Re: MODELING THE USS WILL ROGERS

During the construction of my model I took a break to assemble a Tamiya model of the M-4 Sherman tank for a neighbor. It was a welcome break from sanding and shaping but I have to say that building from scratch is a lot more satisfying than assembling a model from a kit. So now back to the USS Will Rogers.

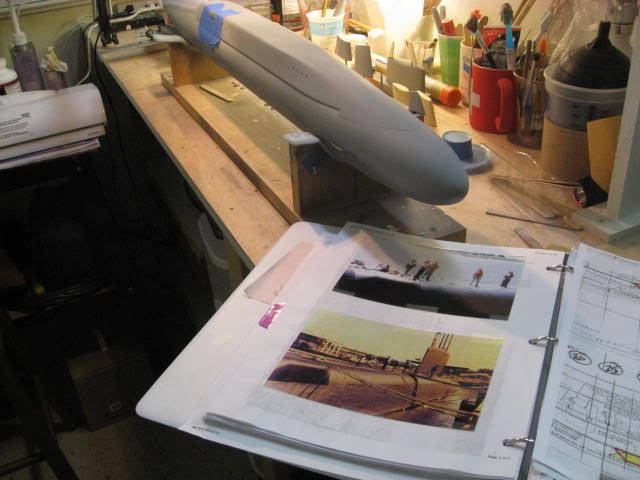

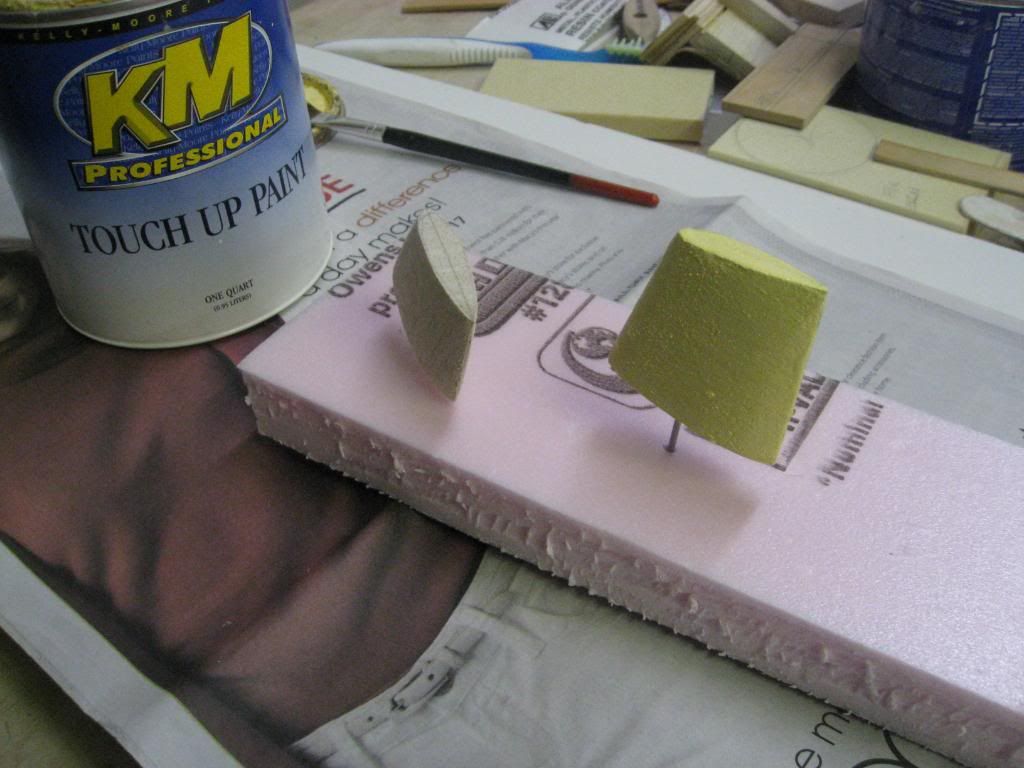

Here’s the hull and superstructure almost complete. There is some touch up work needed but that will come later. The strange looking pieces on the bench next to the hull are not for the submarine. They were for the M-4 Sherman.

