After seeing two of these boats at out bi monthly gathering at the lake, I bought one.

I assembled it from the instructions. ( ac ouple of changes in wiring)

Got it to the lake and it ran very well but it did not turn very well. (35', maybe more)

After a year I realized I was not taking this boat to the lake very often.

Why? I was not happy with the turing. It was hard to maneuver. I could not get out of the way of other boats.

After thinking about this I thought I would try some ideas to help it turn.

First was to extend the front of the rudder 1/4".

This helps but was not something to write home about. I reduced the turn by 5' or 6'.

I ran this for a few months. Again, not happy.

Then I remembered reading about log tubs haviong fishtail rudders.

I had looked at many photos. It is such a simple devise and I thought I could make one of these fishtail rudders as an extension to the otiginal rudder.

4 days before a gatherinhg, I took the project on.

It took less than two hours including paint.

Most of the time was waiting for glue to cure.

I wrote down what I did, showing photos of some of the steps.

I asked Tom if he thought this might be good in the Vault.

He said he thought so, so I am going to copy the information here for all to read and use as they might.

==================

Engel's Akula II - 1/125 scale

Rudder modification

November 2017, I ordered and received this boat from Engel. It took me 21 days to assemble it ready for water trimming. I work no more than 2 hours per day on this kit. It is not a build. It is an assembly or parts pre made and almost pre fitted except some small parts.

Follow the instructions and fit all parts before committing to final assembly. There are a couple of places that making a change in the instructions helped tremendously. Wiring for an example. Instead of a black and red together, try a red a black together but of different sizes. This was a suggestion from another builder with much more experience. In fact it was this man who had already assembled 2 of these boats at the same time that got me to buy this boat. He suggested the wire method.

Back to the rudder modification.

This boat run amazingly well. It dives and surfaces like no other boat I have built. THis is a piston ballast system with an optional Hall's Sensor. (Get the sensor) This boat is easy to prepare to run. It is my first dry hull boat and I like it a lot.

Now for the dislikes.

I ran the boat for a little over a year. Maybe 7 or 8 times during a year. I did not like the turning radius. 30' to 35' circles is too much. Makes coming in to shore a real challenge. Forward and backwards to get close enough to retrieve.

I finally became so frustrated, I modified the rudder. My approach was to remove 1/4" of the rudder skag and extend the rudder forward in to the water flow in front of the rudder shaft.

This reduced the turning radius to about 24'. A little more than 10' reduction. I ran the boat about 6 months with this modification. But the turning radius is still too much.

Some where I read about river log tugs having a fishtail rudder for quick maneuvering of logs rafts. So I looked in to it farther.

Well it was simple enough. Just a couple of angle iron extensions at the very back of the rudder. Then I found an engineering chart showing numbers of straight and fishtail rudders. Comparing the two There were several variations of size for the fishtail.

Out on my work bench I measured the Akula II rudder and guess at how big to make the extension. I picked up some scrap pieces of 1/16" thick sheet plastic from the trash box. And I proceeded to make an extension with plans to make it removable.

