Anyone 3d print their submarine ?

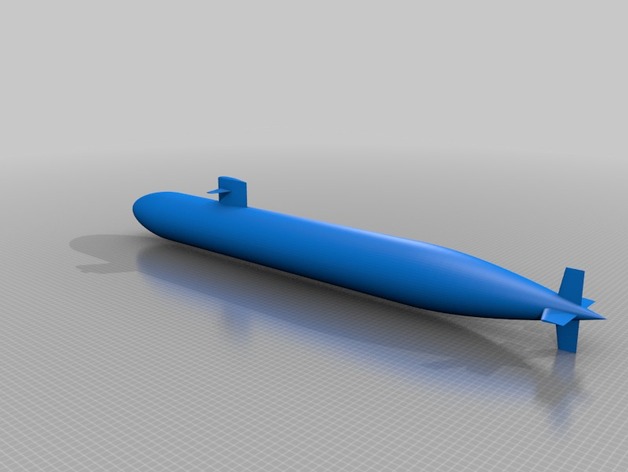

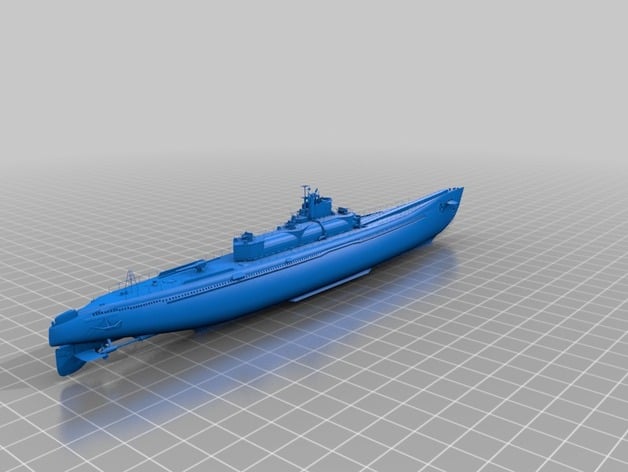

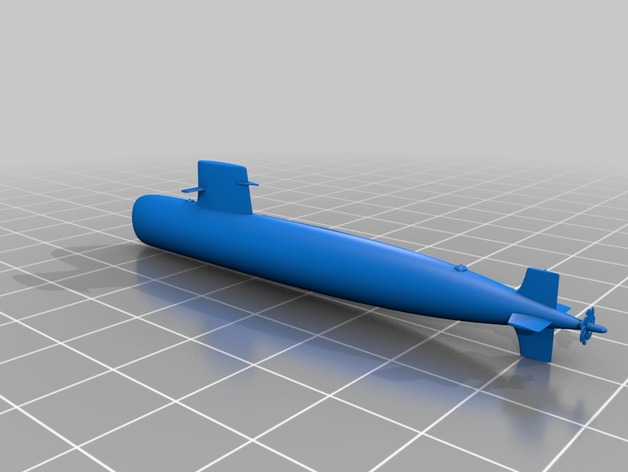

There seems to be a lot of 3d models of submarines out there, that can be modified for RC use. Seems like an "easy" way to get a nice scale submarine outline.

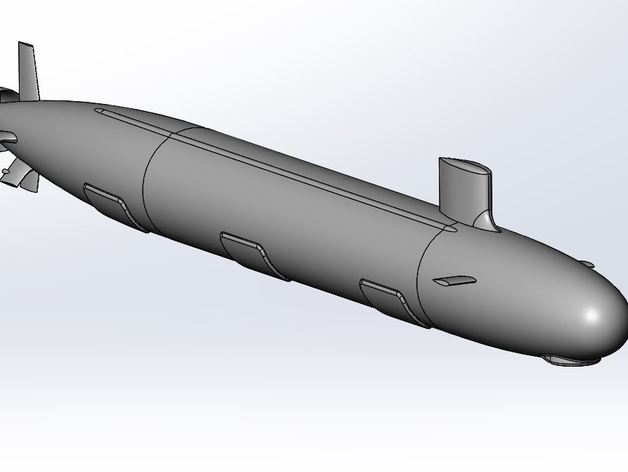

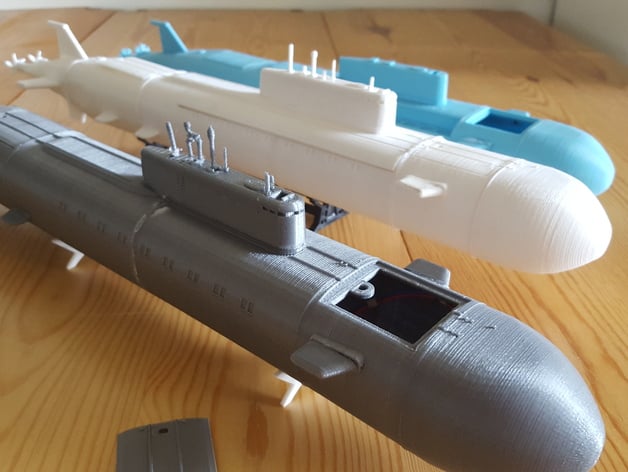

This LA class Flight I , is printed in ABS. PLA plastic would be just as good I imagine ?

How thick a hull would be best in plastic ? 4mm ?

I was thinking of making a PVC sewer pipe WTC for it.

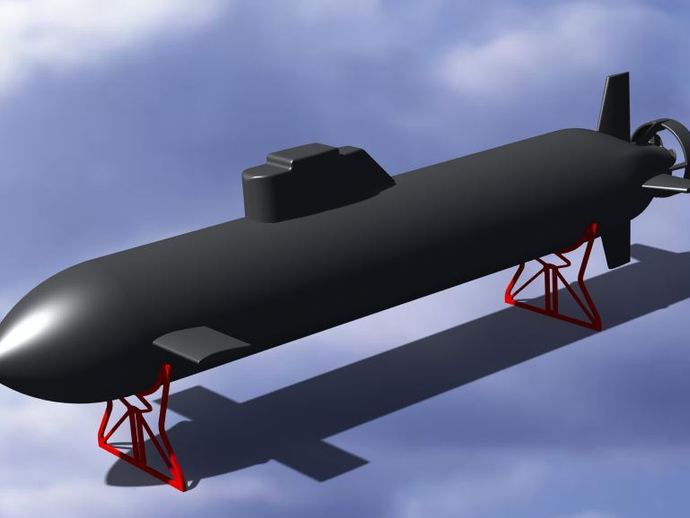

There seems to be a lot of 3d models of submarines out there, that can be modified for RC use. Seems like an "easy" way to get a nice scale submarine outline.

This LA class Flight I , is printed in ABS. PLA plastic would be just as good I imagine ?

How thick a hull would be best in plastic ? 4mm ?

I was thinking of making a PVC sewer pipe WTC for it.

Comment