Hello everyone,

I'm new to the subcommittee and its forums but I have just started a new project and wanted to share it and collaborate with people with a lot more RC sub experience than I have. I think I came to the right place.

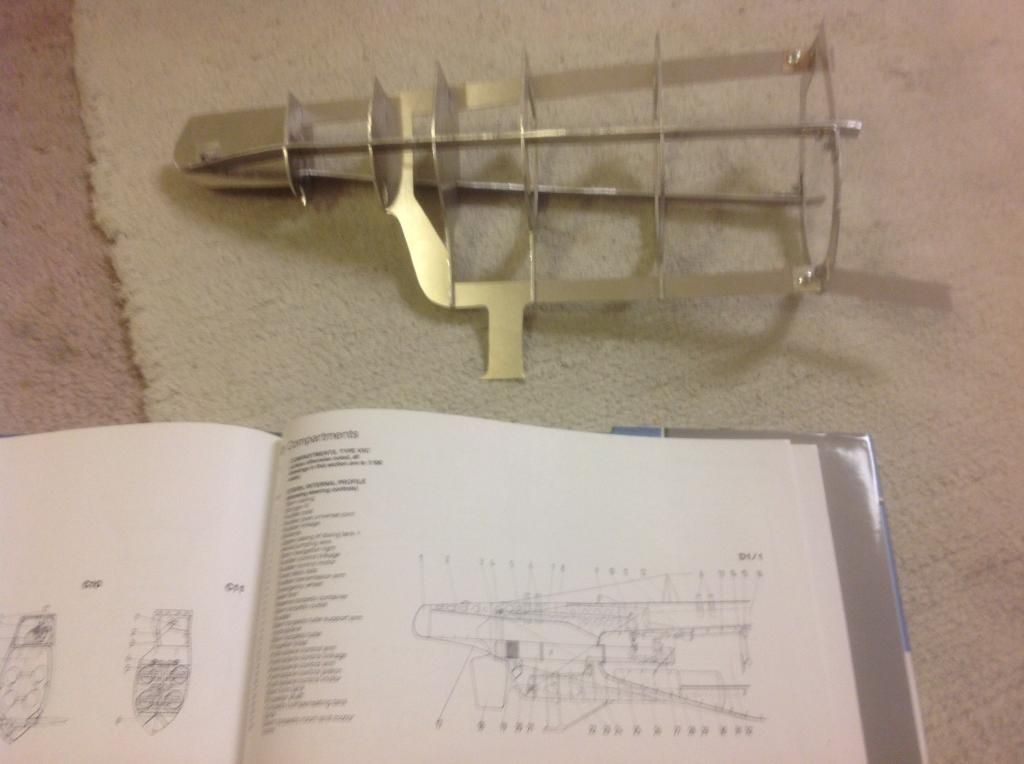

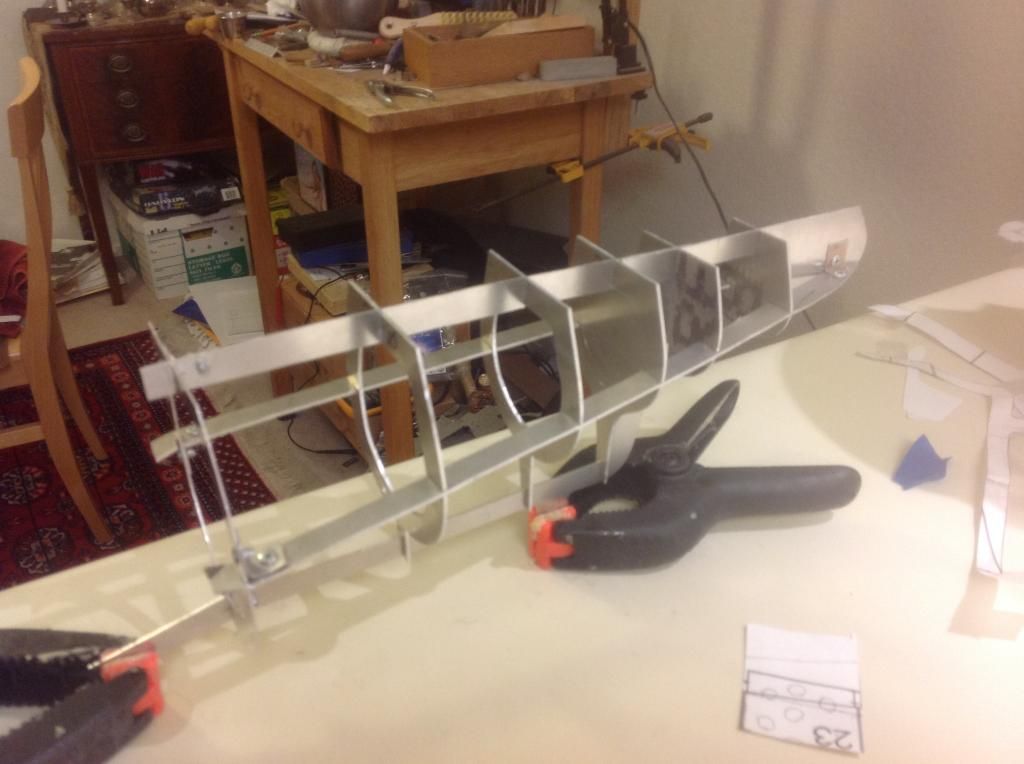

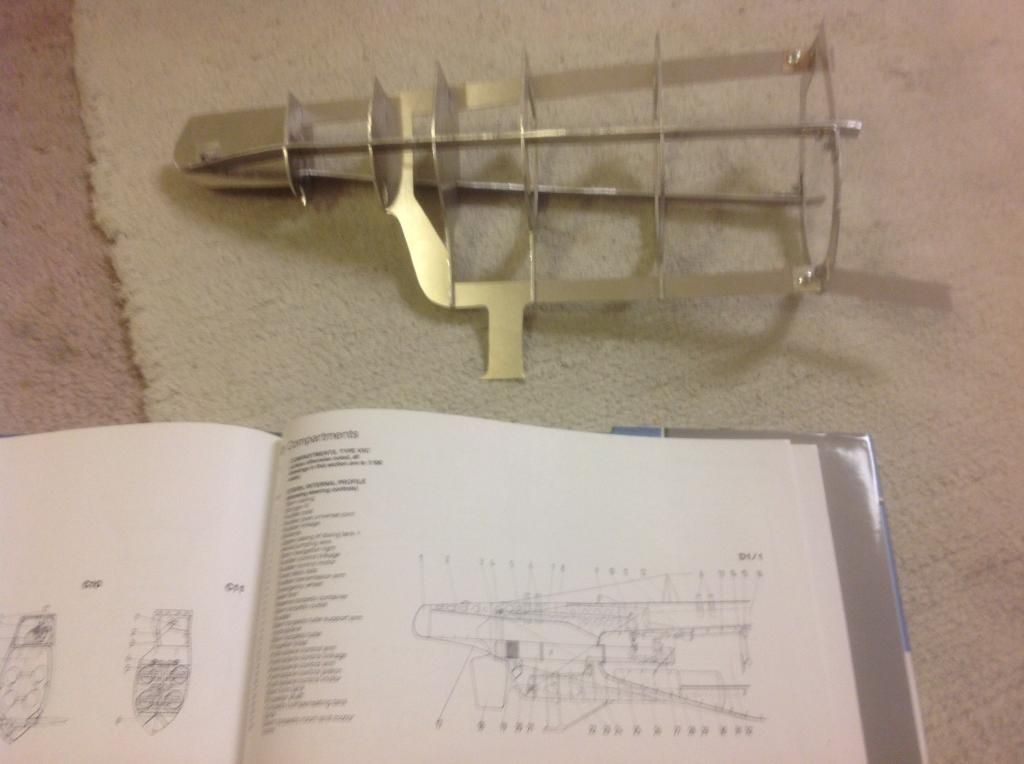

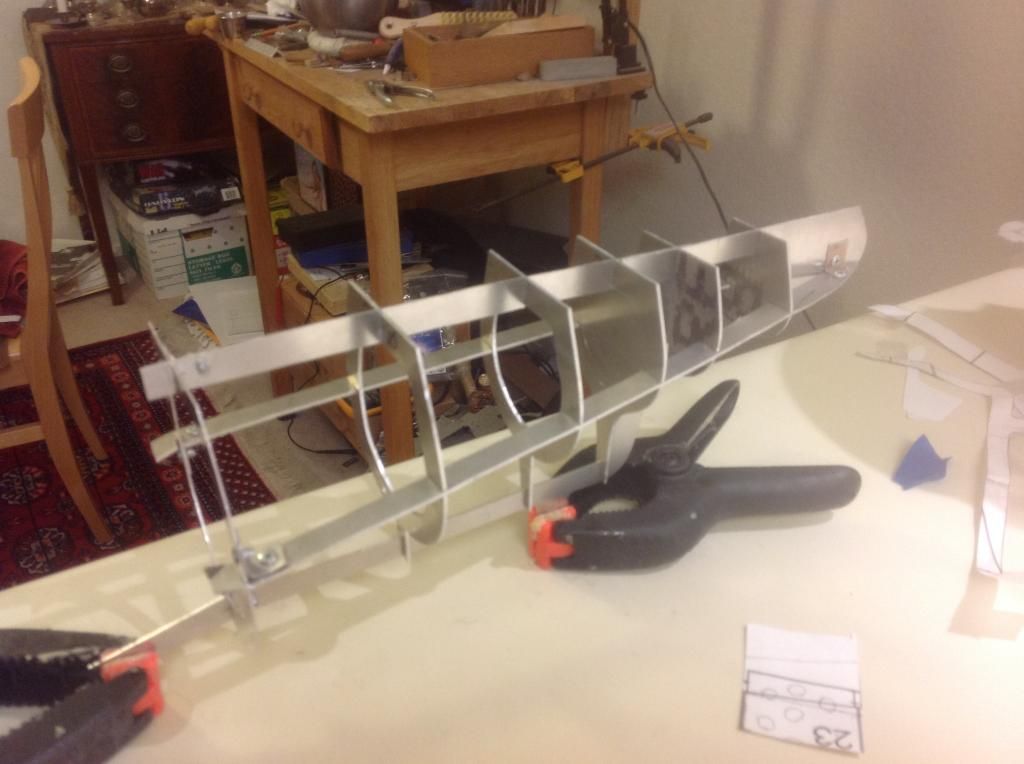

I have been building and flying RC airplane models for many years. I'm also a private pilot and built and test flew my own replica WWI Fokker DVIII about 9 years ago. I have always wanted to build a large scale RC Type VIIC u-boat. And being a scratch-building kind of woman I decided to build mine out of metal. The superstructure will be all aluminum and I plan to make the sea hull from thin sheet brass. Three