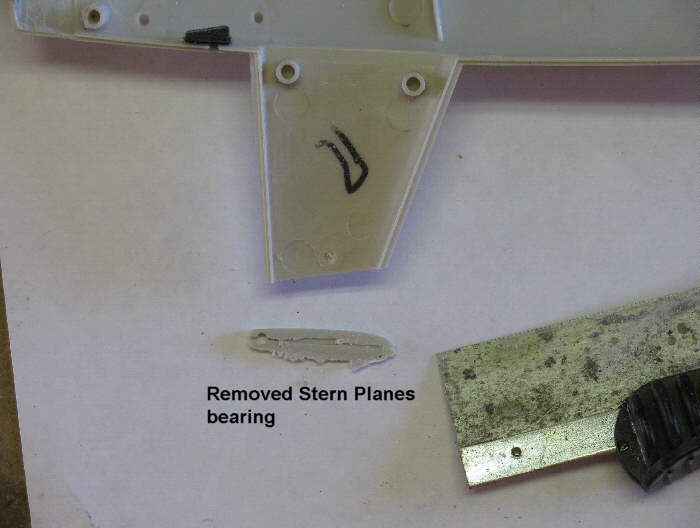

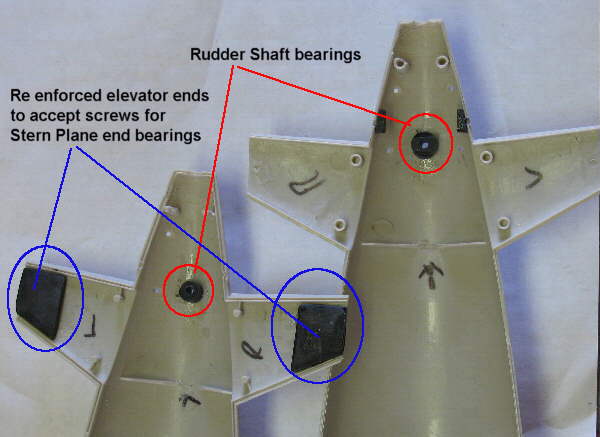

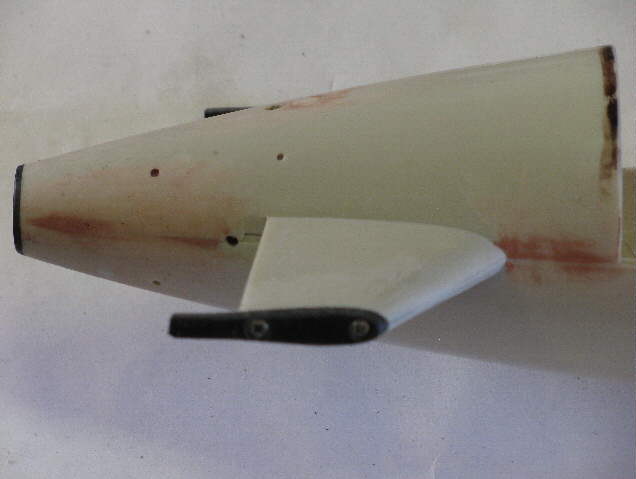

While assembling the rear diving plane, I stripped the hole that the 4-40 set screw goes into. Tom suggested putting CA in the hole and putting bar soap on the threads of the set screw. That worked on another part, but not this time. I've tried several times with no effect. Any other suggestions? I'm close to putting the whole kit on the shelf and going back to armor models.

Thx

Farlan

Thx

Farlan

Comment