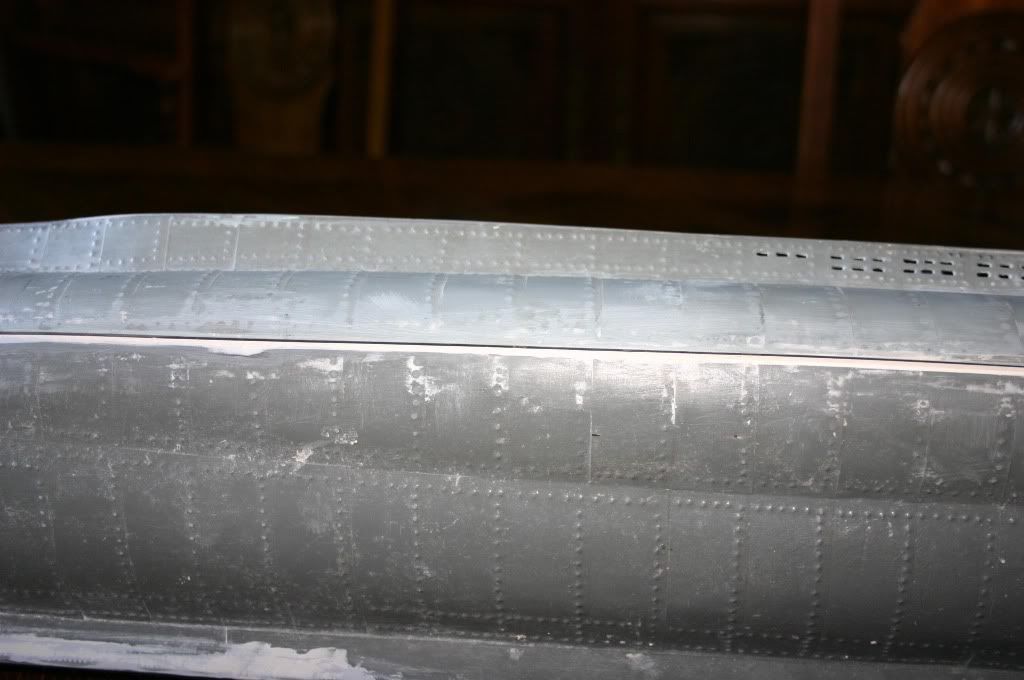

My Sheerline type VII has just come to the top of my 'get opn and do 'list. It got shelved cos I was having troubles minimising the gap, when joined, of the two halves of the hull.

So come on someone how the hell do | fill the gap?

I have tried all sorts. I tried cellotape on one half of the joint joining the two halves making secure and then putting filler in the gap. It worked!!! but taking the two halves apart and taking the tape of the gap magically reappears. Grrrr

Now I am beginning to wonder if its something to do with the fact that the two halves are flexible ie easily flexed when squeezed.

So my next plan is to reinforce the the two haves by building frames from fibre glass matt.

Question anyone got any good ideas. Please.

Thanks Fred

So come on someone how the hell do | fill the gap?

I have tried all sorts. I tried cellotape on one half of the joint joining the two halves making secure and then putting filler in the gap. It worked!!! but taking the two halves apart and taking the tape of the gap magically reappears. Grrrr

Now I am beginning to wonder if its something to do with the fact that the two halves are flexible ie easily flexed when squeezed.

So my next plan is to reinforce the the two haves by building frames from fibre glass matt.

Question anyone got any good ideas. Please.

Thanks Fred

Comment