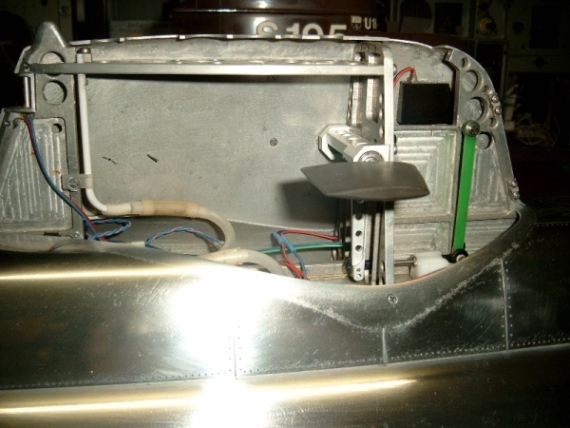

Idea for magnetic pushrod connection.

Saw this Klein tool for fishing wires using a magnet.

Uses wheeled handle that does not mar the wall.

What if you made a push rod with the wheels (or Teflon)

and magnetic connection to make a pushrod that does

not use a seal and have a leak point and does not

damage the water tight compartment?

Senor Merriman did sliding magnets in one of his small

WTC.

Saw this Klein tool for fishing wires using a magnet.

Uses wheeled handle that does not mar the wall.

What if you made a push rod with the wheels (or Teflon)

and magnetic connection to make a pushrod that does

not use a seal and have a leak point and does not

damage the water tight compartment?

Senor Merriman did sliding magnets in one of his small

WTC.

Comment