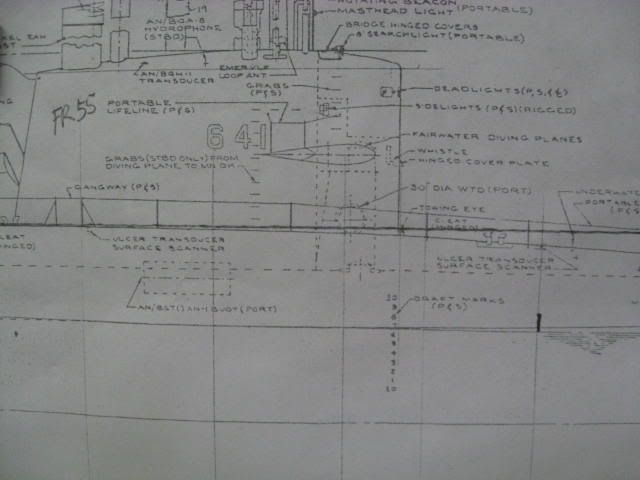

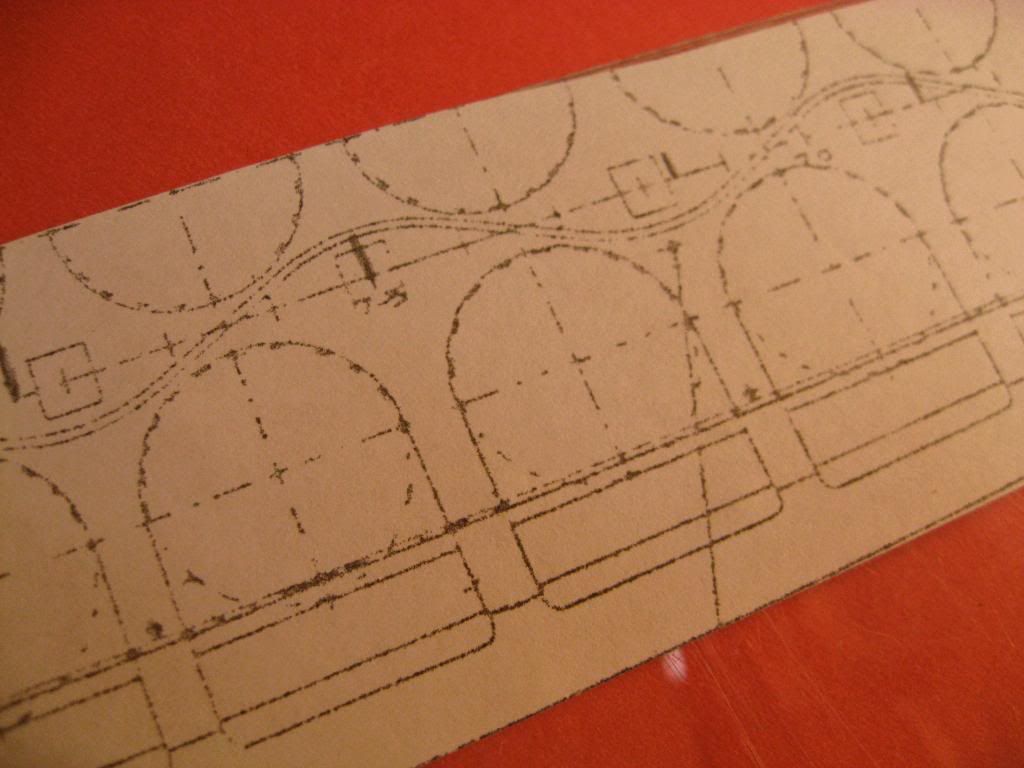

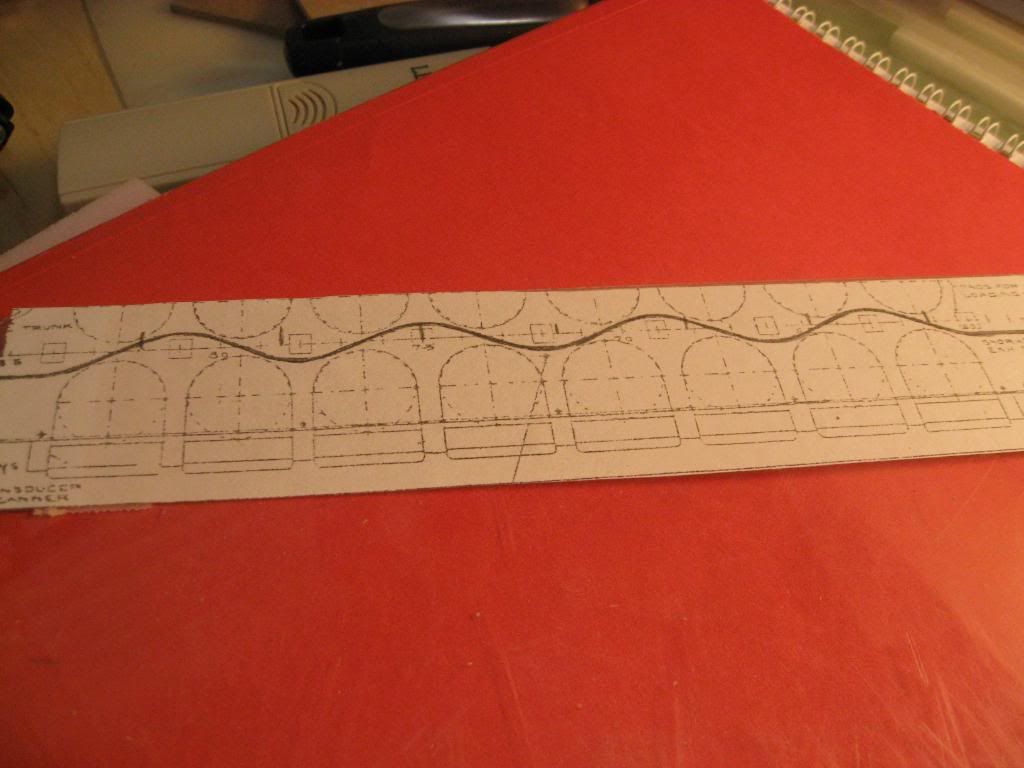

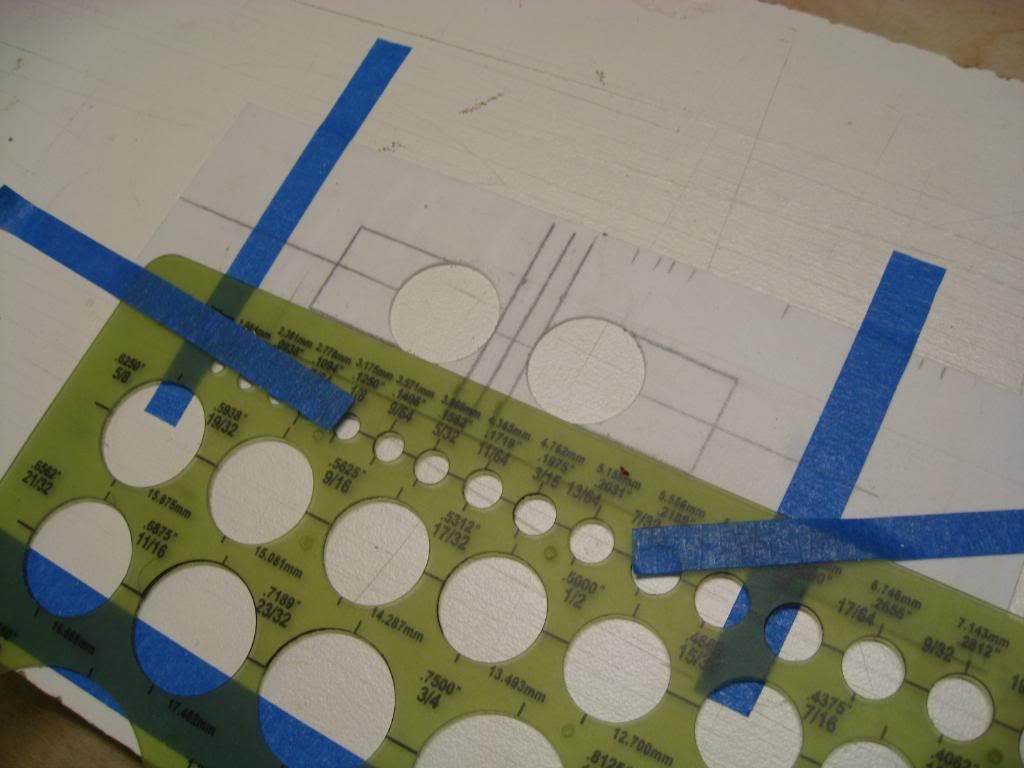

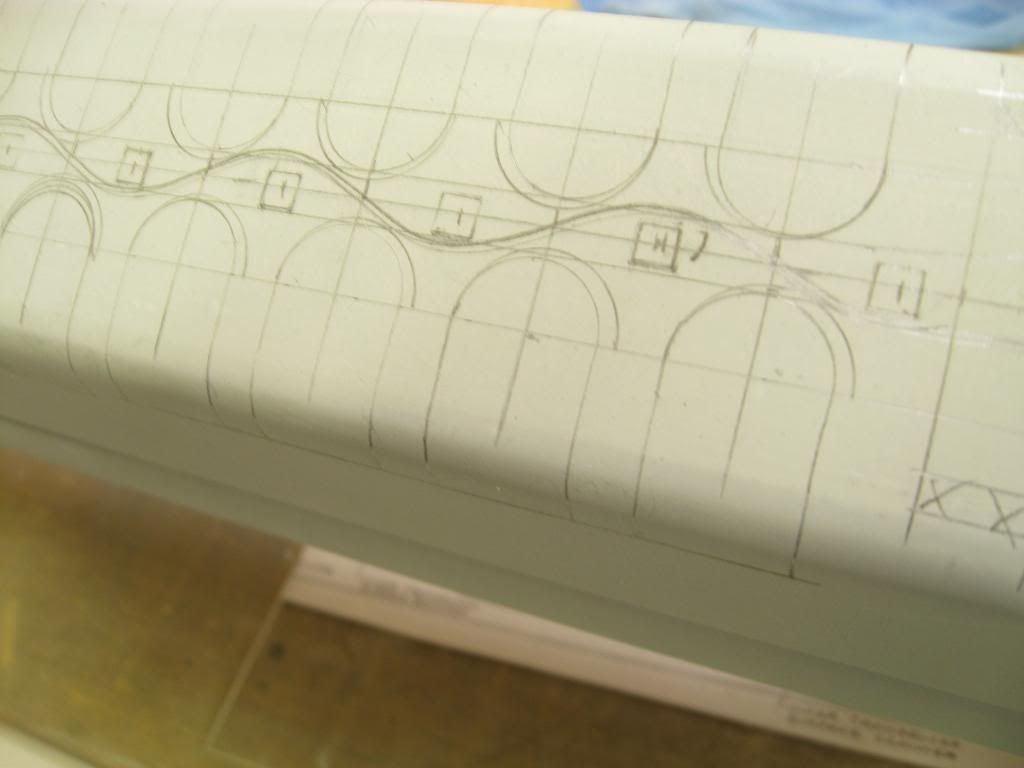

My research of the Forty-One For Freedom turned up several pictures that are invaluable in building my model. Since the basic shape of the Lafayette and Benjamin Franklin Class boats is the same in most cases it was easy to get photos of details I wanted to represent. In many ways the photos are even more help than the set of drawings I found because they depict shape, color, contrast, etc.

