For several years I've been researching this boat to build a display model. Why this boat? Well, my name is William Rogers but at the US Merchant Marine Academy my knick name was "Will" Rogers. I worked a few years at sea as a marine engineer so I know my way around ships and engine rooms. But after visiting the USS Redfin in Baltimore many years ago, I was hooked on subs as a hobby. Since then I’ve built several RC and display models but my goal has long been to model the "Willy R" as she was known to many. The plan is to build in 1:120 scale and represent as accurately as possible the detail I've researched. This will include such things as main ballast tank flood holes, main and aux seawater suctions and discharges, secondary propulsion motor and a host of other goodies.

Since I don't have a lathe, I decided to use pink foam as the hull reinforced by 1/4" all thread stock as the centerline axis. I'm using a drill press, bandsaw, sander, dremel, and several other hand tools. So, here we go.

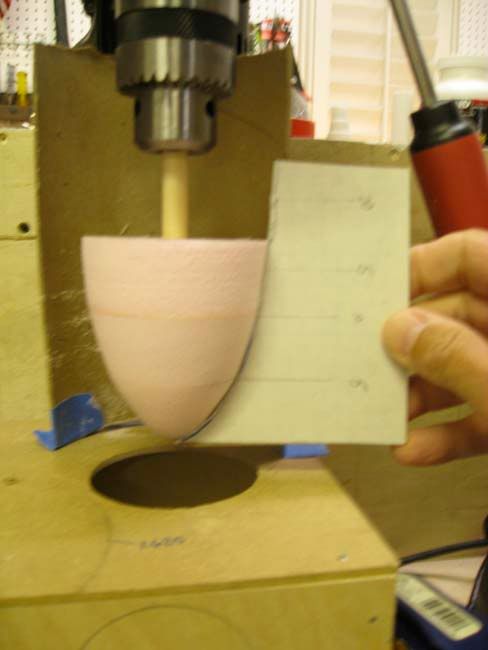

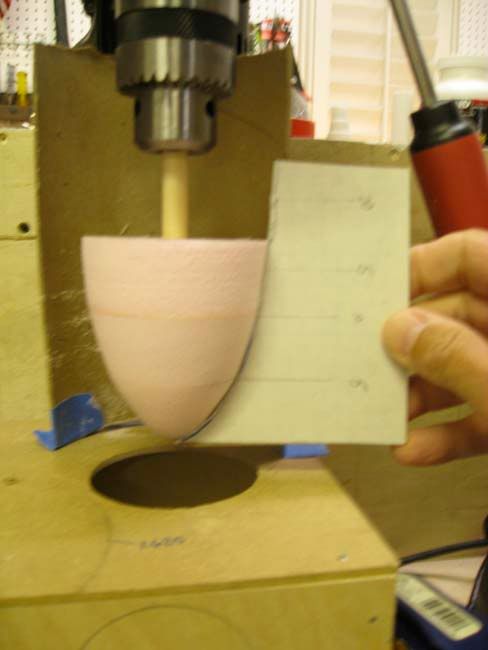

The first picture is of my dust collector box set up at the drill press and connected to my shop vac.

Three rough circles of foam were glued together and mounted on the mandel for "turning" on the drill press using various grades of sandpaper glued to tongue depressors as the cutting tool.

This was the first attempt at shaping the bow. Note that I used a wooden dowel instead on the mandrel. After a few failed attempts to shape the bow in foam I switched to balsa for the final. The pink foam didn't hold up that well at the bow.

For smoothing the hull I cut a mailing tube in half, glued sandpaper to the inside and used it to sand the wallboard joint compound after it dried.

This is the hull nearing completion of the first step. Later I fiberglassed over the hull to add strength.

"Will" Rogers

SSSBN659

Since I don't have a lathe, I decided to use pink foam as the hull reinforced by 1/4" all thread stock as the centerline axis. I'm using a drill press, bandsaw, sander, dremel, and several other hand tools. So, here we go.

The first picture is of my dust collector box set up at the drill press and connected to my shop vac.

Three rough circles of foam were glued together and mounted on the mandel for "turning" on the drill press using various grades of sandpaper glued to tongue depressors as the cutting tool.

This was the first attempt at shaping the bow. Note that I used a wooden dowel instead on the mandrel. After a few failed attempts to shape the bow in foam I switched to balsa for the final. The pink foam didn't hold up that well at the bow.

For smoothing the hull I cut a mailing tube in half, glued sandpaper to the inside and used it to sand the wallboard joint compound after it dried.

This is the hull nearing completion of the first step. Later I fiberglassed over the hull to add strength.

"Will" Rogers

SSSBN659

Comment