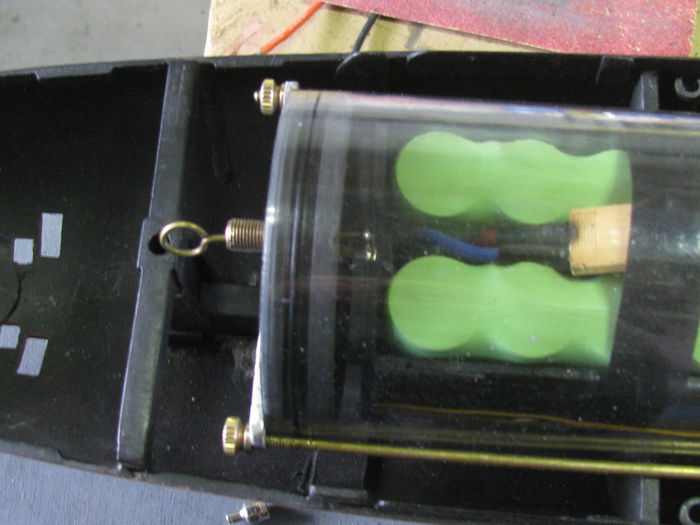

Hey guys. So i'm building a sub from scratch on my own. Its for the challenge and to keep me busy during covid. I have the electronics all done, and on a tray that fits my wtc.

But now i'm trying to make my WTC....WATER TIGHT! Here's where I am. I am using a ABS pipe. (yes I know acrylic clear is better but for my purposes this will have to do until I can justify the expense) Inside diameter is 76mm.

I could not find a O ring that was 76mm. But I do have one that is 3 inches. So about 76.2 mm.

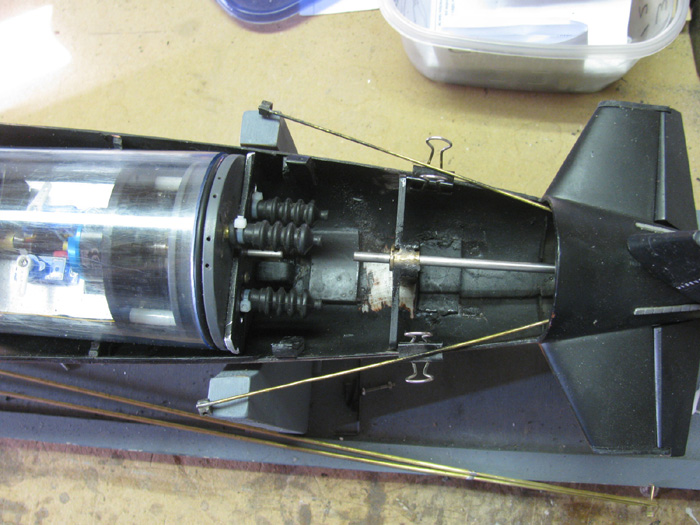

I am 3d printing most of the parts I need. While this has worked very well for the hull and everything else. The end caps are giving me trouble. I cannot seem to a good fit/seal. I have done about 6 or 7 attempts with okay seals. But nothing 100% water tight. I am always getting a bit of leaking. I can print caps that fit with a very high degree of precision. I even tried some outside the box thinking. Got some gasket sheet. And cut a collar around the cap and fit it. Had some seeping.

So here's where I'm at. Even though I'm printing at 100% infill the print may be porous. I have a way of sealing it. Which I will try when I'm off work next. (12 hour shift nurse...losing my mind right now).

I've also found that the o ring has a bit of play to it. I printed a cap that fits perfectly the 76mm. I was thinking rather than inside the tube to place it between end cap lip and lip of the cylinder and use the pressure of the threaded rods to stop water from entering. For this I'll work on the edges of the cylinder and make sure they are true and as smooth as possible.

I'm sure this is as clear as mud. But I'm at work and just trying to fire this off between tasks.

Any help/advice would be appreciated.

What steps am I missing? What am i doing wrong?

But now i'm trying to make my WTC....WATER TIGHT! Here's where I am. I am using a ABS pipe. (yes I know acrylic clear is better but for my purposes this will have to do until I can justify the expense) Inside diameter is 76mm.

I could not find a O ring that was 76mm. But I do have one that is 3 inches. So about 76.2 mm.

I am 3d printing most of the parts I need. While this has worked very well for the hull and everything else. The end caps are giving me trouble. I cannot seem to a good fit/seal. I have done about 6 or 7 attempts with okay seals. But nothing 100% water tight. I am always getting a bit of leaking. I can print caps that fit with a very high degree of precision. I even tried some outside the box thinking. Got some gasket sheet. And cut a collar around the cap and fit it. Had some seeping.

So here's where I'm at. Even though I'm printing at 100% infill the print may be porous. I have a way of sealing it. Which I will try when I'm off work next. (12 hour shift nurse...losing my mind right now).

I've also found that the o ring has a bit of play to it. I printed a cap that fits perfectly the 76mm. I was thinking rather than inside the tube to place it between end cap lip and lip of the cylinder and use the pressure of the threaded rods to stop water from entering. For this I'll work on the edges of the cylinder and make sure they are true and as smooth as possible.

I'm sure this is as clear as mud. But I'm at work and just trying to fire this off between tasks.

Any help/advice would be appreciated.

What steps am I missing? What am i doing wrong?

Comment