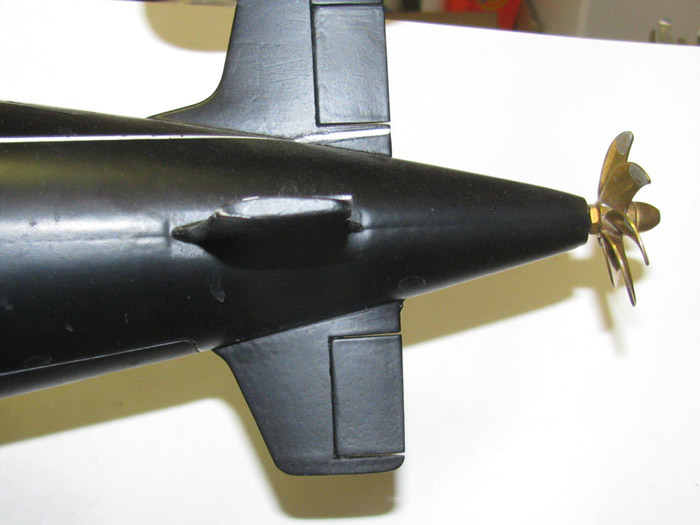

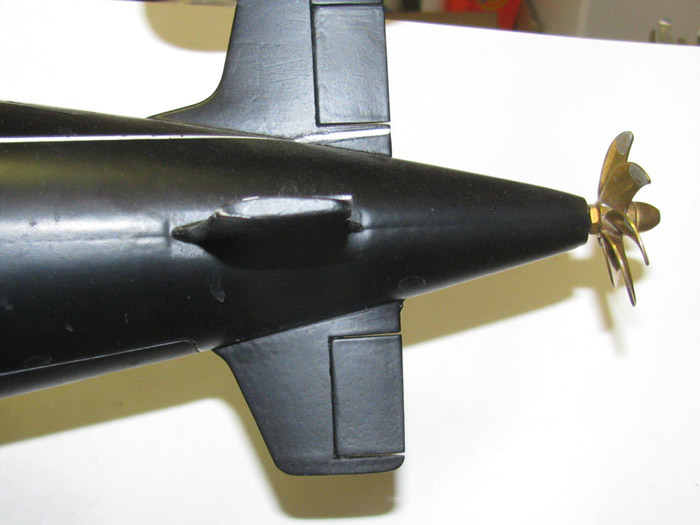

Here is the original rudders on the Akula II.

(I am not going to show the first modification. It was not very effective)

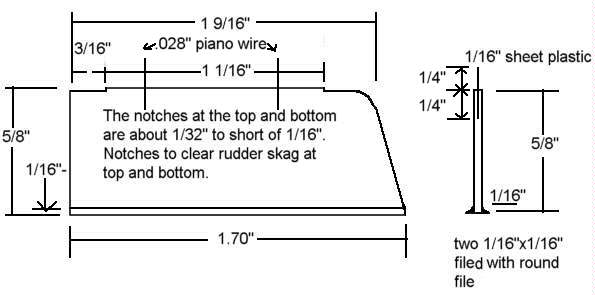

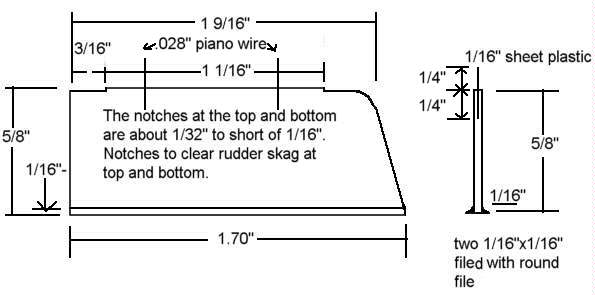

Here is the planned modification.

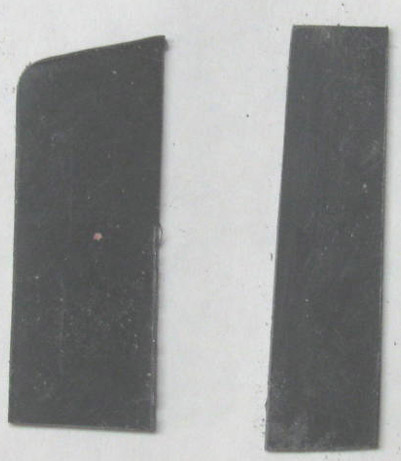

I cut a piece of plastic in to the shape I wanted to extend my rudder by.

Rounded off the top to fit the hull curve.

The other piece of plastic was cut in half to make the fishtail parts.

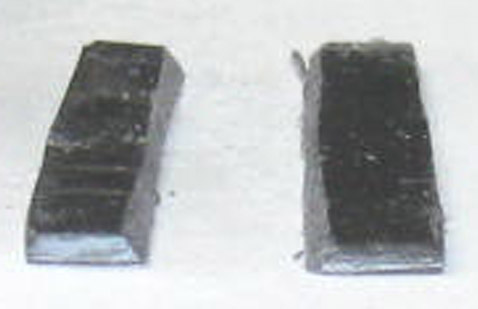

I started beveling the two fishtail strips.

