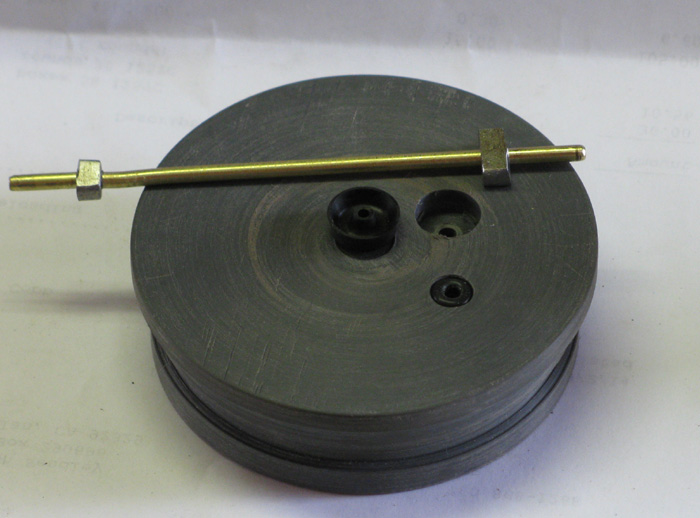

Can somebody please advise if anybody else can outsource this part other than Dave Meriman ? See pic.

I tried to get it from him (long story), he promised to ship it two weeks ago under warranty, and still haven’t got it. I tried to email him, call him, no response, nothing. I even kindly sent him an email offering to pay for it and shipping as well (Priority Mail or next day), no response at all whatsoever. Sorry to say but his customer service really sucks.

Please, help, I was looking forward to run my boat this weekend but I guess that will be a futile endeavor.

Much appreciated.

I tried to get it from him (long story), he promised to ship it two weeks ago under warranty, and still haven’t got it. I tried to email him, call him, no response, nothing. I even kindly sent him an email offering to pay for it and shipping as well (Priority Mail or next day), no response at all whatsoever. Sorry to say but his customer service really sucks.

Please, help, I was looking forward to run my boat this weekend but I guess that will be a futile endeavor.

Much appreciated.

Comment