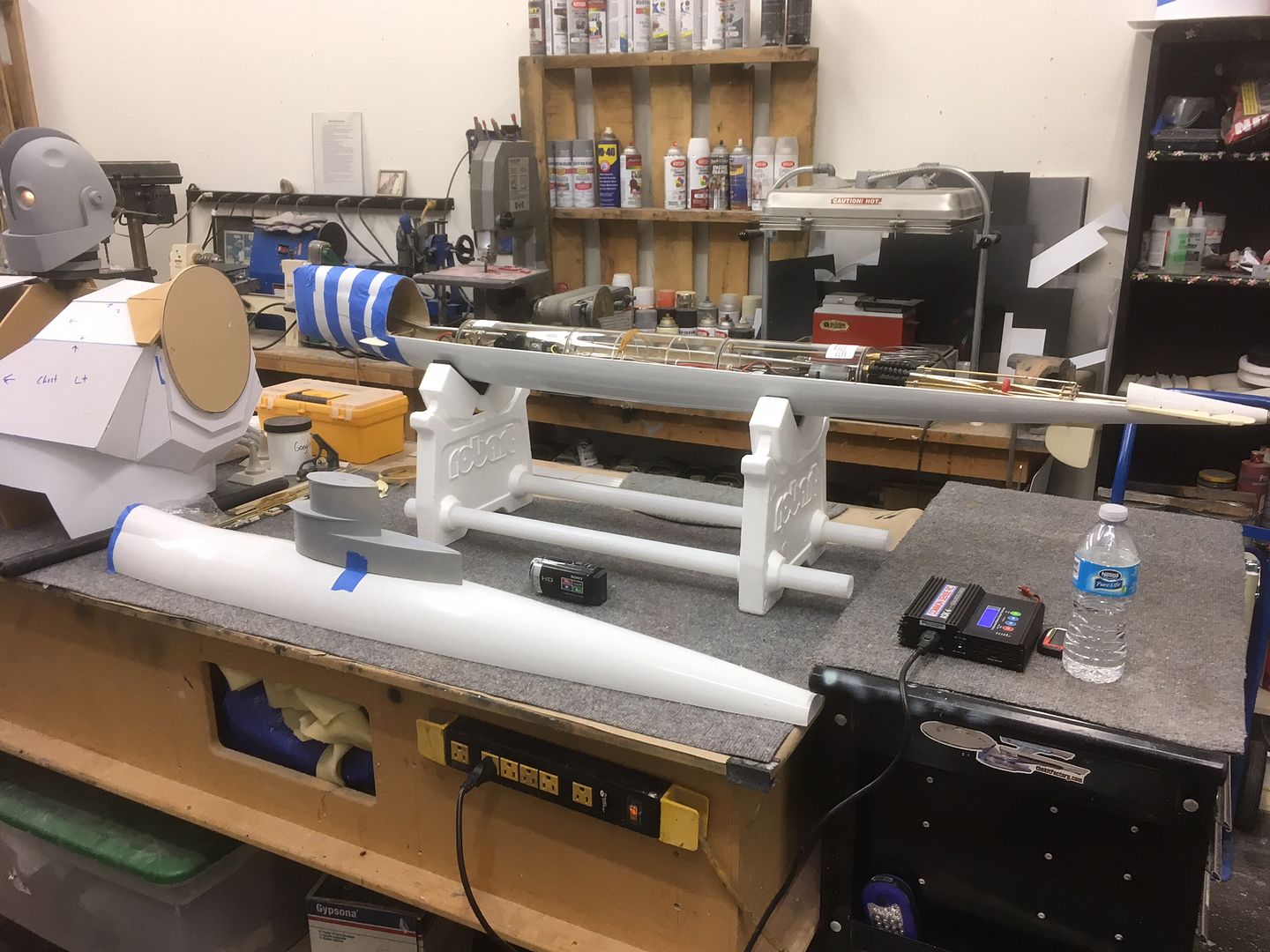

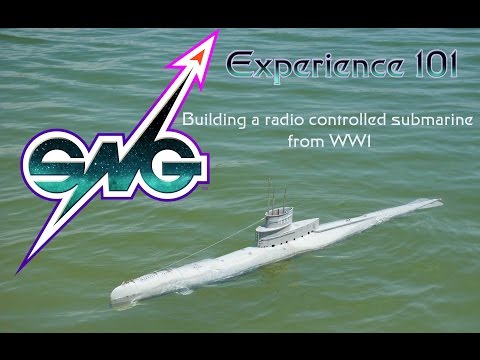

Yet another build for my client Steve Fisher of the R Class WW1 boat I built for myself awhile back. As usual another great kit from Bob Dimmack.