Once the bevel was straight and 45 degrees, the strips were cemented to the rudder piece.

I put a few drops of cement on the part edge and smoothed with a damp finger.

After it all cured, I trimmed the parts with scissors to shape.

After trimming to shape, I used a very small round file to shape the fishtail edges.

I used .028" piano wire to drill two holes in the new rudder and matching placement in the original rudder.

I had thought I would make the rudder extension removable. After looking at it, I decided to mount it permanently. If I wanted to remove it, a razor saw would take a few seconds. Besides, most people looking at the boat do not know the extension is not original to the boat or they do not notice it. No one noticed the 1/4" extension to the rudder.

Now this is where the reward comes.

Taking it to the lake.

This modification did not disturbed the trim at all.

First test was running on the surface. Before, to make turns the boat had to be desks awash or the turn was wider.

Okay, I think something is wrong. I stop the boat to look and see if I have collected weeds on the stern planes.

Why the boat turned to the right making a 7' radius turn.

No weeds. Okay, Continue the test. Turn to the left. Same 7' turning radius.

Stop the boat and trim it at periscope depth. Continue the slow run. The boat turned a 6' to 7' circle. Now turn in the other direction. Same thing again.

I spent the next 2 hours making small circles in front my chair. Surfaced, submerged at various depths.

I can not believe how well the fishtail rudder extension works. Something that took me all of about 2 hour to make including glue curing time and painting repair.

My Skipjack turns a little quicker but not by much.

Now the Akula II spends more time at the lake. It is a pleasure to run. . . NOW.

This fishtail rudder extension turns a 35' radius in to a 7' radius.

I recommend if you build an Akula II, try the extension.

I am sure it will work for any scale if you scale the rudder extension as well.

I assembled it from the instructions. ( ac ouple of changes in wiring)

Got it to the lake and it ran very well but it did not turn very well. (35', maybe more)

After a year I realized I was not taking this boat to the lake very often.

Why? I was not happy with the turing. It was hard to maneuver. I could not get out of the way of other boats.

After thinking about this I thought I would try some ideas to help it turn.

First was to extend the front of the rudder 1/4".

This helps but was not something to write home about. I reduced the turn by 5' or 6'.

I ran this for a few months. Again, not happy.

Then I remembered reading about log tubs haviong fishtail rudders.

I had looked at many photos. It is such a simple devise and I thought I could make one of these fishtail rudders as an extension to the otiginal rudder.

4 days before a gatherinhg, I took the project on.

It took less than two hours including paint.

Most of the time was waiting for glue to cure.

I wrote down what I did, showing photos of some of the steps.

I asked Tom if he thought this might be good in the Vault.

He said he thought so, so I am going to copy the information here for all to read and use as they might.

==================

Engel's Akula II - 1/125 scale

Rudder modification

November 2017, I ordered and received this boat from Engel. It took me 21 days to assemble it ready for water trimming. I work no more than 2 hours per day on this kit. It is not a build. It is an assembly or parts pre made and almost pre fitted except some small parts.

Follow the instructions and fit all parts before committing to final assembly. There are a couple of places that making a change in the instructions helped tremendously. Wiring for an example. Instead of a black and red together, try a red a black together but of different sizes. This was a suggestion from another builder with much more experience. In fact it was this man who had already assembled 2 of these boats at the same time that got me to buy this boat. He suggested the wire method.

Back to the rudder modification.

This boat run amazingly well. It dives and surfaces like no other boat I have built. THis is a piston ballast system with an optional Hall's Sensor. (Get the sensor) This boat is easy to prepare to run. It is my first dry hull boat and I like it a lot.

Now for the dislikes.

I ran the boat for a little over a year. Maybe 7 or 8 times during a year. I did not like the turning radius. 30' to 35' circles is too much. Makes coming in to shore a real challenge. Forward and backwards to get close enough to retrieve.

