Today it's my turn.

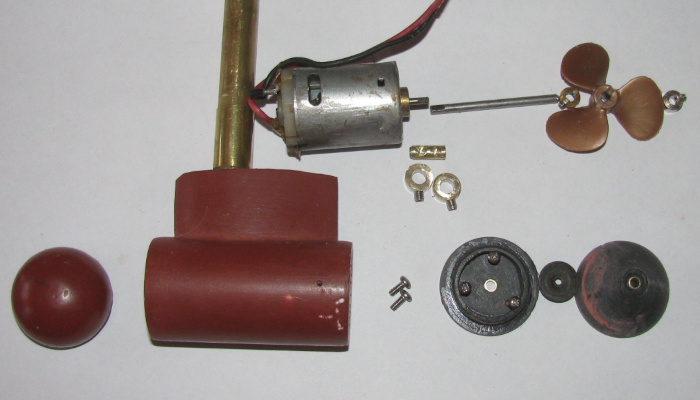

Yesterday, I made several parts for a new Z pod.

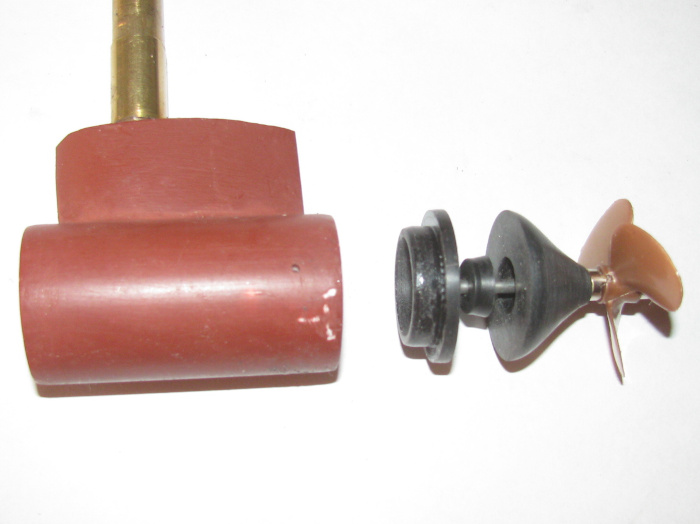

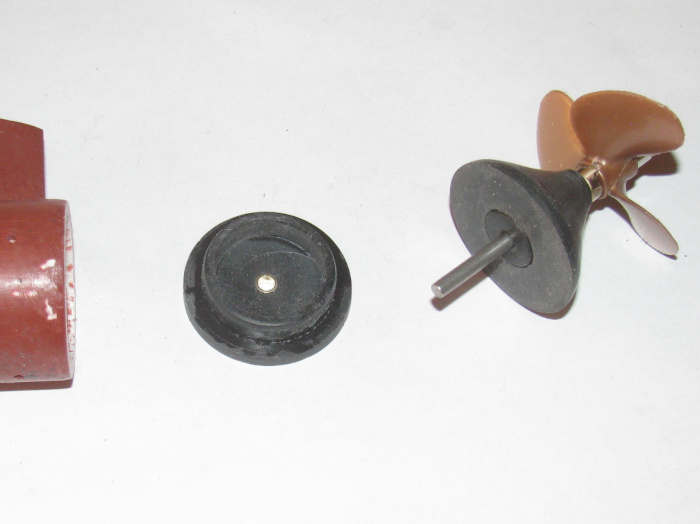

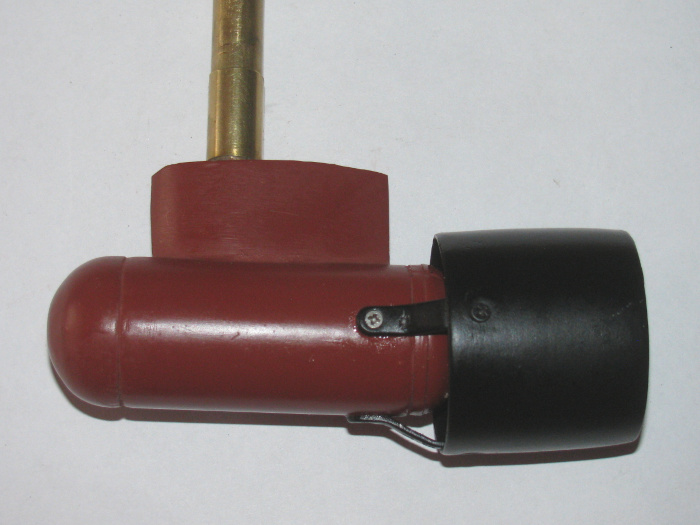

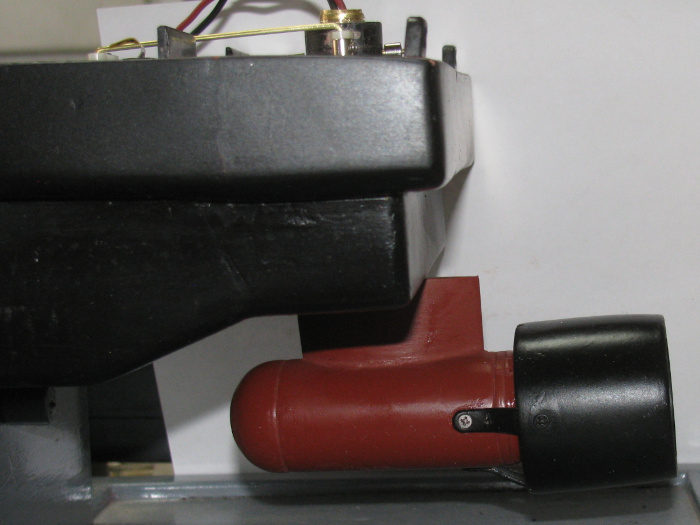

I modified an old tail cone and made the new propeller shafts for the new motor.