Made a nice beefy prop shaft support and mounted the rudder bearings using Dental Acrylic. Highly strong and very water proof this acrylic sets up hard as a rock in minutes. Been using it for years in my movie industry work works perfect for boats too.

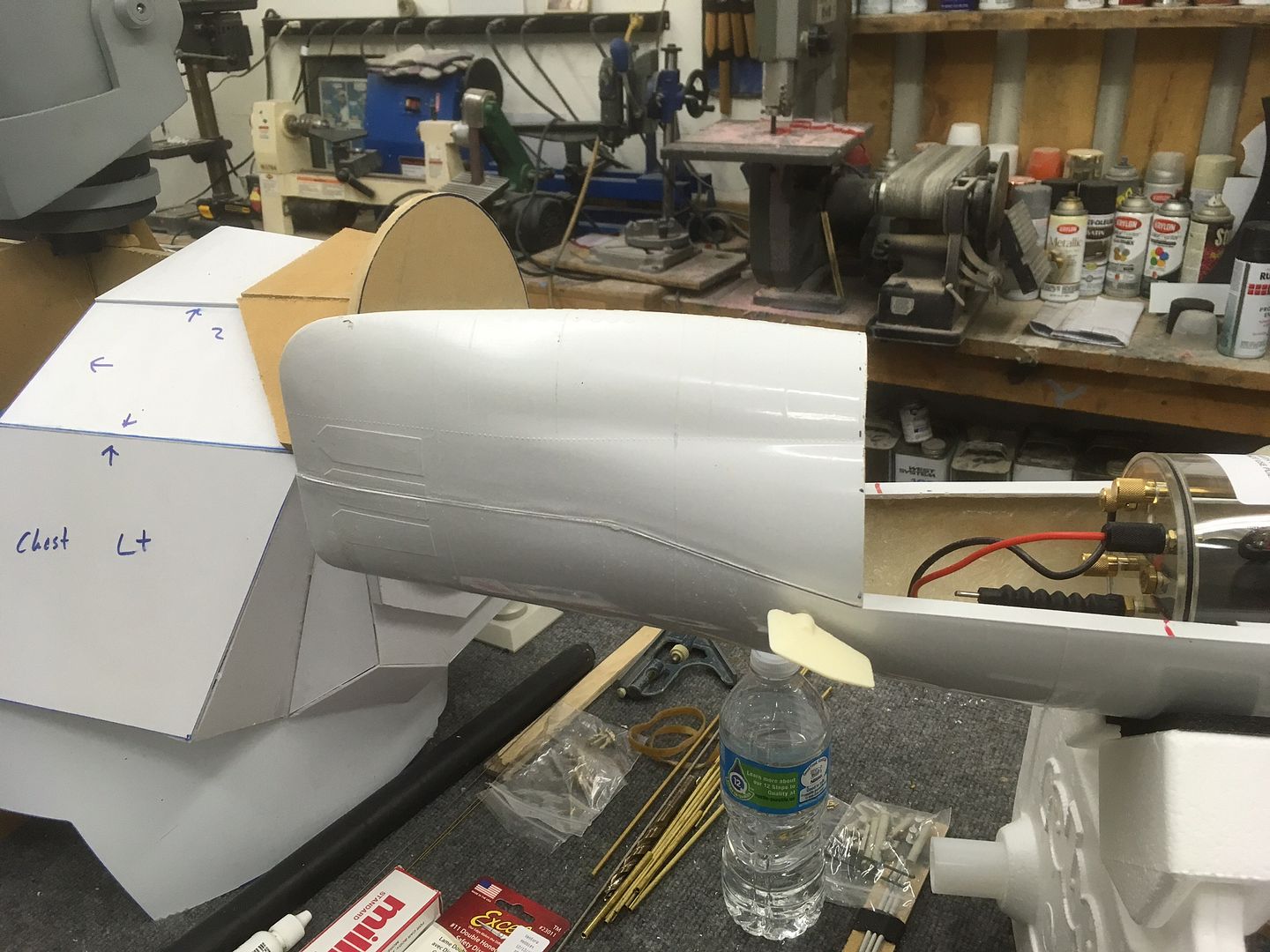

See here is Bob's new 3.5 inch cylinder. It's a real beauty. Will be mounting it today. I am shooting a video log of it for our show, "the SNG Experience" that will cover most of the steps up to her first trials.

More tomorrow.

Made a nice beefy prop shaft support and mounted the rudder bearings using Dental Acrylic. Highly strong and very water proof this acrylic sets up hard as a rock in minutes. Been using it for years in my movie industry work works perfect for boats too.

See here is Bob's new 3.5 inch cylinder. It's a real beauty. Will be mounting it today. I am shooting a video log of it for our show, "the SNG Experience" that will cover most of the steps up to her first trials.

More tomorrow.

Comment