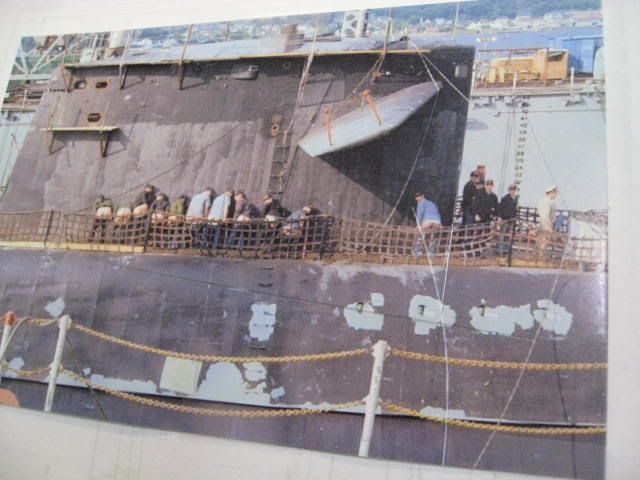

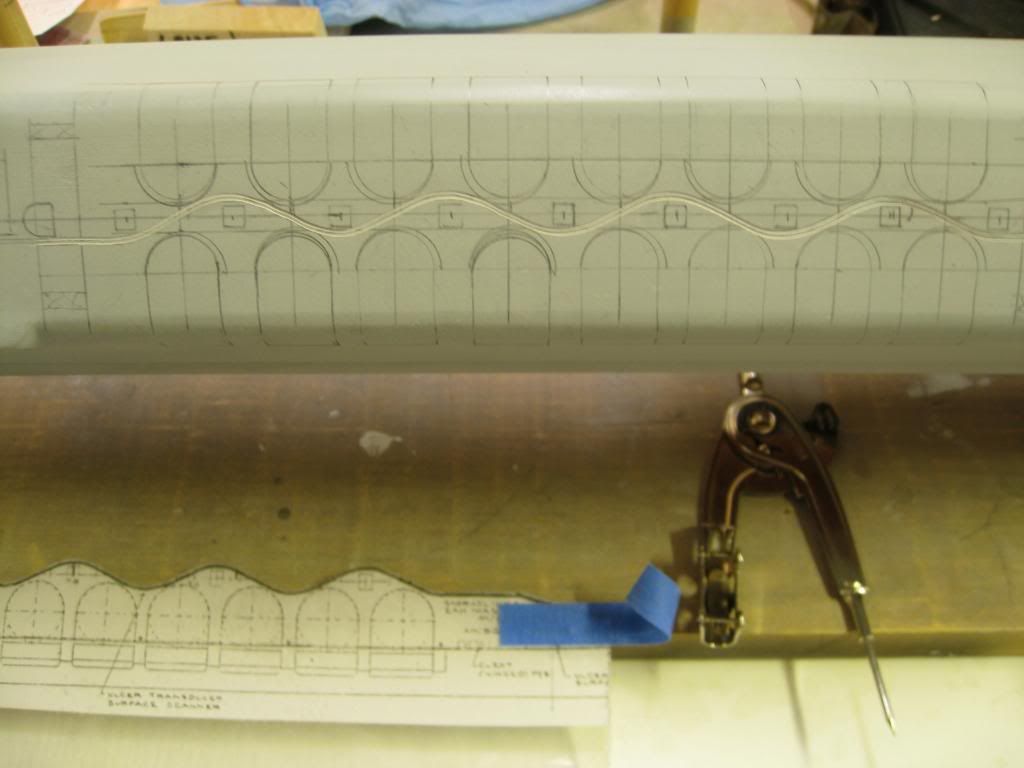

My next step was to tackle the BQR-15 Towed Array as depicted in the following two photos. Interestingly, I found pictures of SSBN 619 with a towed array and one of 629 without one. Go figure that one out. Anyway, I was able to confirm that Will Rogers had one. Note the detail these photos provide.

