Fellow Sub Builders,

The current set-up on my Akula is via magnets, however in my own personal experience I've found it to be unreliable, not "rock solid" functioning - in two ocassions I've been lucky I had the boat on the surface and close to "shore" to be able to rescue it, only to discover upon inspection the magnets were disconnected from one another, not a good thing. A big risk to my investment. So, I've decided to go a different route, perhaps not as quick-release as the magnets but definitely will be much

more safe and secure. I know some of you swear by the magnets but unfortunately this hasn't been my experience.

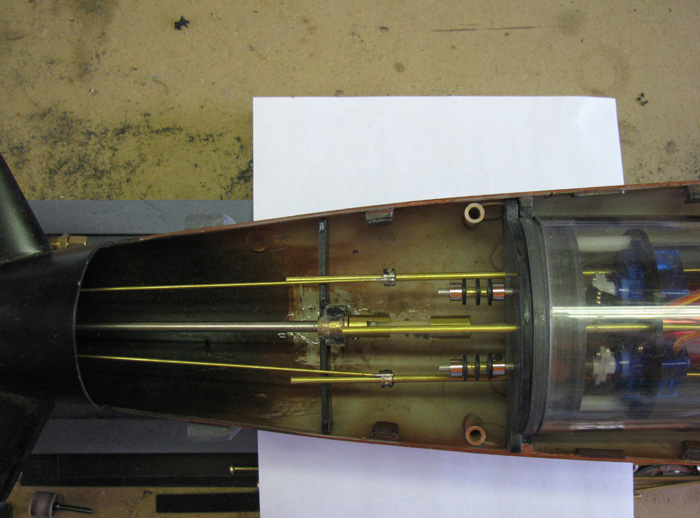

Can you advise which would be a better set-up, either via clevices or ball-links? and if so, how would you set it up, I'm just looking for ideas as I don't intend to reinvent the wheel.

I'll appreciate your comments in advance,

Thanks,

Corsaire

The current set-up on my Akula is via magnets, however in my own personal experience I've found it to be unreliable, not "rock solid" functioning - in two ocassions I've been lucky I had the boat on the surface and close to "shore" to be able to rescue it, only to discover upon inspection the magnets were disconnected from one another, not a good thing. A big risk to my investment. So, I've decided to go a different route, perhaps not as quick-release as the magnets but definitely will be much

more safe and secure. I know some of you swear by the magnets but unfortunately this hasn't been my experience.

Can you advise which would be a better set-up, either via clevices or ball-links? and if so, how would you set it up, I'm just looking for ideas as I don't intend to reinvent the wheel.

I'll appreciate your comments in advance,

Thanks,

Corsaire

Comment