I still have a problem which is the only thing holding me up from getting ahead. I'm attaching pics to explain it better, it's about the upper and lower hull line-up.

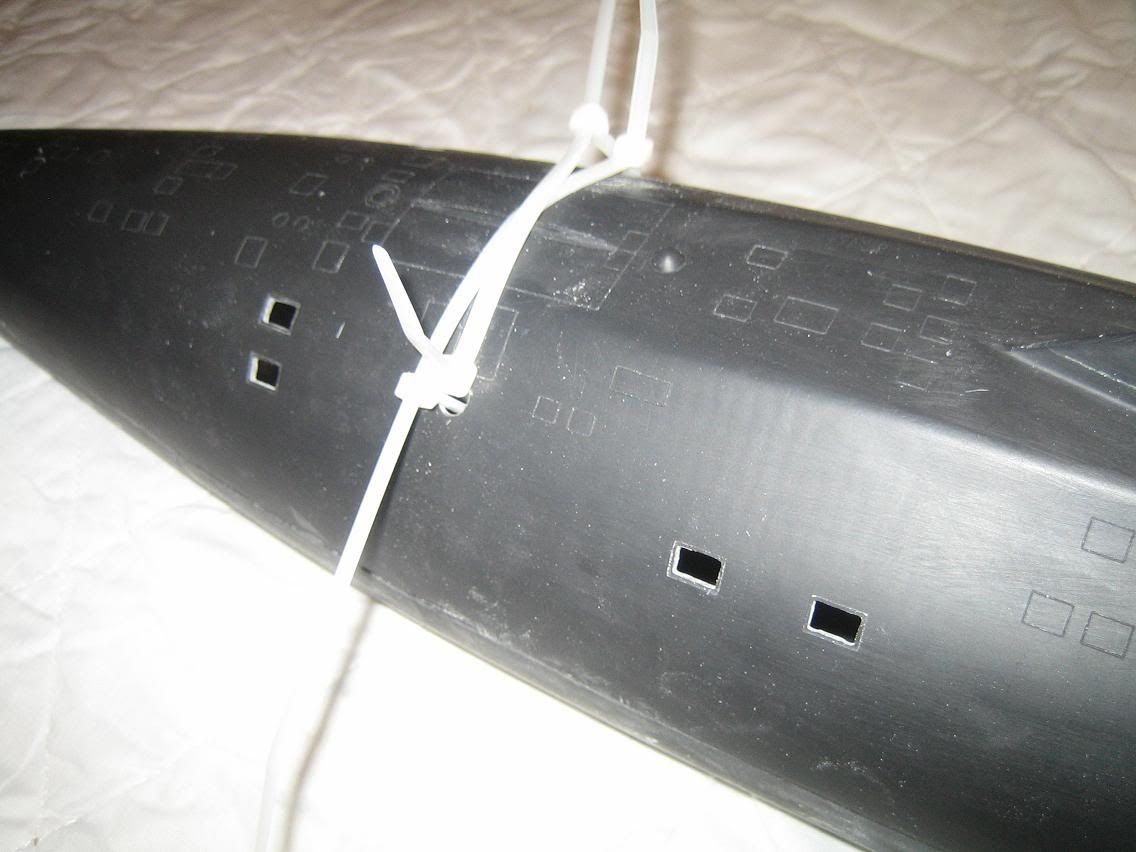

I made a FG lip on the upper hull to engage the already glued stern top piece. But the problem is this, as you can see in the pics there's a gap as the upper hull sits on the lower hull, everything else alongside the all around lip sits perfectly towards the bow, but if I try to engage the FG lip into the stern top piece it'll throw everything out of alignment, in other words the upper hull will overlap the lower hull at the seam line. I hope my explanation makes sense.

Even if I try to place the FG lip inside the stern top piece I'd still had the same problem!