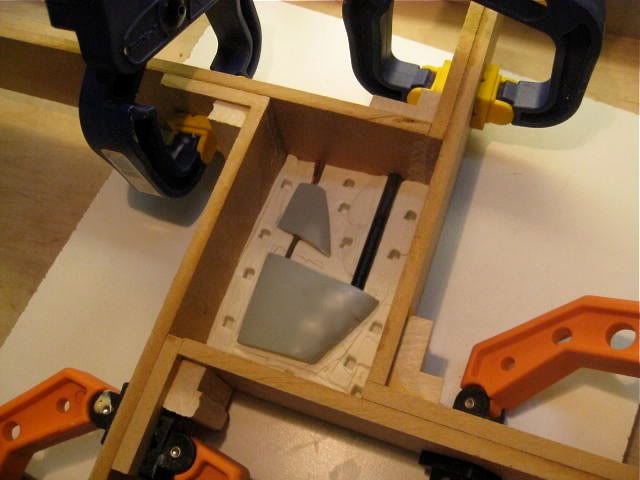

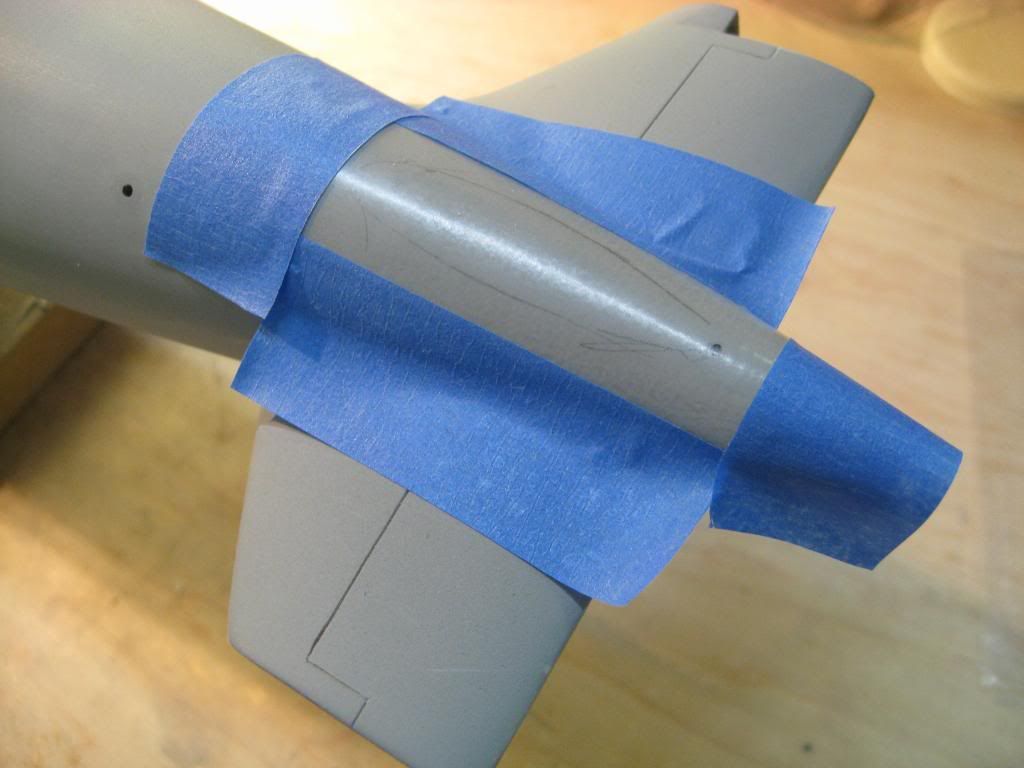

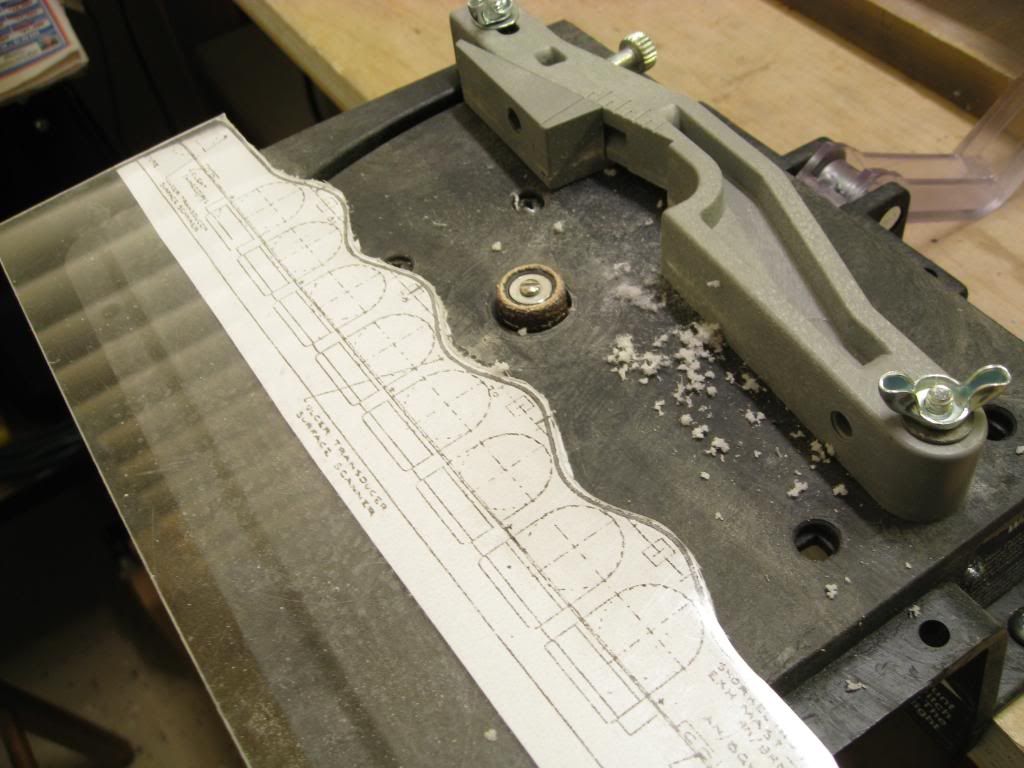

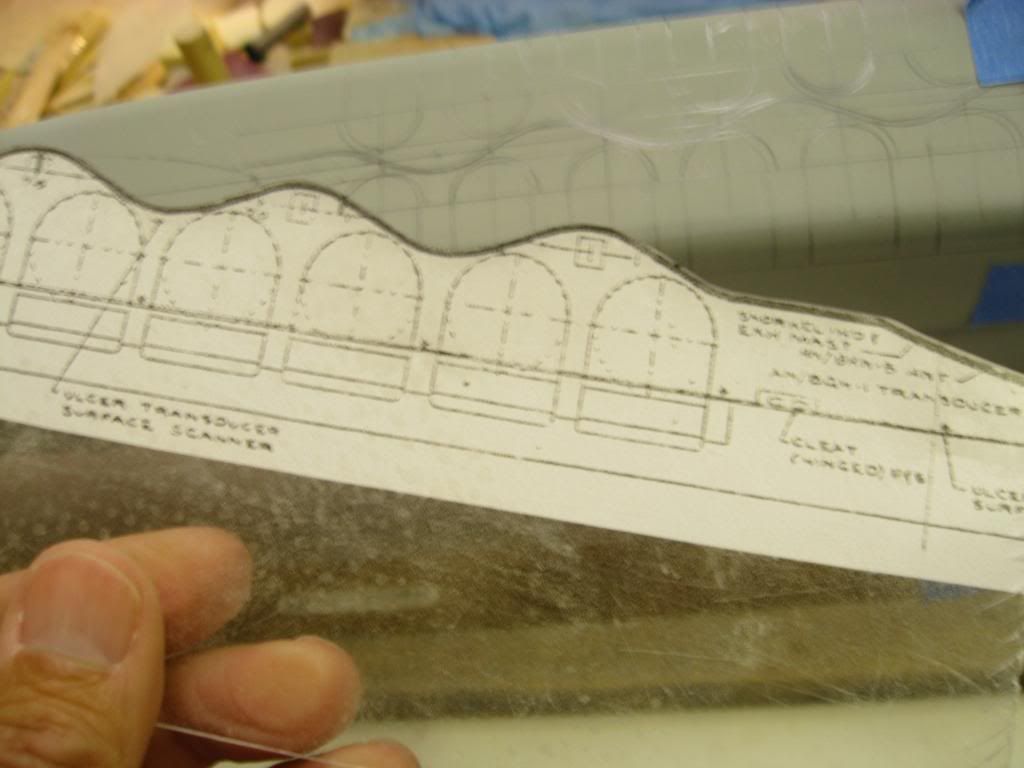

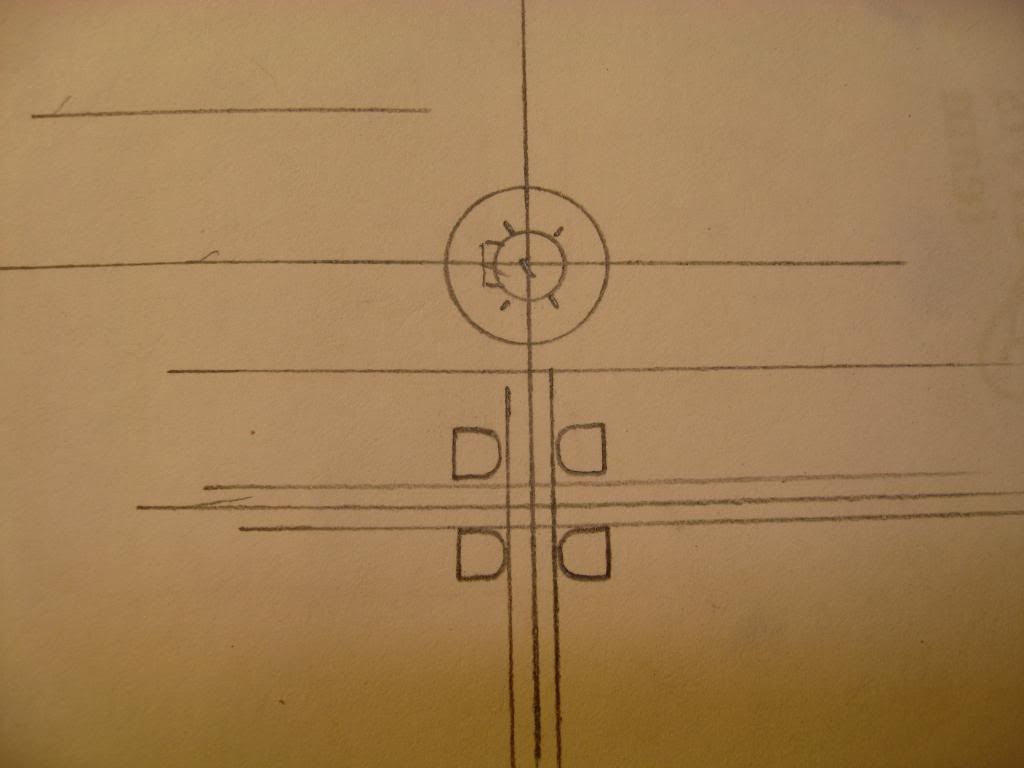

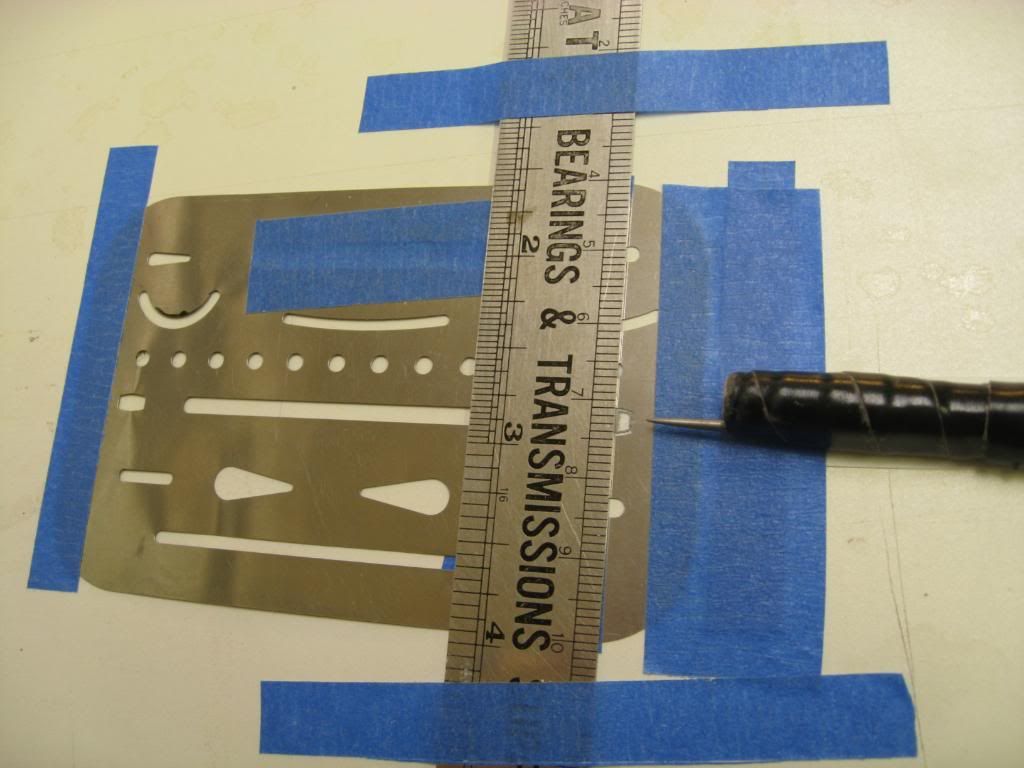