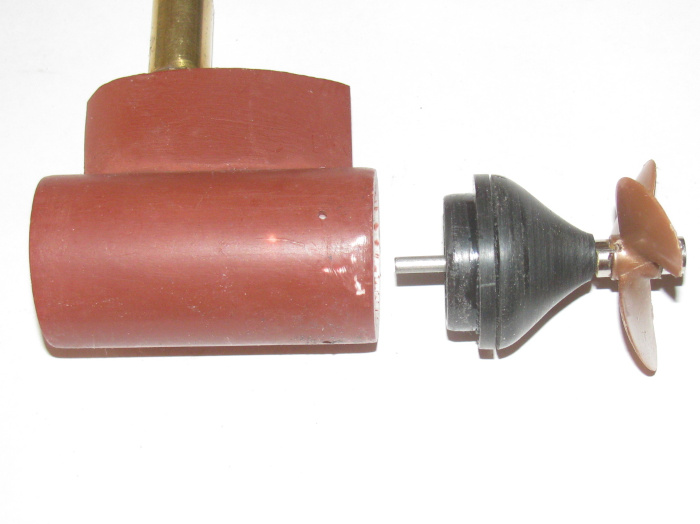

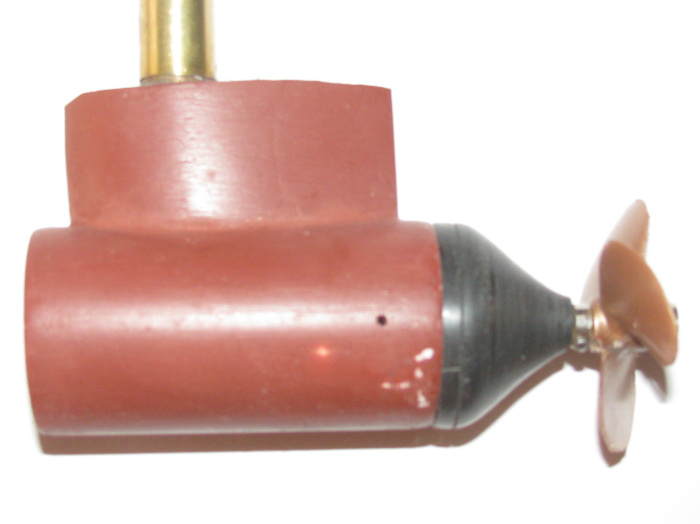

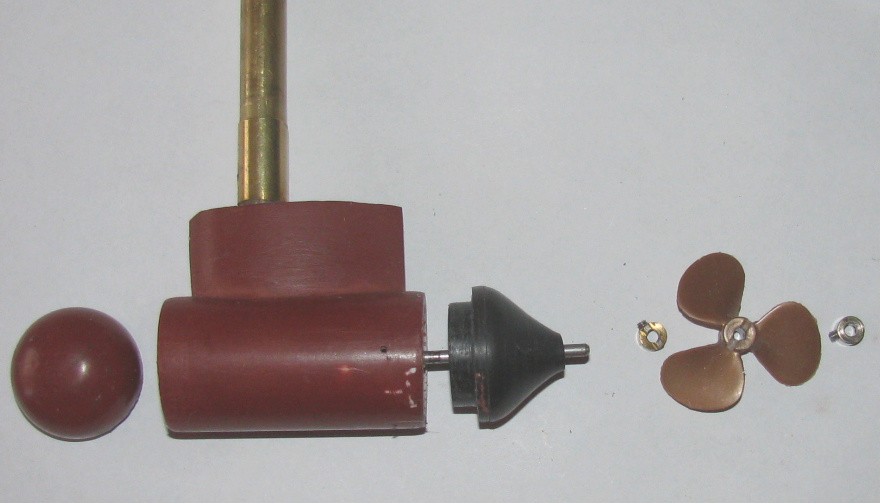

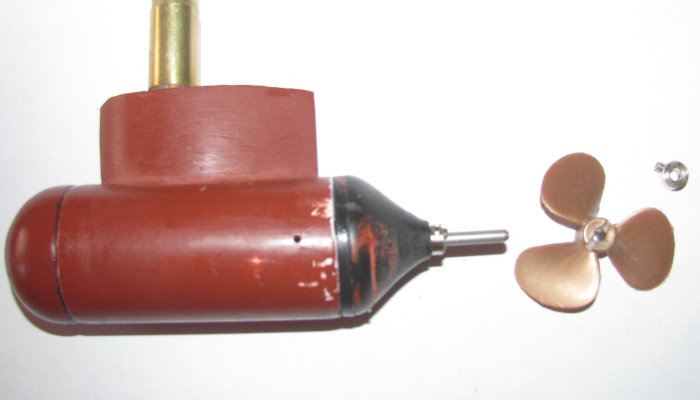

This morning I went out to the shop to assemble the tail cone , shafts and motor in tot he pod body.

I can not find these parts any where.

I spent 30 minutes looking every where I worked on it yesterday.

I had to go in to town but I am back now.

My plan is to get my little flash light and go crawl around the floor looking under every thing and moving every thing on the shelf under the work bench.

It has got to be there some where.

I do not want not make a new tail cone.

It is made in two pieces with a cup seal inside.

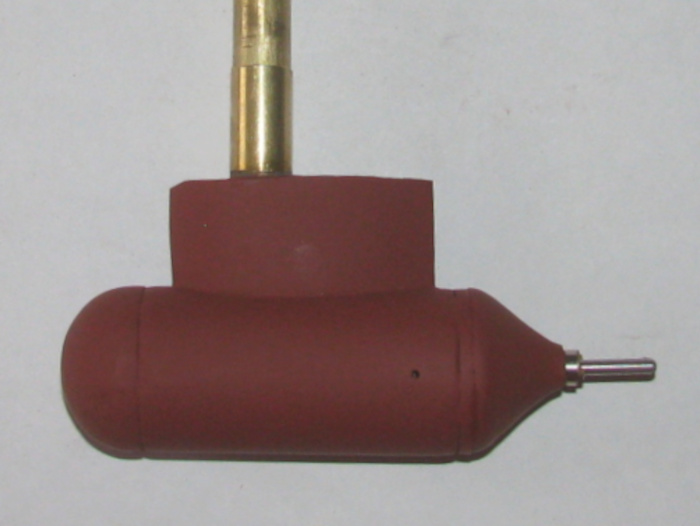

It has been on my rescue barge for a year and a couple of months.

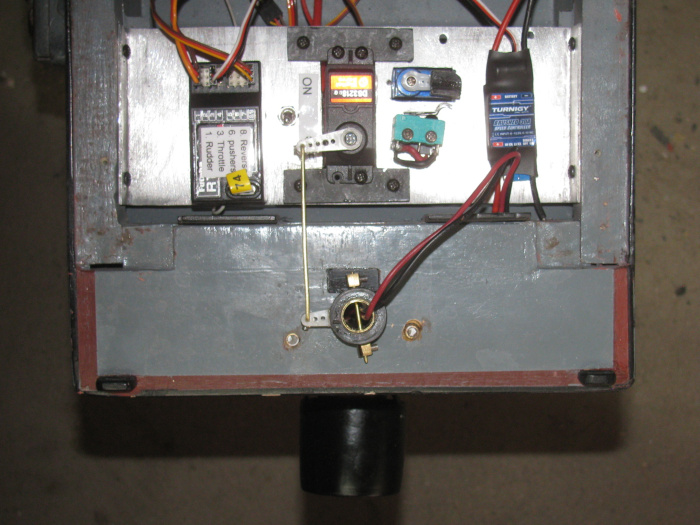

When I opened up the pod last week, there was no signed of water and not signed of rust inside the pod.

I got to find the tail cone which as the shafts in it.

Yep, it's one of those days. ;^(

Yesterday, I made several parts for a new Z pod.

I modified an old tail cone and made the new propeller shafts for the new motor.

This morning I went out to the shop to assemble the tail cone , shafts and motor in tot he pod body.

I can not find these parts any where.

I spent 30 minutes looking every where I worked on it yesterday.

I had to go in to town but I am back now.

My plan is to get my little flash light and go crawl around the floor looking under every thing and moving every thing on the shelf under the work bench.

It has got to be there some where.

I do not want not make a new tail cone.

It is made in two pieces with a cup seal inside.

It has been on my rescue barge for a year and a couple of months.

When I opened up the pod last week, there was no signed of water and not signed of rust inside the pod.

I got to find the tail cone which as the shafts in it.

Yep, it's one of those days. ;^(

Comment