days ago I started cutting out bulkheads from aluminum scrap and today I have the superstructure of the aft end of the boat mostly finished.

I have based my plans on the combination of a paper model and the drawings in Westwood's Type VII U-boat book.

Here are a few photos of what I've done so far:

[/URL]

[/URL]

I plan to build my own dive system and working torpedo system later on and will be looking for constructive input into those.

More updates as the work progresses.

Gwen

I'm new to the subcommittee and its forums but I have just started a new project and wanted to share it and collaborate with people with a lot more RC sub experience than I have. I think I came to the right place.

I have been building and flying RC airplane models for many years. I'm also a private pilot and built and test flew my own replica WWI Fokker DVIII about 9 years ago. I have always wanted to build a large scale RC Type VIIC u-boat. And being a scratch-building kind of woman I decided to build mine out of metal. The superstructure will be all aluminum and I plan to make the sea hull from thin sheet brass. Three days ago I started cutting out bulkheads from aluminum scrap and today I have the superstructure of the aft end of the boat mostly finished.

I have based my plans on the combination of a paper model and the drawings in Westwood's Type VII U-boat book.

Here are a few photos of what I've done so far:

[/URL]

[/URL]

I plan to build my own dive system and working torpedo system later on and will be looking for constructive input into those.

More updates as the work progresses.

Gwen

Comment