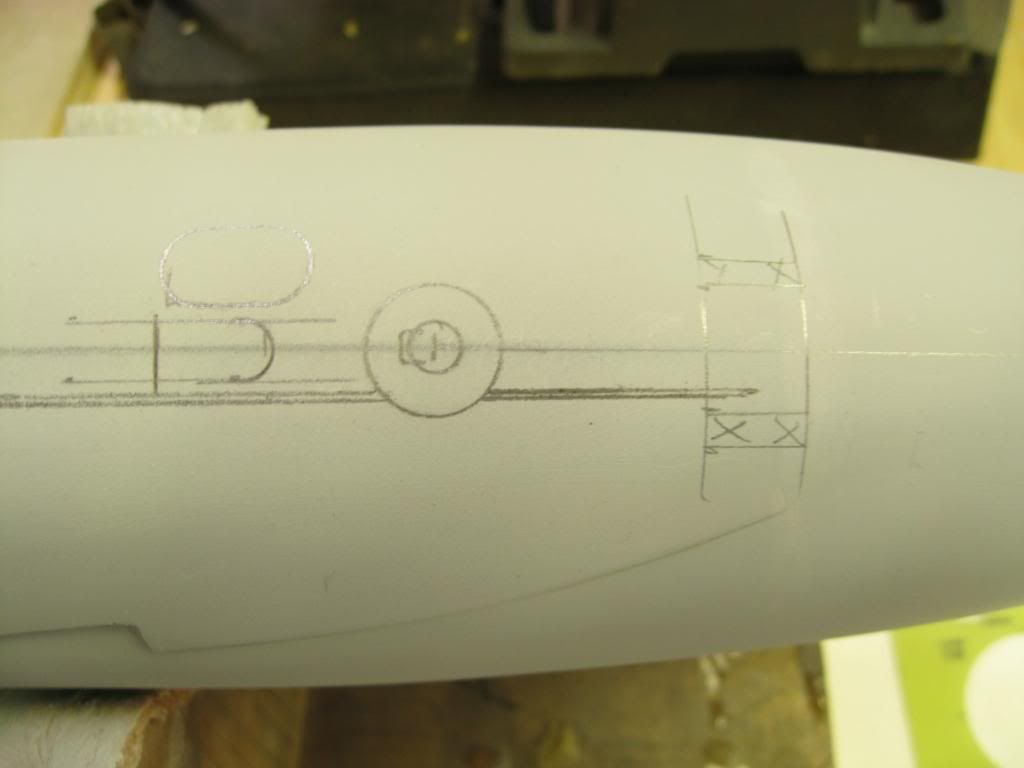

From the drawings and photos I drew an outline of the array fairing on the hull and then taped it. Using the polyester filler I built up a rough shape. I tried using a screed made from a used iTunes card with a semi-circular