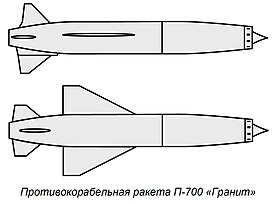

I've been thinking and would it be possible to convert a pneumatic 1:32 torpedo into a P-700 Granit? My problem is that I can't find the measurements to scale the thing down. I'm also wondering what'll happen to a pneumatic torpedo once it leaves the water.

P-700 Granit dimensions

Collapse

X

-

Tags: None

-

P-700 Granit

10 meters long = 33.46 feet

.85 meters in diameter = 33.46 inches

If you use a P-700 to start,

it would need to be in 1/51 scale to get the diameter exact.

It would be .50" too long.

I think it would be easier to just stack some plastic sheets pieces to make the nose. Thent he same for the tail.

Using a drill press to spin it and shape it.

Then a piece of straight plastic tubing to make the body.

Make the nose and tail out of wood.

Make a clay mold and pour the pieces again using tubing for the body.

Just my thoughts.

I think once the plastic pieces are glued together and cured, it would take maybe 20 minutes to turn the parts for two or three units.

-

Awesome! Thanks Ralph. It looks like I left some info out though. What I'm thinking is take an off the shelf 1:32 torpedo system and modifying the torpedo to look like the P-700 and then installing the launch system at 40 degrees upright in my 1:96 Oscar II. I think the sub missiles have a closed nose which should make a conversion easier on a off the shelf torpedo. What kind of plastic were you thinking of using? Sadly I don't have the know how to make a mold and a casting. At any rate I have the dimensions: 4.18"X.35" and according to my measurements, I have enough room to make the forward most silos work.

At any rate I have the dimensions: 4.18"X.35" and according to my measurements, I have enough room to make the forward most silos work.

OH before I forget! I can't use real rockets or fireworks! Most of my operational areas will be parks and under Oregon law, no model rockets in parks and NO fireworks that travel higher then a foot. Plus we only get fireworks for three weeks out of the year.

(https://www.portlandoregon.gov/fire/article/378384)

Comment

-

-

Ah, thanks. It looks like the cover was jettisoned after it broke the surface.Originally posted by Ralph --- SSBN 598 View PostHere's a fun site.

Soviet/Russian Cruise Missiles

Comment

-

Looking at the line drawing, It should be that hard to make it out of plastic or wood.

It does not have complicated shapes.

A dowel rod and some flat pieces shaped.

While looking around I saw a photo of the P-700 that has a nose cone shaped like a torpedo.

Next photo shows ship launch and nose cone cover released.

P-700 with nose cone

Down just a little further is a photo of P-700 in the launch tubes of a submarine with the hatches open.

Comment

-

Confirmed - both the air-breathing engine cover in the front and the booster section at the rear are blown off at various stages of the launch. If you're going to launch while submerged you're probably better off to model the P700 with the cover on.

Learning to cast what you need is really the best way to do this kind of thing, IMO. Glueing additional parts on to an existing form will leave weak-points that you won't want to have to contend with - Remember that at worst you'll only get a single flight out of each missile you make, and at best these things are going to have to contend with some significant stresses/forces when they come splashing down so it's worth your while to spend a minimum of effort on each one. Casting missiles yourself will reduce your touch-time to an absolute minimum and will allow you to make the most accurate shape possible at the same time.

You say "I have enough room to make the forward most silos work" (Emphasis mine) Consider the reaction forces on your boat during a missile launch, as well as the effects on static trim. I quite deliberately chose the aft-most four tubes for my launchers as these are the closest to the boat's CG so any changes in trim would be kept to a minimum as a consequence of missile launches. I don't know what your plans are for launching, but when I pop Granits off I do it while submerged and underway and there's no perceivable change in my trim or attitude.

Here's another link with some great info: http://militaryrussia.ru/blog/topic-398.htmlKevin McLeod - OSCAR II driver

KMc Designs

Comment

-

-

I hope this clarifies, I was thinking of modifying this kind of system. (http://www.rcsubs.co.uk/operational-torpedoes) Now everyone has more experience at this then I do so I'm open to ideas. My WTC is rather large so only the first 4 bays are accessible but CG is about where the sail is. I might "refit" the boat after it's done to add armaments but for now I'm gathering info before I try it. Now I'm not sure how the gas torpedoes work so I need an explanation on how they operate if I need to make the missiles myself. Sub Driver has a gas system as well, but I can't figure out how you charge the tank, or what gases are used. I am interested in hearing more from Kevin about the recoil as that is an issue. I am using a water tight deck rather then a water tight tube so I have less space in the hull, but I have more room in the WTC.

Comment

-

I hope it doesn't sound like I'm disregarding anyone's advice. I really do appreciate everything everyone has done for me so far. If it sounds like I'm putting someone off, just let me know, it's something I'm not aware of.

Anyways, Ralph, I take it you're saying to build a mockup and make a cast out of it? I don't have the tools to make a plastic mold so I'd need a way to make a mold and cast with limited resources.