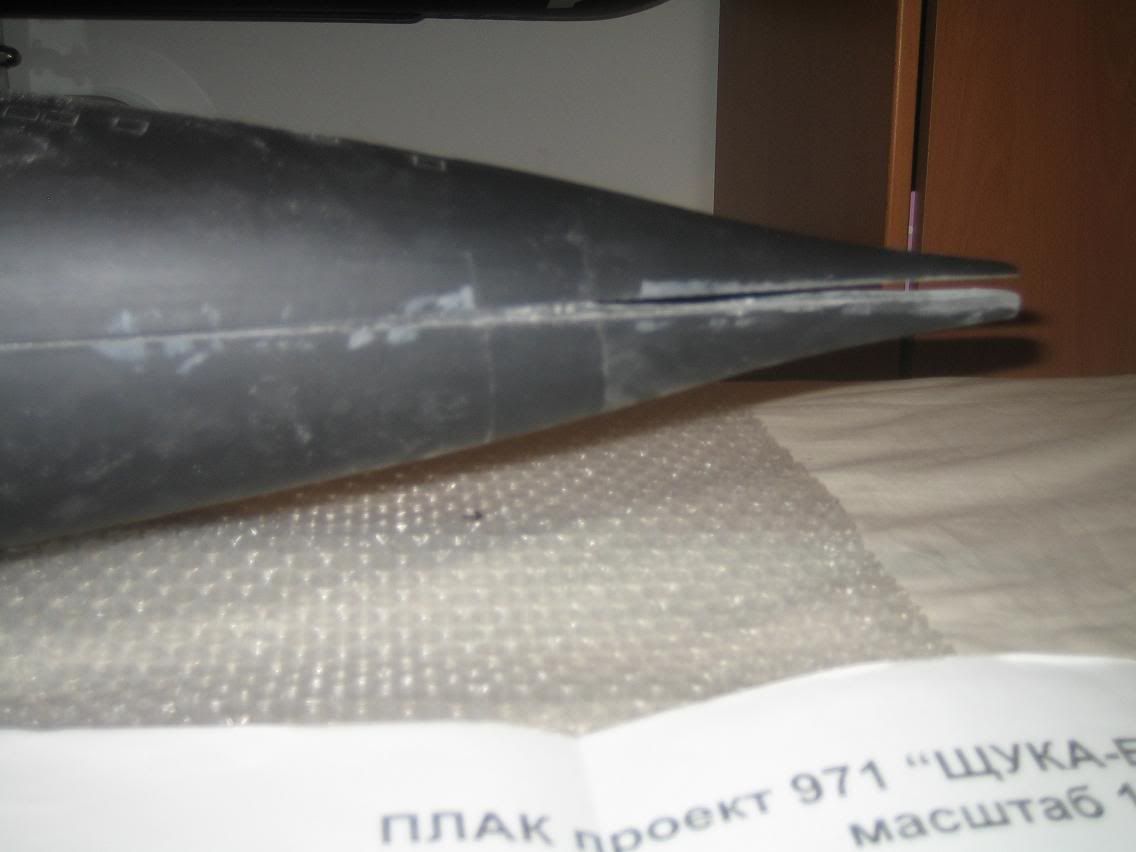

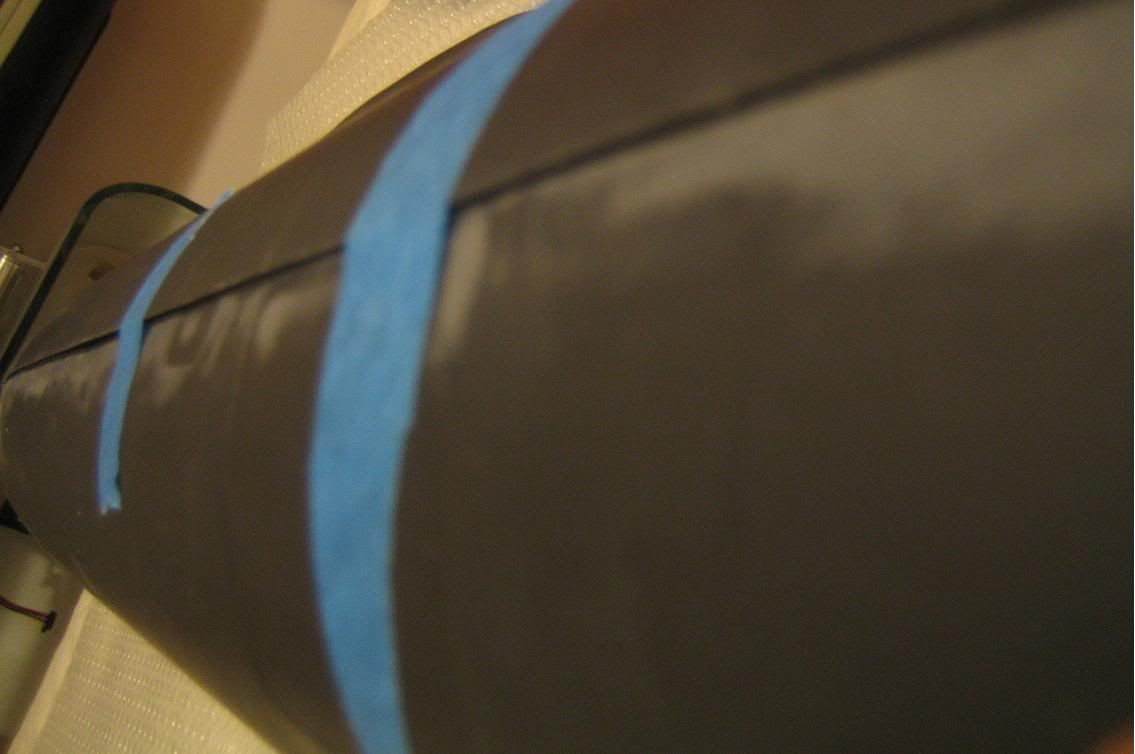

Pic # 28 shows the gap I'm talking about and # 29 the seam towards the bow which upper hull sits just fine over the lower one.

Thanks,

Brian

I made a FG lip on the upper hull to engage the already glued stern top piece. But the problem is this, as you can see in the pics there's a gap as the upper hull sits on the lower hull, everything else alongside the all around lip sits perfectly towards the bow, but if I try to engage the FG lip into the stern top piece it'll throw everything out of alignment, in other words the upper hull will overlap the lower hull at the seam line. I hope my explanation makes sense.

Even if I try to place the FG lip inside the stern top piece I'd still had the same problem!

Pic # 28 shows the gap I'm talking about and # 29 the seam towards the bow which upper hull sits just fine over the lower one.

Thanks,

Brian

Comment