notch cut in the side. This didn’t work out very well so I finally “troweled†on the filler using the flat edge of the card.

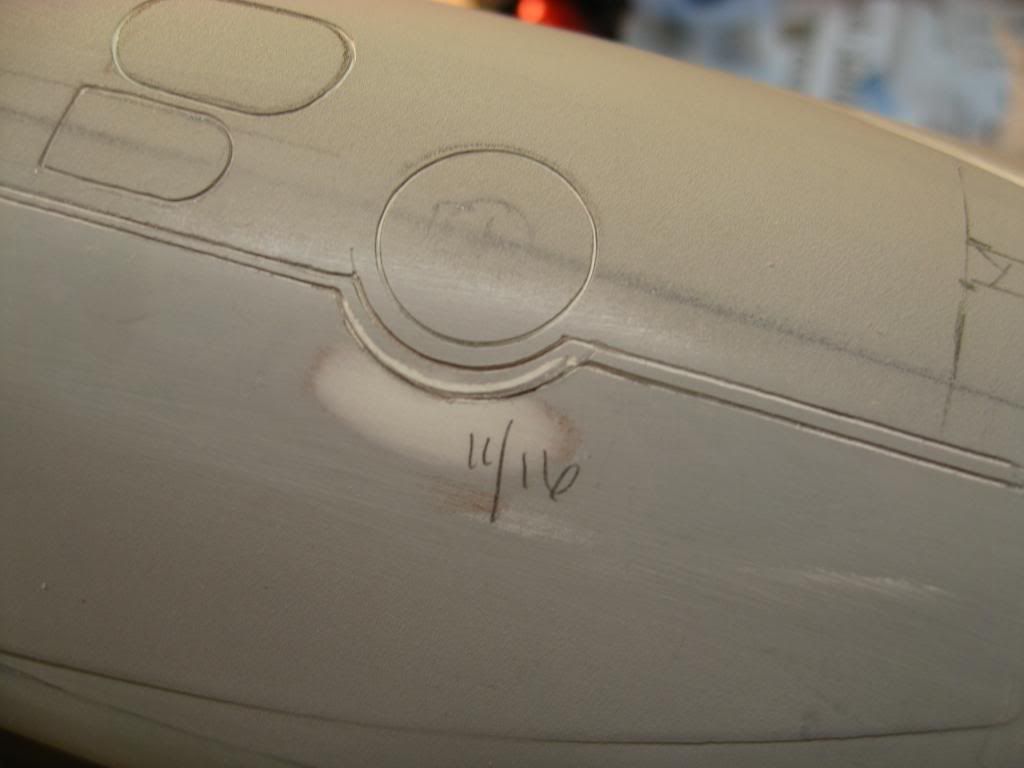

After sanding and shaping the array began to look pretty good compared to the photos.

