I am new to the world of subs and ABS plastic hulls...but I do have over 25 years building nitro and Fast Electric wood and fiberglass hulls so I am familiar with boat modeling.

In general what type and viscosity CA should I be using for the various ABS joints?

My biggest concern is that we never used CA for our race boats as it is not waterproof only used epoxy and glass resins.

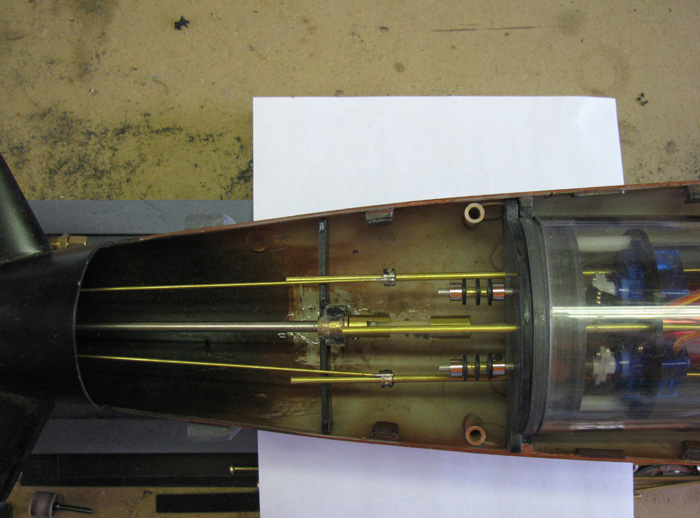

I also noticed that the pushrod ends had magnets CA'd on them to connect from the WTC to the links for the control surfaces. Again the CA is in general not waterproof. Is that blue fuel tubing I see in the photos supposed to slide over the magnets holding the two ends together or am I missing something?

The photos are not very clear.

Second question is on finishing and painting the outer (wet) hull.

I saw in one of the build threads he was using glazing then sanding & priming.

What type of "glazing" works best on ABS plastic?

What type of primer?

What type of paint?

I know, these are pretty basic questions but I want to get it right the first time.

Thanks for your help.

Pete

In general what type and viscosity CA should I be using for the various ABS joints?

My biggest concern is that we never used CA for our race boats as it is not waterproof only used epoxy and glass resins.

I also noticed that the pushrod ends had magnets CA'd on them to connect from the WTC to the links for the control surfaces. Again the CA is in general not waterproof. Is that blue fuel tubing I see in the photos supposed to slide over the magnets holding the two ends together or am I missing something?

The photos are not very clear.

Second question is on finishing and painting the outer (wet) hull.

I saw in one of the build threads he was using glazing then sanding & priming.

What type of "glazing" works best on ABS plastic?

What type of primer?

What type of paint?

I know, these are pretty basic questions but I want to get it right the first time.

Thanks for your help.

Pete

Comment