Hi gang

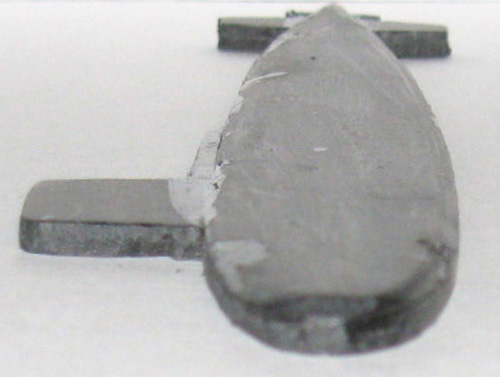

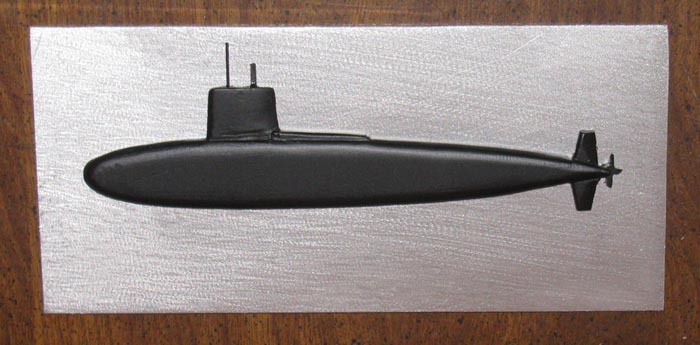

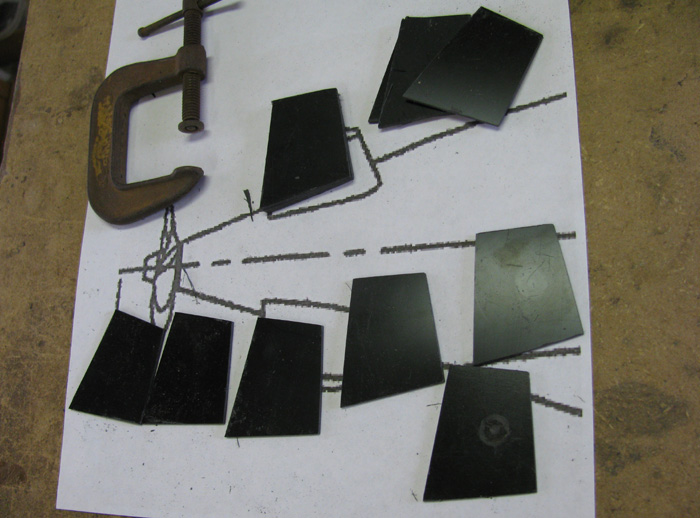

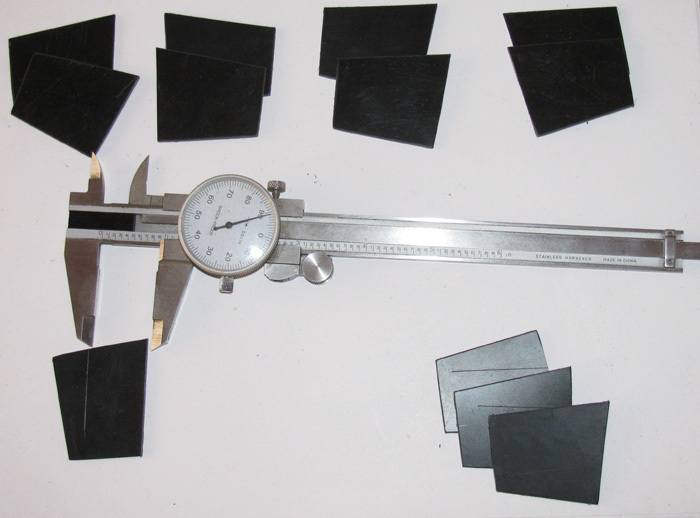

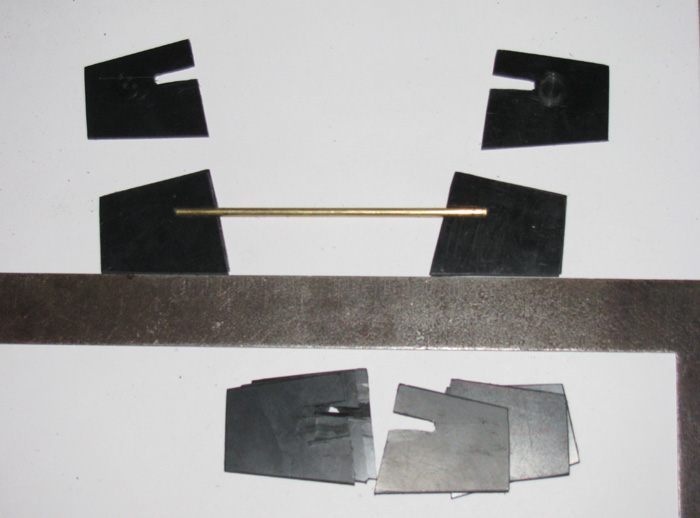

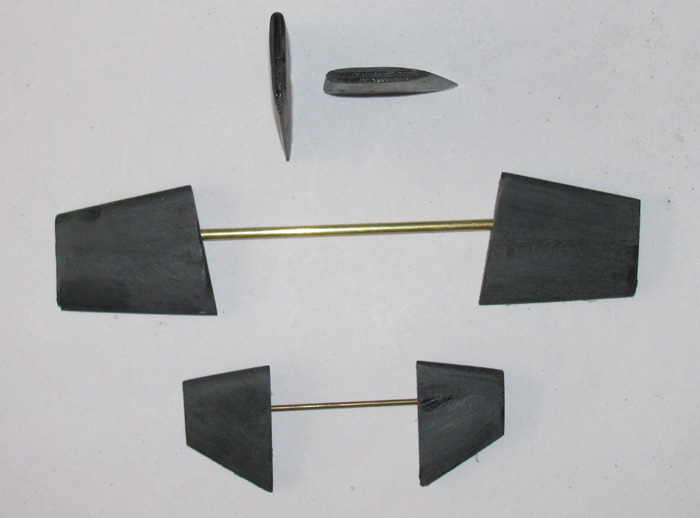

I'm looking for someone who is skilled in creating molds and casting resin appendages for a sub. I have two Thor 1/6 Sturgeon hulls but only one set of parts. I would need everything reproduced except for the prop. Picture below. If you are interested, email me directly at eckloss@mac.com with your bid.

-erich

I'm looking for someone who is skilled in creating molds and casting resin appendages for a sub. I have two Thor 1/6 Sturgeon hulls but only one set of parts. I would need everything reproduced except for the prop. Picture below. If you are interested, email me directly at eckloss@mac.com with your bid.

-erich

Comment