Comment

-

-

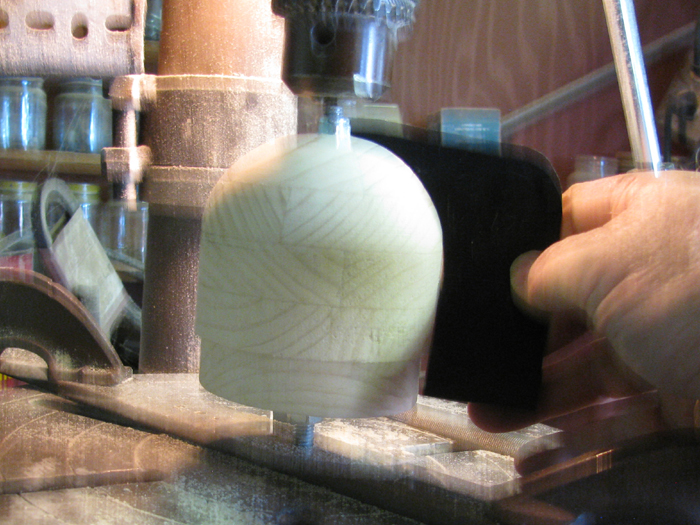

For limited parts, you can make a pattern from anything as long as it is ridgid.

Then you use modeling clay and press your pattern in to the clay half way.

You then place another piece of clay over your pattern.

Forgot, pattern should be polished with wax to keep clay from sticking.

You can make the nose cone and tail section.

The middle could be a standard piece of thin plastic tubing cut to length.

You make the nose and tail sections one at a time.

Clay works for minimum numbers needed.

I personally think this is more work that making the pieces needed directly.

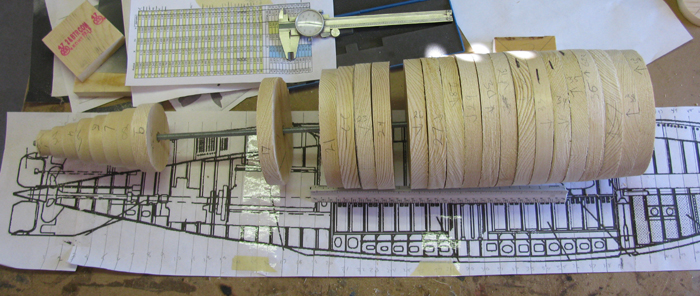

I think the size of your missile, .66" diameter, I would make a block of balsa wood.

I would glue smaller pieces on to a small brass rod ... 1/8" or even 3/32" rod.

I would then turn it in a drill press and shape it with files as it spun.

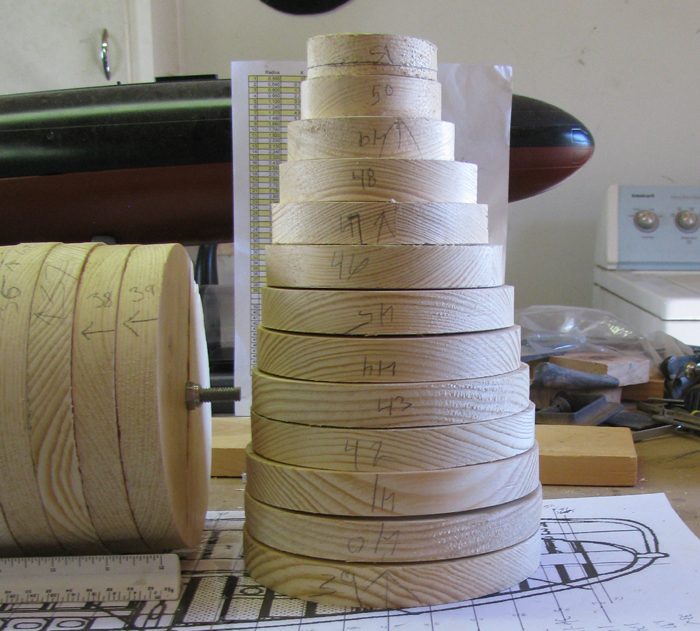

Here is an example of a bow section I made for Gotland using 3/4" pine boards glued together.

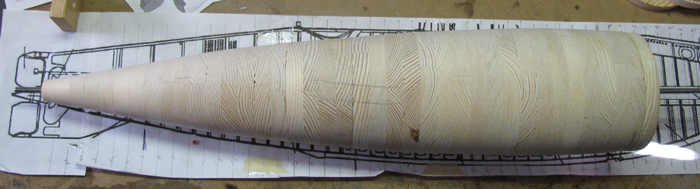

Currently using the same process for a hull plug.

First I made 3/4" disks to the large diameter to be cut down later.

There is lots of disk that were made.

Then the disk were glues together and final shaping took place.

There were three section for the back 2/3 of the boat.

Once they were glues together, the sections were blended together.

The bow disks are cut and turned to large diameter.

They have not been glue together yet.

Other things have gotten in the way.

The bow can not be spun to shape.

It will be hand filed and sanded

The point of all this is I think due to the size of torpedo and missiles, the parts could be turned on a drill press or even using a Dremel to spin the parts while shaping with files and sand paper.

After I get the hull plug finished, I will be making 3 torpedoes in 1/24 scale.

Old Whitehead that are 19'x18" or .75"x7.75"

Comment

-

Thanks Ralph. Jeff's archive knowledge of the SCR points to a series of stainless tubes for the operational components. I don't have the tools to pull of that kind of fabrication. I could do your recommendation for the master and molds though.

Comment

Comment