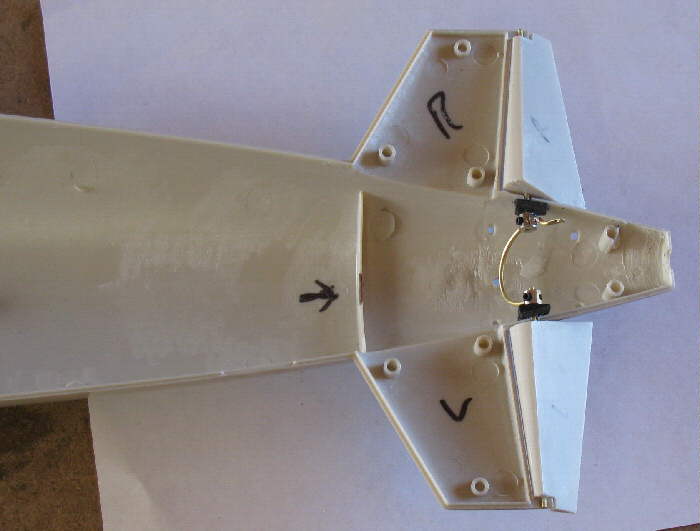

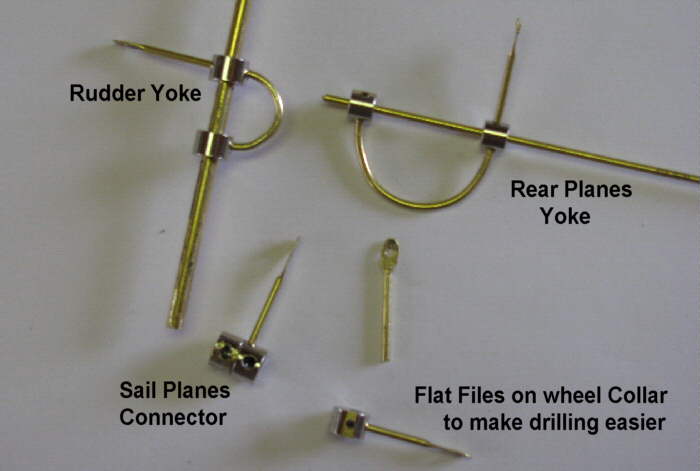

Alright, I'm tired of fighting this thing. Could anyone proved some photos of the control setup they used on the sub (not the WTC) so I can get an idea on why everything I've tried doesn't work?

So, my brass control links on the rods that go to the dive planes and rudder both broke (too thin) and I don't have the tools to make another one. Plus the rudder and dive planes are both set so I can't remove them to get another link over the rods (except if it's small enough, I *might* be able to get one on the rudder). I then turned to the plastic servo arms and modified them to fit, but NOTHING seems to want to bond to them and the rods. Any help is much appreciated.

JP

So, my brass control links on the rods that go to the dive planes and rudder both broke (too thin) and I don't have the tools to make another one. Plus the rudder and dive planes are both set so I can't remove them to get another link over the rods (except if it's small enough, I *might* be able to get one on the rudder). I then turned to the plastic servo arms and modified them to fit, but NOTHING seems to want to bond to them and the rods. Any help is much appreciated.

JP

Comment