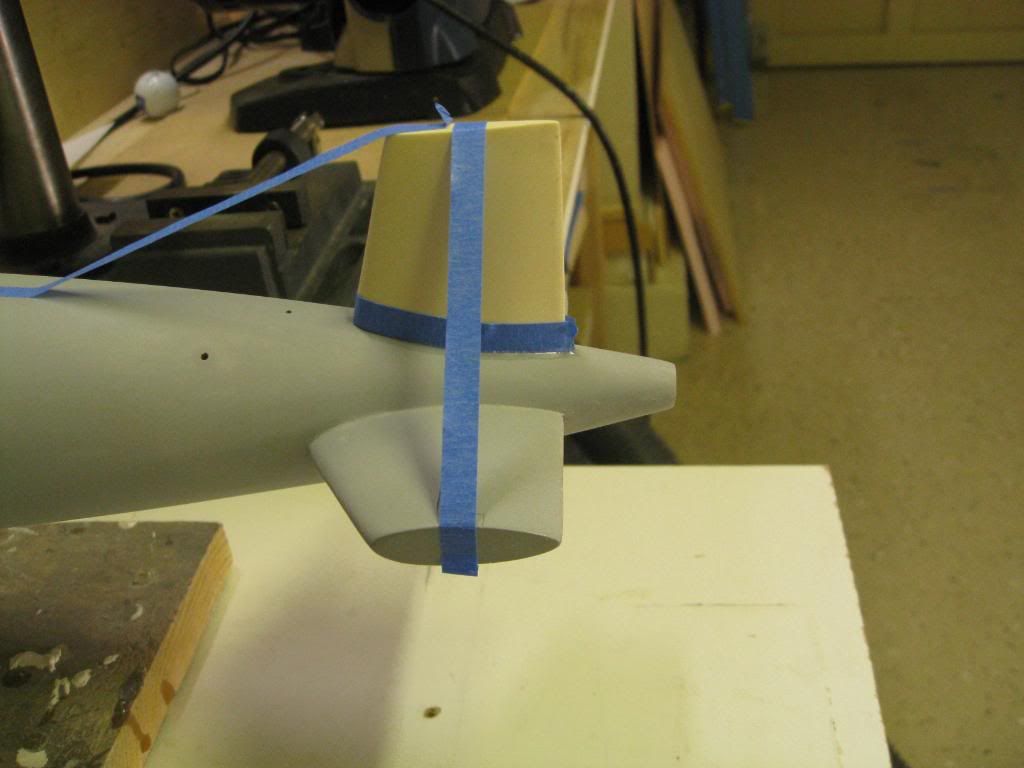

When it looked like I thought it should I pulled the last of the tape away from the filler to reveal a sharp edge depicting where the fairing intersected the hull. There were several holidays that needed filling but that was easily corrected.

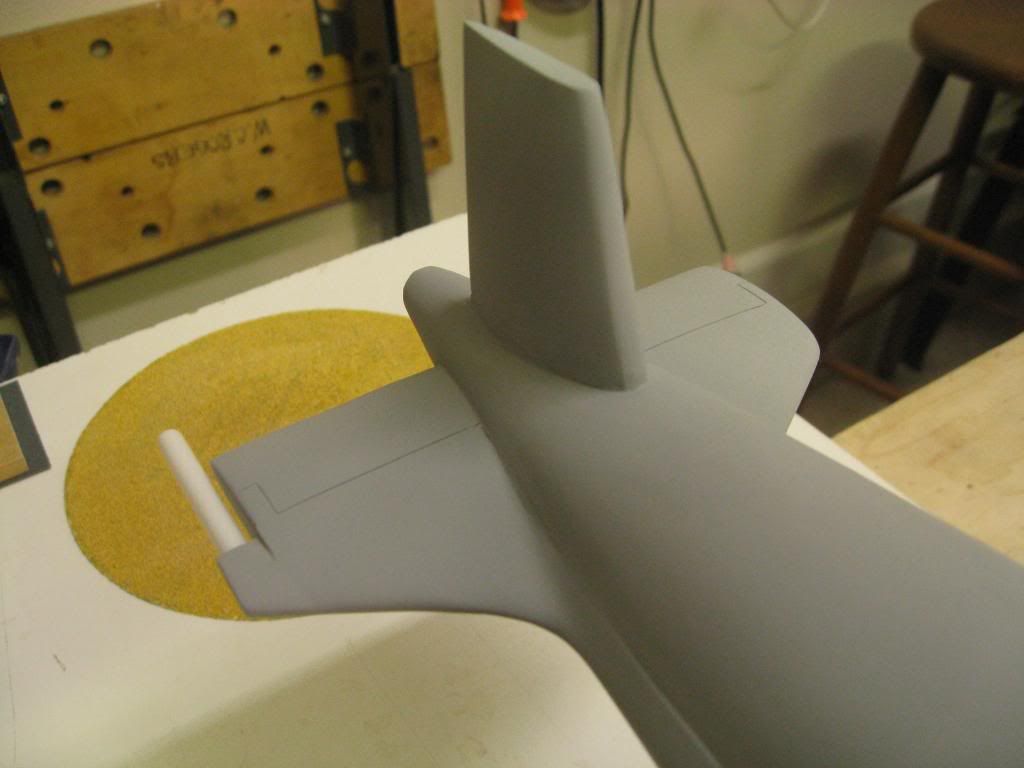

I’ll have more later on the problems I had with the intersection of several compound curves where the fairing, the hull and the superstructure meet. That was a real challenge.

“Will†Rogers

SSBN659

During the construction of my model I took a break to assemble a Tamiya model of the M-4 Sherman tank for a neighbor. It was a welcome break from sanding and shaping but I have to say that building from scratch is a lot more satisfying than assembling a model from a kit. So now back to the USS Will Rogers.

Here’s the hull and superstructure almost complete. There is some touch up work needed but that will come later. The strange looking pieces on the bench next to the hull are not for the submarine. They were for the M-4 Sherman.

My research of the Forty-One For Freedom turned up several pictures that are invaluable in building my model. Since the basic shape of the Lafayette and Benjamin Franklin Class boats is the same in most cases it was easy to get photos of details I wanted to represent. In many ways the photos are even more help than the set of drawings I found because they depict shape, color, contrast, etc.

My next step was to tackle the BQR-15 Towed Array as depicted in the following two photos. Interestingly, I found pictures of SSBN 619 with a towed array and one of 629 without one. Go figure that one out. Anyway, I was able to confirm that Will Rogers had one. Note the detail these photos provide.

From the drawings and photos I drew an outline of the array fairing on the hull and then taped it. Using the polyester filler I built up a rough shape. I tried using a screed made from a used iTunes card with a semi-circular notch cut in the side. This didn’t work out very well so I finally “troweled†on the filler using the flat edge of the card.

After sanding and shaping the array began to look pretty good compared to the photos.

When it looked like I thought it should I pulled the last of the tape away from the filler to reveal a sharp edge depicting where the fairing intersected the hull. There were several holidays that needed filling but that was easily corrected.

I’ll have more later on the problems I had with the intersection of several compound curves where the fairing, the hull and the superstructure meet. That was a real challenge.

“Will†Rogers

SSBN659

Comment