I finally became so frustrated, I modified the rudder. My approach was to remove 1/4" of the rudder skag and extend the rudder forward in to the water flow in front of the rudder shaft.

This reduced the turning radius to about 24'. A little more than 10' reduction. I ran the boat about 6 months with this modification. But the turning radius is still too much.

Some where I read about river log tugs having a fishtail rudder for quick maneuvering of logs rafts. So I looked in to it farther.

Well it was simple enough. Just a couple of angle iron extensions at the very back of the rudder. Then I found an engineering chart showing numbers of straight and fishtail rudders. Comparing the two There were several variations of size for the fishtail.

Out on my work bench I measured the Akula II rudder and guess at how big to make the extension. I picked up some scrap pieces of 1/16" thick sheet plastic from the trash box. And I proceeded to make an extension with plans to make it removable.

Here is the original rudders on the Akula II.

(I am not going to show the first modification. It was not very effective)

Here is the planned modification.

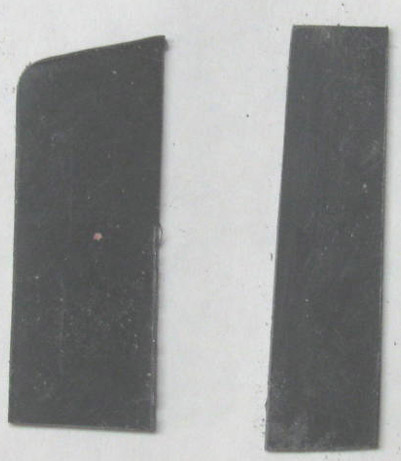

I cut a piece of plastic in to the shape I wanted to extend my rudder by.

Rounded off the top to fit the hull curve.

The other piece of plastic was cut in half to make the fishtail parts.

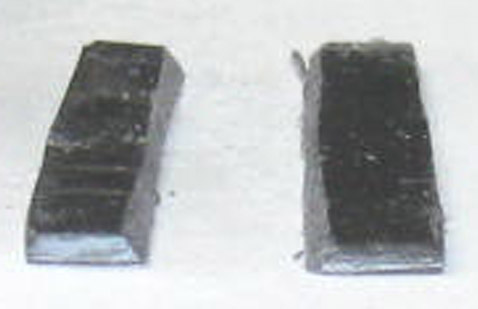

I started beveling the two fishtail strips.

Once the bevel was straight and 45 degrees, the strips were cemented to the rudder piece.

I put a few drops of cement on the part edge and smoothed with a damp finger.

After it all cured, I trimmed the parts with scissors to shape.

After trimming to shape, I used a very small round file to shape the fishtail edges.

I used .028" piano wire to drill two holes in the new rudder and matching placement in the original rudder.

I had thought I would make the rudder extension removable. After looking at it, I decided to mount it permanently. If I wanted to remove it, a razor saw would take a few seconds. Besides, most people looking at the boat do not know the extension is not original to the boat or they do not notice it. No one noticed the 1/4" extension to the rudder.

Now this is where the reward comes.

Taking it to the lake.

This modification did not disturbed the trim at all.

First test was running on the surface. Before, to make turns the boat had to be desks awash or the turn was wider.

Okay, I think something is wrong. I stop the boat to look and see if I have collected weeds on the stern planes.

Why the boat turned to the right making a 7' radius turn.

No weeds. Okay, Continue the test. Turn to the left. Same 7' turning radius.

Stop the boat and trim it at periscope depth. Continue the slow run. The boat turned a 6' to 7' circle. Now turn in the other direction. Same thing again.

I spent the next 2 hours making small circles in front my chair. Surfaced, submerged at various depths.

I can not believe how well the fishtail rudder extension works. Something that took me all of about 2 hour to make including glue curing time and painting repair.

My Skipjack turns a little quicker but not by much.

Now the Akula II spends more time at the lake. It is a pleasure to run. . . NOW.

This fishtail rudder extension turns a 35' radius in to a 7' radius.

I recommend if you build an Akula II, try the extension.

I am sure it will work for any scale if you scale the rudder extension as well.

Comment