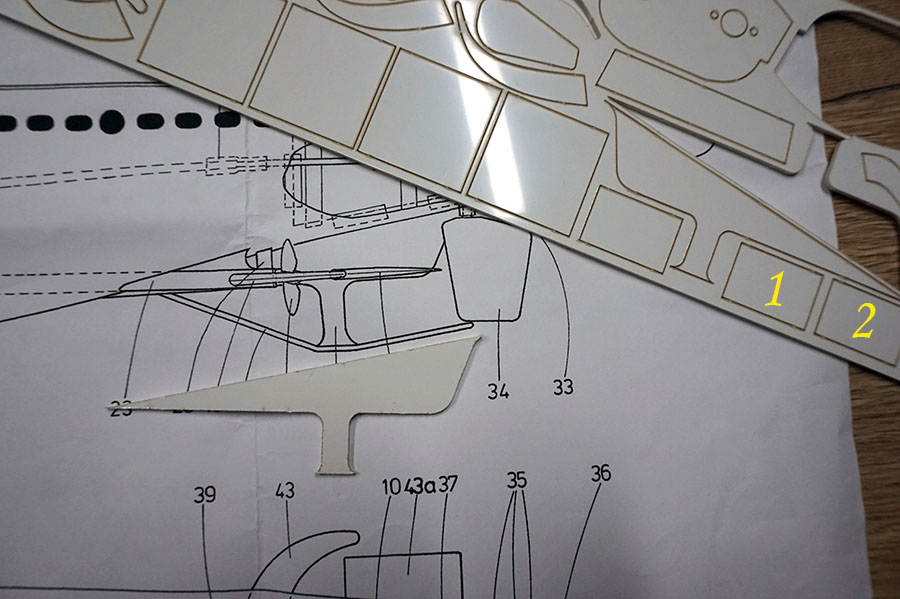

The content of this box is rather modest and makes me wonder was it even worth the cheap price, but no one should cry over a spilled milk

I did look for other building threads but either I'm not doing something correctly or this is is not a popular thing here

My name is Jakub (Jacob) and I'm from Poland. This is my first post here and I'm very happy to join

Since a while I was a rather silent "read only" fan of this forum, but the time has finally came to write something of my own.

Since a while I was a rather silent "read only" fan of this forum, but the time has finally came to write something of my own.I bought myself the Krick VIIB kit as it was a dusty, cheap thing in my local store. I intend to use it as a learning platform how to work with ABS based hulls, as in the future I would like to assemble something more detailed and complicated, but still ABS based - like the Robbe's type XXI (as a static diver). I also have to learn some weathering as I have never done it before.

The content of this box is rather modest and makes me wonder was it even worth the cheap price, but no one should cry over a spilled milk

I did look for other building threads but either I'm not doing something correctly or this is is not a popular thing here

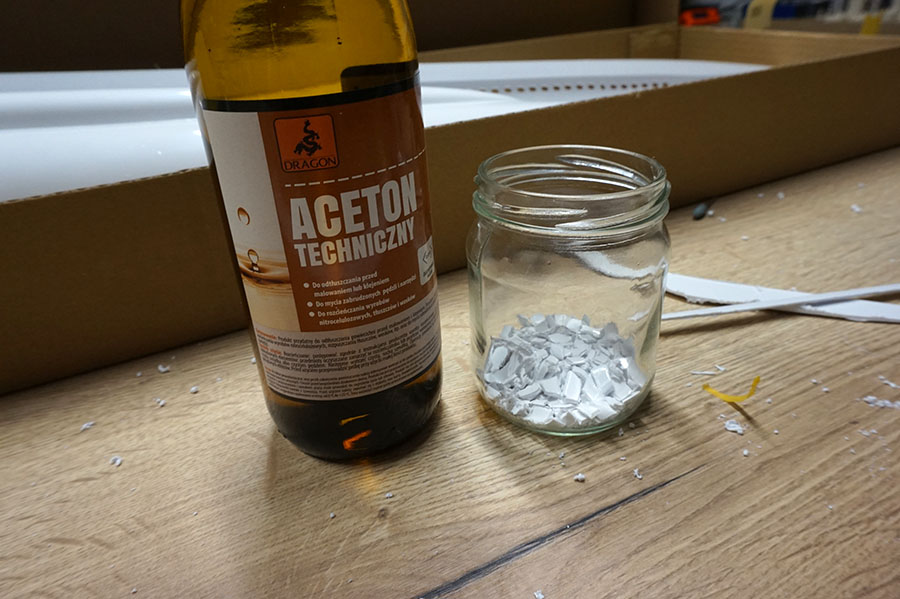

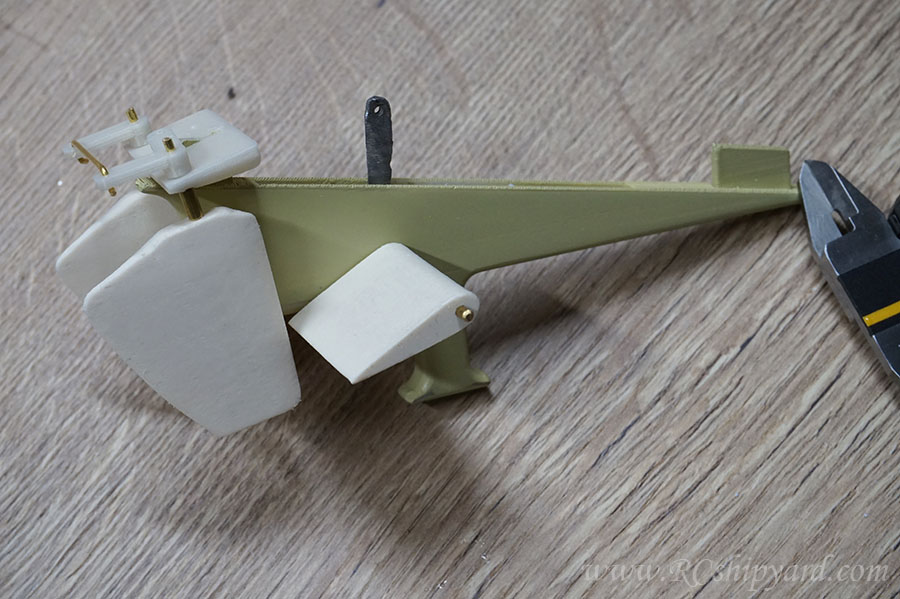

The bond of the keel with hull is solid, but these bubbles wherever they came from will have great impact on sanding time.

The bond of the keel with hull is solid, but these bubbles wherever they came from will have great impact on sanding time.

Comment